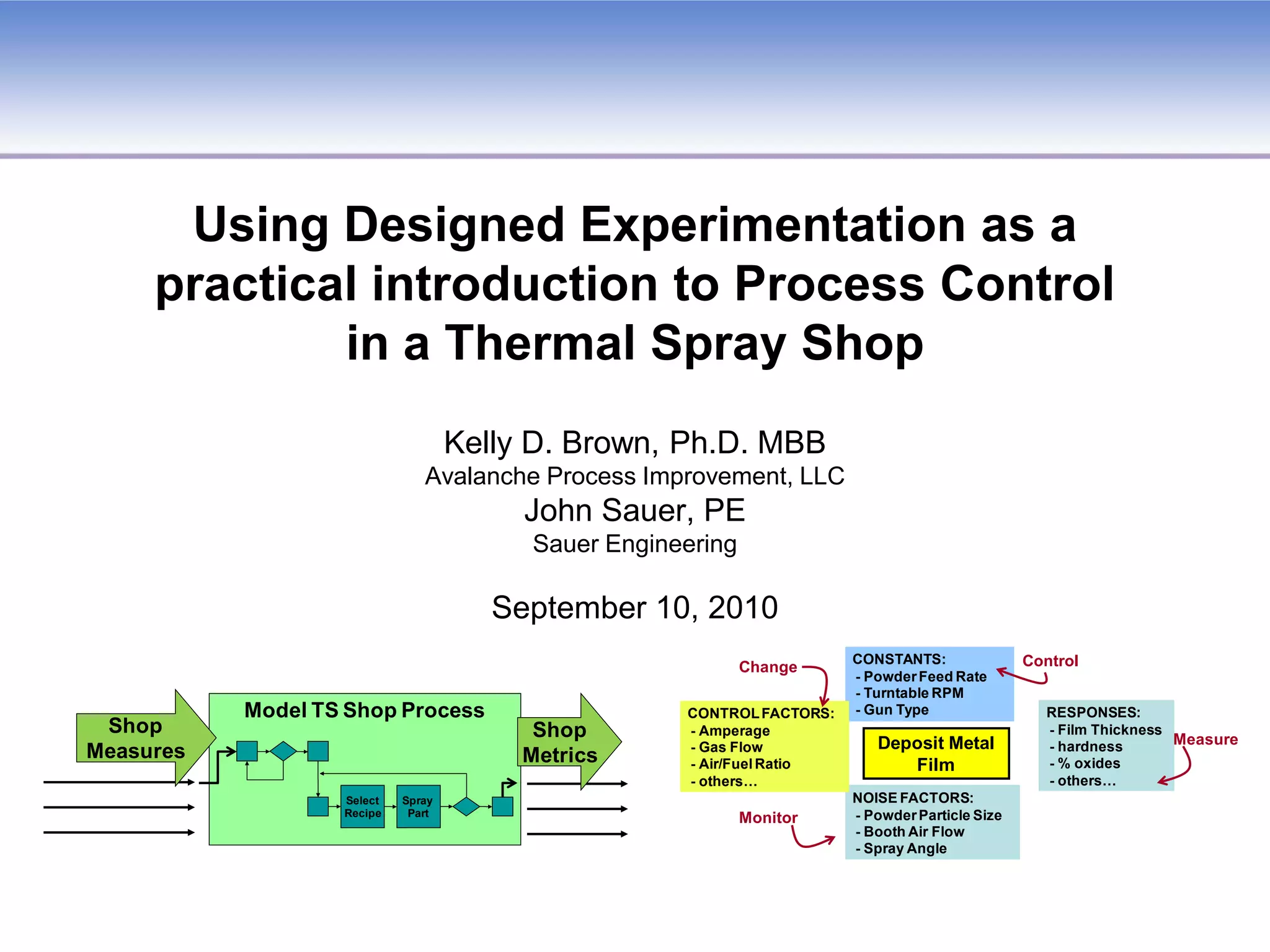

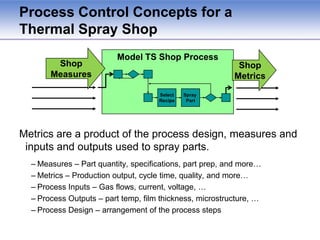

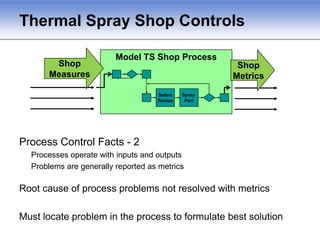

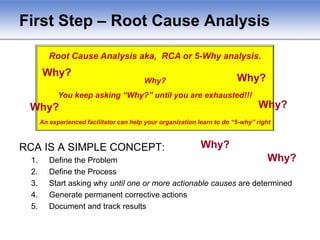

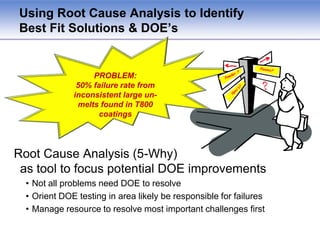

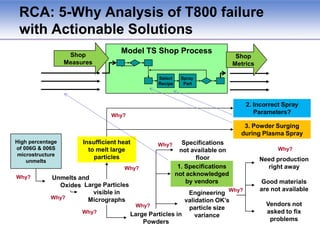

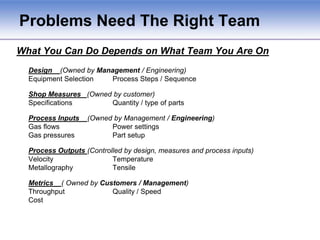

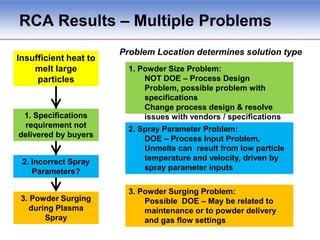

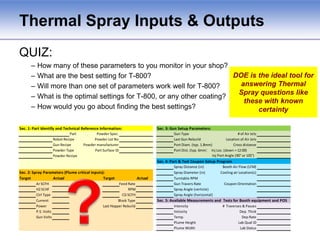

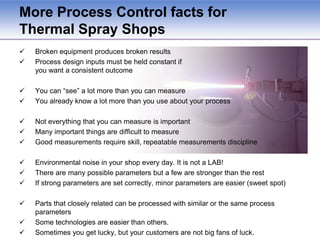

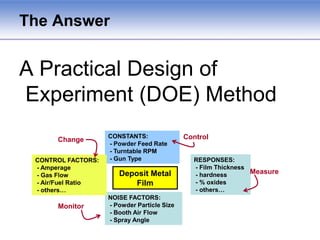

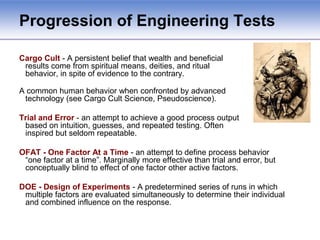

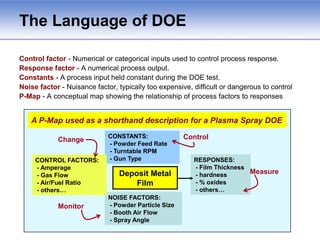

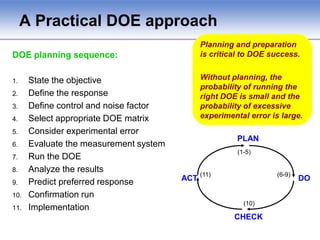

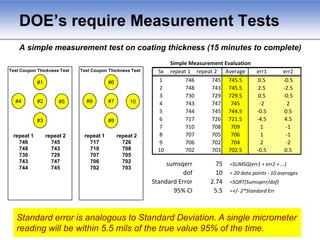

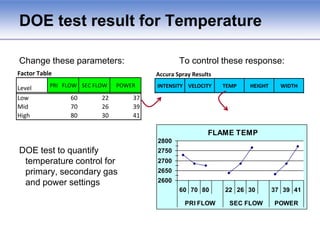

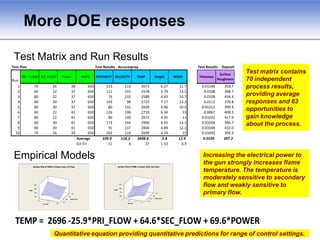

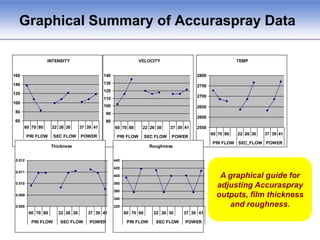

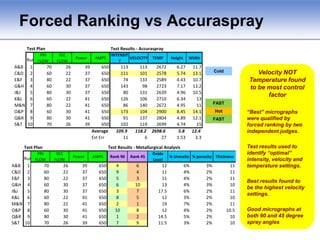

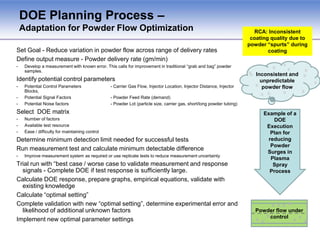

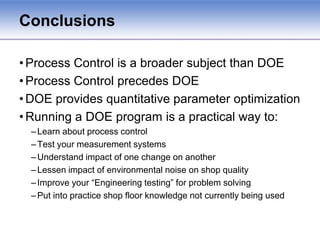

This document discusses using designed experiments (DOE) as an introduction to process control in a thermal spray shop. It provides an overview of process control concepts and an example of using root cause analysis to troubleshoot issues. It then discusses how advanced process control can be achieved through DOE to optimize thermal spray processes. Two approaches to implementing DOE are described - a project model with a consultant leading large tests, and an operational training model where small problems are solved through planning DOE tests. Benefits of DOE include providing confident solutions for multi-factor processes and improving measurement and process understanding.