This document provides an overview of drip irrigation, including:

1. A definition of drip irrigation and a brief history of its development from ancient times to modern innovations using plastic pipes and emitters in the 1950s-60s.

2. Advantages of drip irrigation like high application efficiency, water savings, suitability for marginal soils, lower energy use than sprinklers, and ability to apply fertilizers precisely. Disadvantages include high initial costs and risk of emitter clogging.

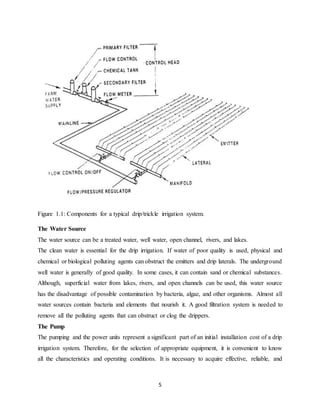

3. Key components of a drip irrigation system including the water source, pump, filtration system, controls, distribution pipes, and emitters. Water quality, pump sizing, and uniform water application are