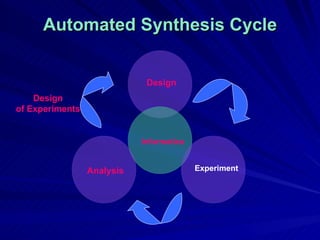

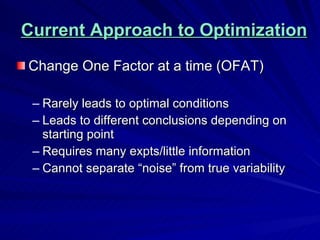

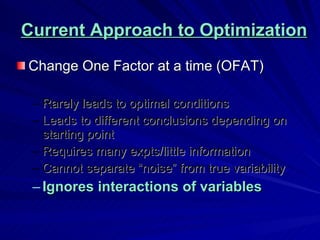

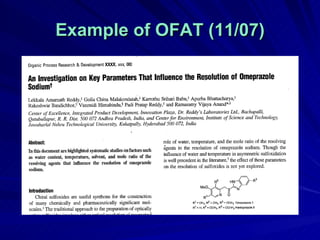

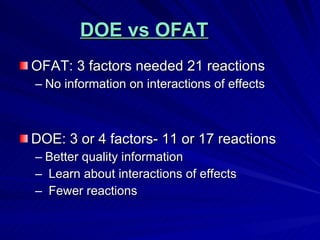

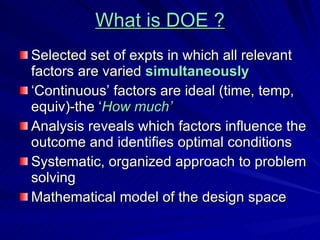

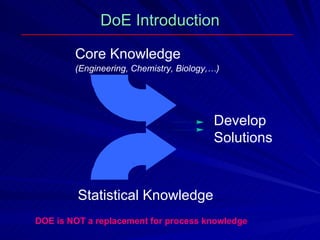

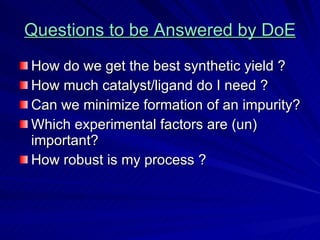

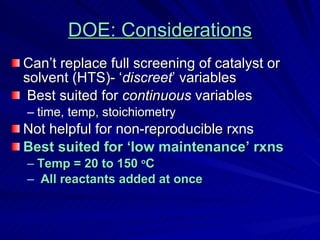

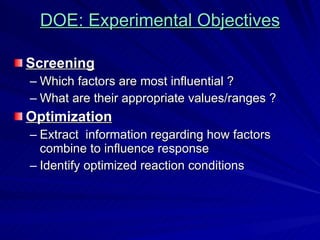

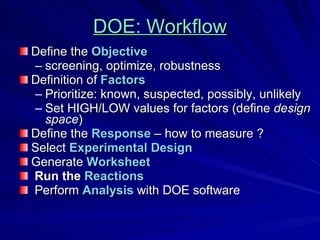

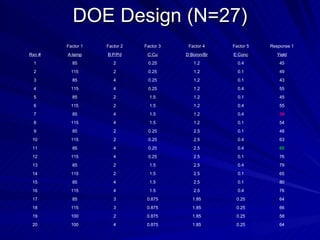

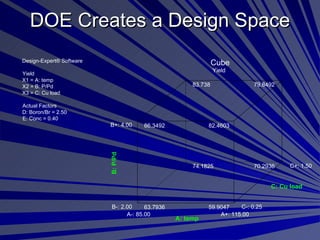

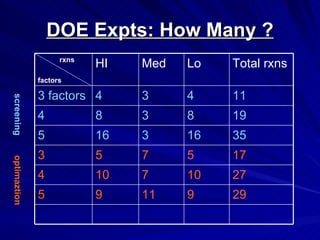

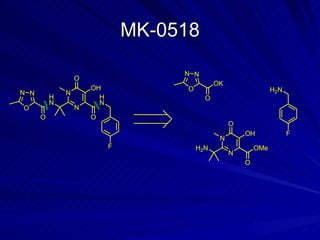

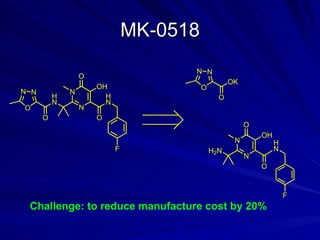

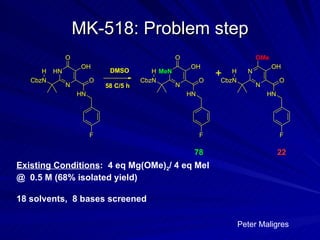

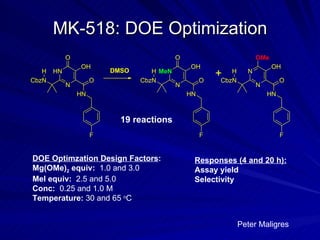

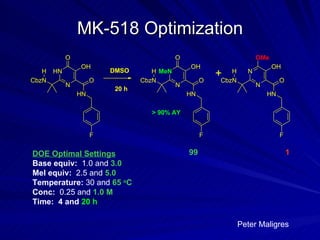

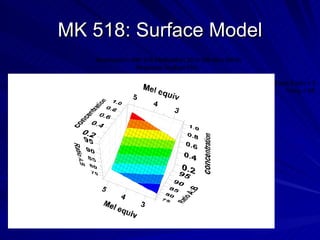

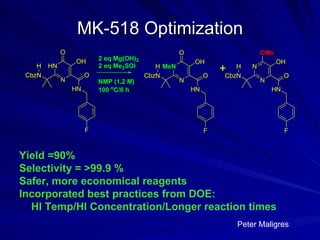

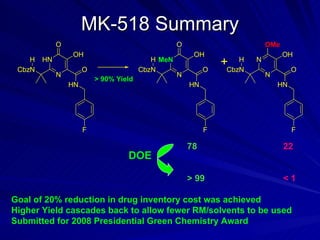

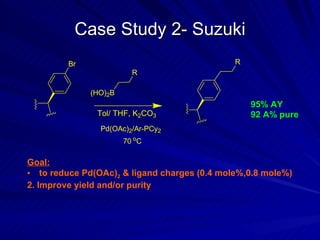

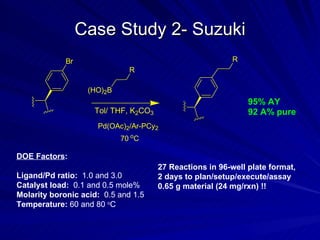

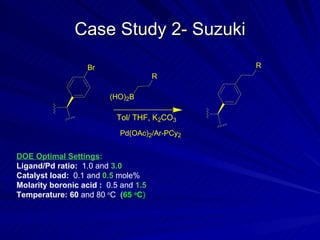

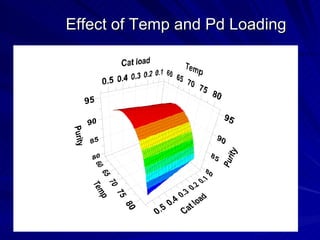

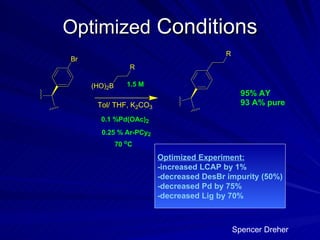

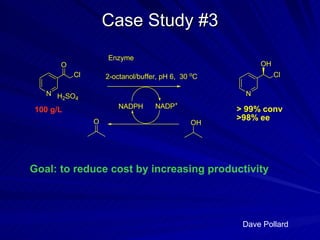

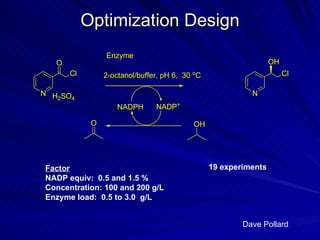

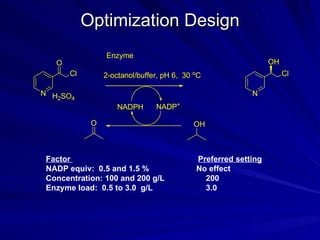

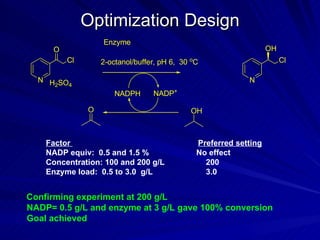

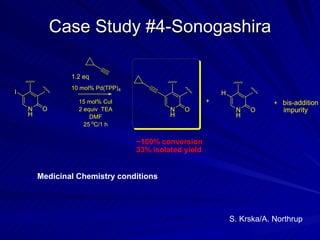

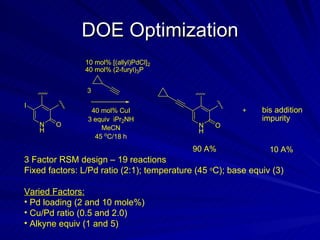

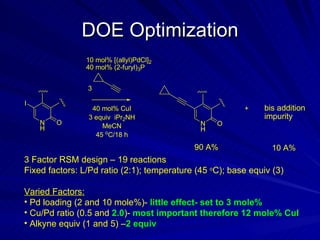

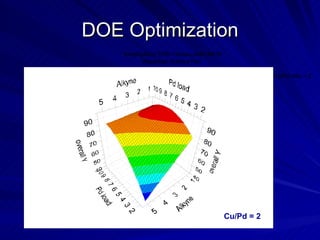

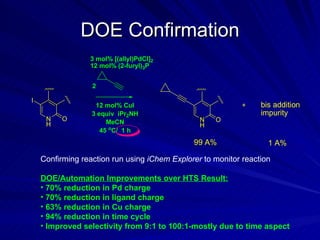

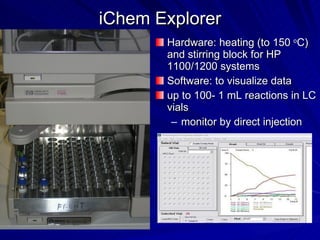

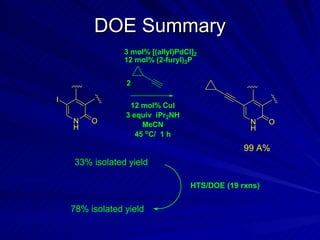

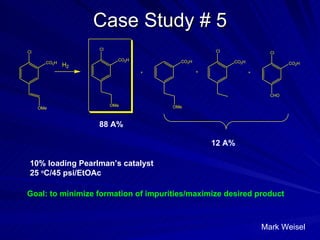

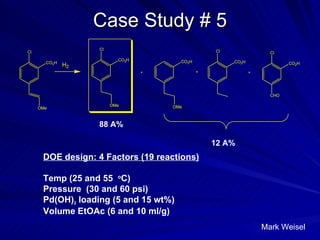

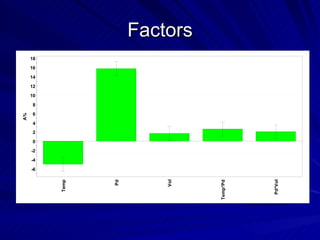

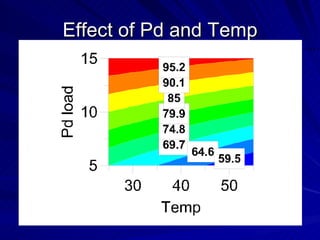

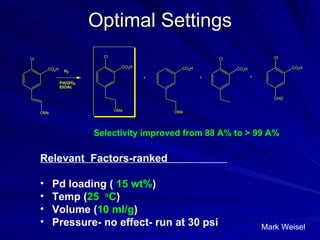

The document discusses how design of experiments (DOE) can help optimize chemical reactions and processes in a more efficient manner than traditional trial-and-error approaches. It provides examples of how pharmaceutical companies have used DOE to reduce costs and improve yields for key reaction steps. DOE allows researchers to systematically vary multiple reaction factors at once to understand their effects and interactions, requiring fewer total experiments than one-factor-at-a-time testing.