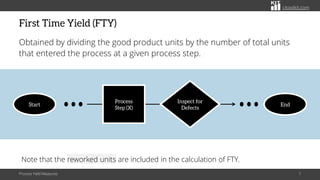

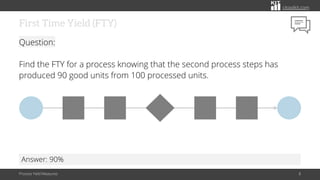

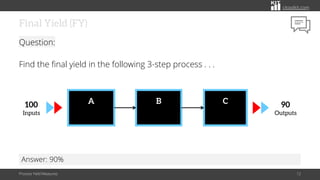

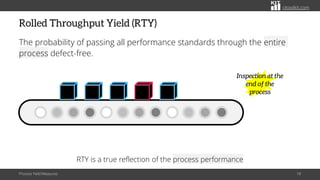

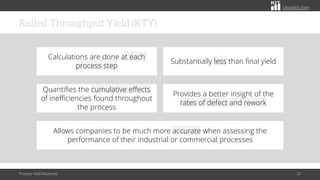

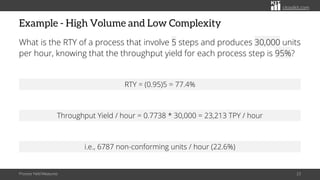

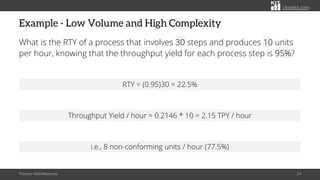

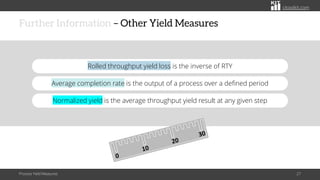

The document discusses process yield measures crucial for evaluating production efficiency, focusing on metrics like First Time Yield (FTY), Final Yield (FY), Throughput Yield (TPY), and Rolled Throughput Yield (RTY). It explains how these metrics help organizations understand and improve their true process yield by identifying inefficiencies, and outlines the calculation methods for each yield type. Additionally, it highlights the importance of accurate data and corrective actions in reflecting actual defect rates during production.