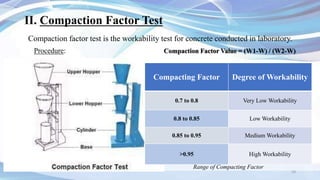

The document discusses the use of "thirsty concrete" or pervious concrete in pavement construction to allow water to permeate through the concrete and be stored, recycled, and reused. It defines thirsty concrete, provides its objectives and properties, and outlines its history and materials used. Experimental tests are also summarized that examine the slump, compaction factor, compressive strength, splitting tensile strength, and permeability of thirsty concrete mixes.

![References

[1] M. Harshavarthana Balaji, M.R.Amarnaath, R.A.Kavin, S. Jaya pradeep (2015). Design of Eco Friendly Pervious Concrete. International Journal of Civil

Engineering and Technology (IJCIET), ISSN, Volume 6, Issue 2, February (2015), pp. 22-29

[2] P.C.Balamurugan, R.Avinash, S.Kalaivani, K.Saran, S.Venkateswaran (2019). Experimental Probe on Thirsty Concrete Using Recycled Aggregate May 2019,

International Journal of Innovative Research in Technology (IJIRT), Volume 5 Issue 12. ISSN: 2349-6002

[3] Mr.Dipanjan Mukherjee (2014). Manage Storm Water by Using Porous Pavement IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE). e-ISSN: 2278-

1684,p-ISSN: 2320-334X, Volume 11, Issue 4 Ver. III (Jul- Aug. 2014), PP 01-03

[4] Carmen T. Agouridis, Jonathan A. Villines and Joe D. Luck (2011). Permeable Pavement for Stormwater Management. University of Kentucky College of

Agriculture, Lexington, KY, 40564.

[5] Abrar Ahmed Khan, Sayed Sarfaraz, Syed Bilal Mansoori, Avinash Patel K L, Poornima K B, Dinesh S Magnur (2017). Study on Porous Concrete with Course

Aggregate and Fine Aggregate Mix Proportions. International Journal of Engineering Research & Technology (IJERT). ISSN: 2278-0181, Vol. 6 Issue 05, May – 2017

[6] Darshan S. Shah, Prof. Jayeshkumar Pitroda, Prof. J. J. Bhavsar (2013). Pervious Concrete: New Era For Rural Road Pavement. International Journal of

Engineering Trends and Technology (IJETT) – Volume 4 Issue 8- August 2013

35](https://image.slidesharecdn.com/thirstyconcrete-240310150852-139d98d5/85/Thirsty-Concrete-application-in-Road-pavement-35-320.jpg)

![[7] Prof. Shilpi S. Bhuinyan, Shreyance Luniya, Mithila Mane, Smit Modi, Rushikesh Tapkir (2019). An Experimental Study on Strength and Properties of Thirsty

Concrete. International Journal Of Innovative Research In Technology (IJIRT) Volume 6 Issue 1 - ISSN: 2349-6002 June 2019

[8] Jaydeepkumar R. Prajapati, Dr. Jayeshkumar R. Pitroda, Prof. Amitkumar D. Raval (2019). Experimental Study On Pervious Concrete With Fly Ash And Metakaolin.

Journal of Emerging Technologies and Innovative Research (JETIR) - Volume 6, Issue 5 - May 2019

[9] Arun. H, Franglin Jose. L, Joegin Raj. K. R, Julius Walter. A.G, M. Murugalingam. (2016). Experimental Investigation On Increasing The Strength Of Pervious

Concrete By Varying The Mix Ingredients, International Journal of Advances in Mechanical and Civil Engineering, ISSN: 2394-2827 Volume-3, Issue-3, Jun.-2016

[10] An Cheng, Hui-Mi Hsu, Sao-Jeng Chao, And Kae-Long Lin (2011). Experimental study on properties of pervious concrete made with recycled aggregate’

International Journal of Pavement Research And Technology Vol.4 No.2, 2011

[11] L. K. Crouch, P.E.; Jordan Pitt; And Ryan Hewitt (2007. Aggregate effects on pervious portland cement concrete static modulus of elasticity” Journal Of Materials

In Civil Engineering Volume 19(7), 561-568 - 2007

36](https://image.slidesharecdn.com/thirstyconcrete-240310150852-139d98d5/85/Thirsty-Concrete-application-in-Road-pavement-36-320.jpg)