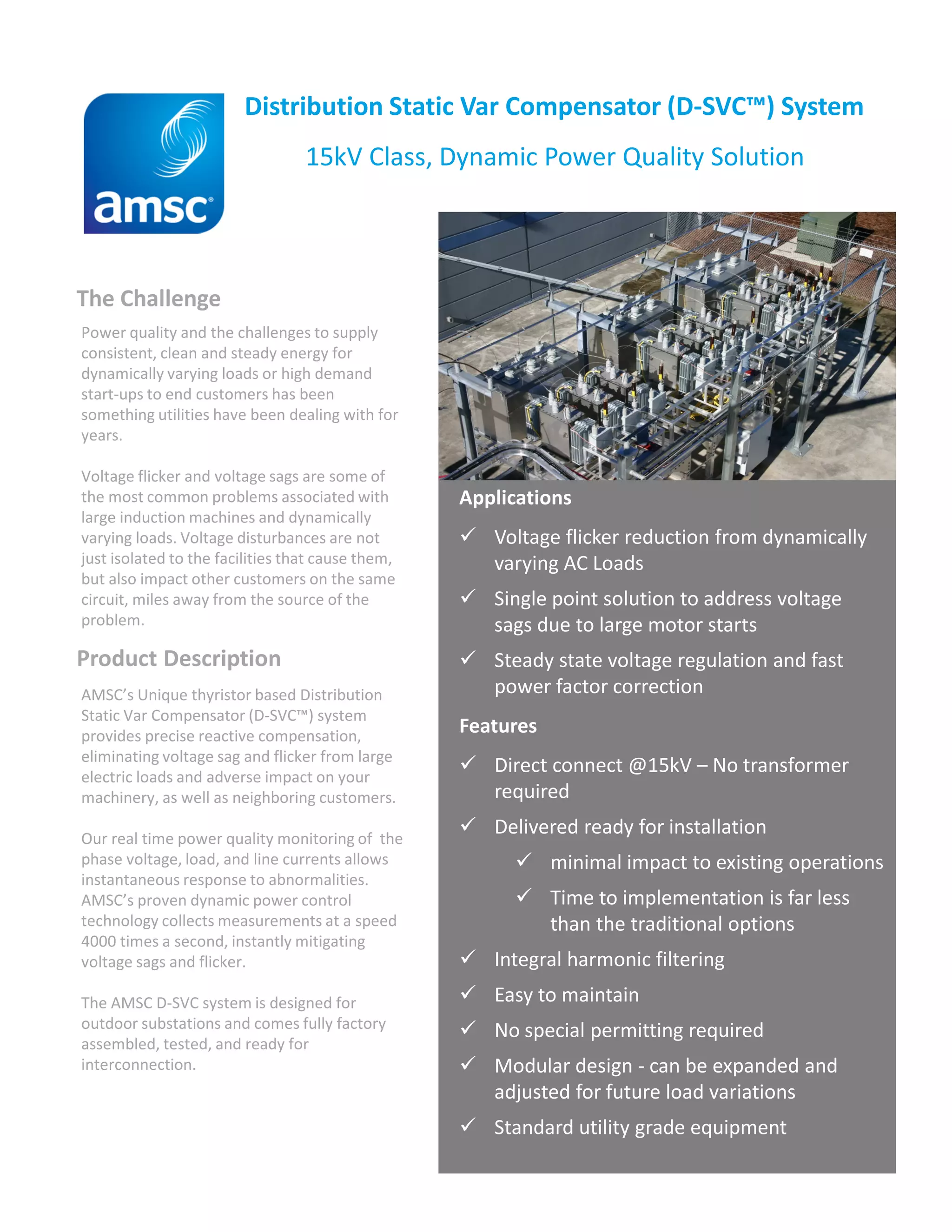

AMSC's Distribution Static Var Compensator (D-SVC) system provides precise reactive compensation to eliminate voltage sags and flicker from large electric loads. It monitors voltage, load, and currents 4000 times per second to instantly mitigate abnormalities. The D-SVC is designed for substations and comes pre-assembled for easy installation. It addresses issues like voltage flicker from varying loads and sags from large motor starts while improving power factor and voltage regulation.