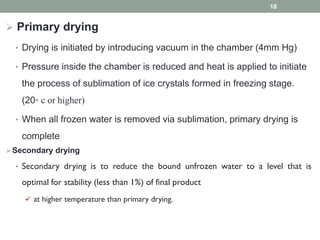

Drying involves the removal of solvents like water or other liquids from a formulation using heat. It is done to stabilize moisture sensitive materials, aid preservation, and prepare granules for tablets and capsules. Common drying methods include hot air oven dryers, vacuum oven dryers, fluidized bed dryers, freeze dryers, drum dryers, and spray dryers. Hot air oven dryers operate by circulating hot air over solid materials spread on trays while vacuum oven dryers dry materials that are heat sensitive under low pressure. Spray dryers dry dilute solutions by spraying the liquid into a hot air stream where each droplet dries quickly.