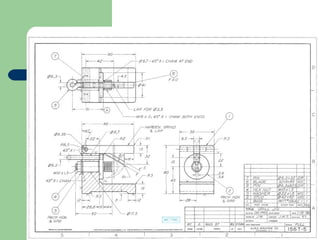

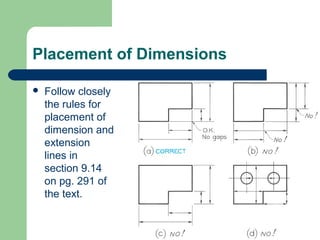

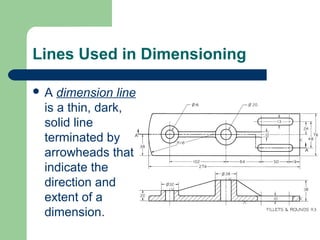

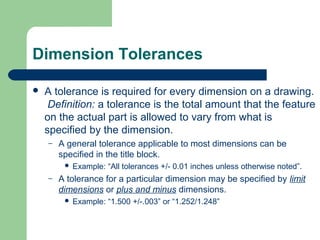

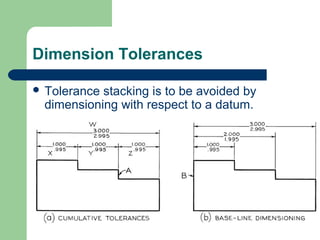

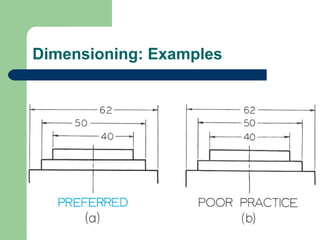

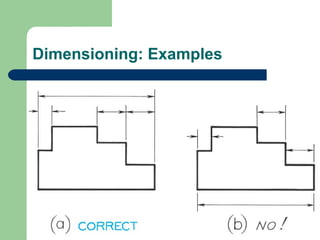

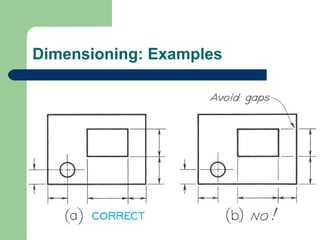

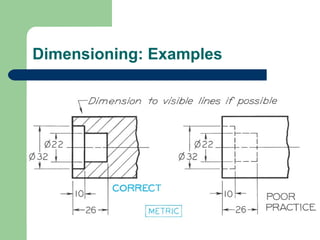

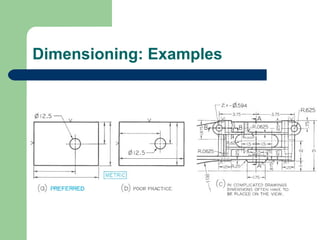

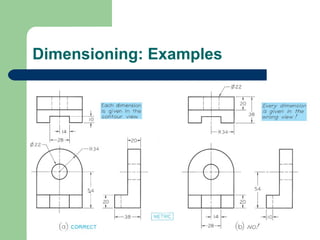

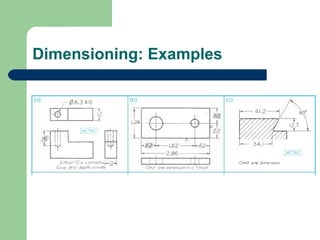

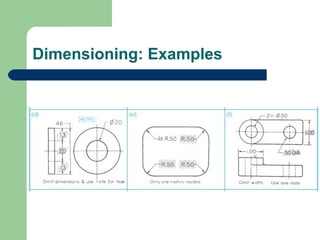

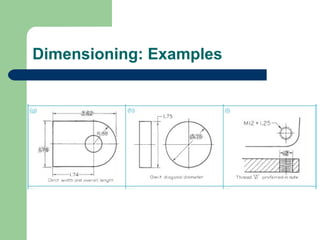

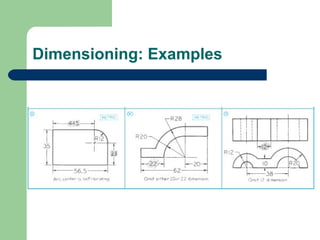

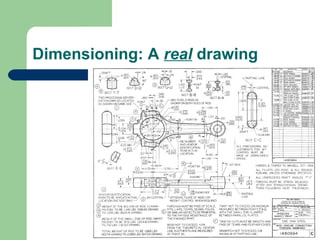

This document provides an overview of dimensioning drawings according to engineering standards. It discusses that dimensions define the sizes and relationships of drawing features and are used for manufacturing and inspection. Drawings with dimensions serve as manufacturing documents. The key aspects of dimensioning covered are choice of dimensions, placement, technique, and specifying tolerances. Guidelines are provided for these aspects according to technical drawing standards.