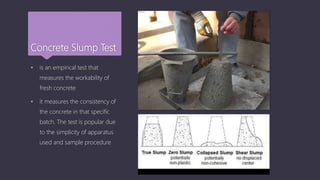

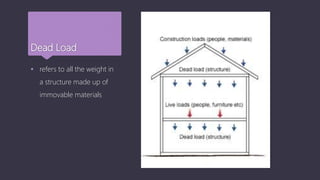

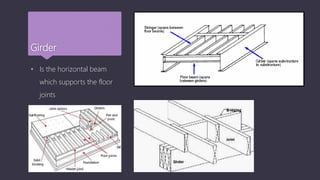

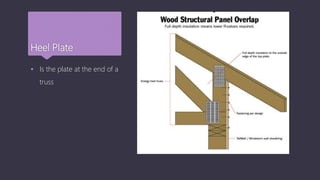

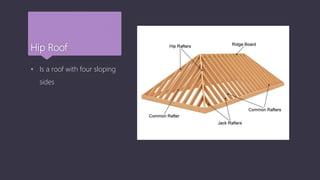

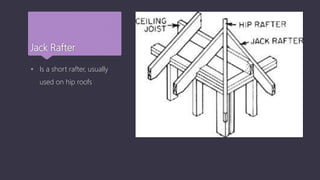

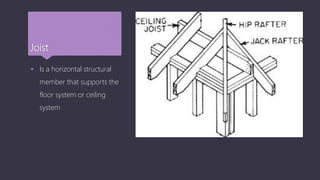

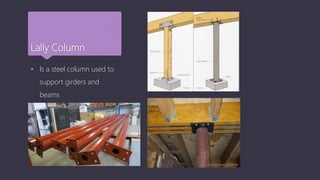

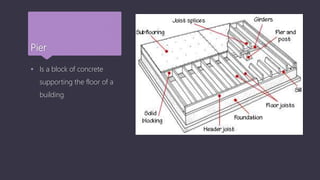

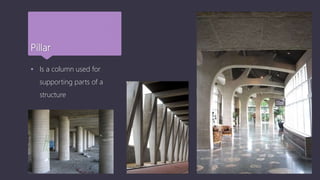

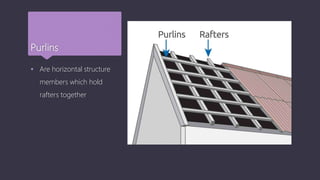

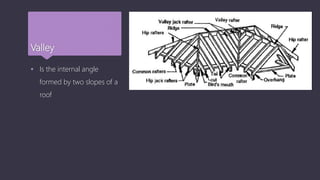

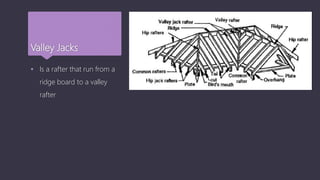

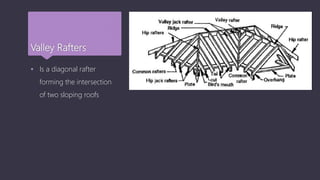

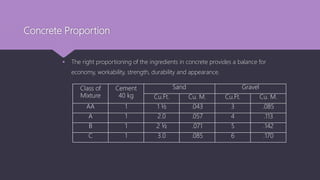

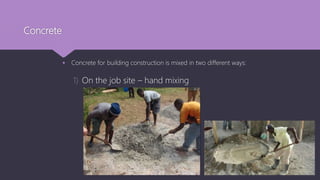

The document discusses various structural elements used in floor and roof framing plans, including girders, joists, piers, pilasters, purlins, ridges, slabs, spans, valleys and more. It also provides details on concrete, including its composition of cement, aggregates and water. Concrete can be plain or reinforced and is proportioned to achieve strength, workability and durability. It sets within a few hours and must be cured for several days to achieve full strength.