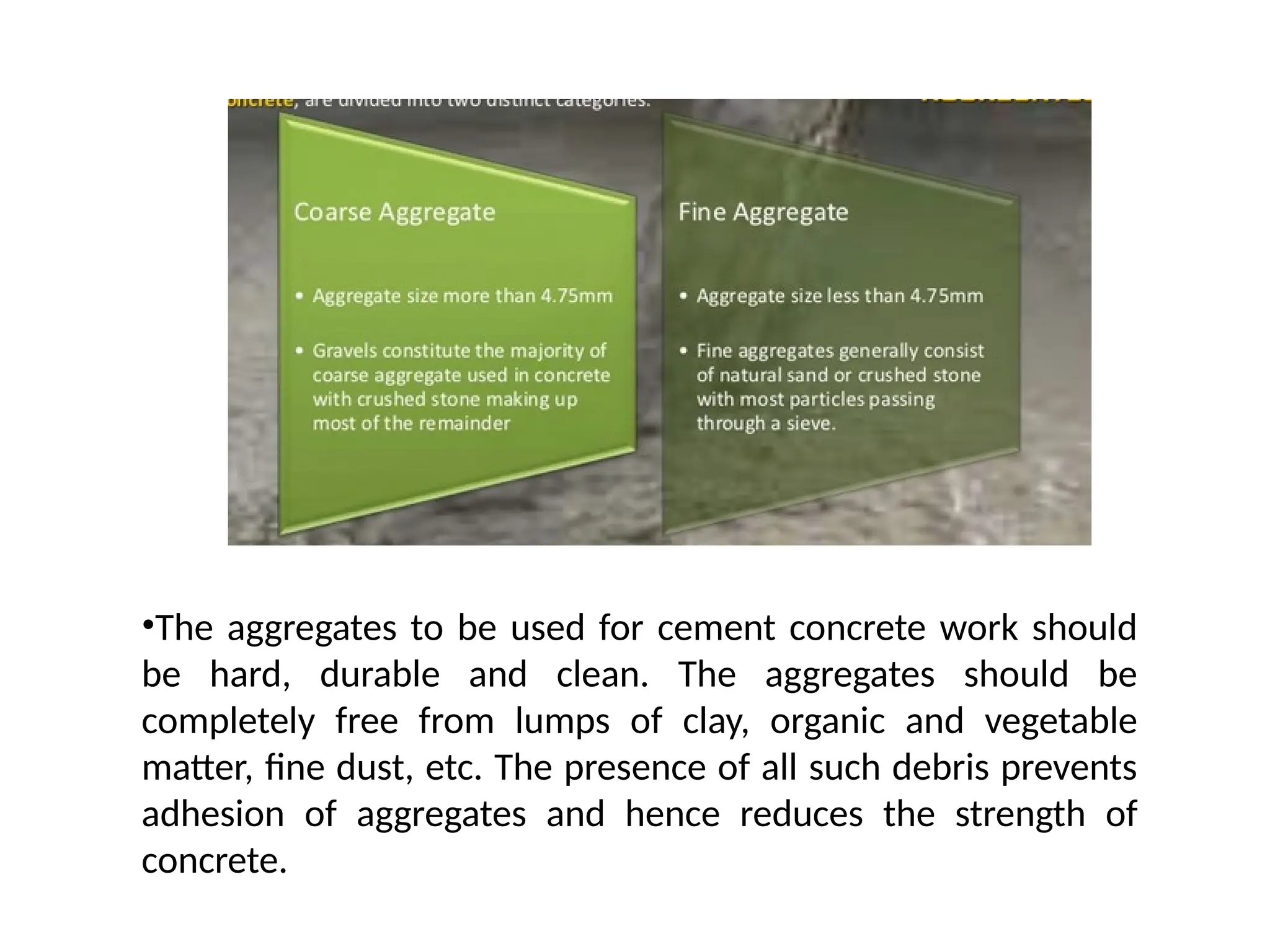

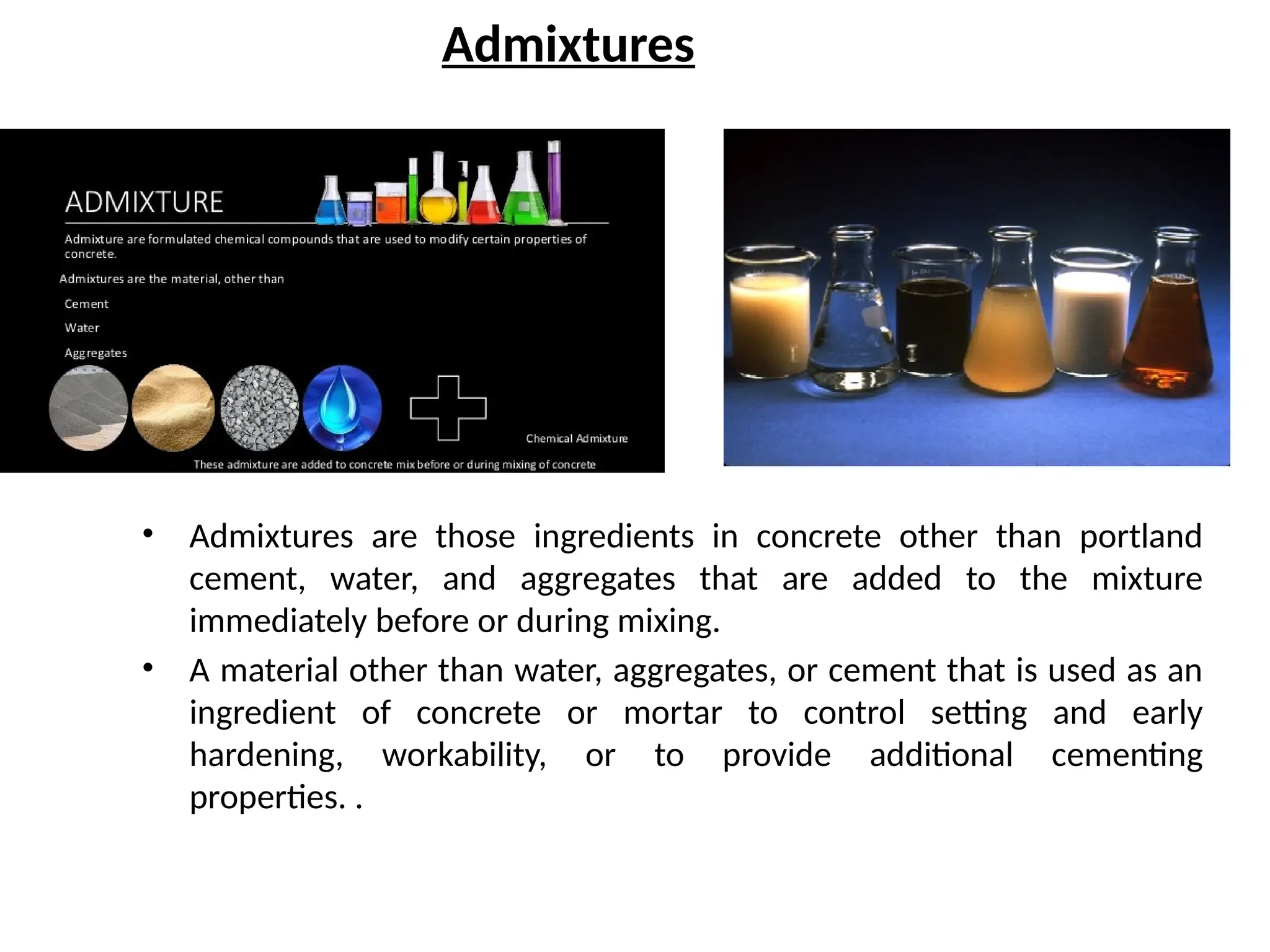

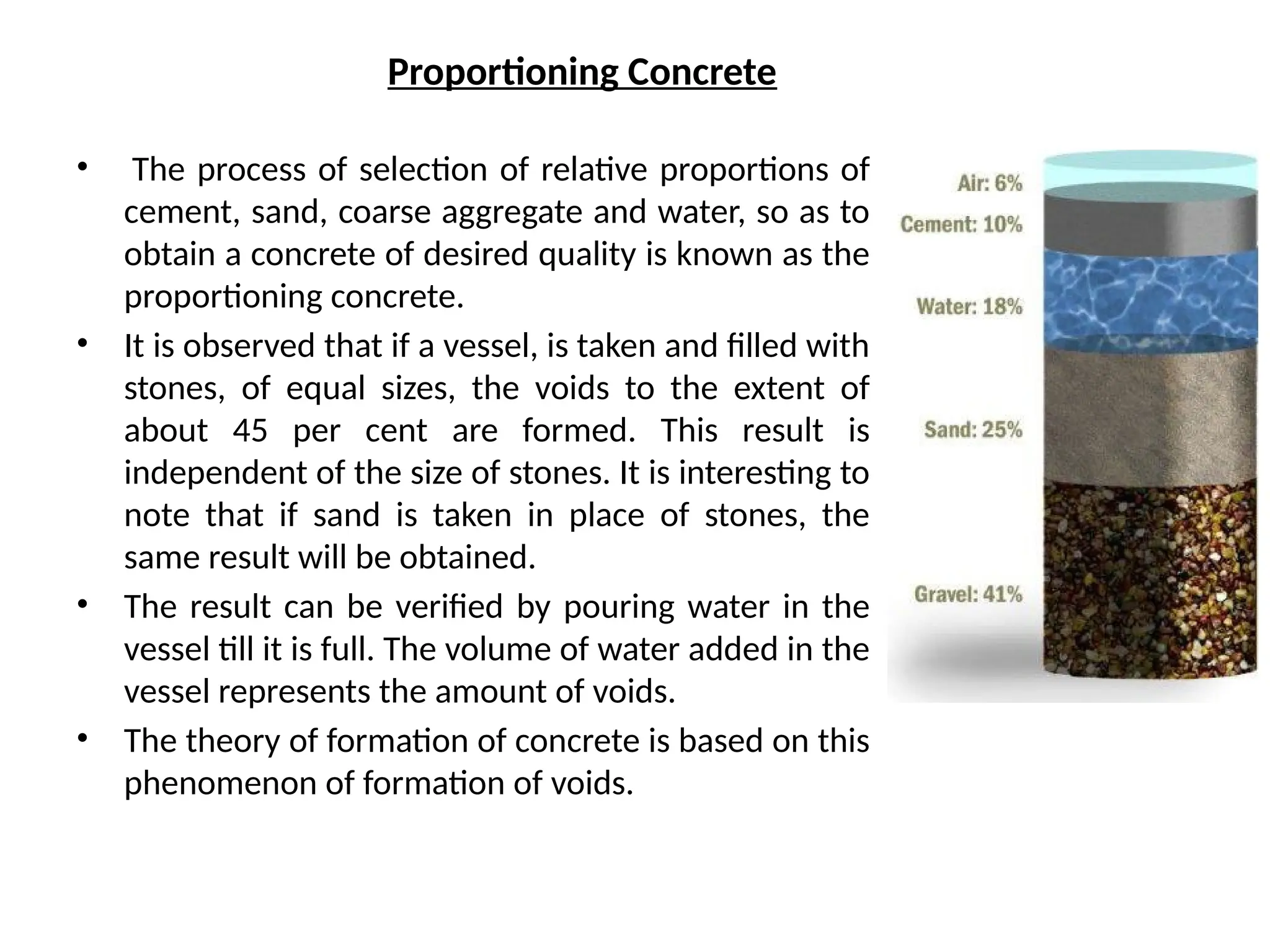

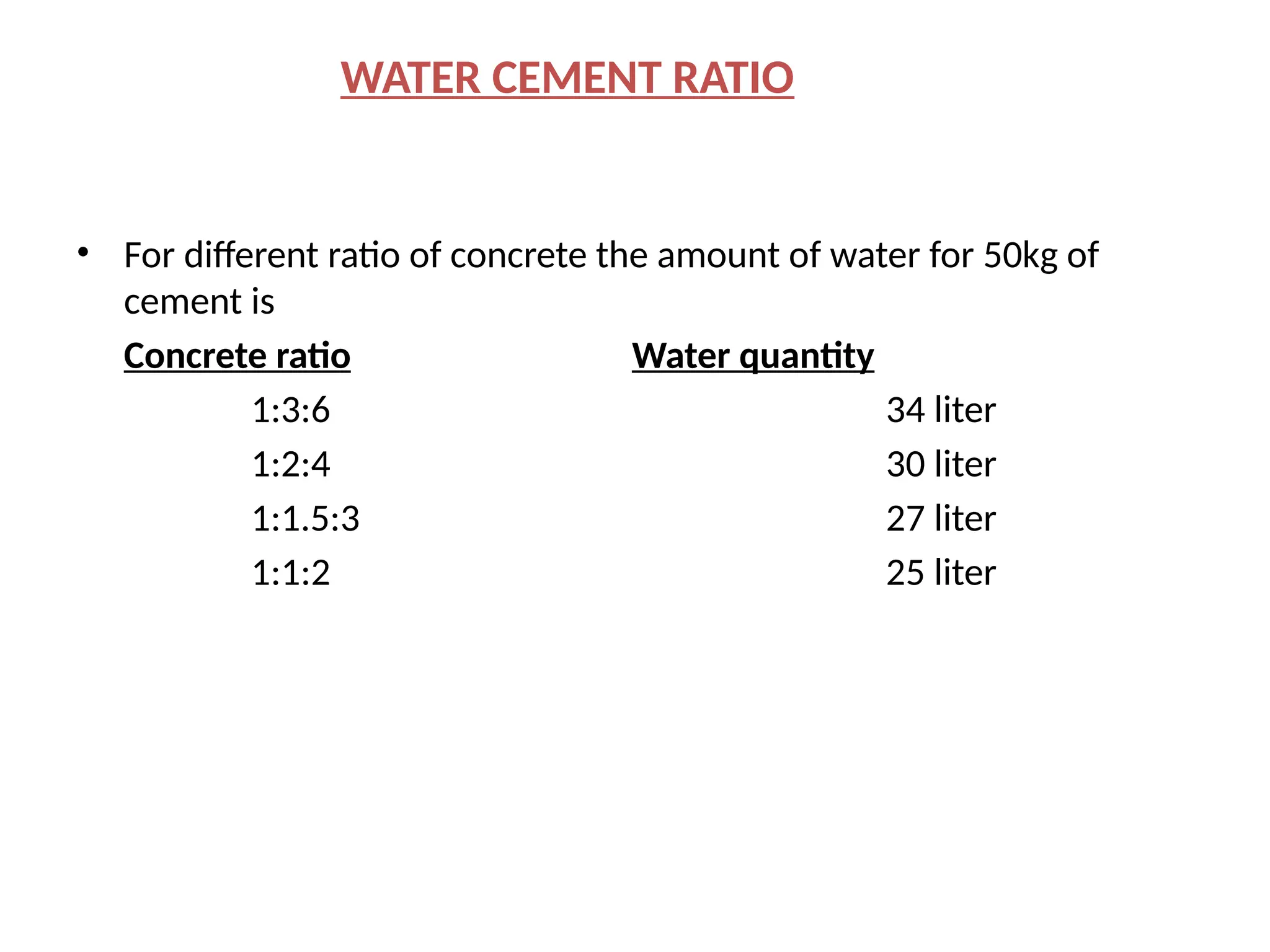

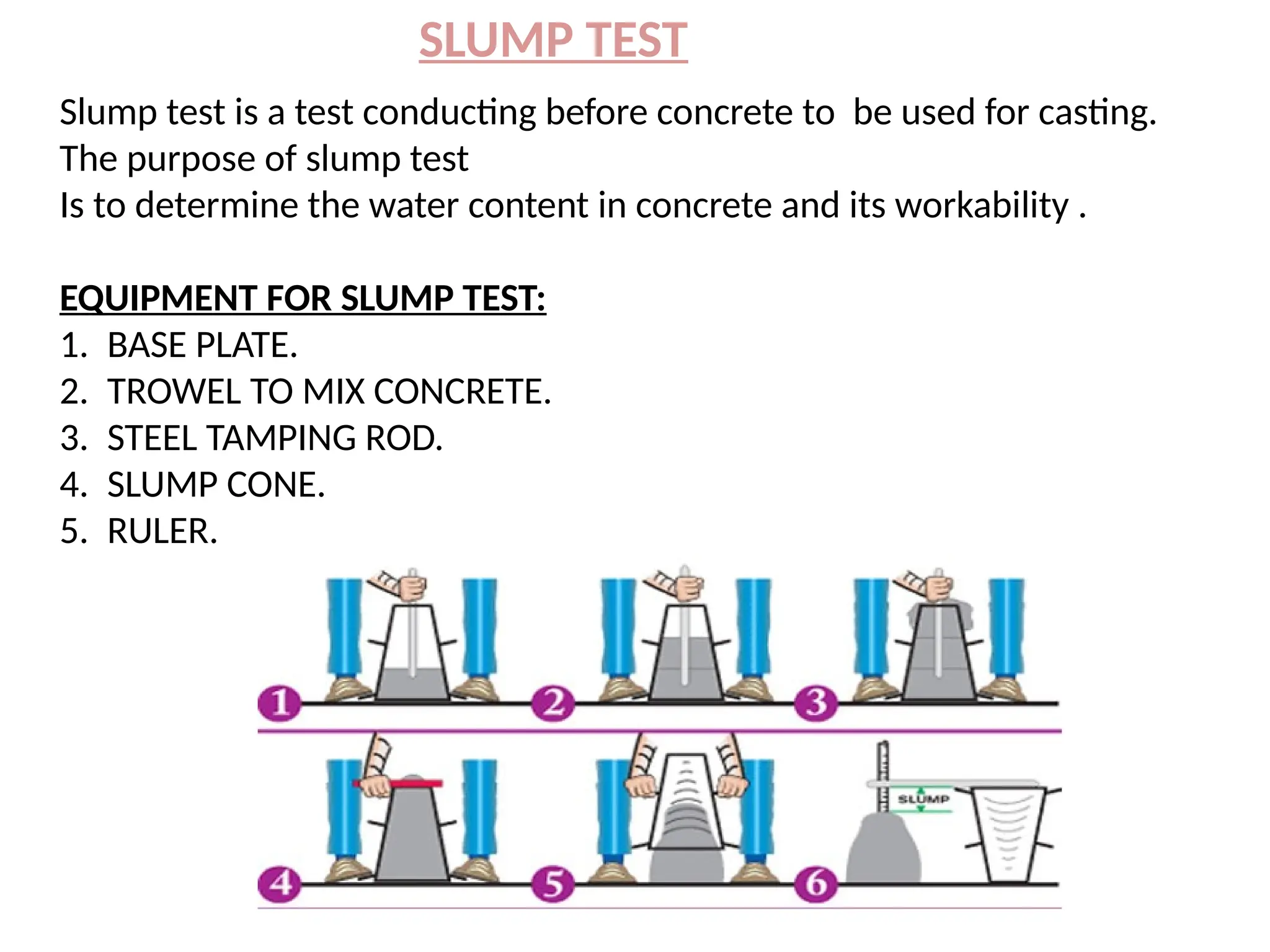

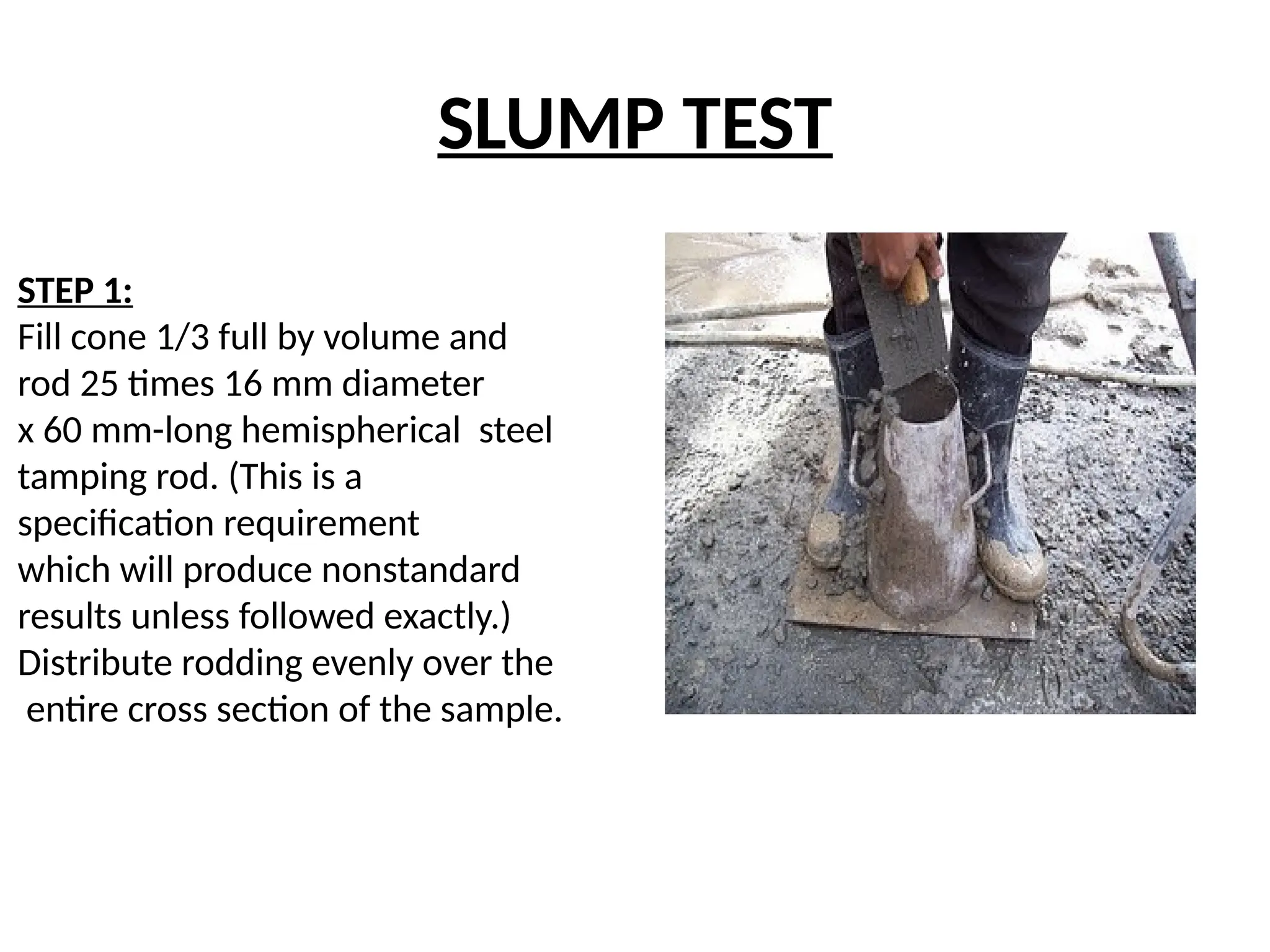

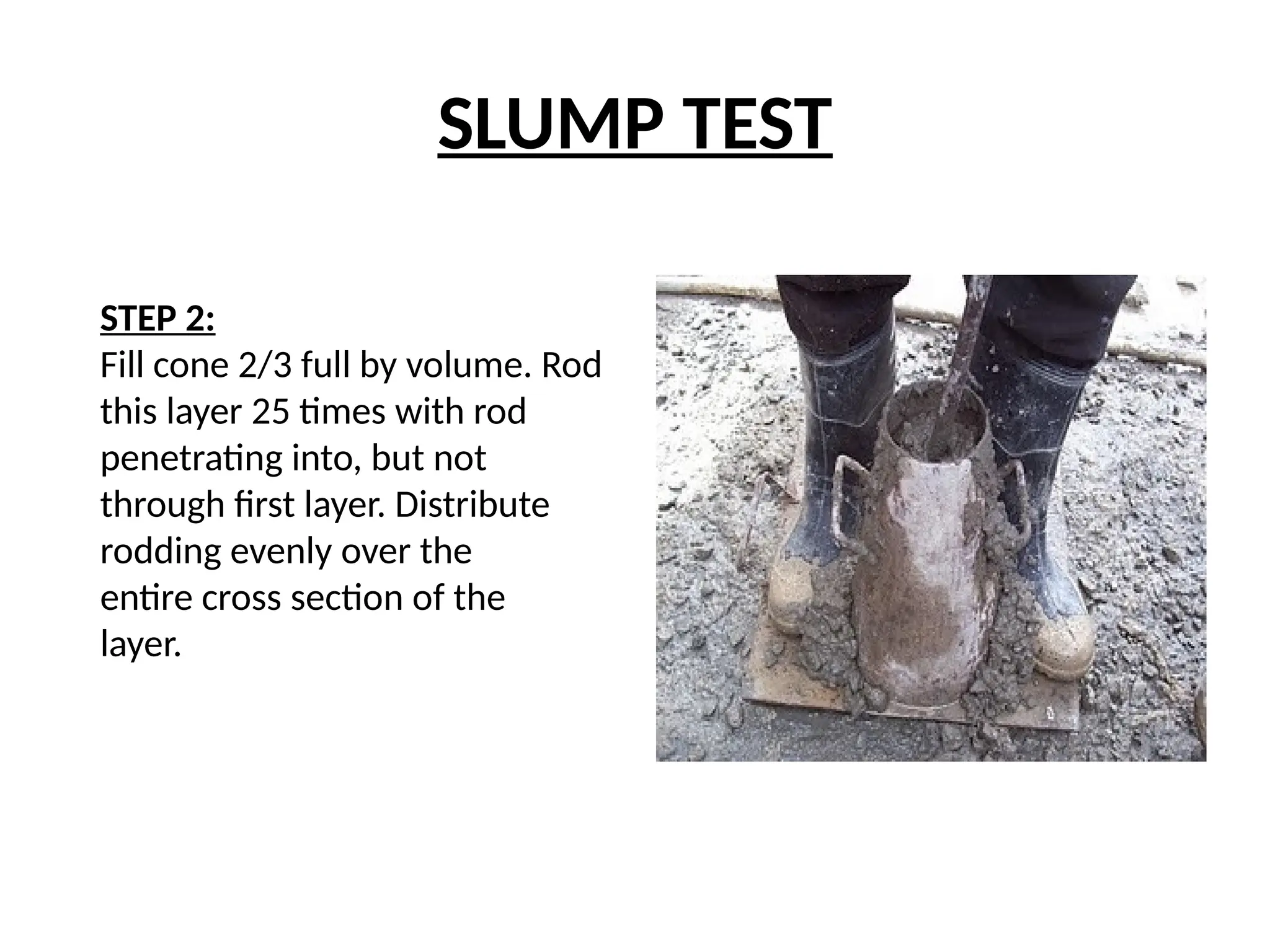

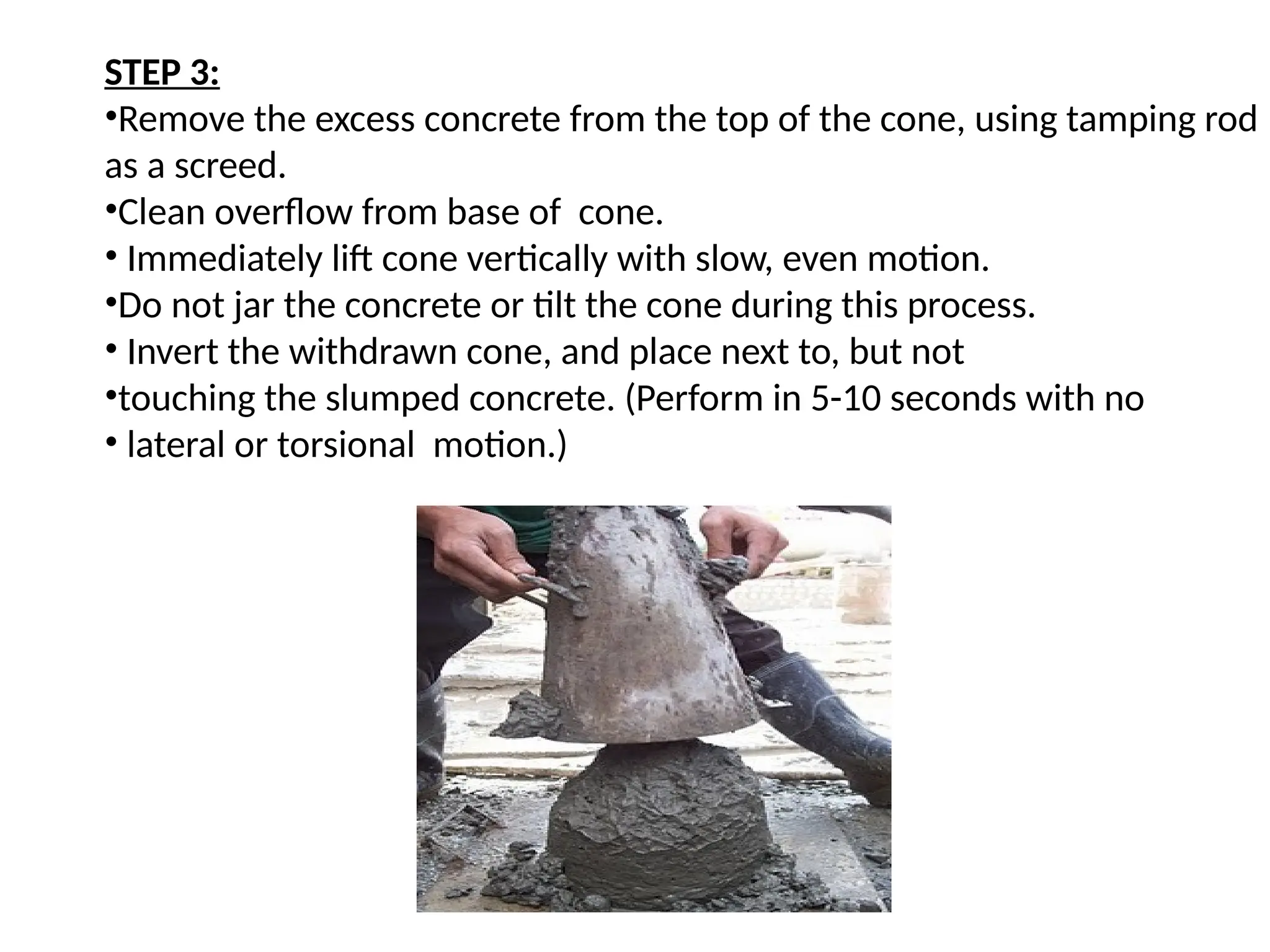

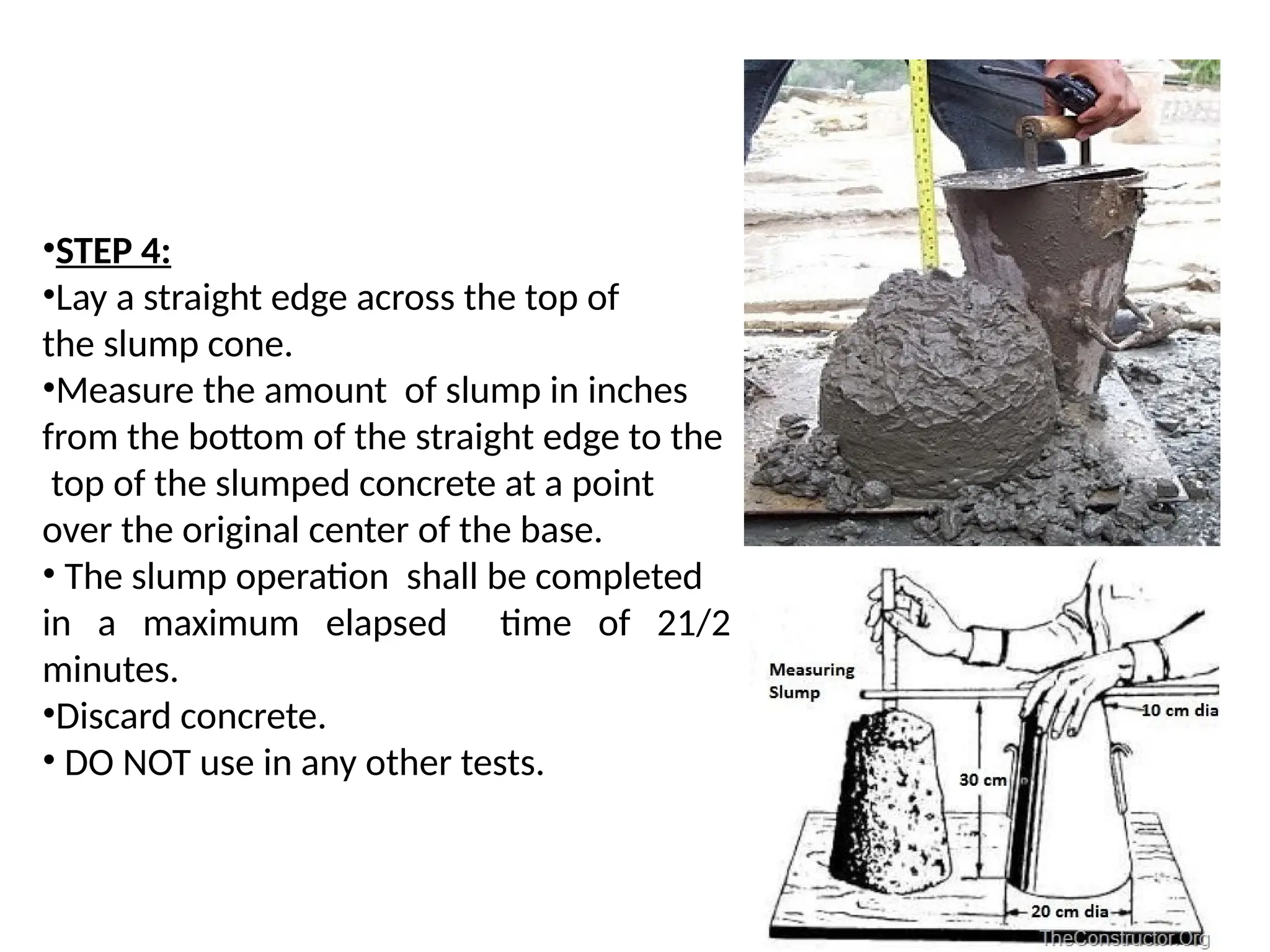

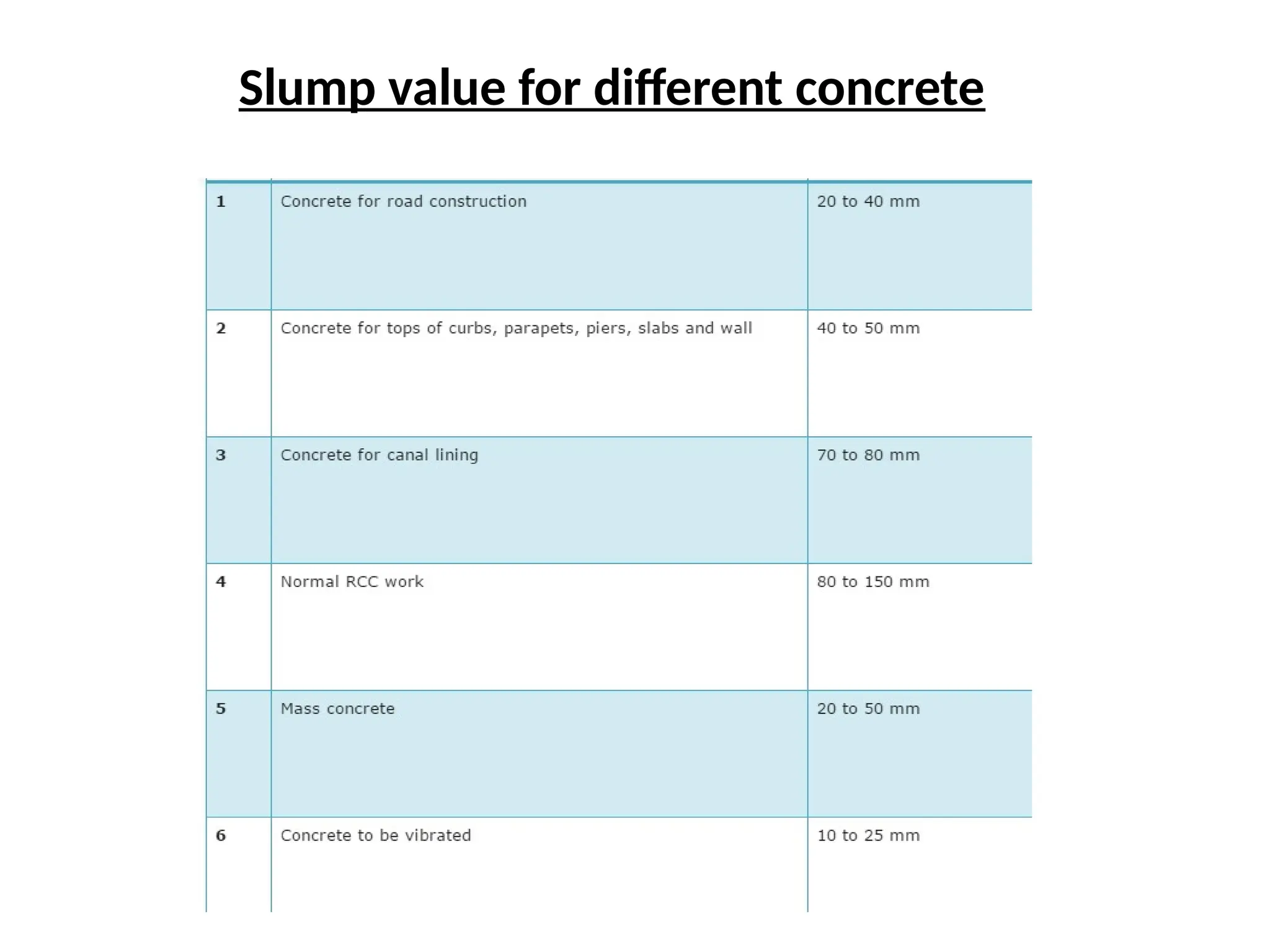

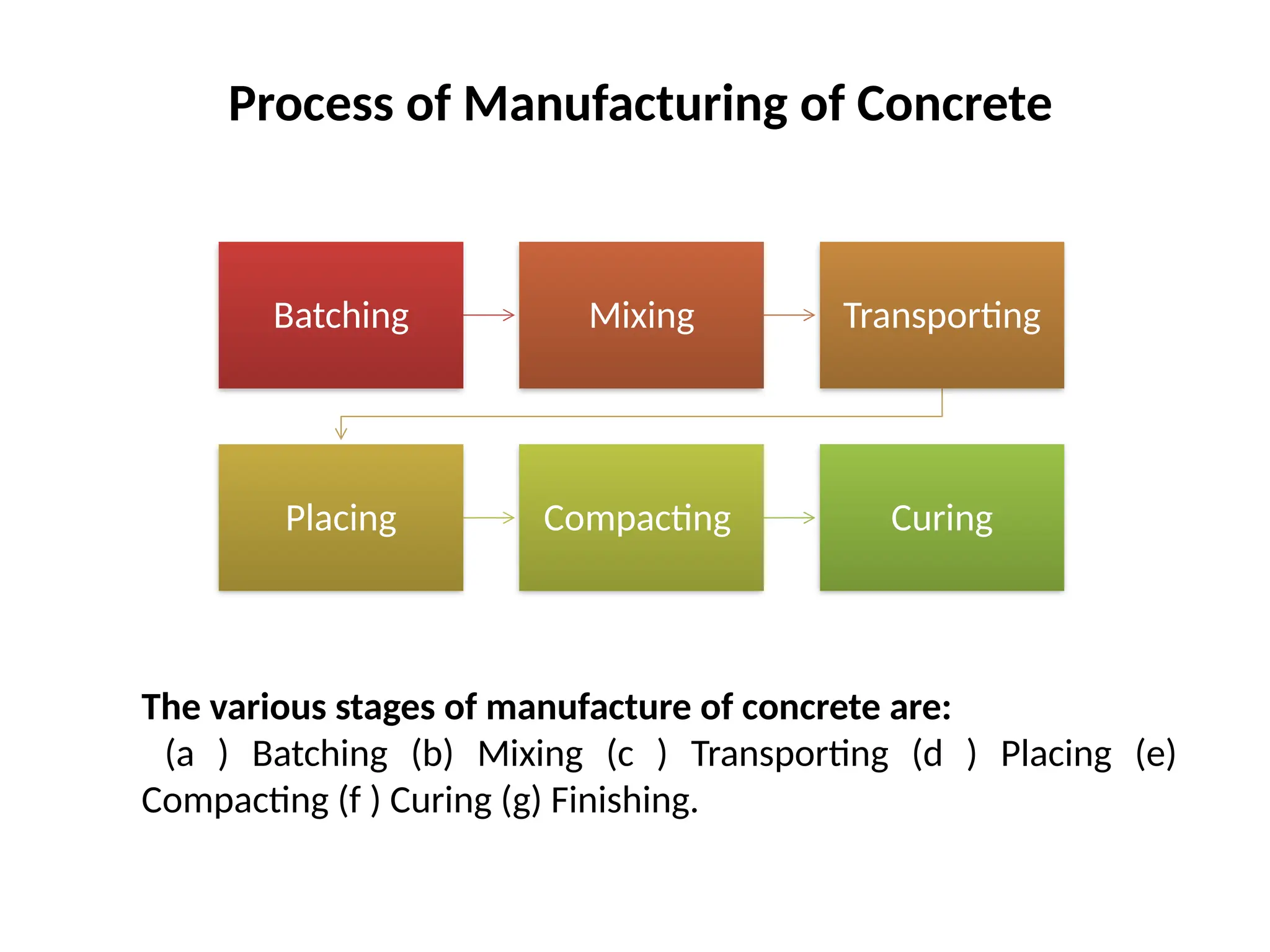

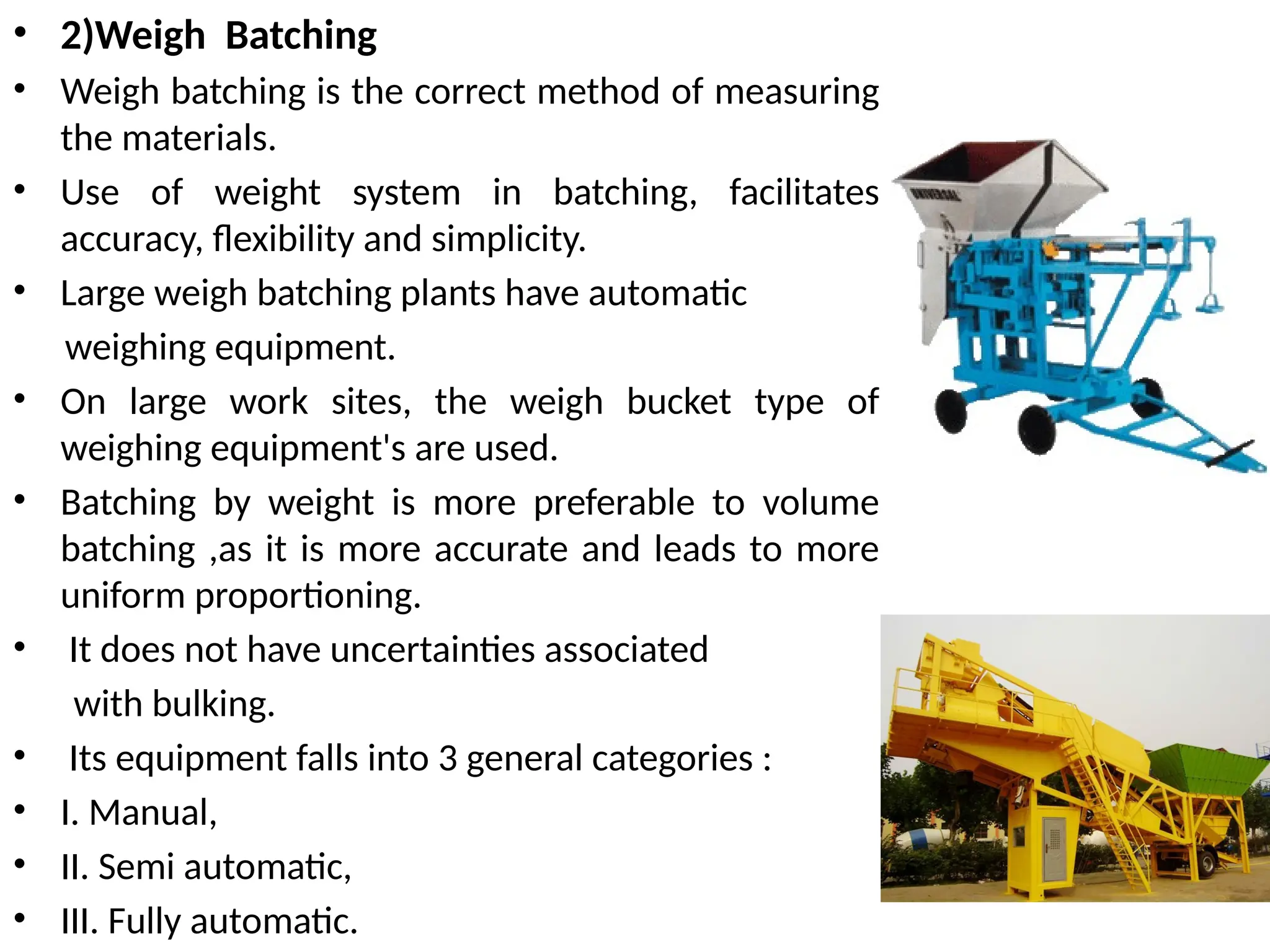

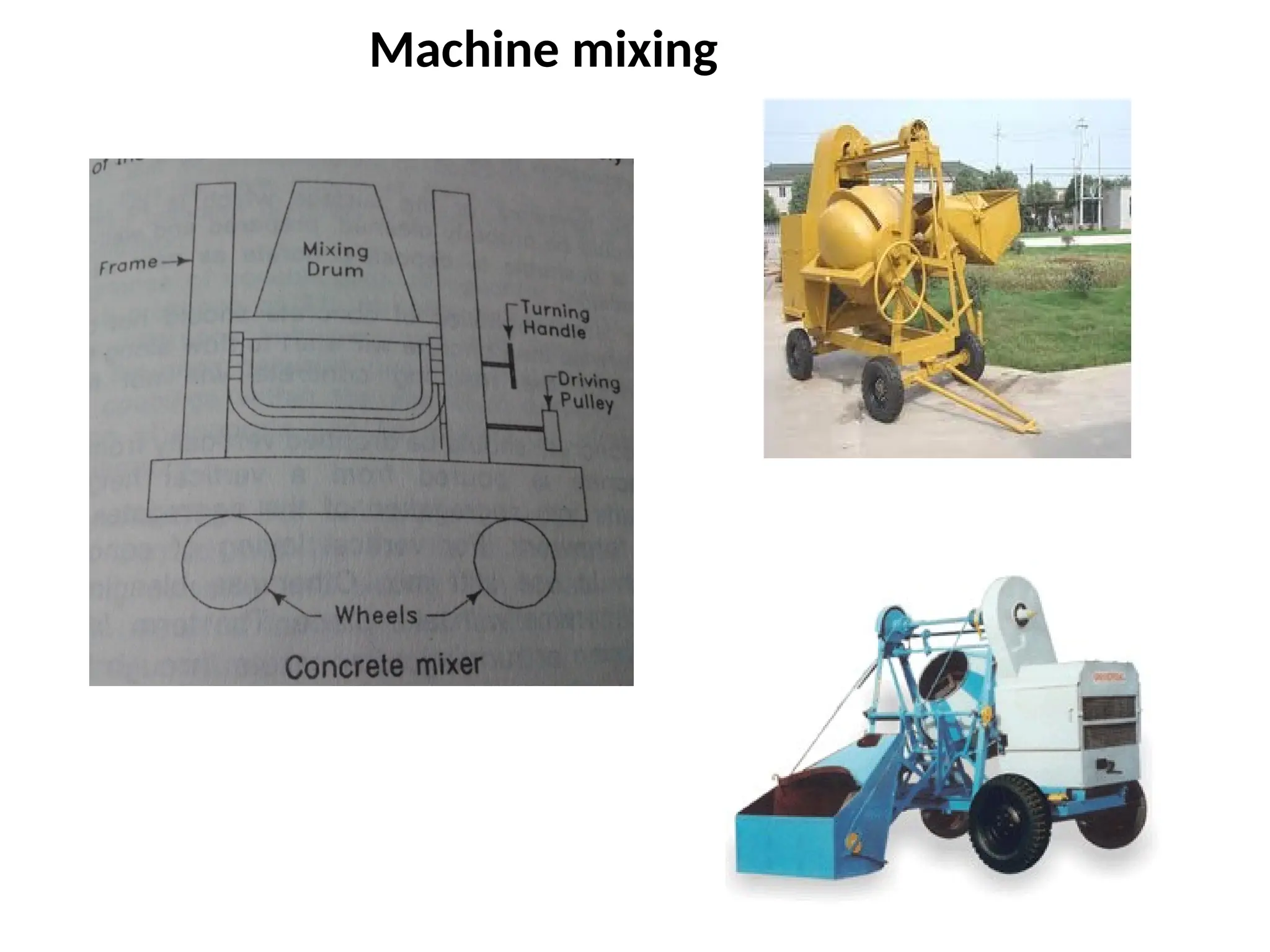

The document provides an overview of concrete, detailing its composition, properties, and benefits in construction. It discusses the materials used in reinforced cement concrete (RCC), the significance of water-cement ratio, and methods for proportioning concrete to achieve desired qualities. Additionally, it explains testing methods like the slump test for measuring workability and highlights the manufacturing process of concrete, including batching and mixing techniques.