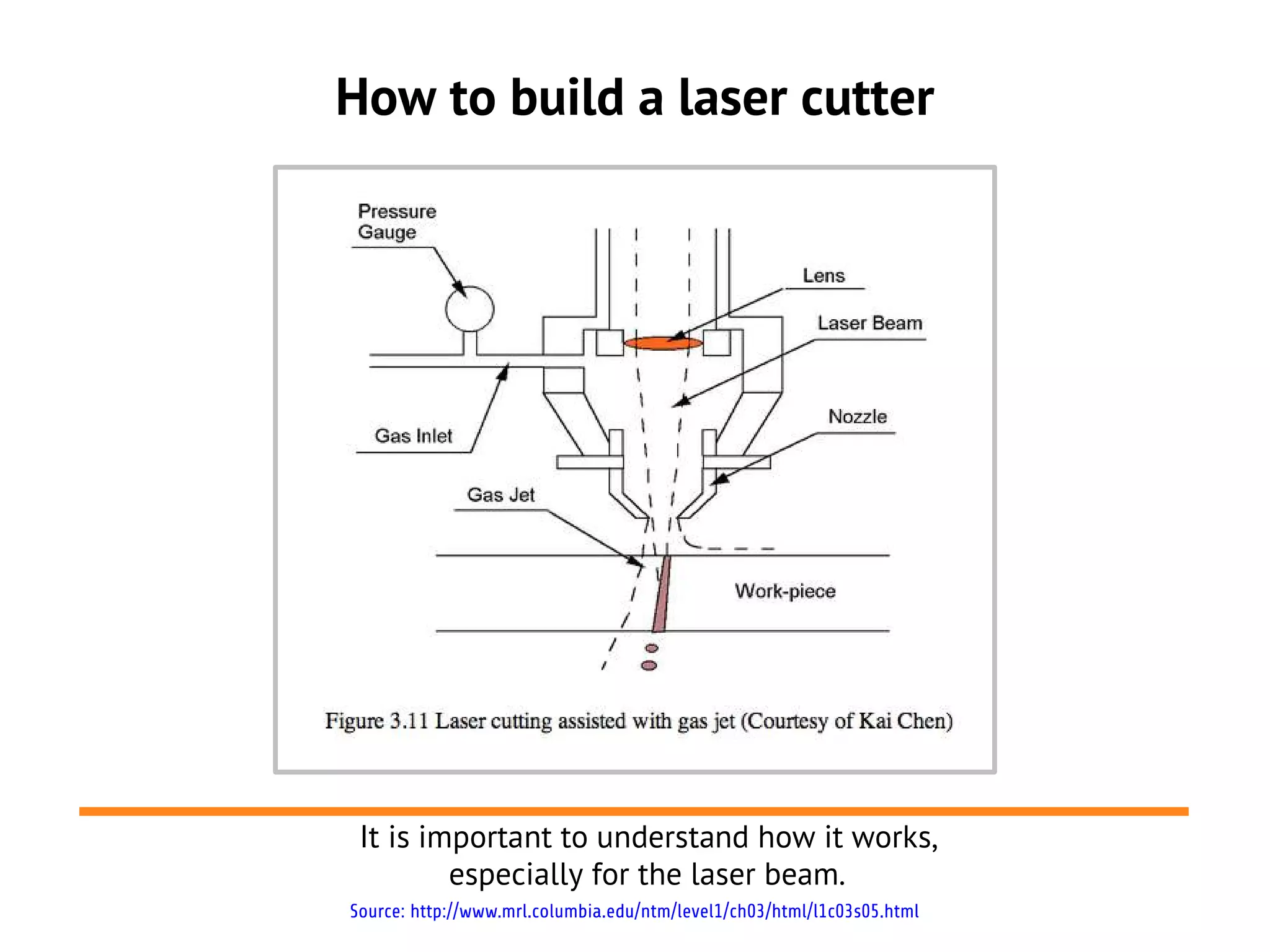

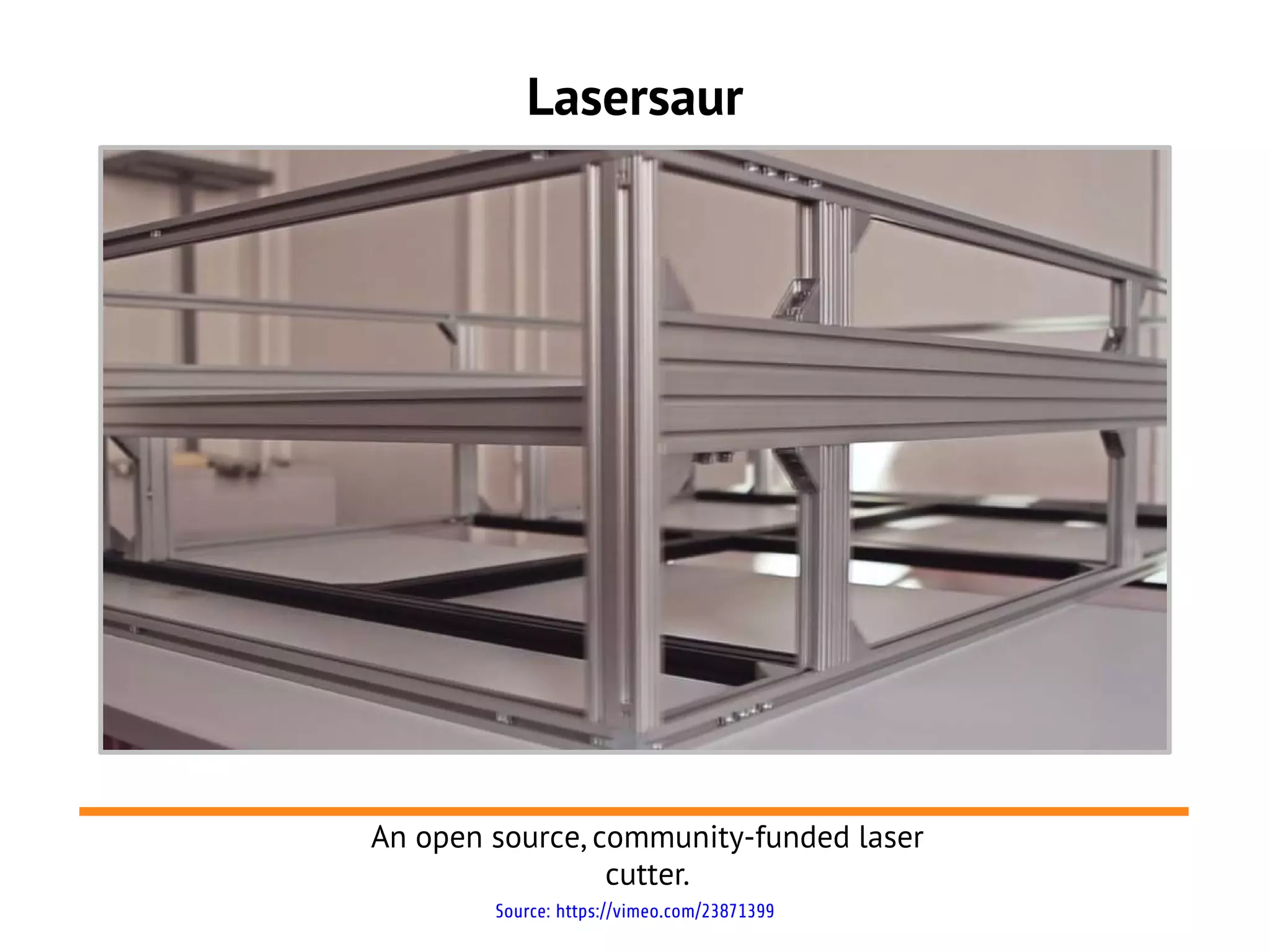

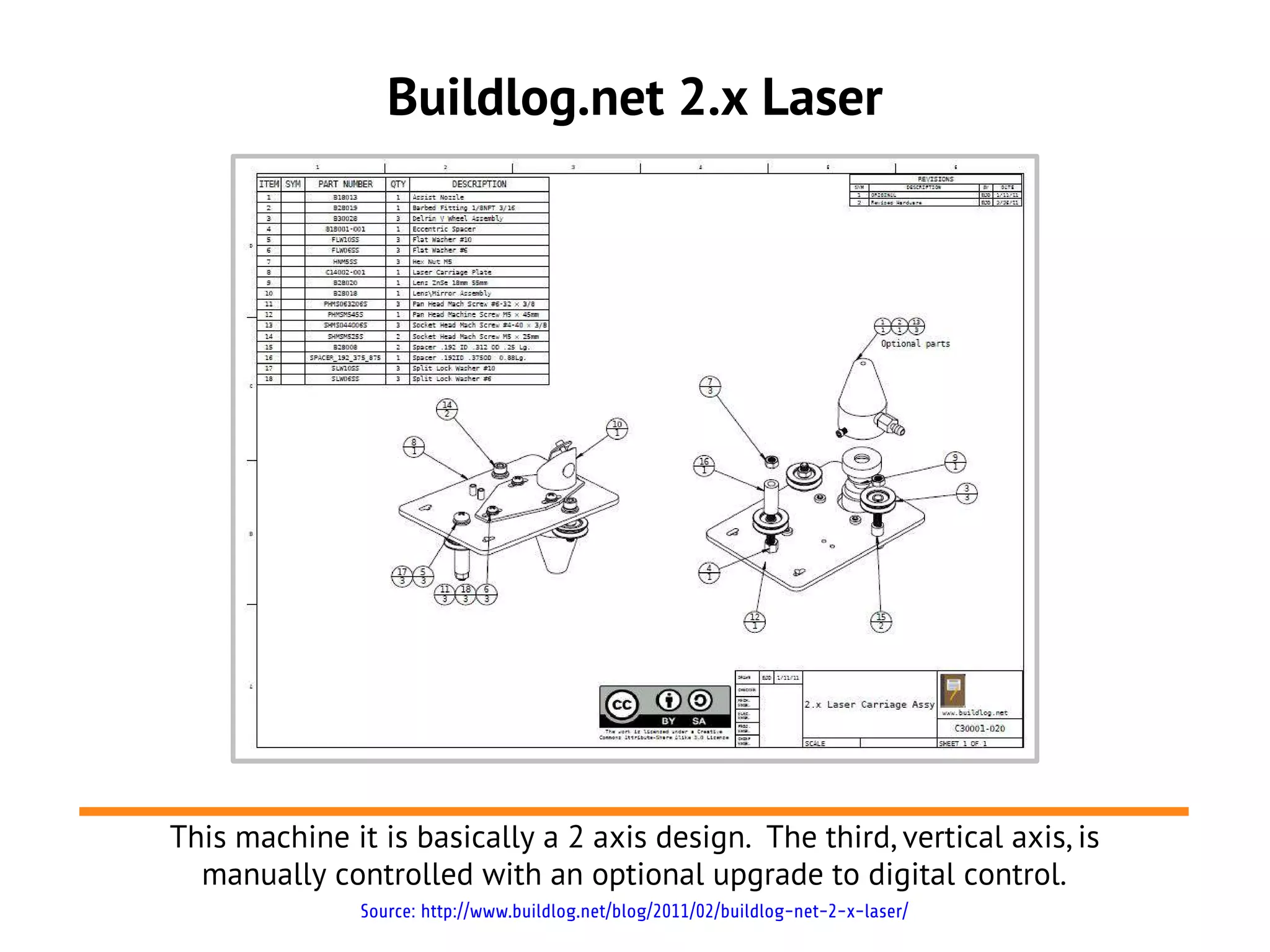

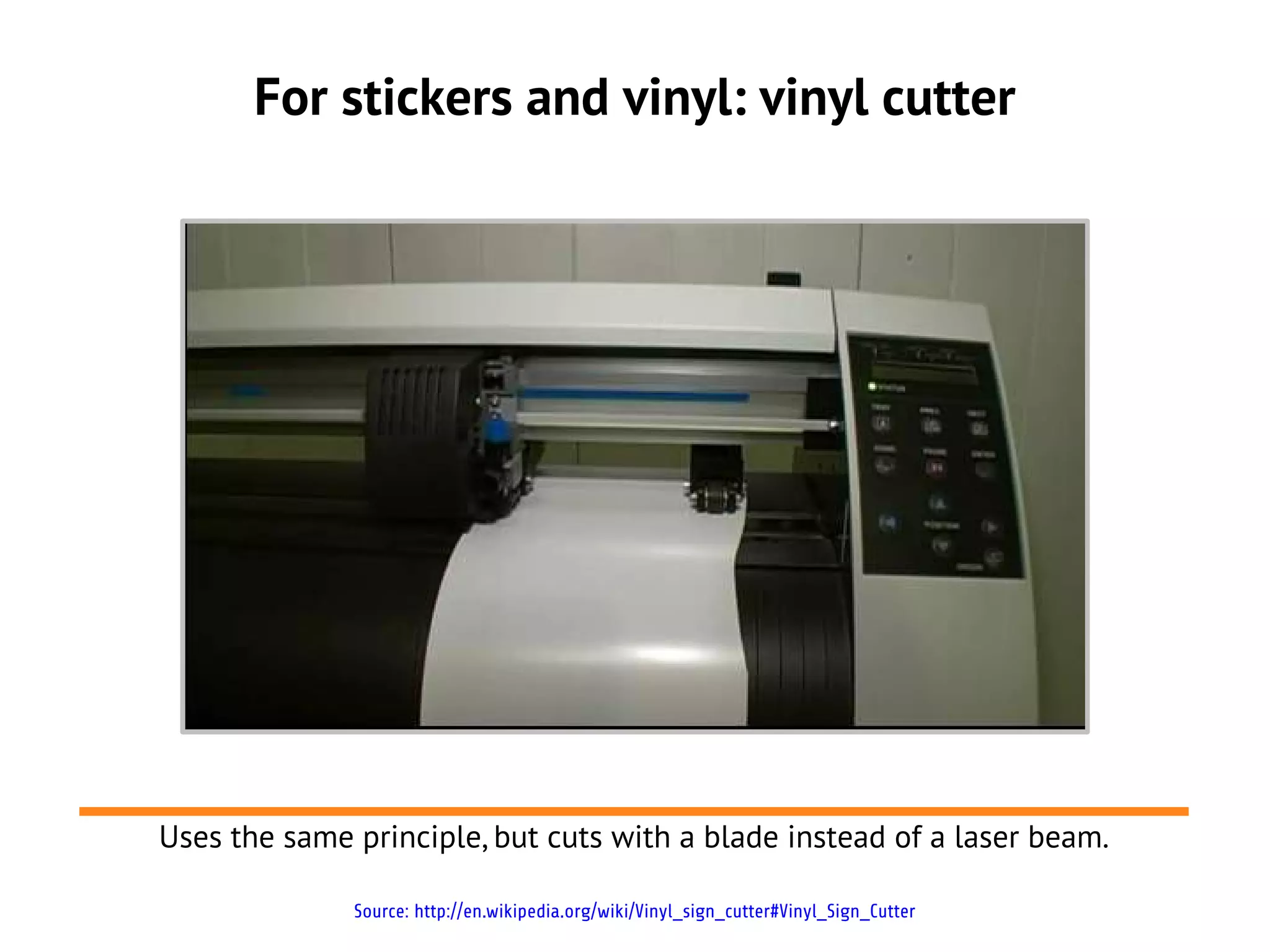

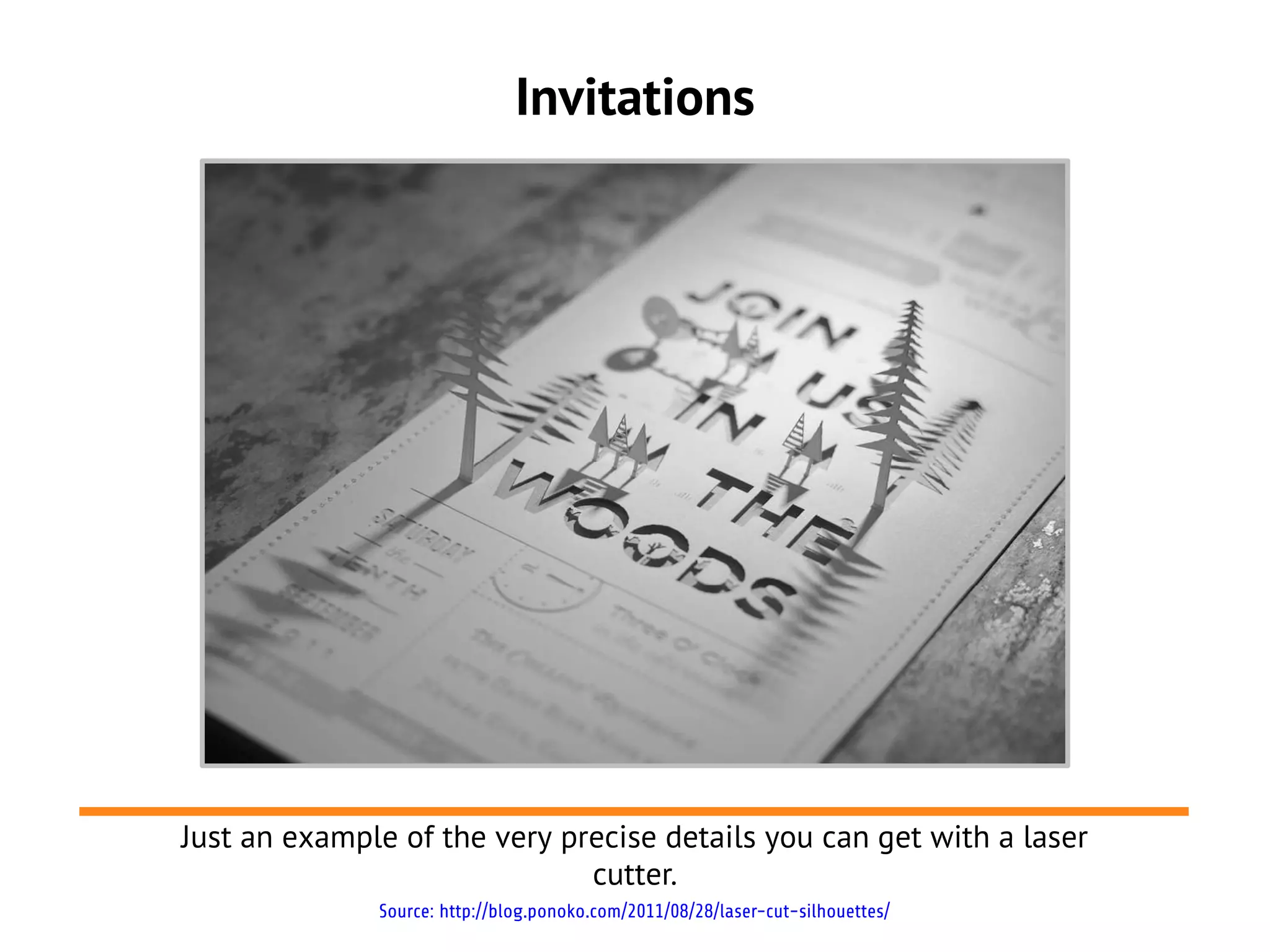

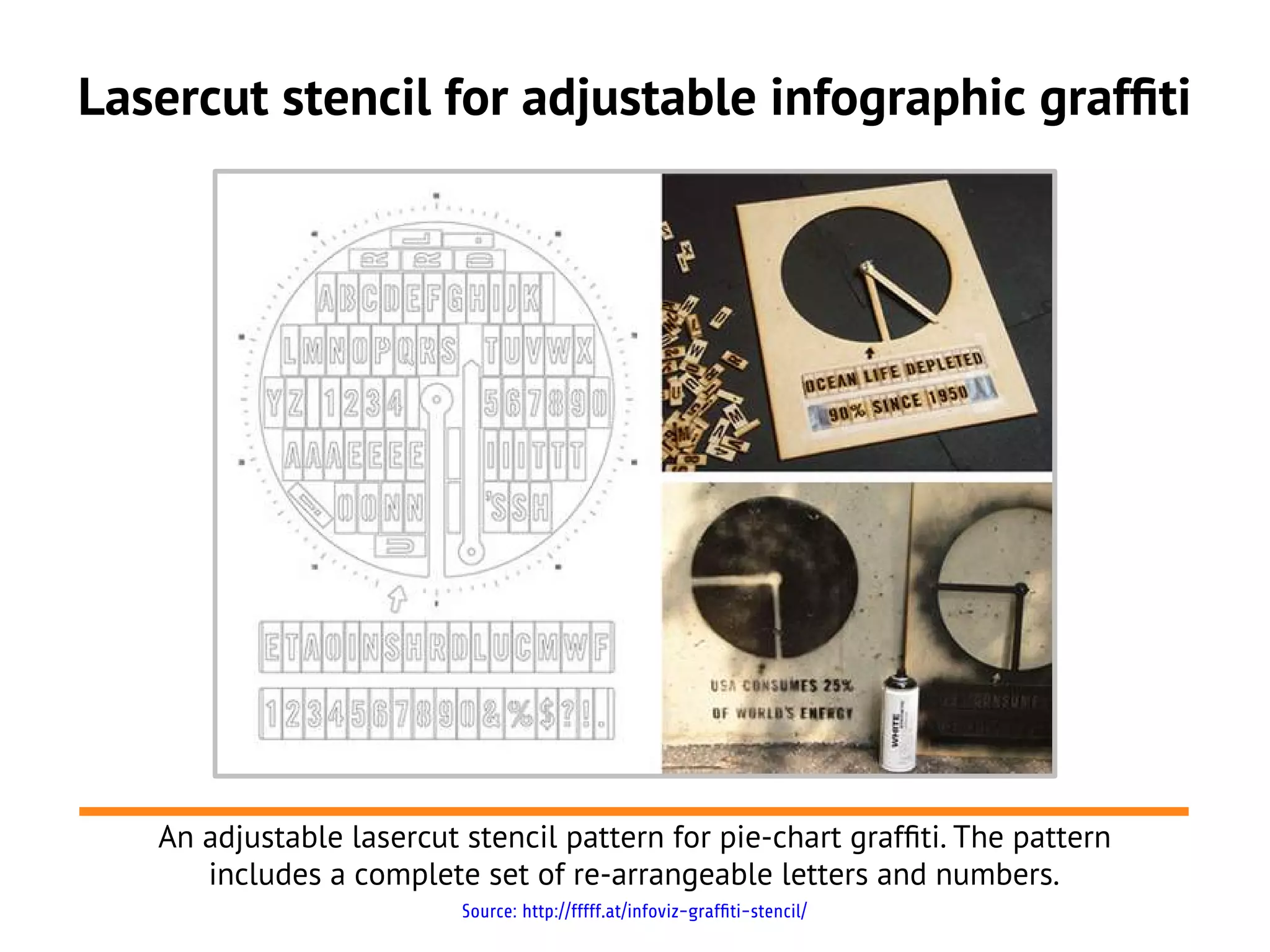

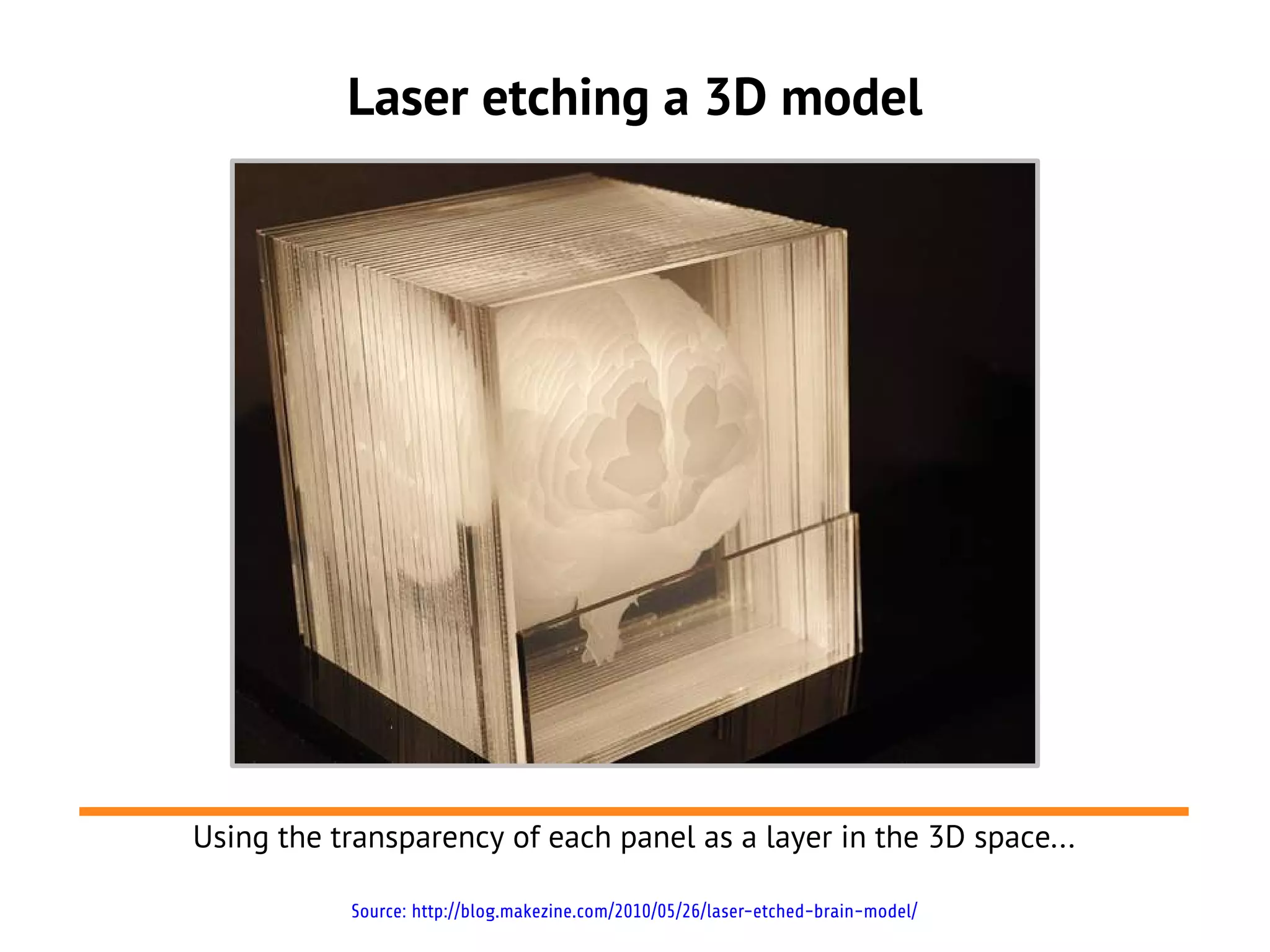

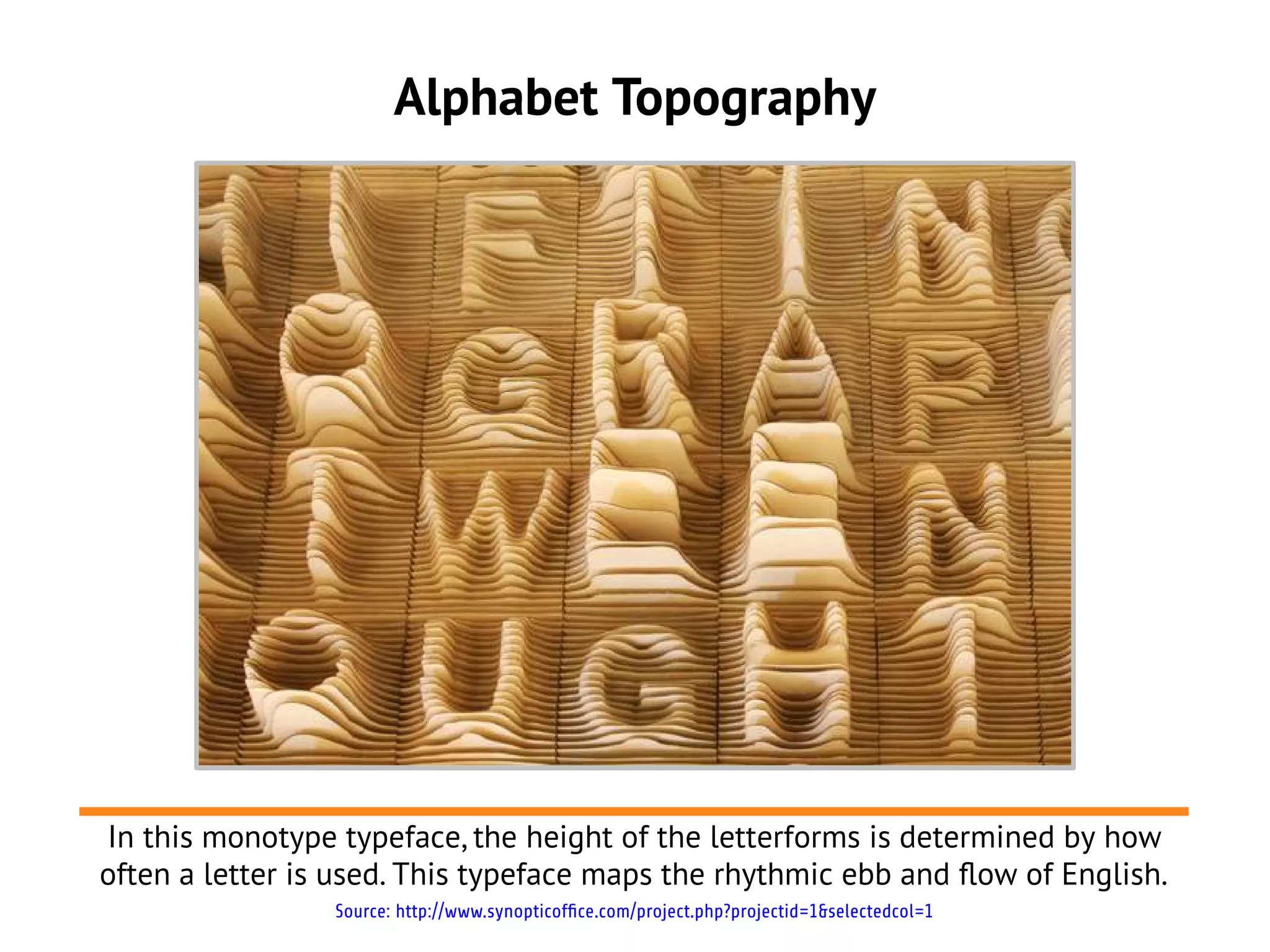

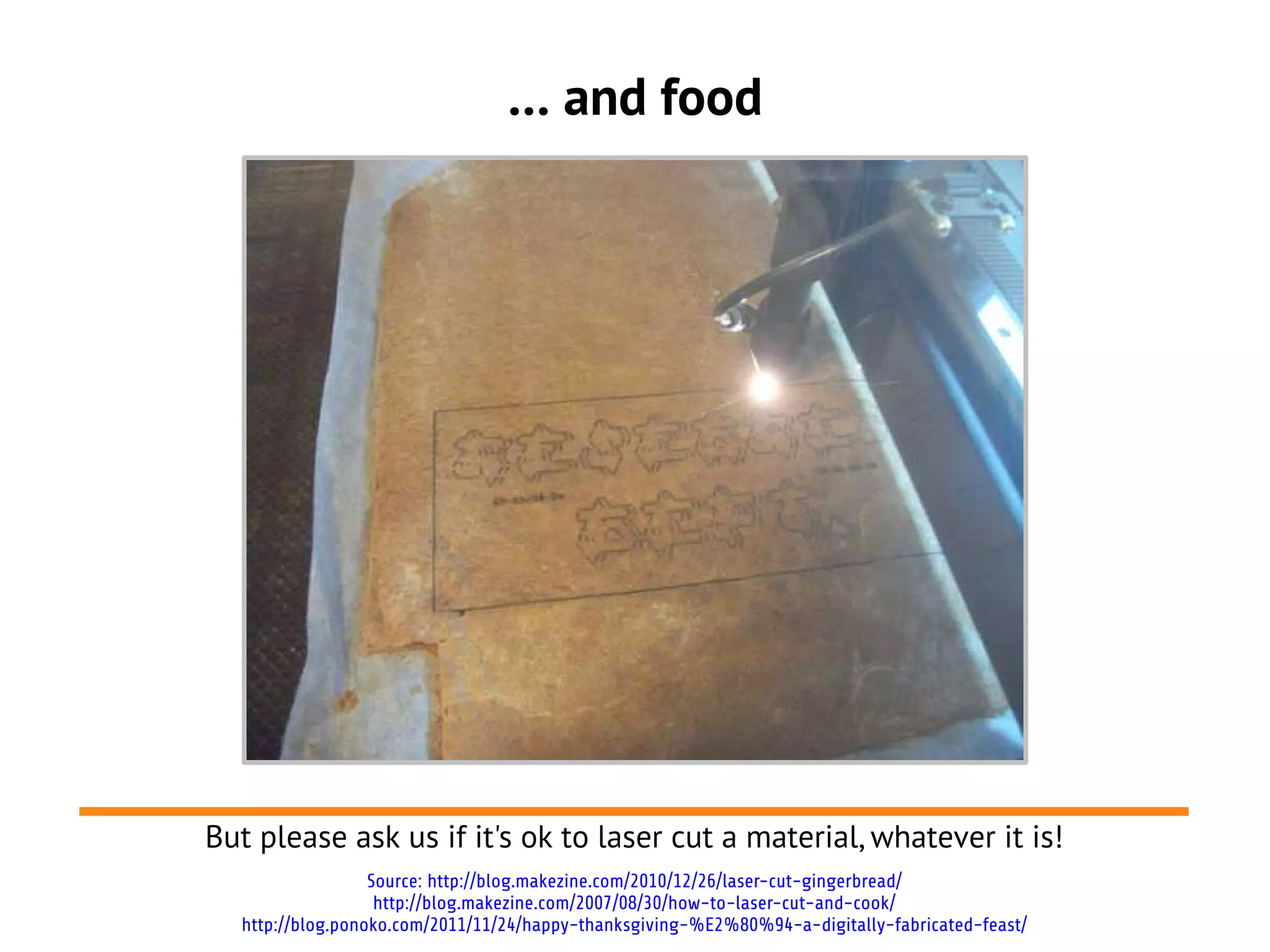

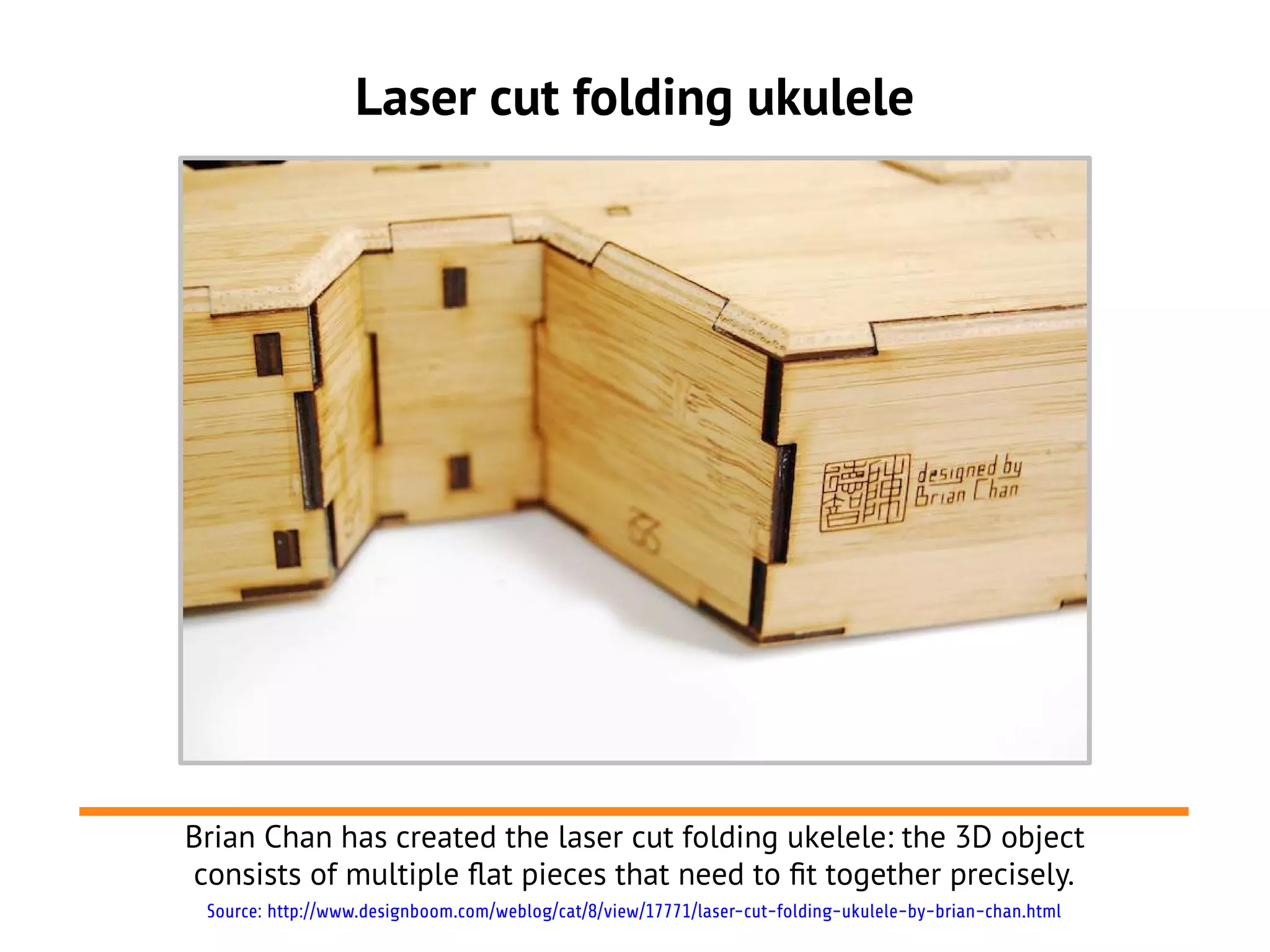

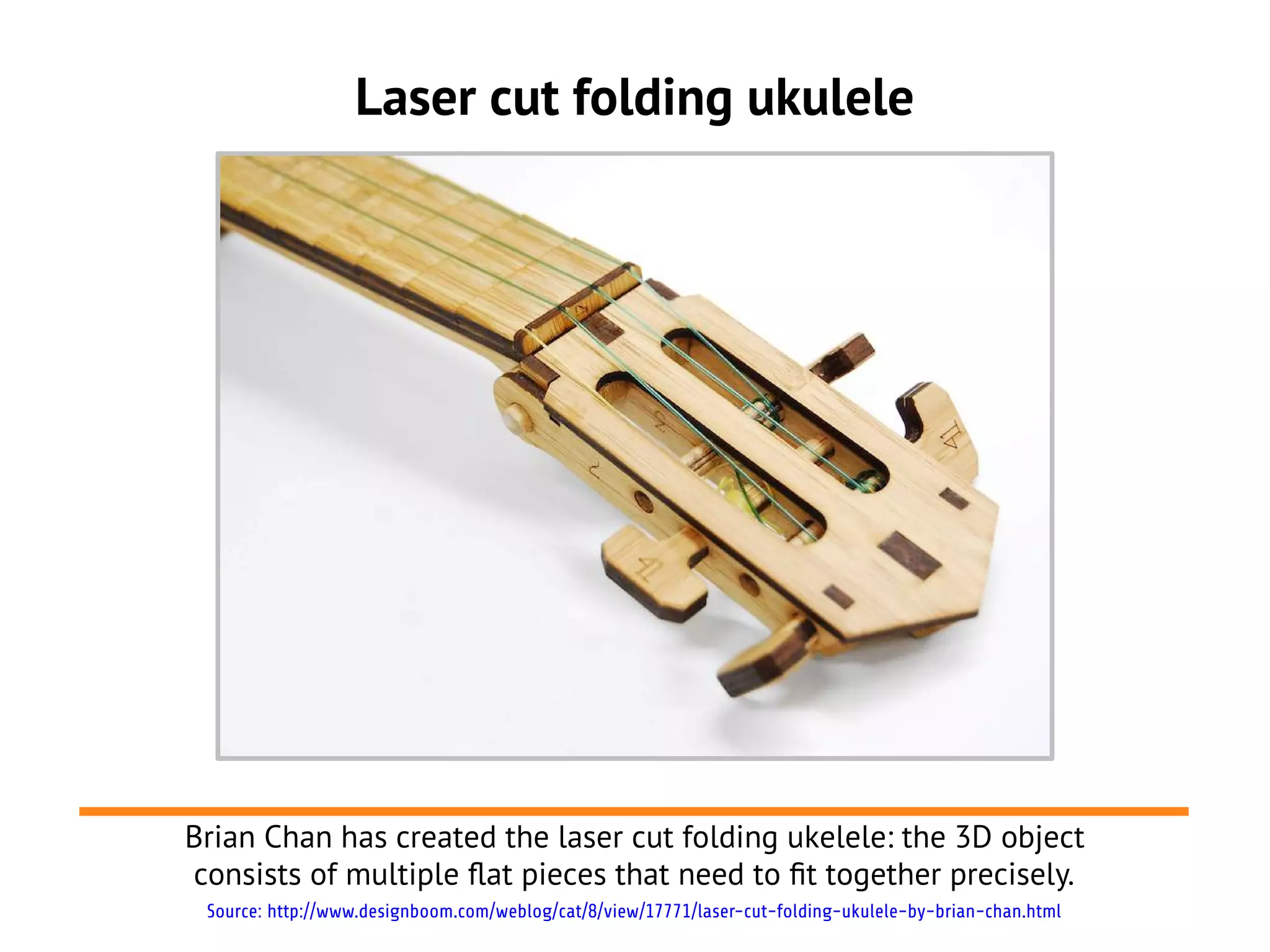

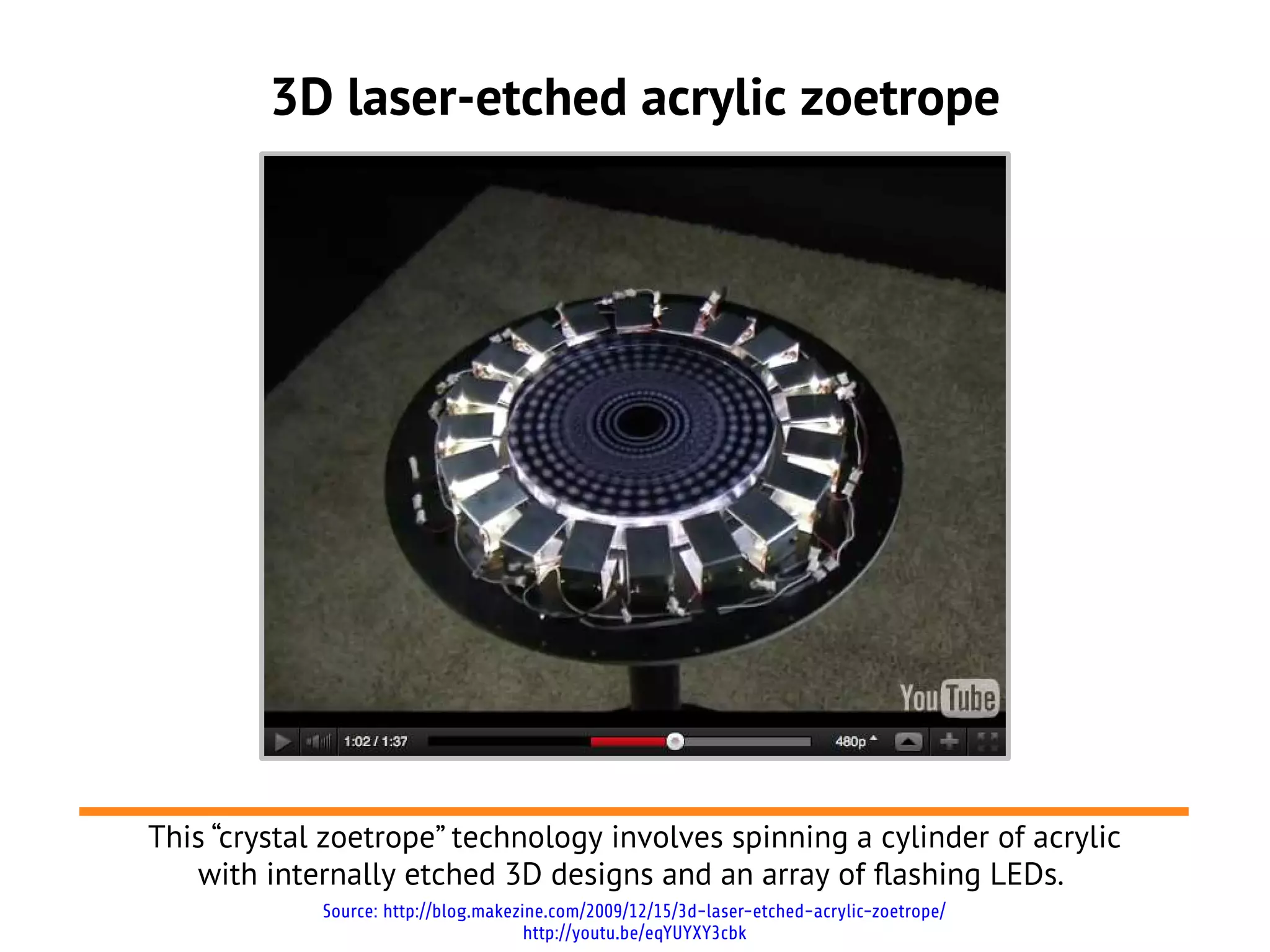

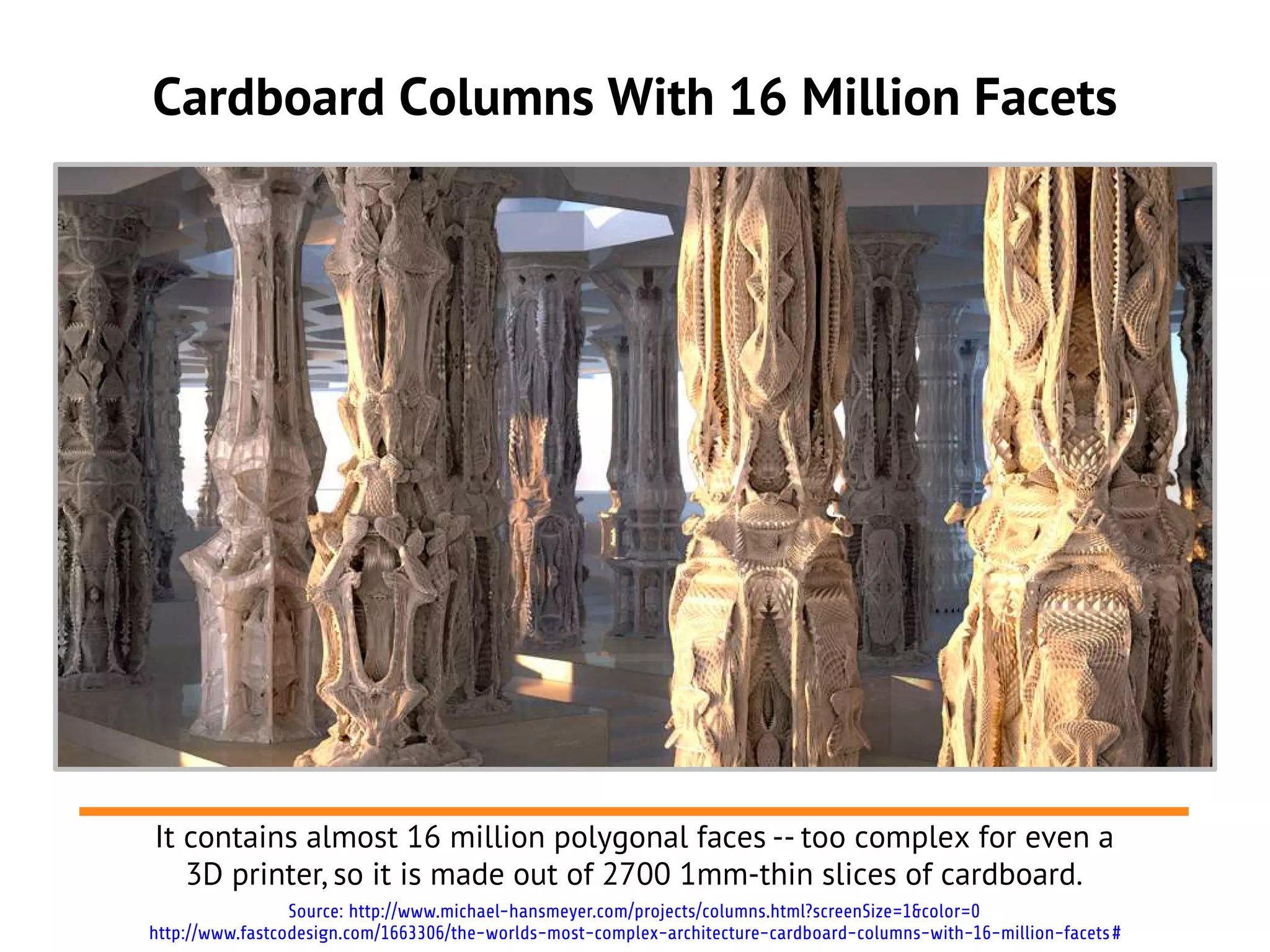

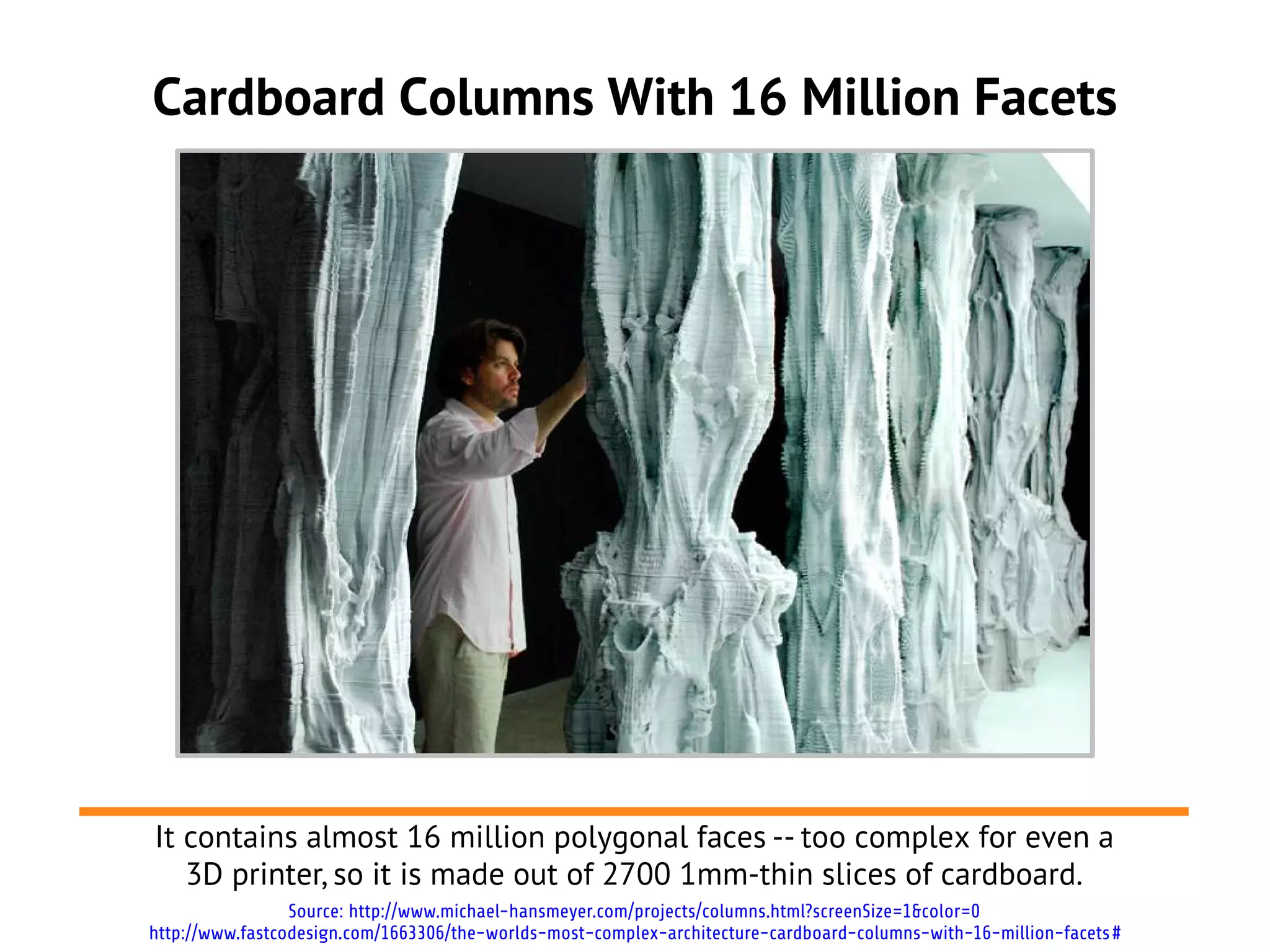

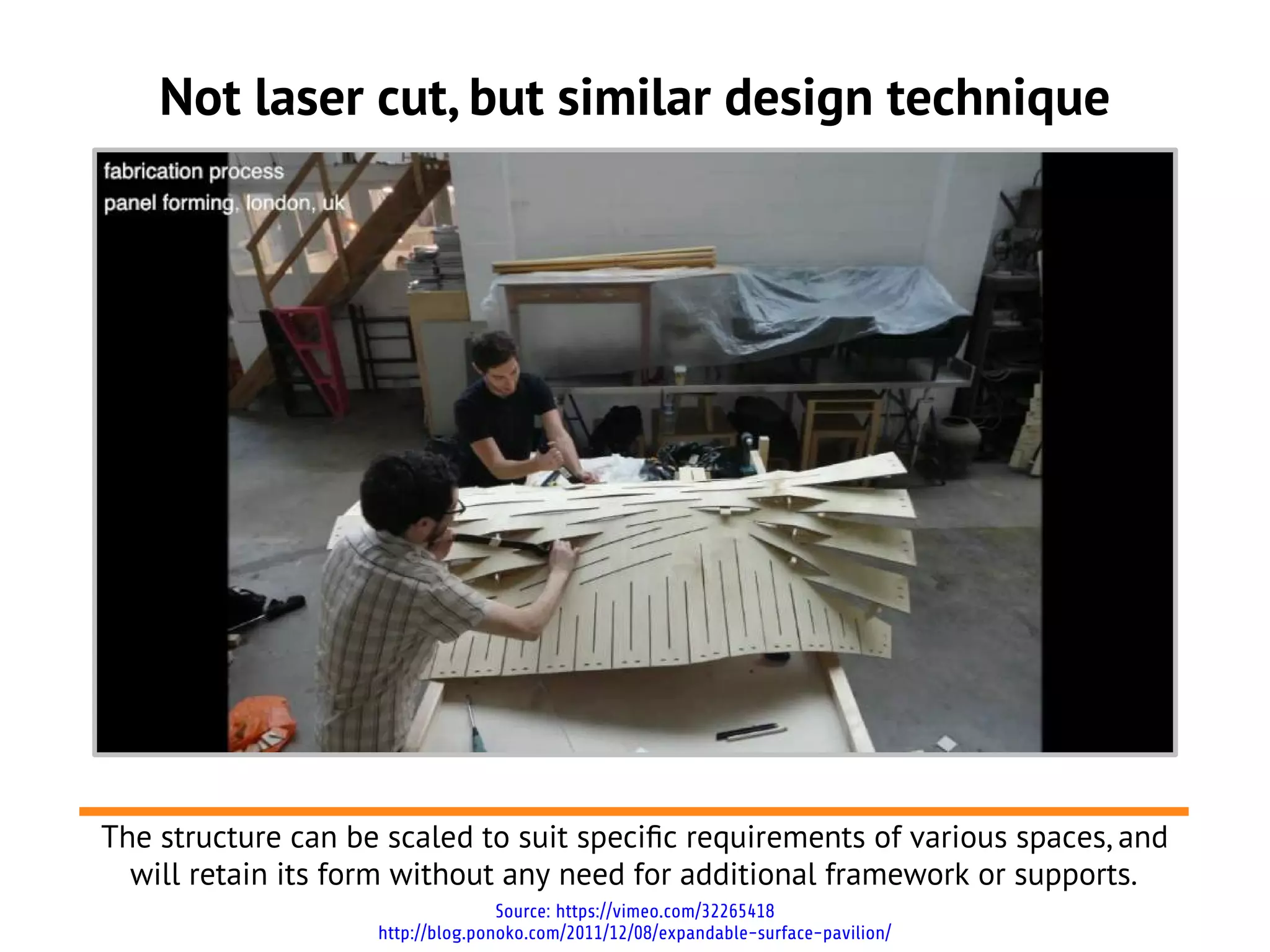

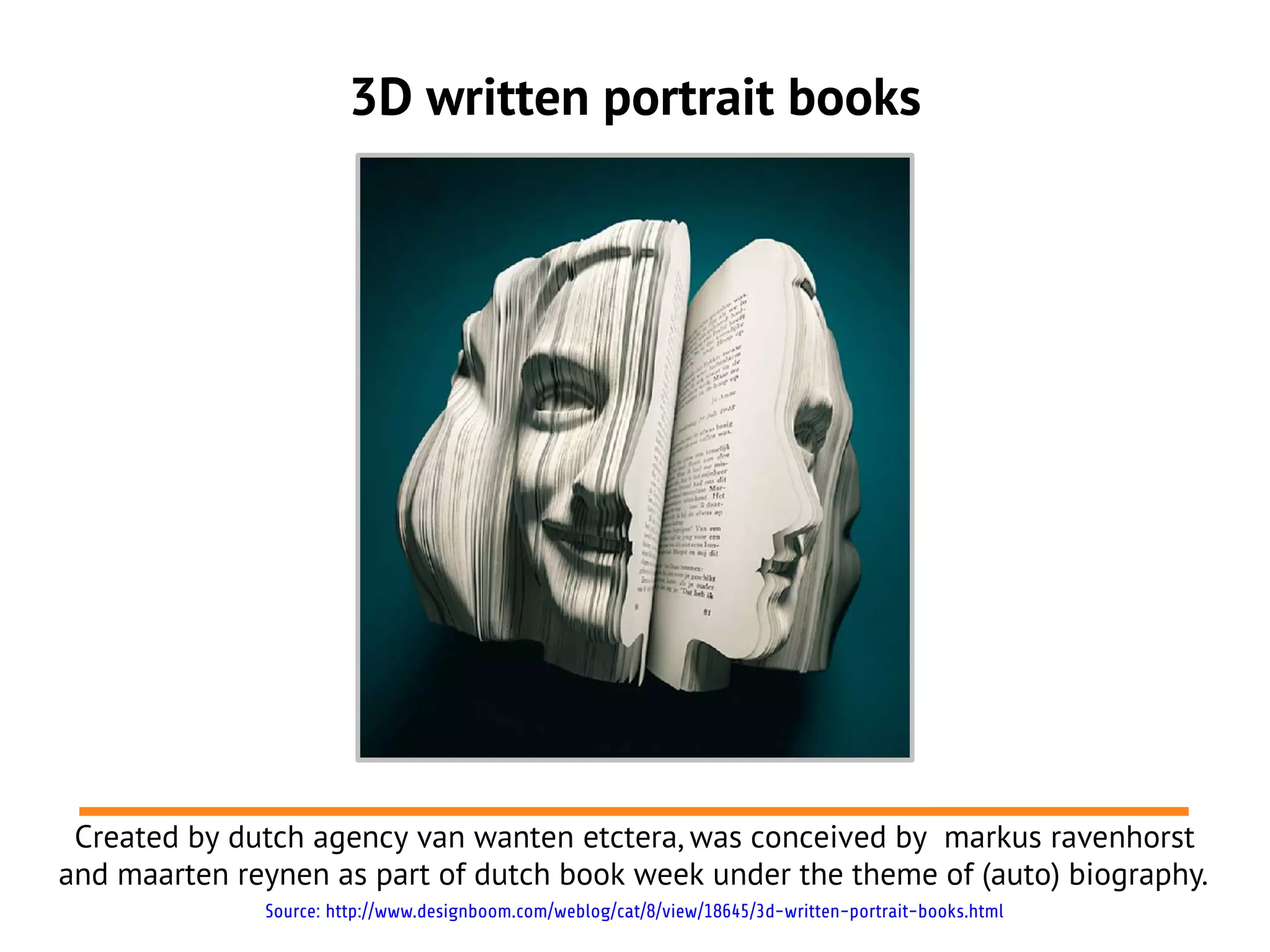

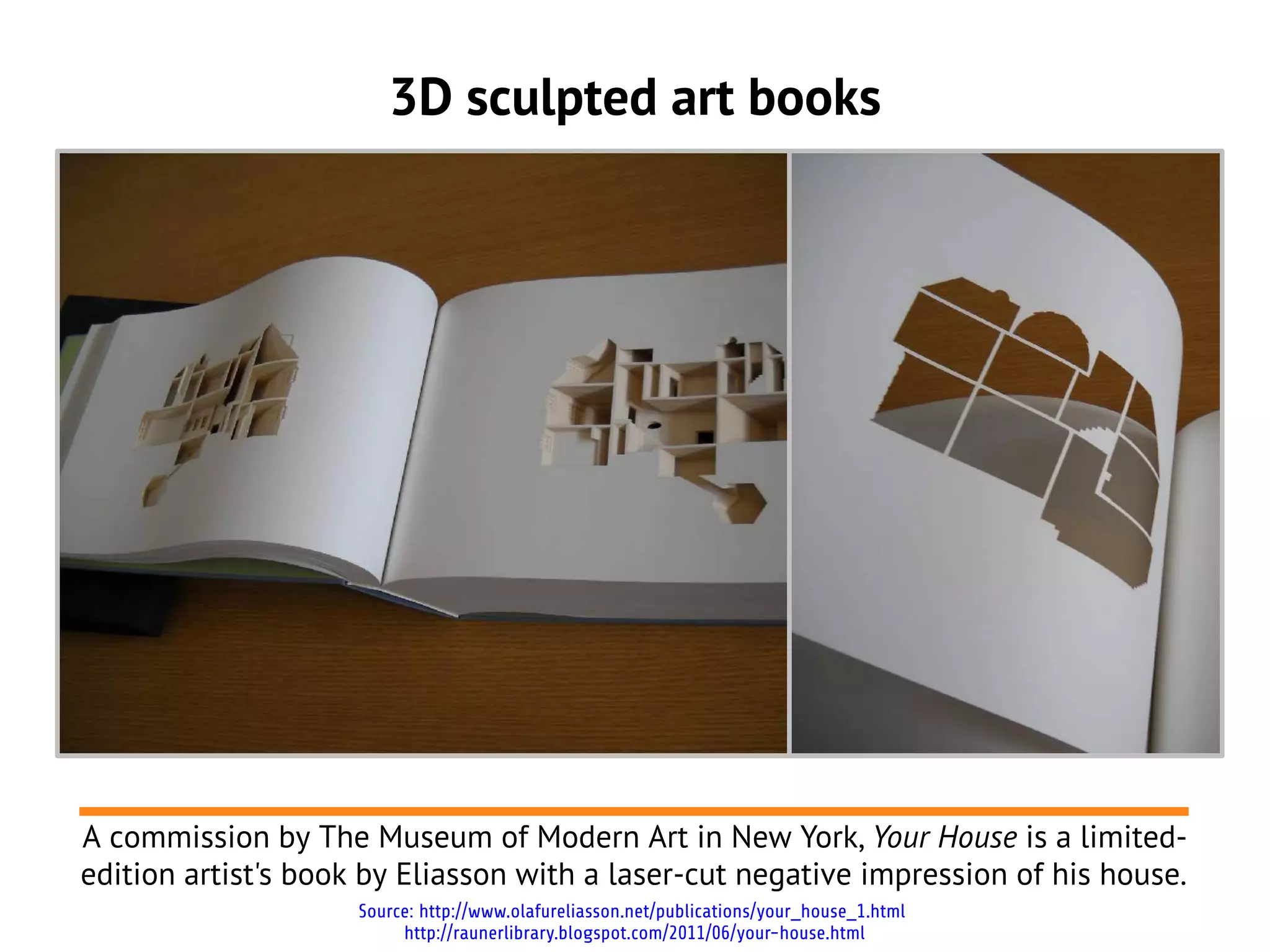

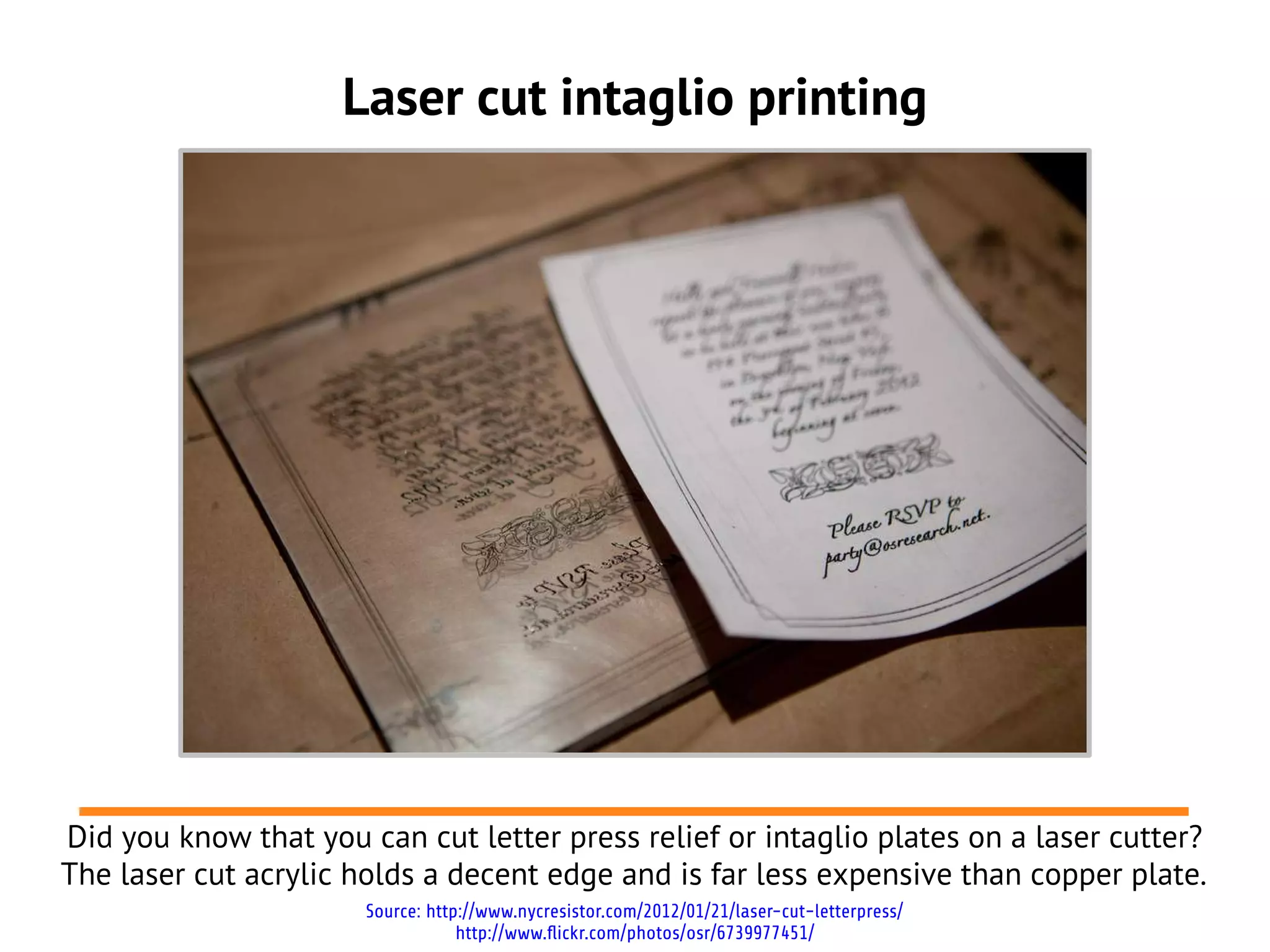

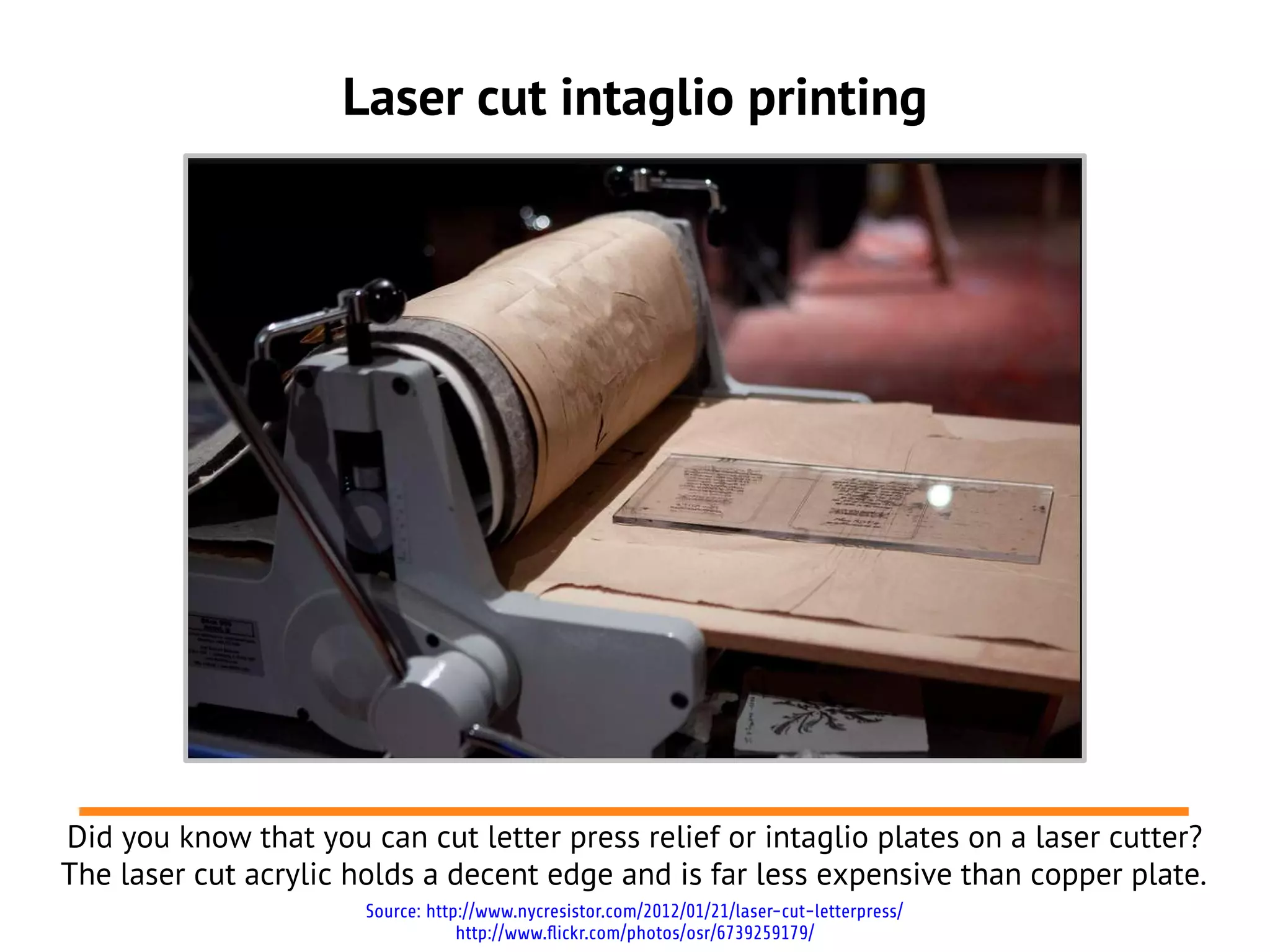

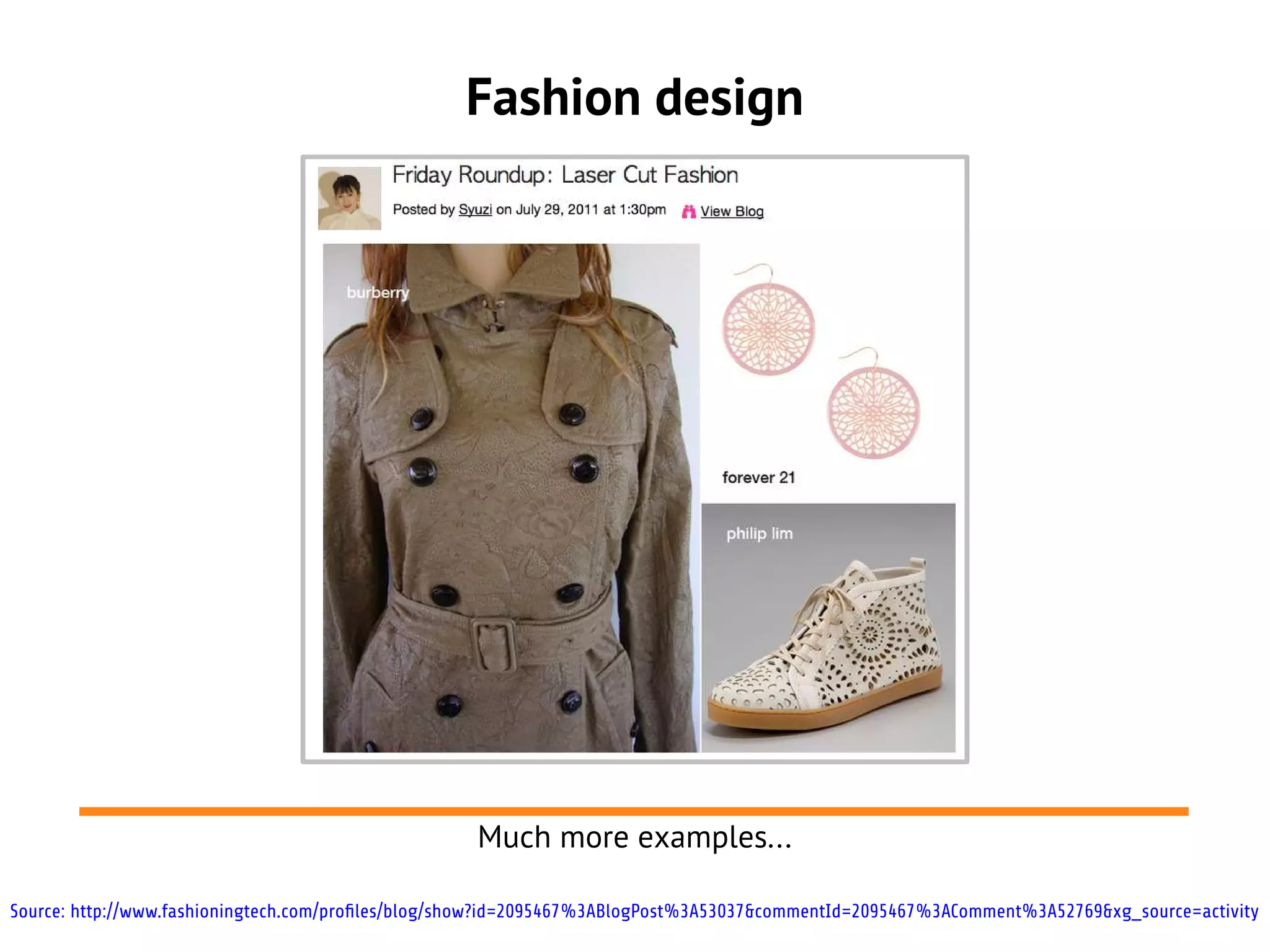

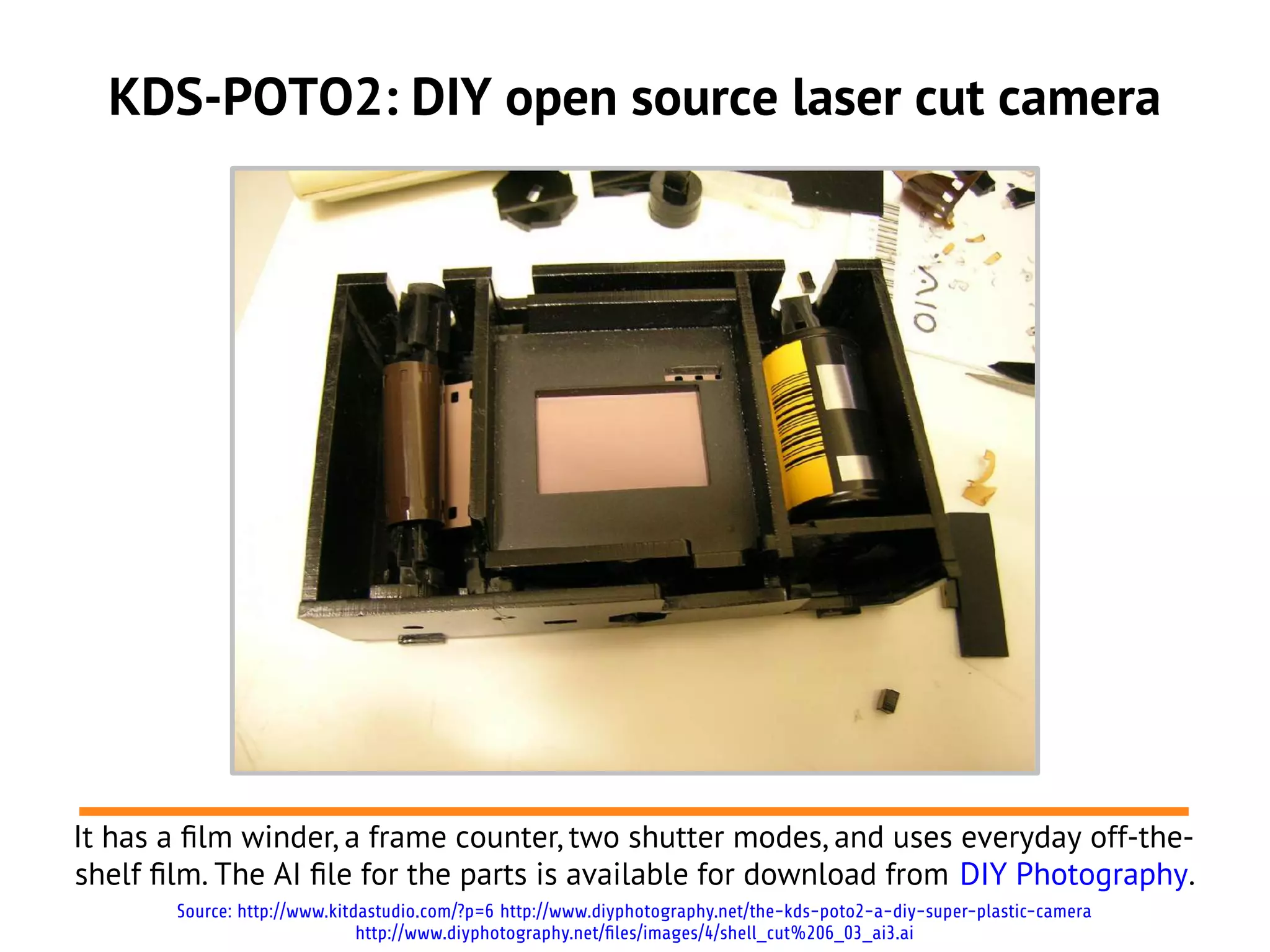

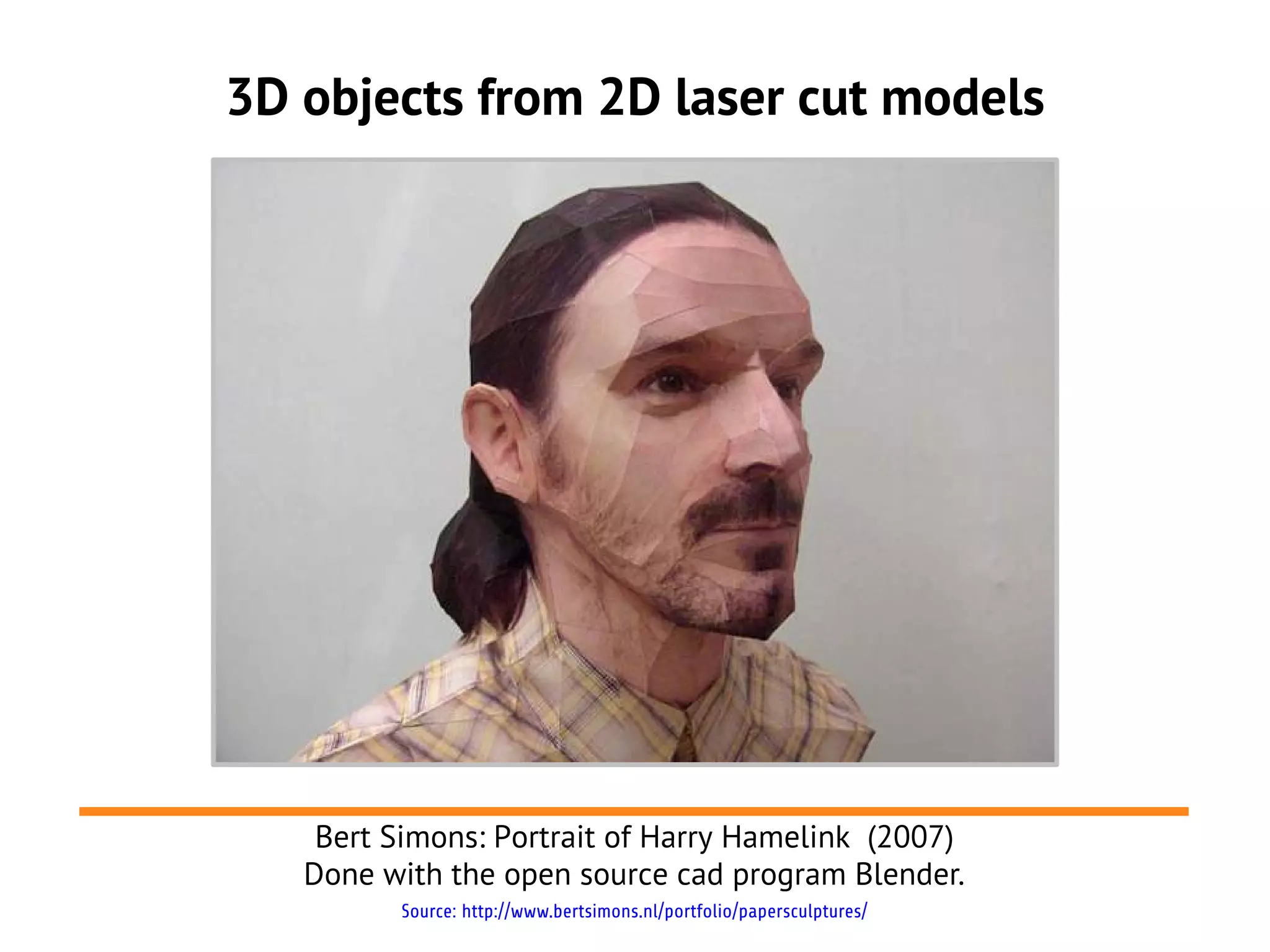

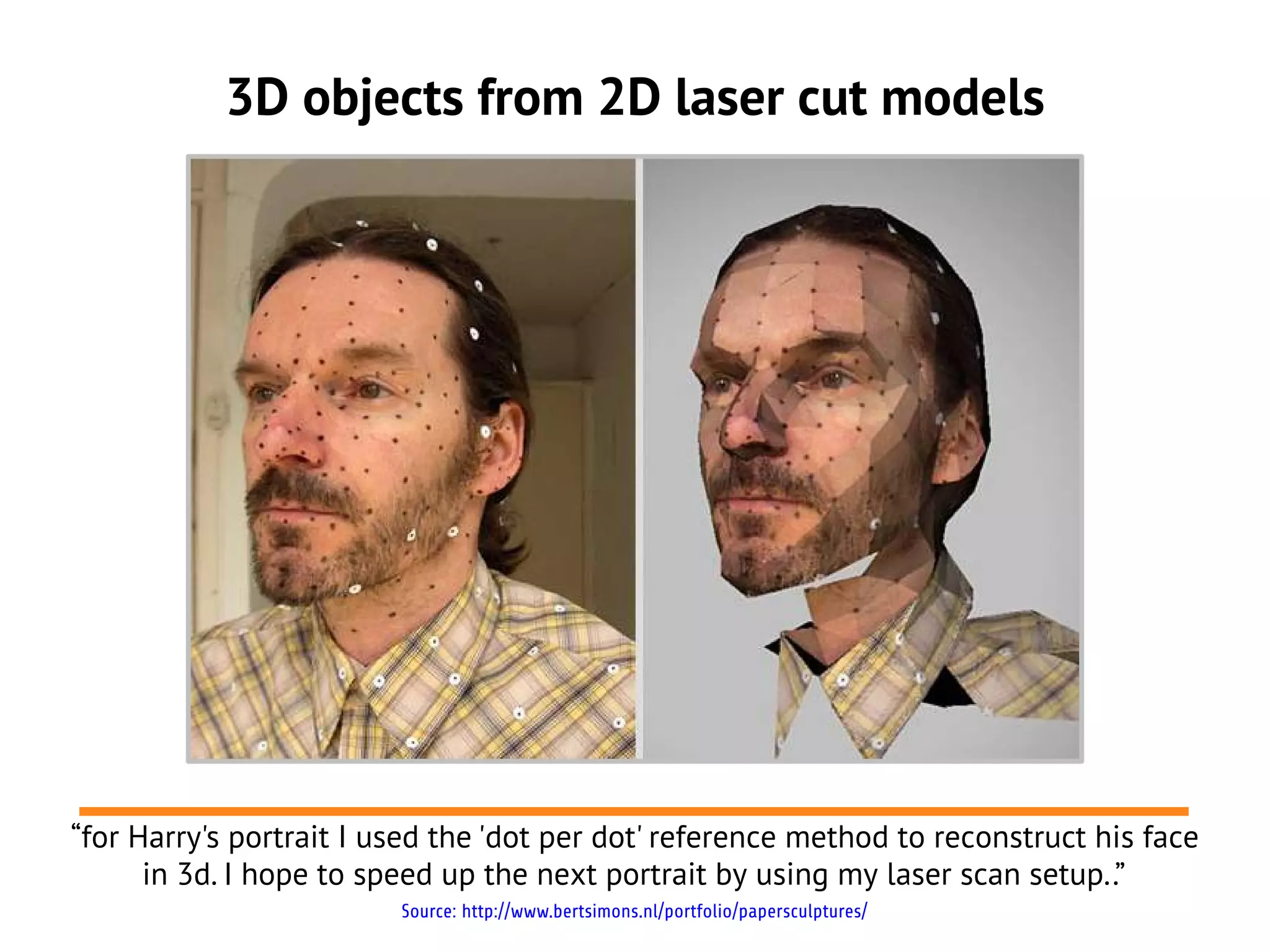

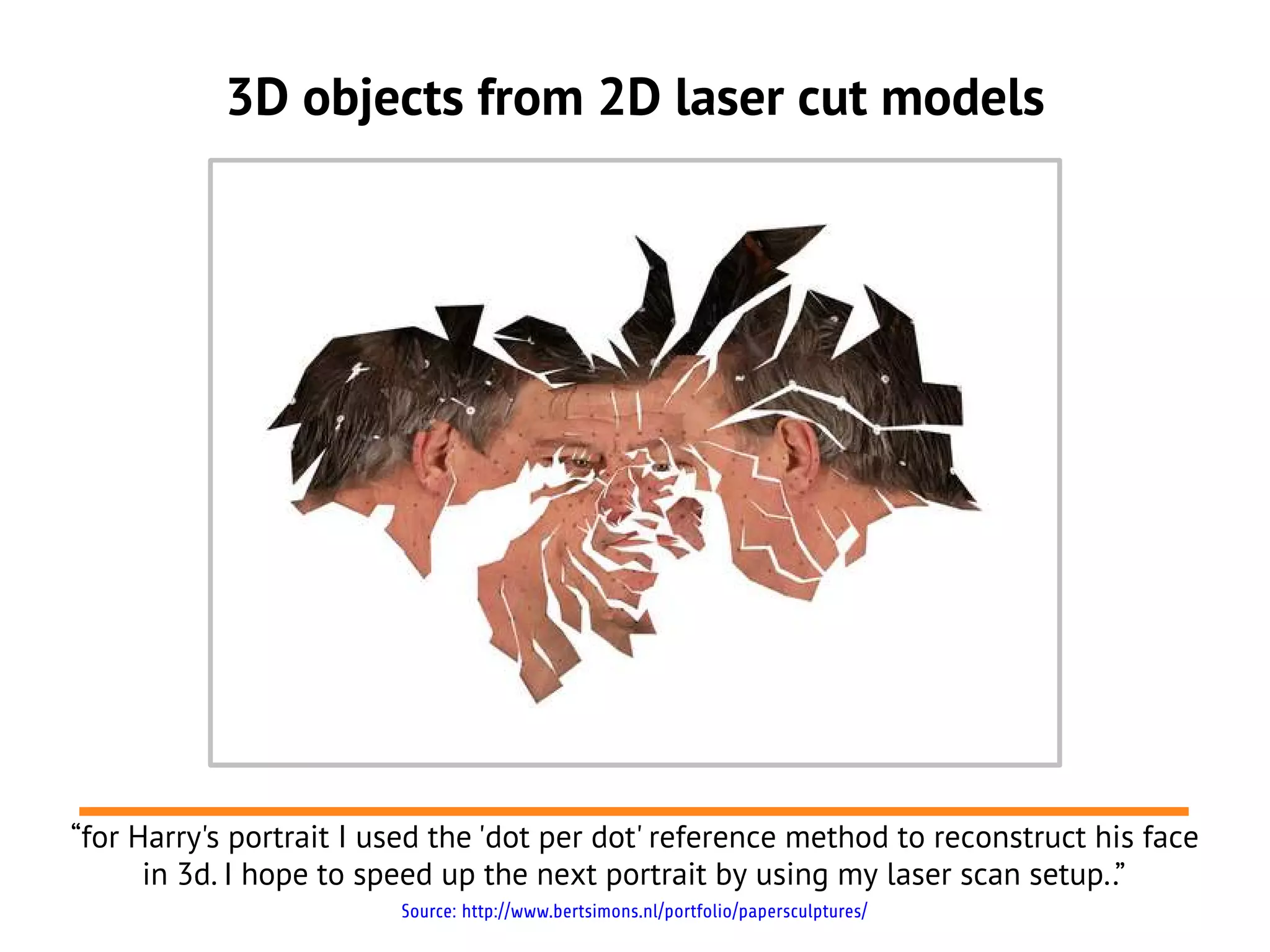

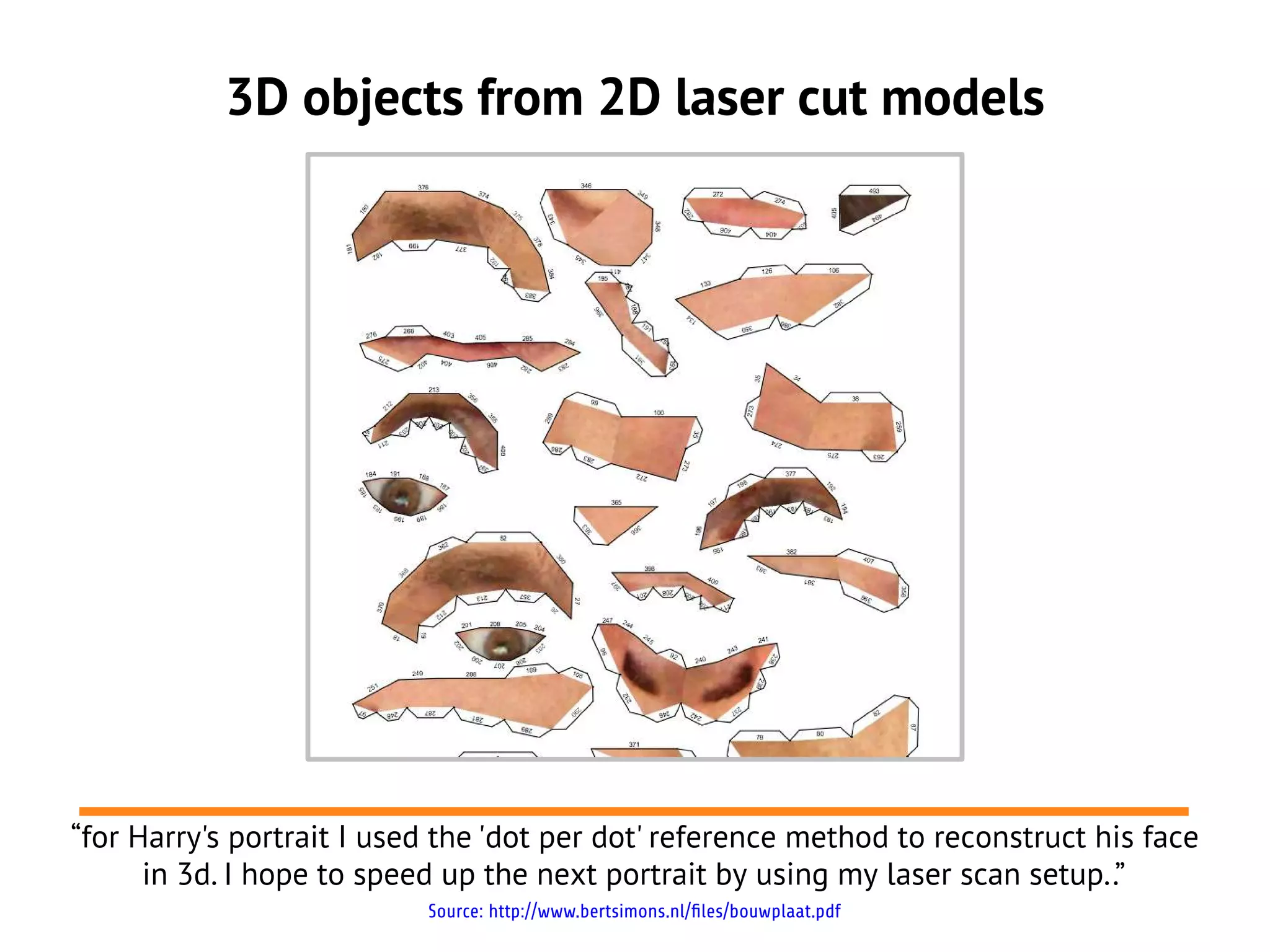

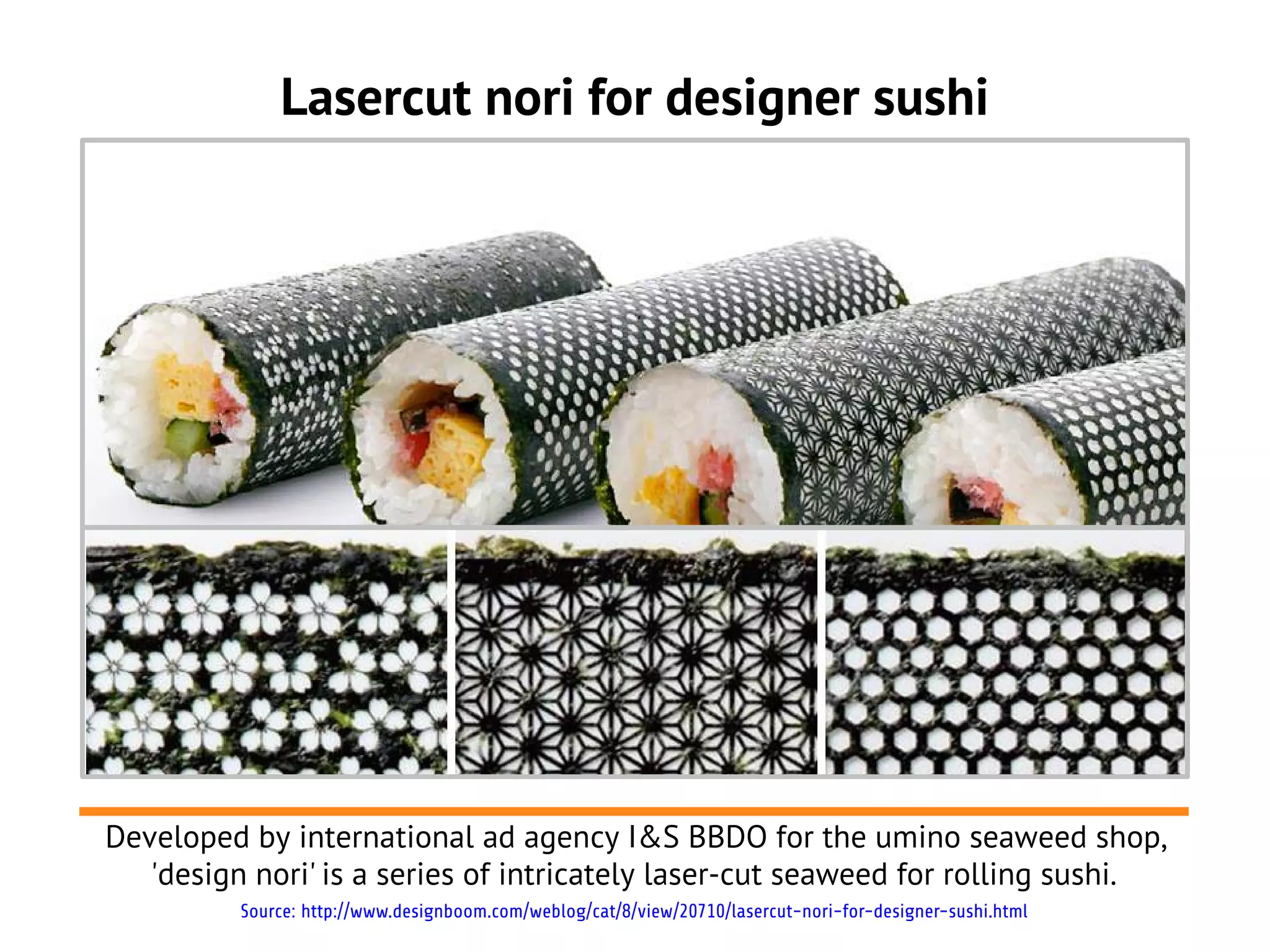

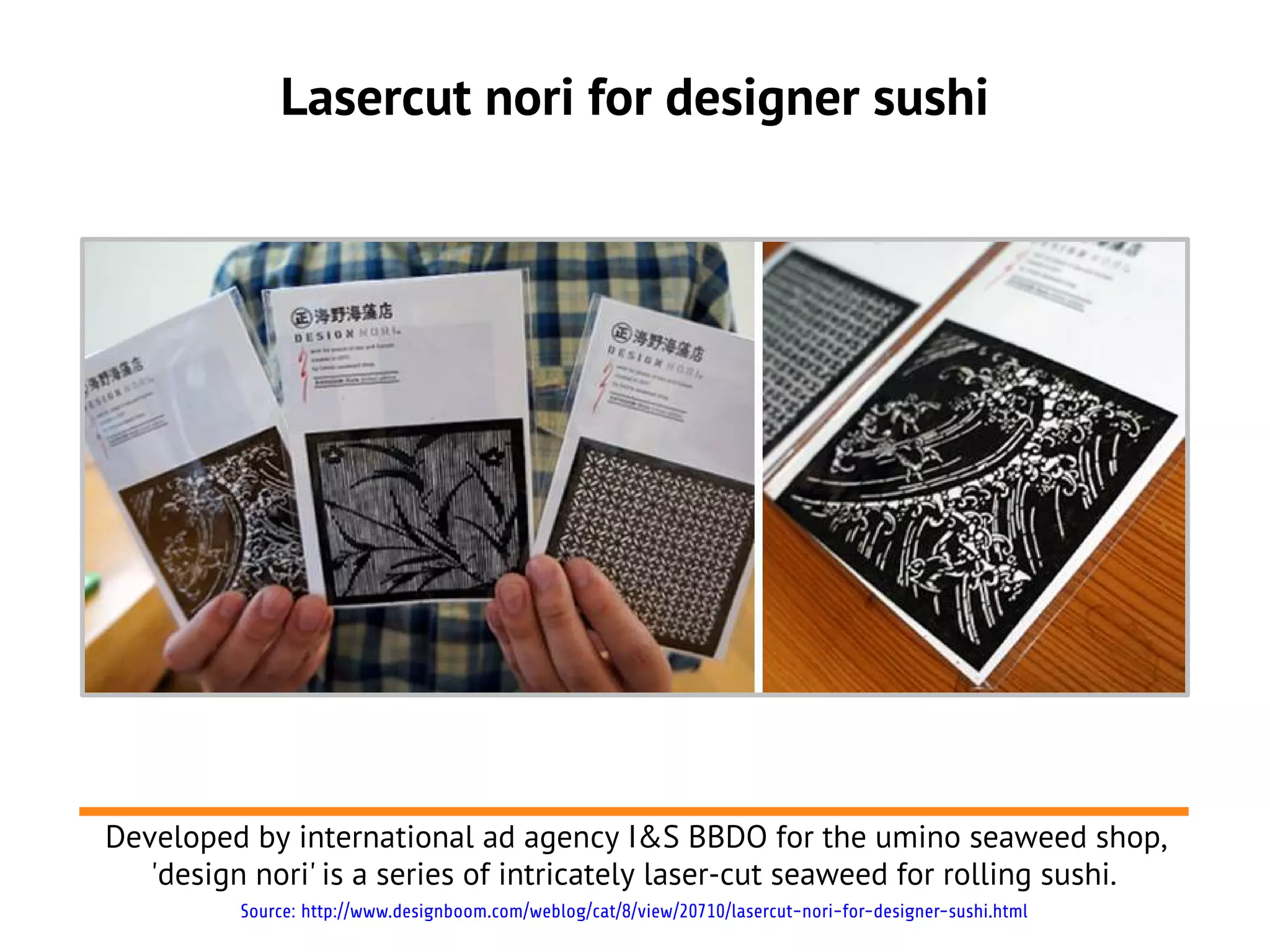

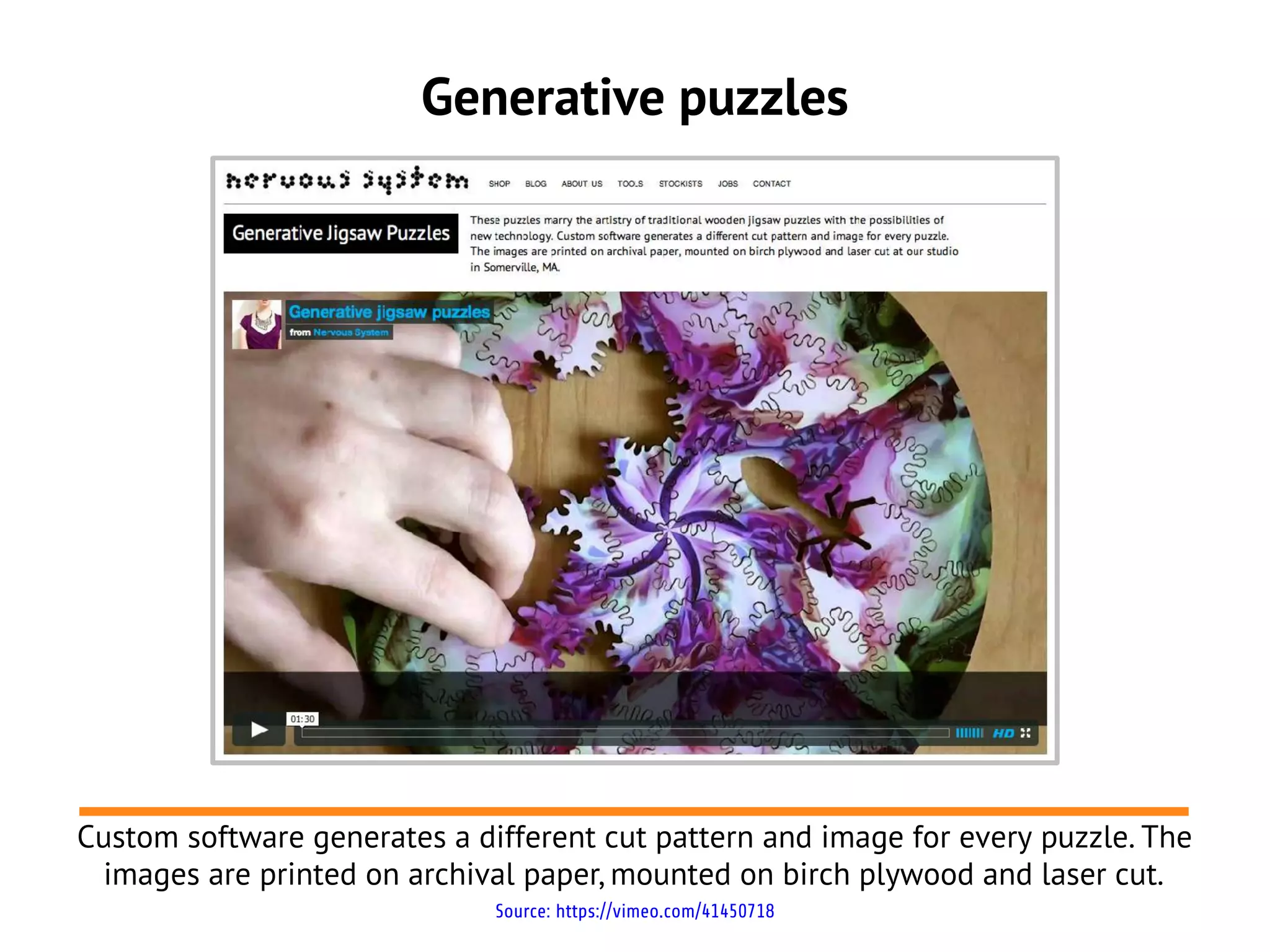

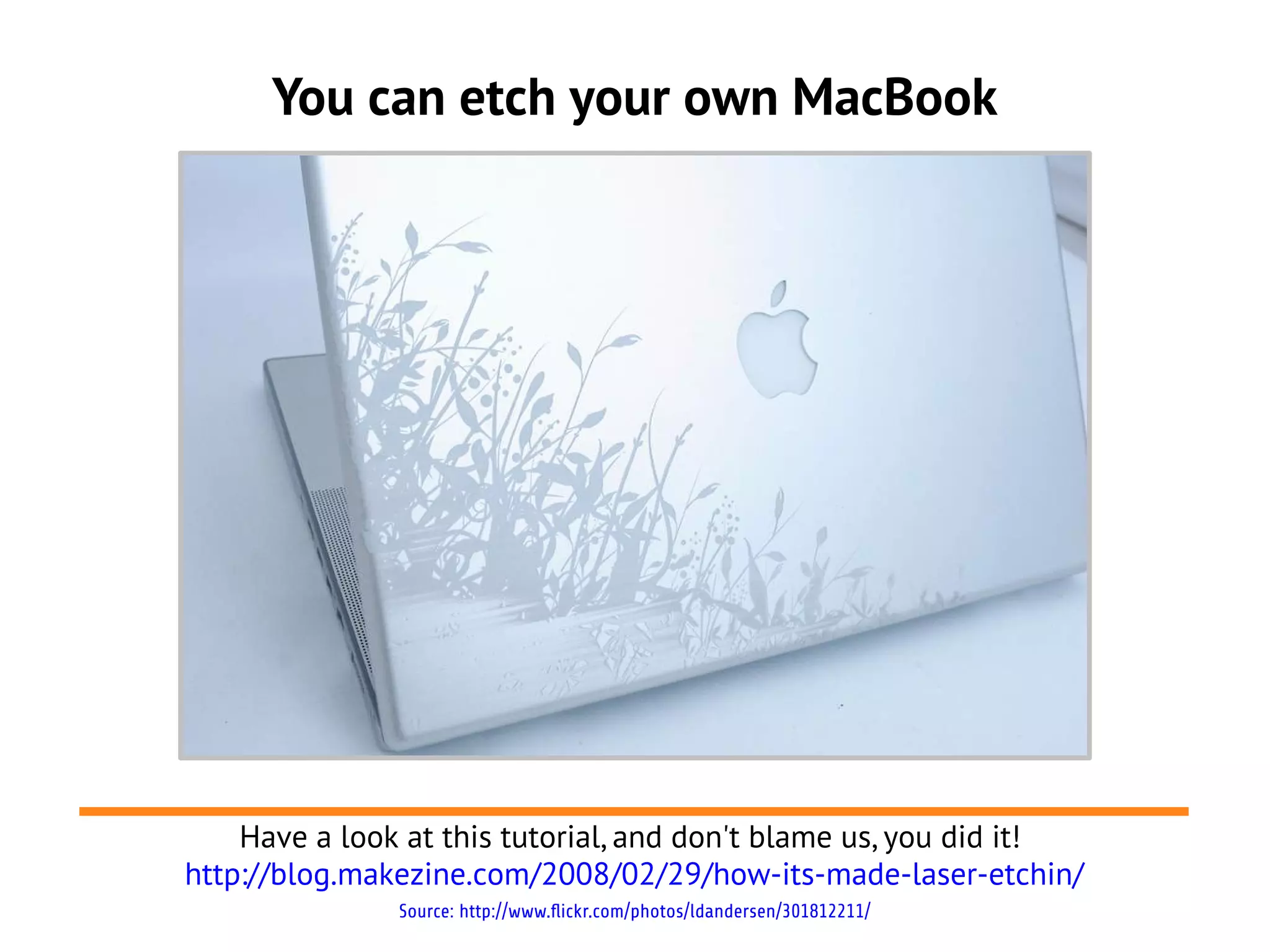

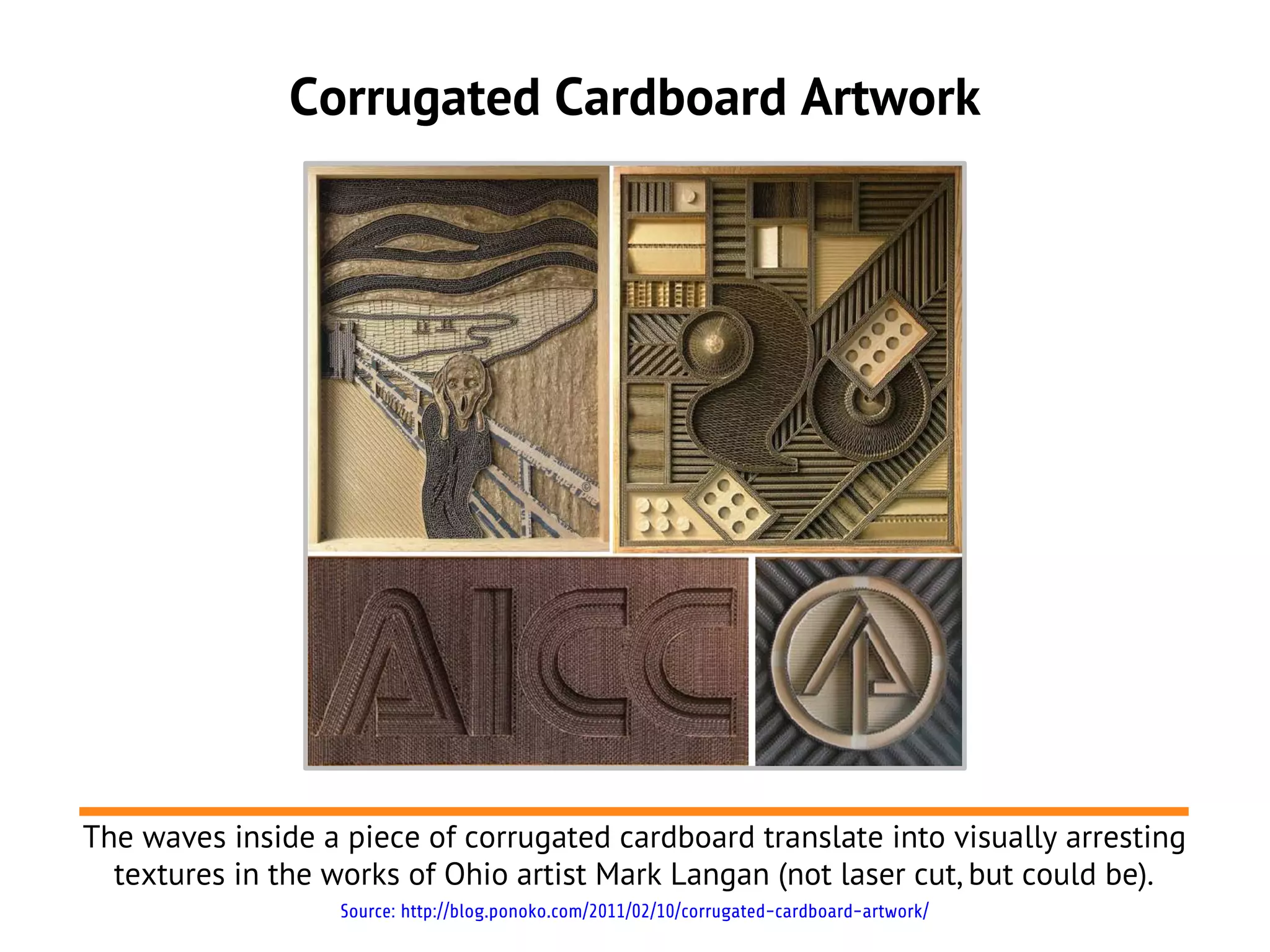

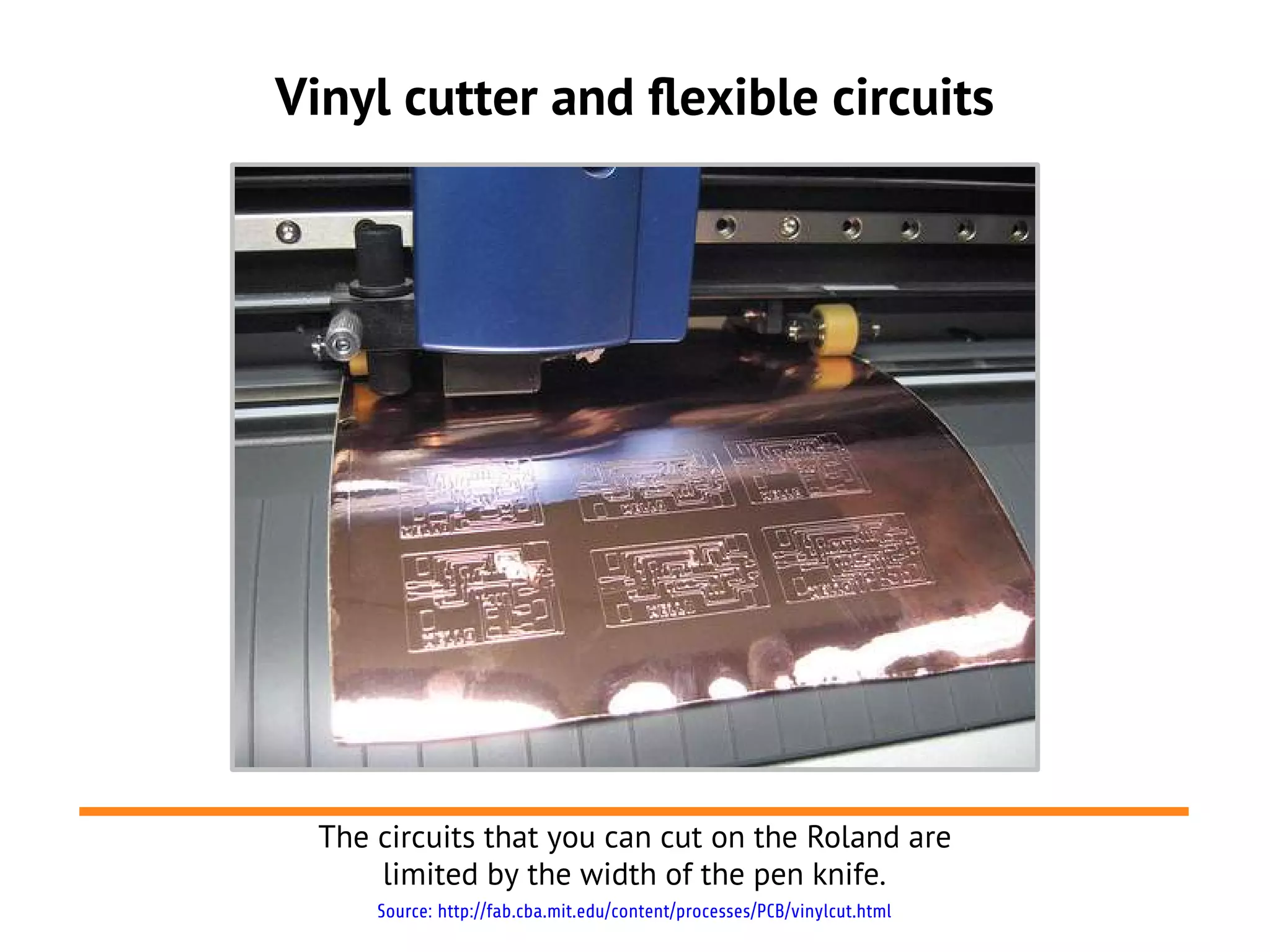

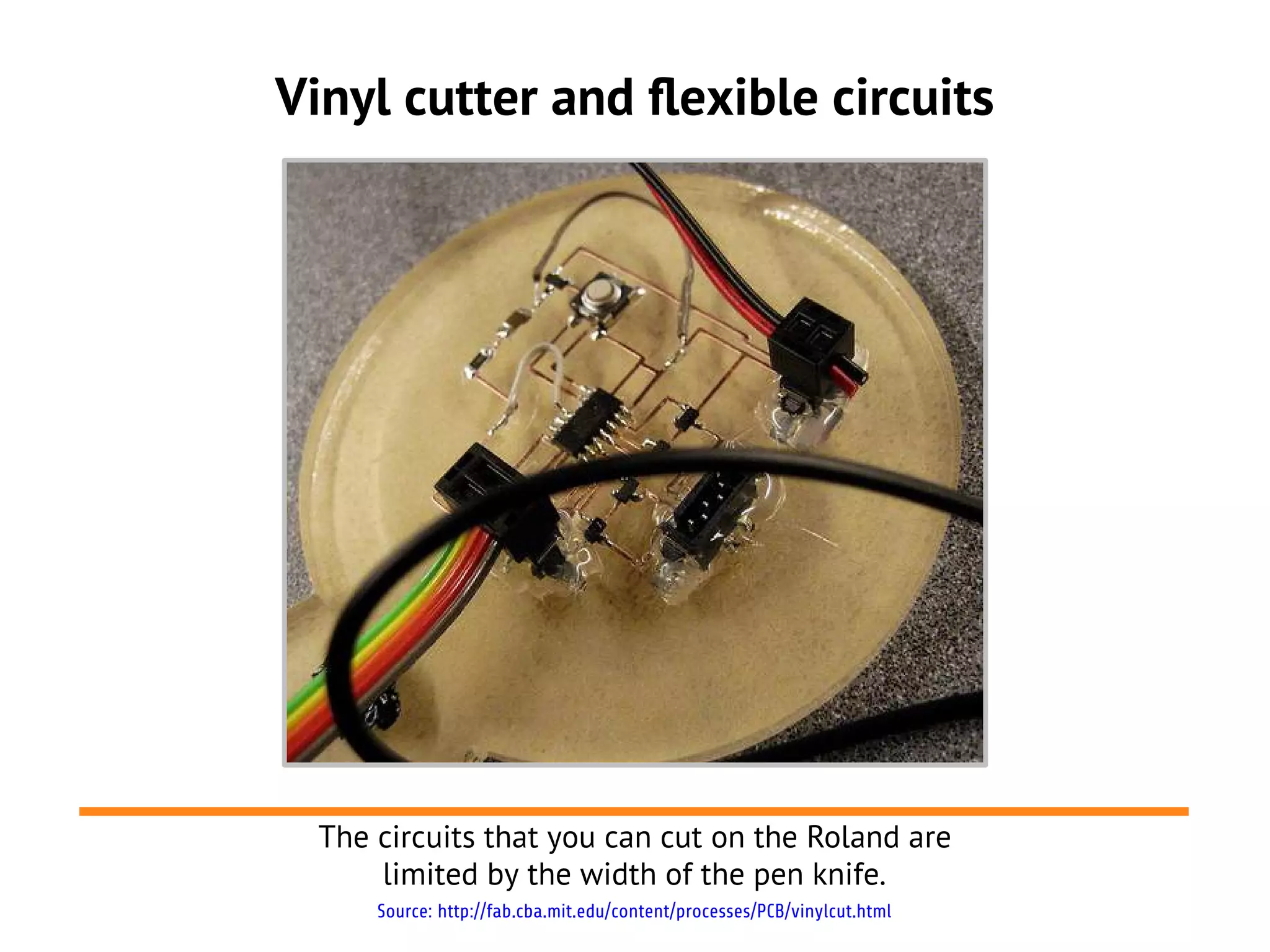

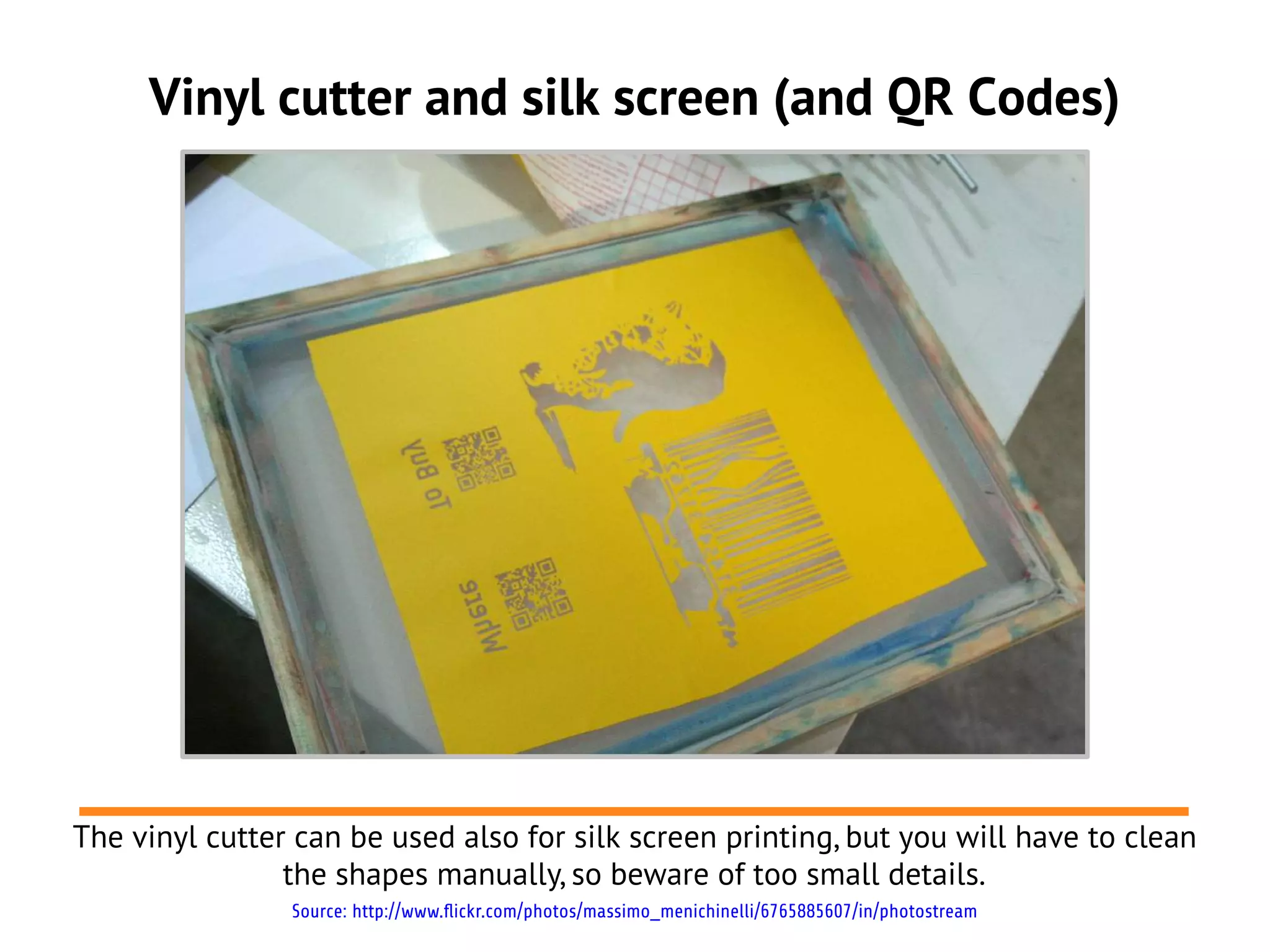

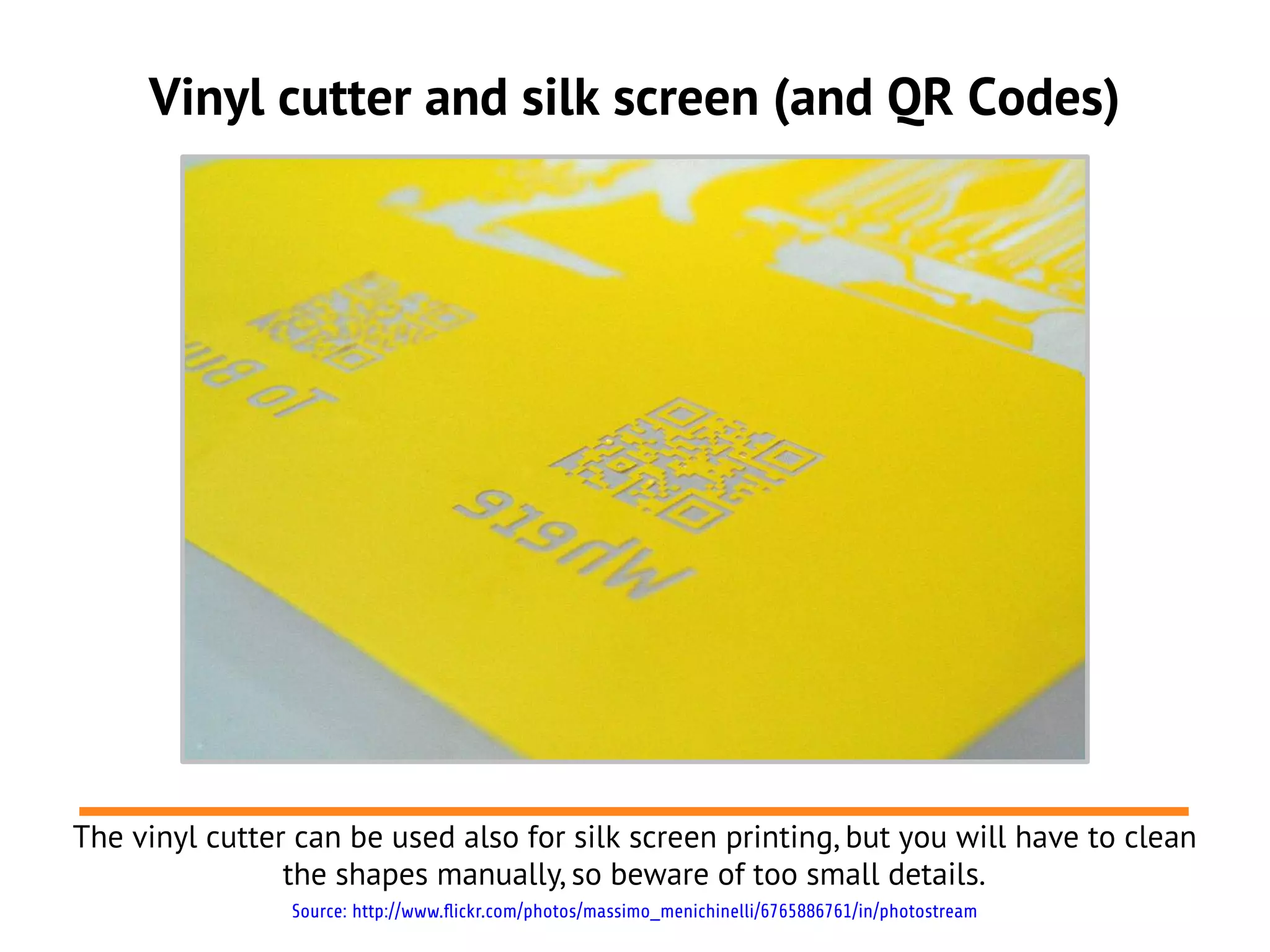

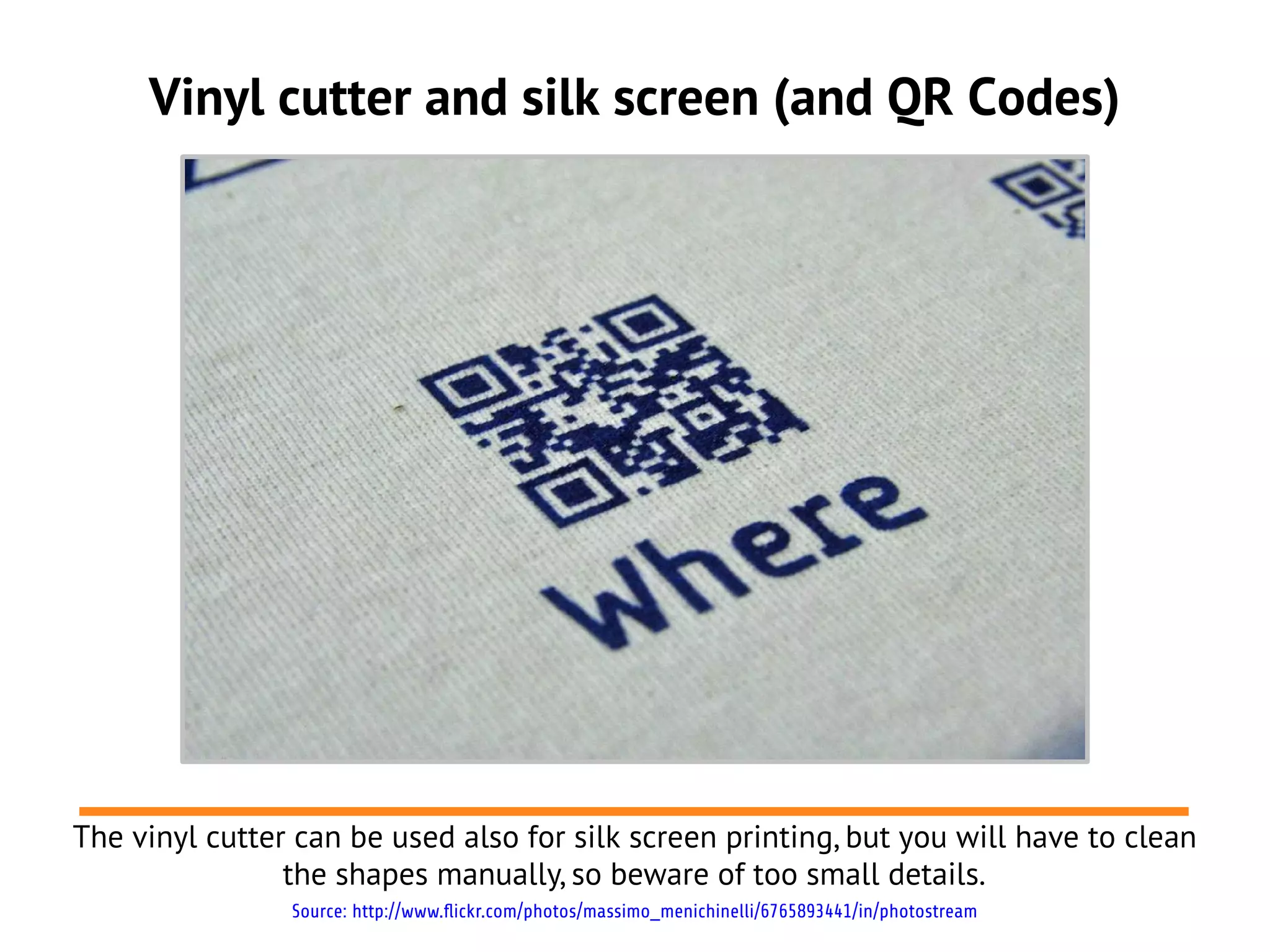

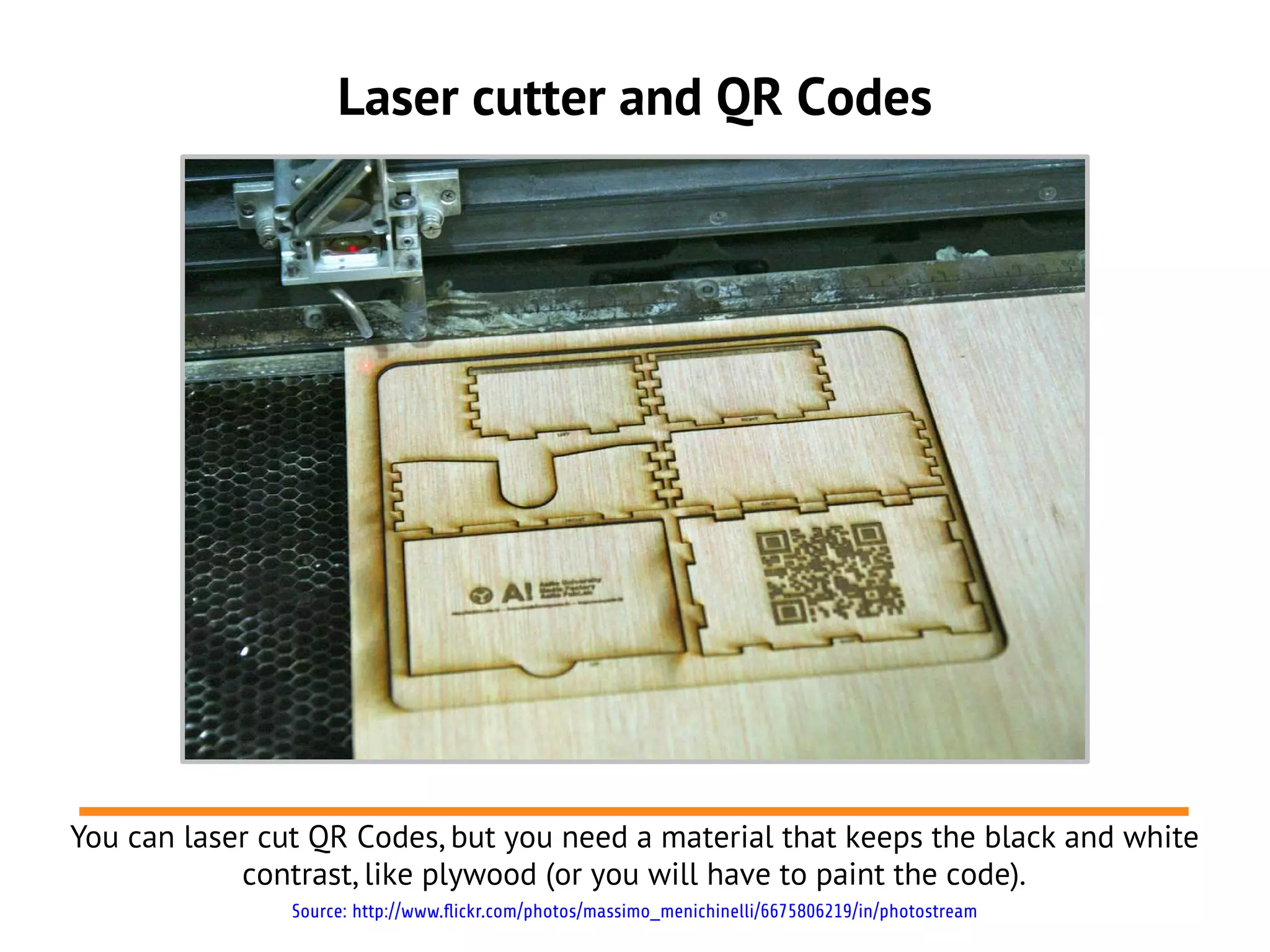

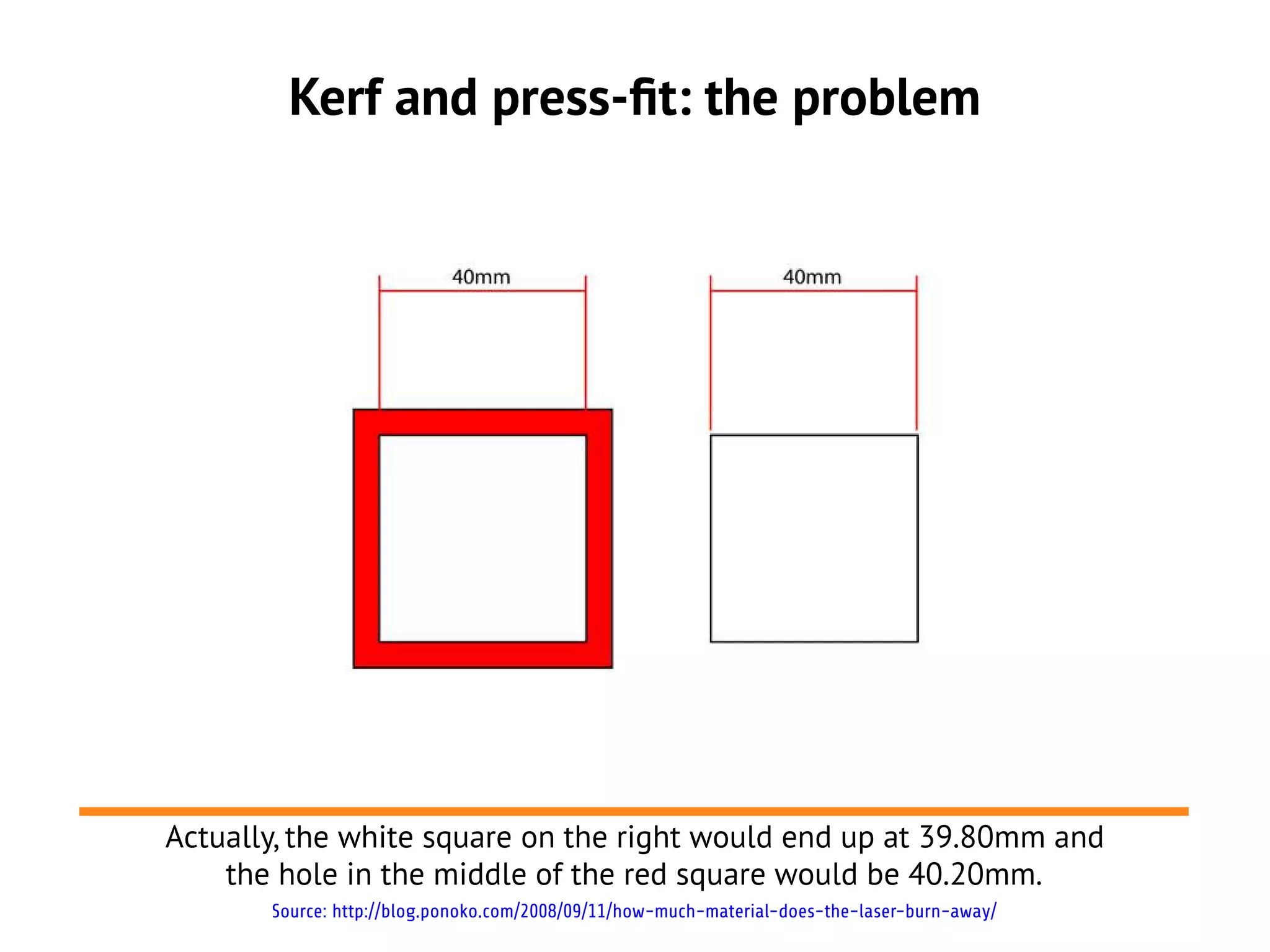

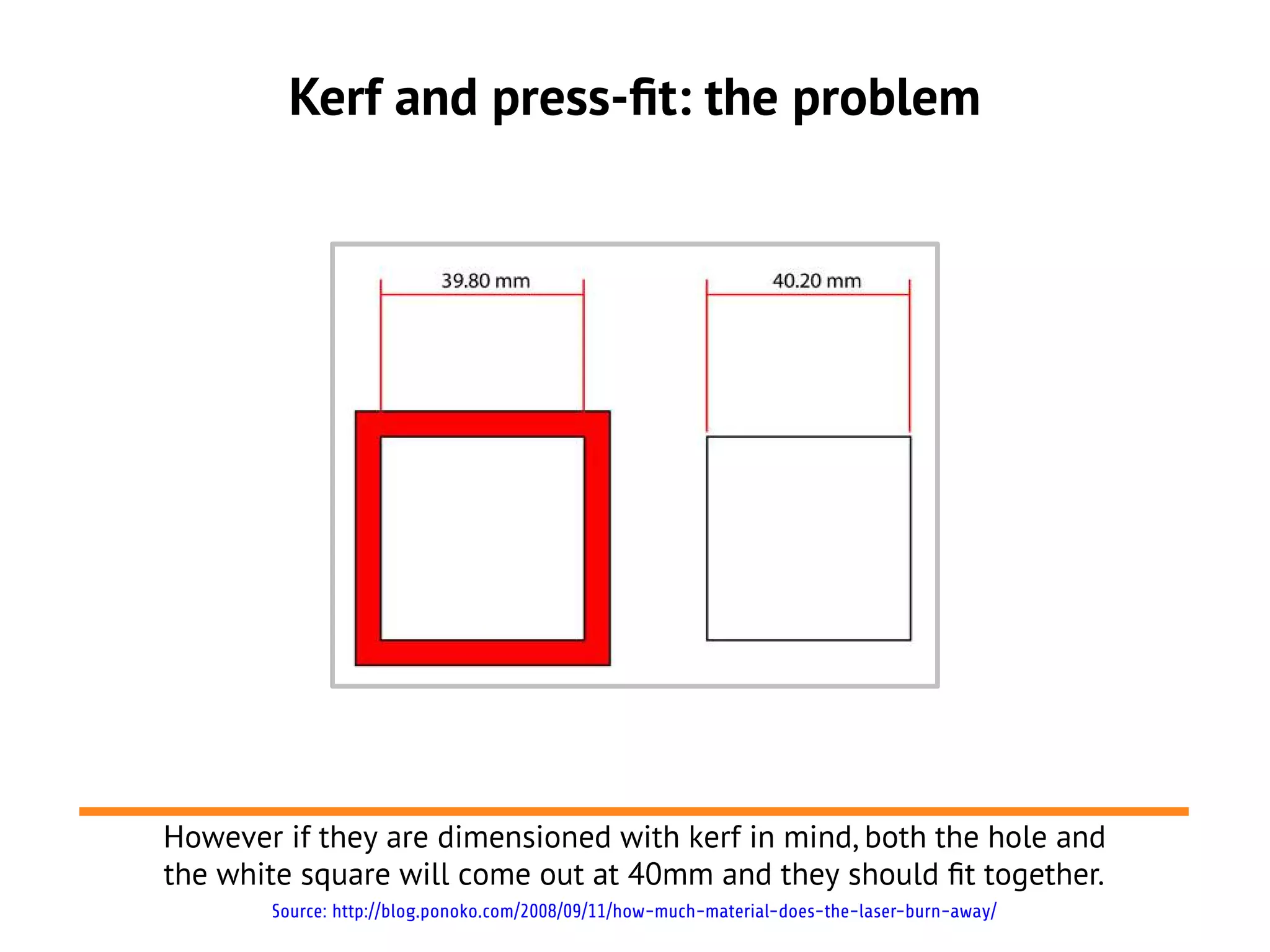

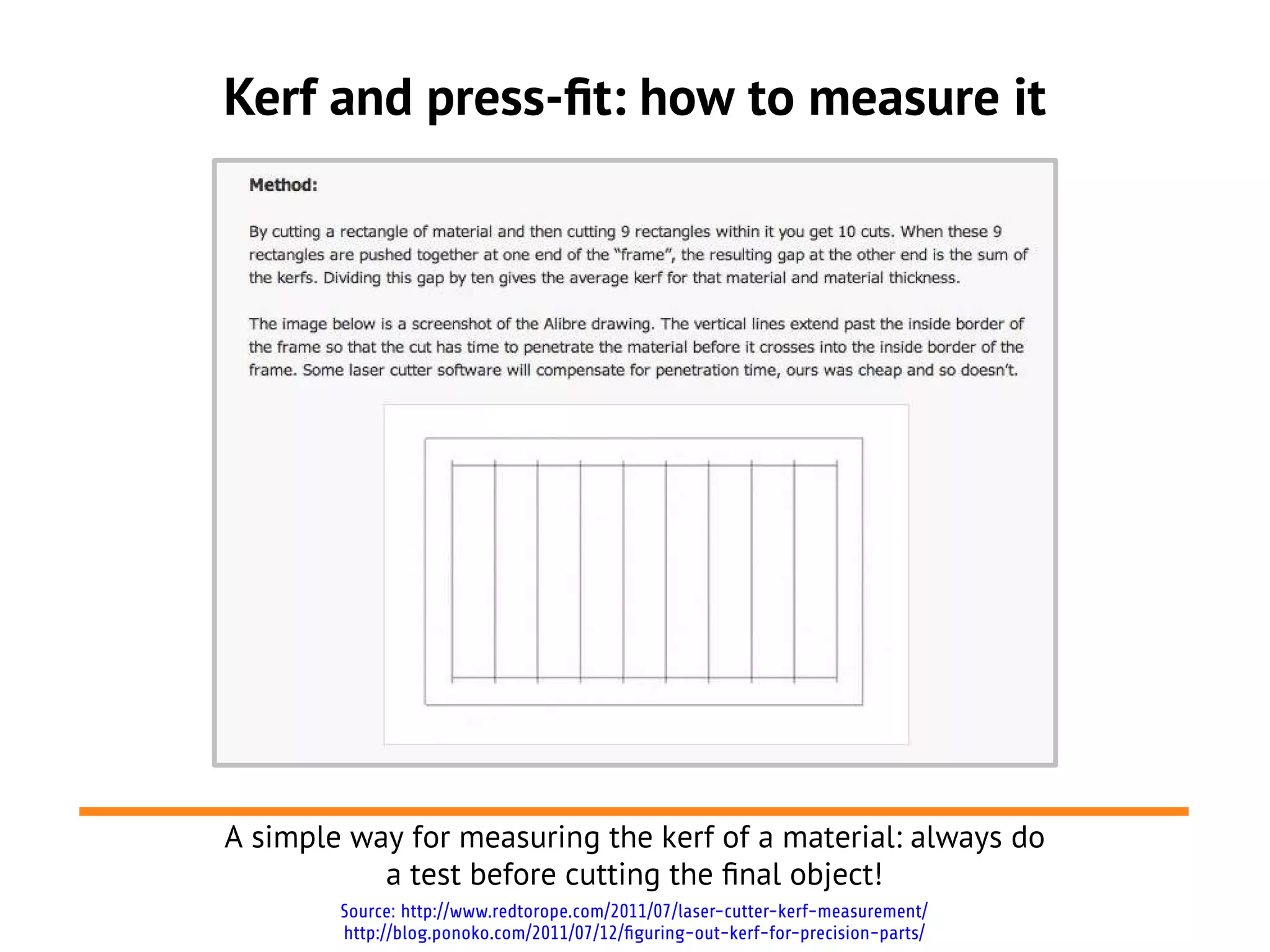

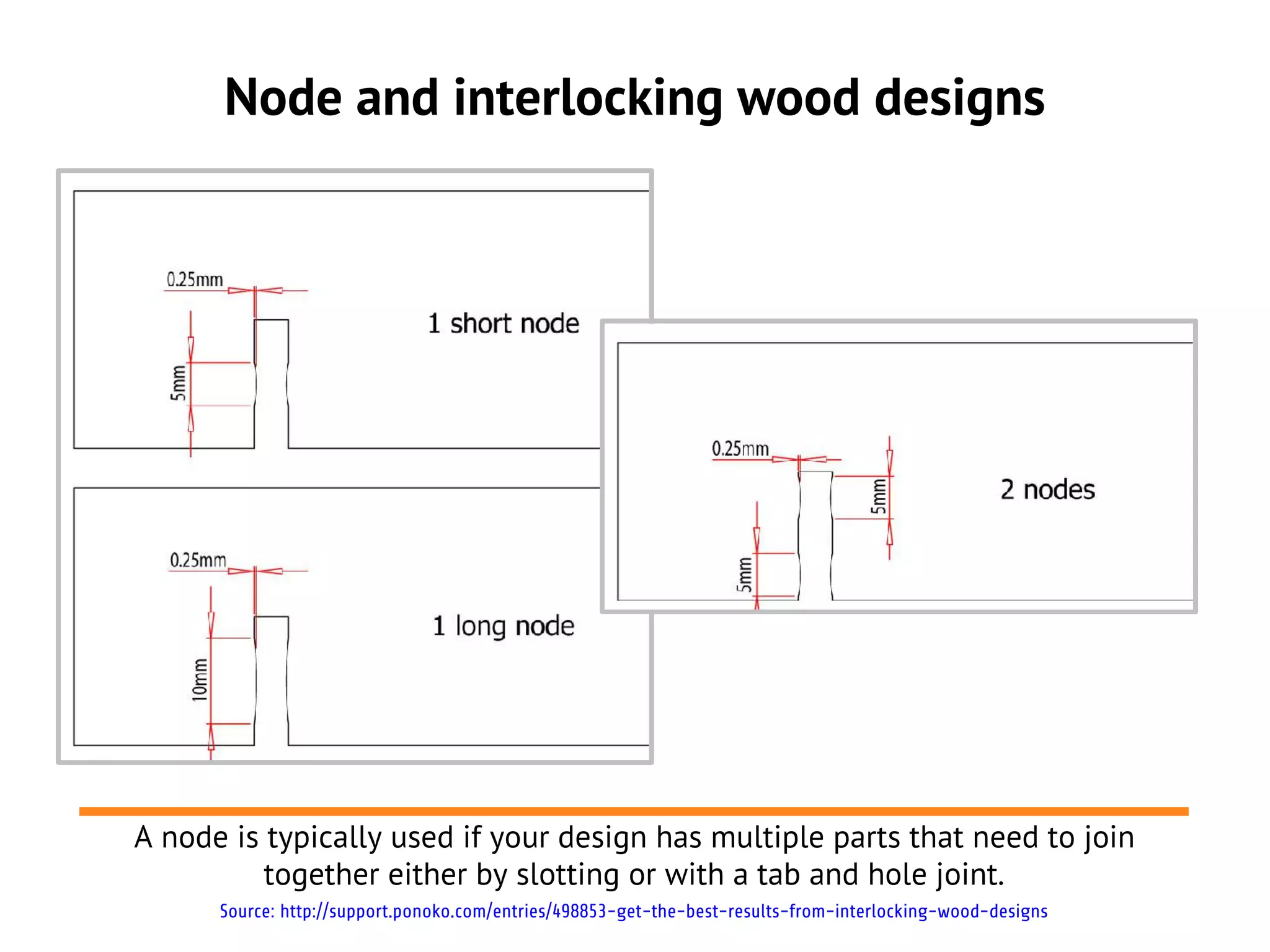

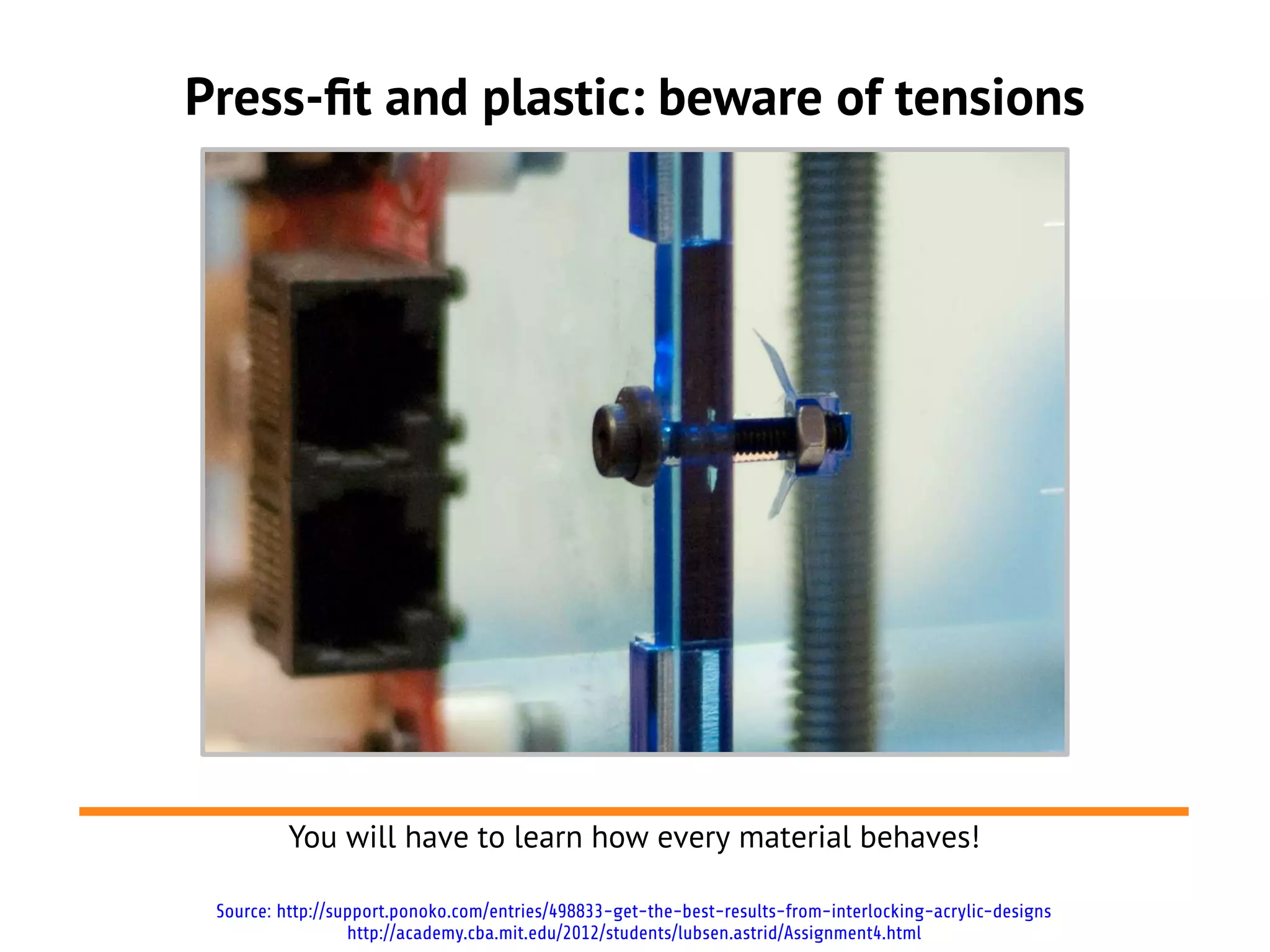

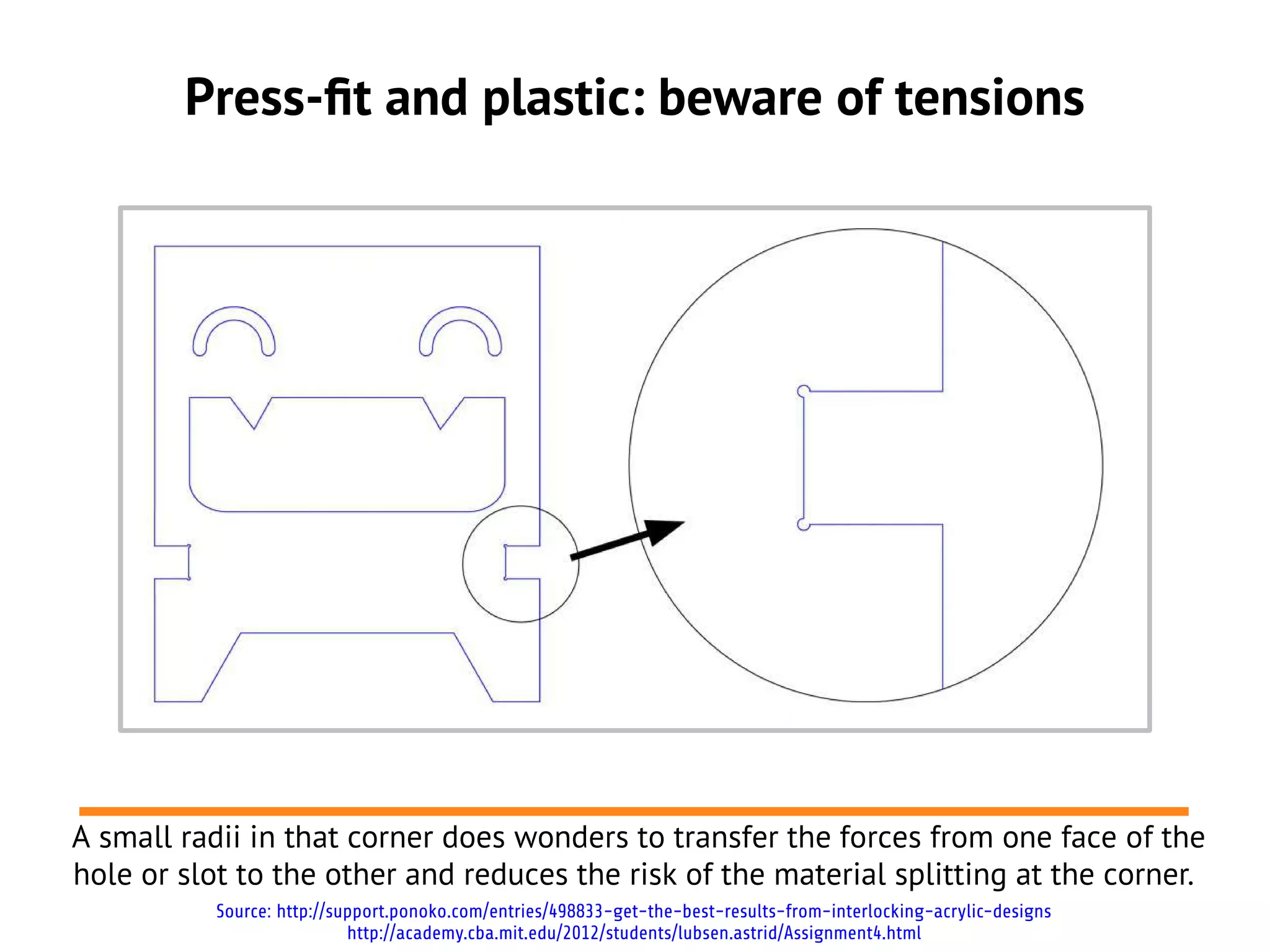

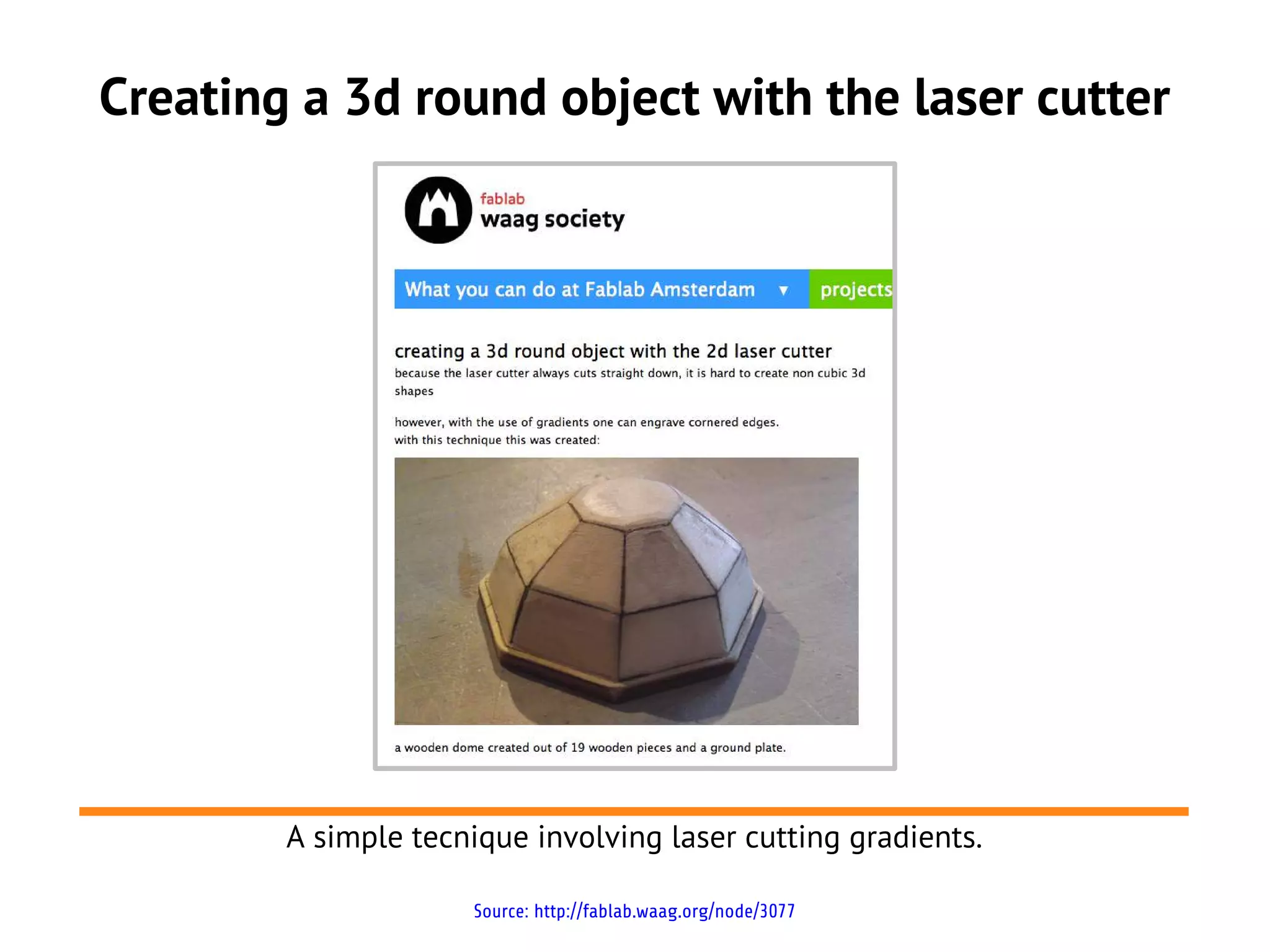

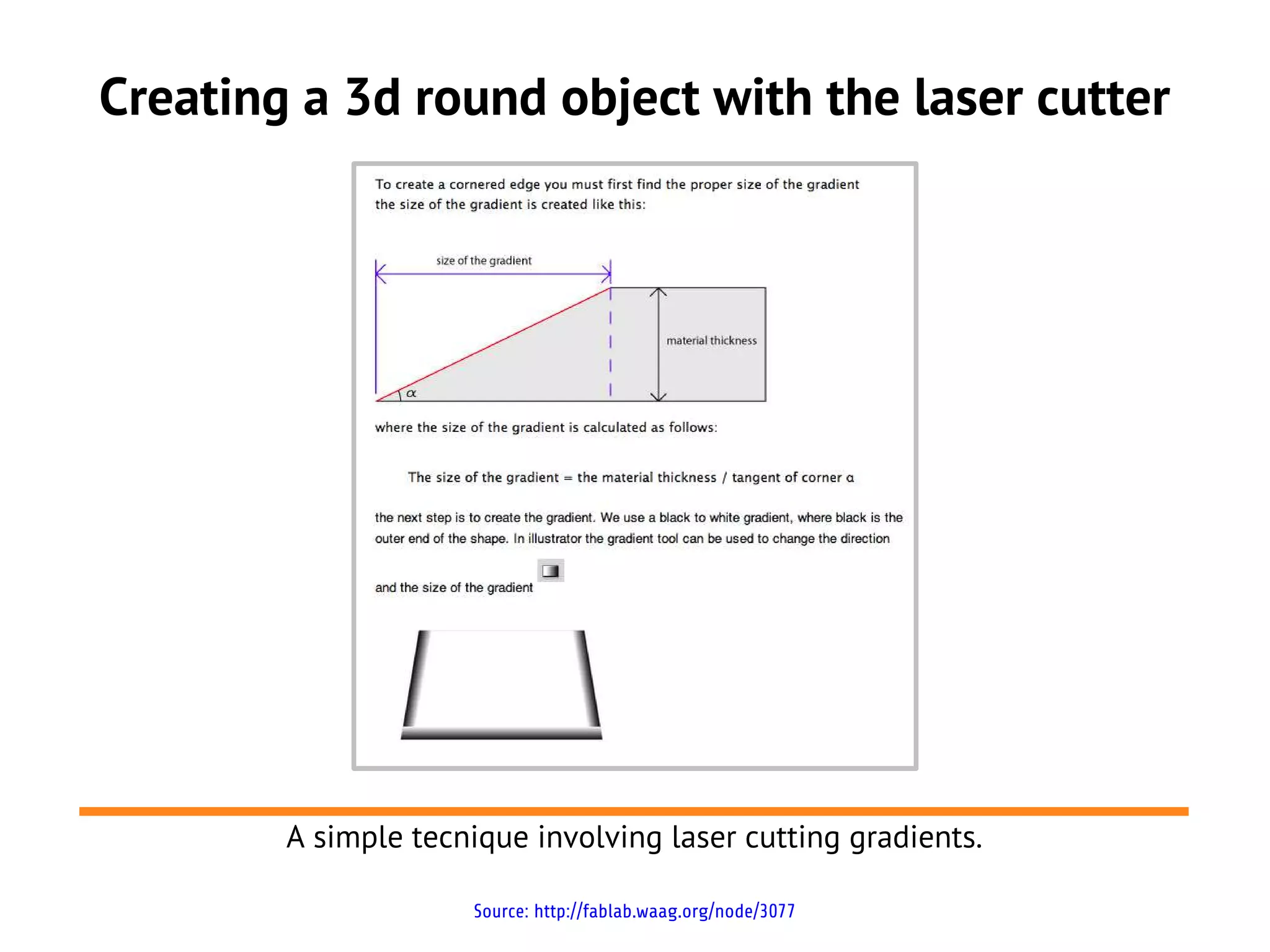

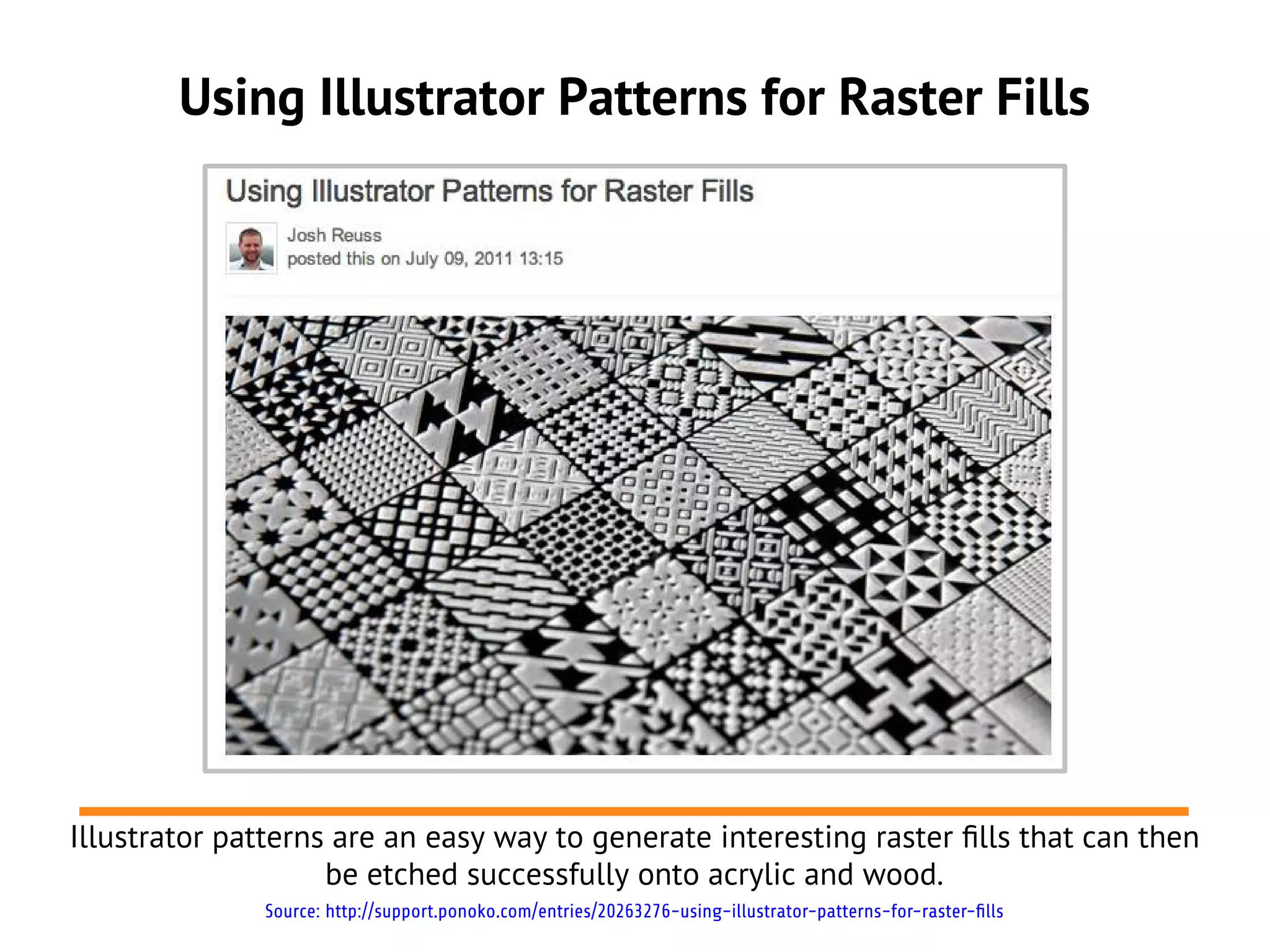

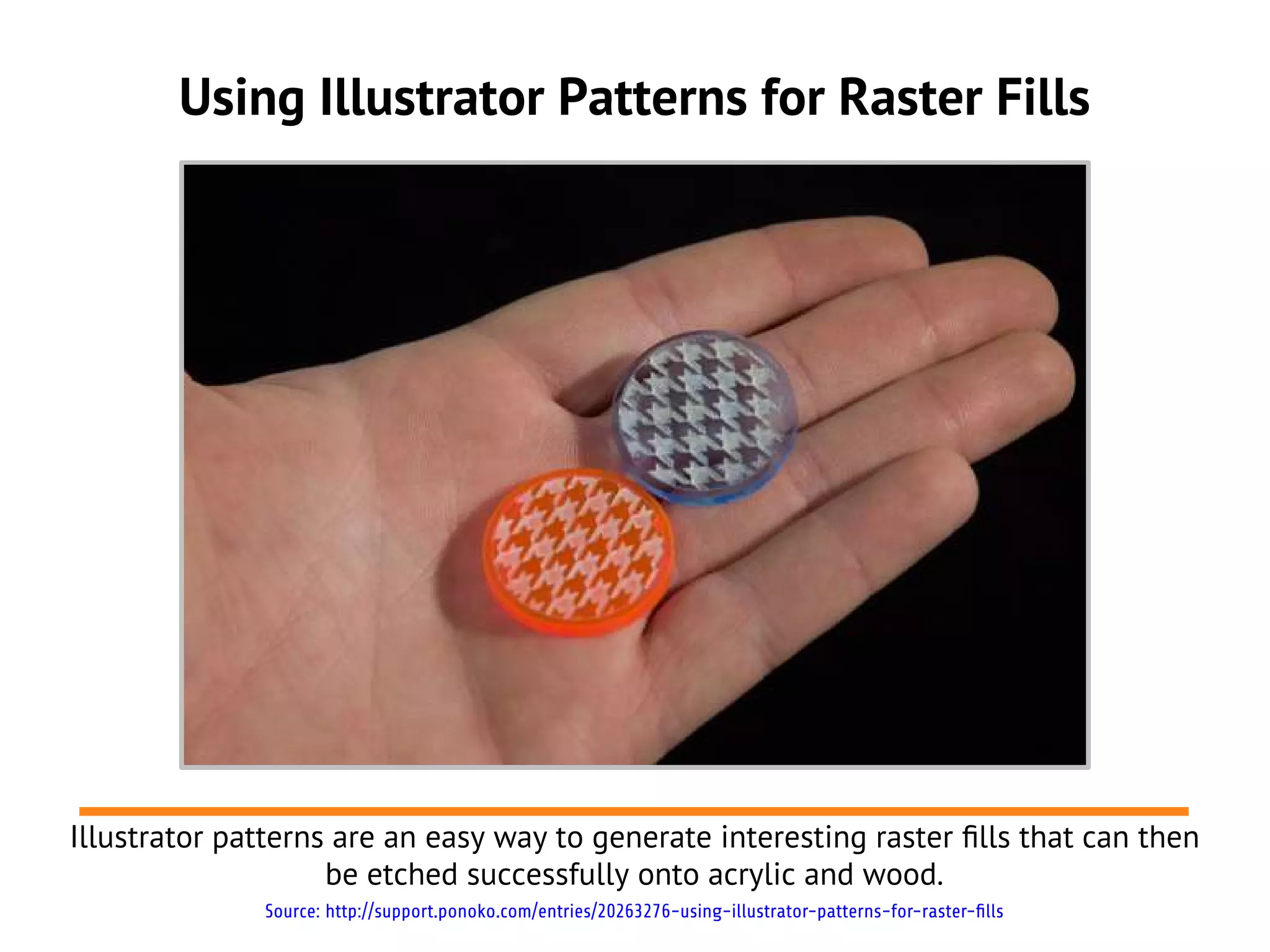

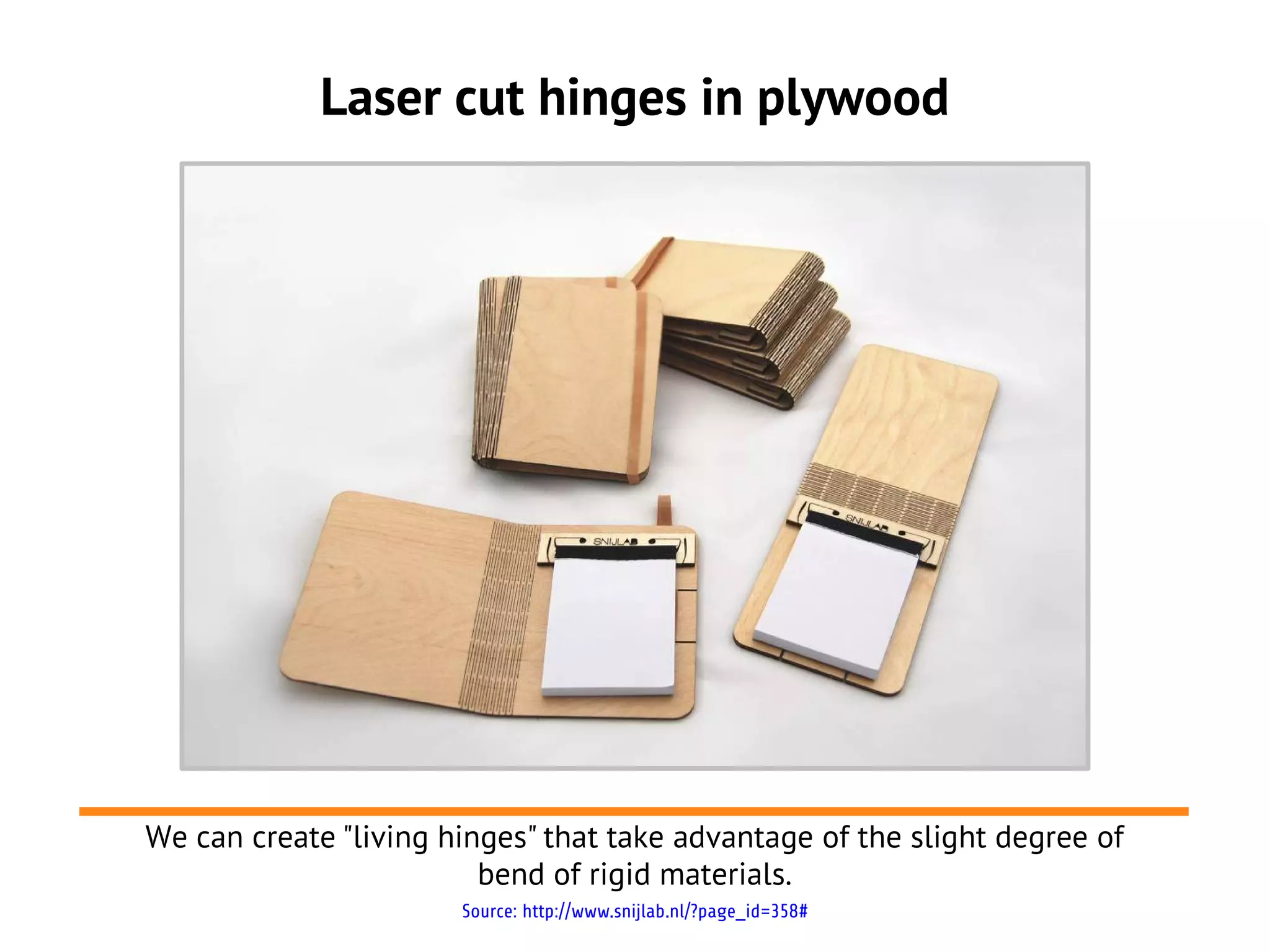

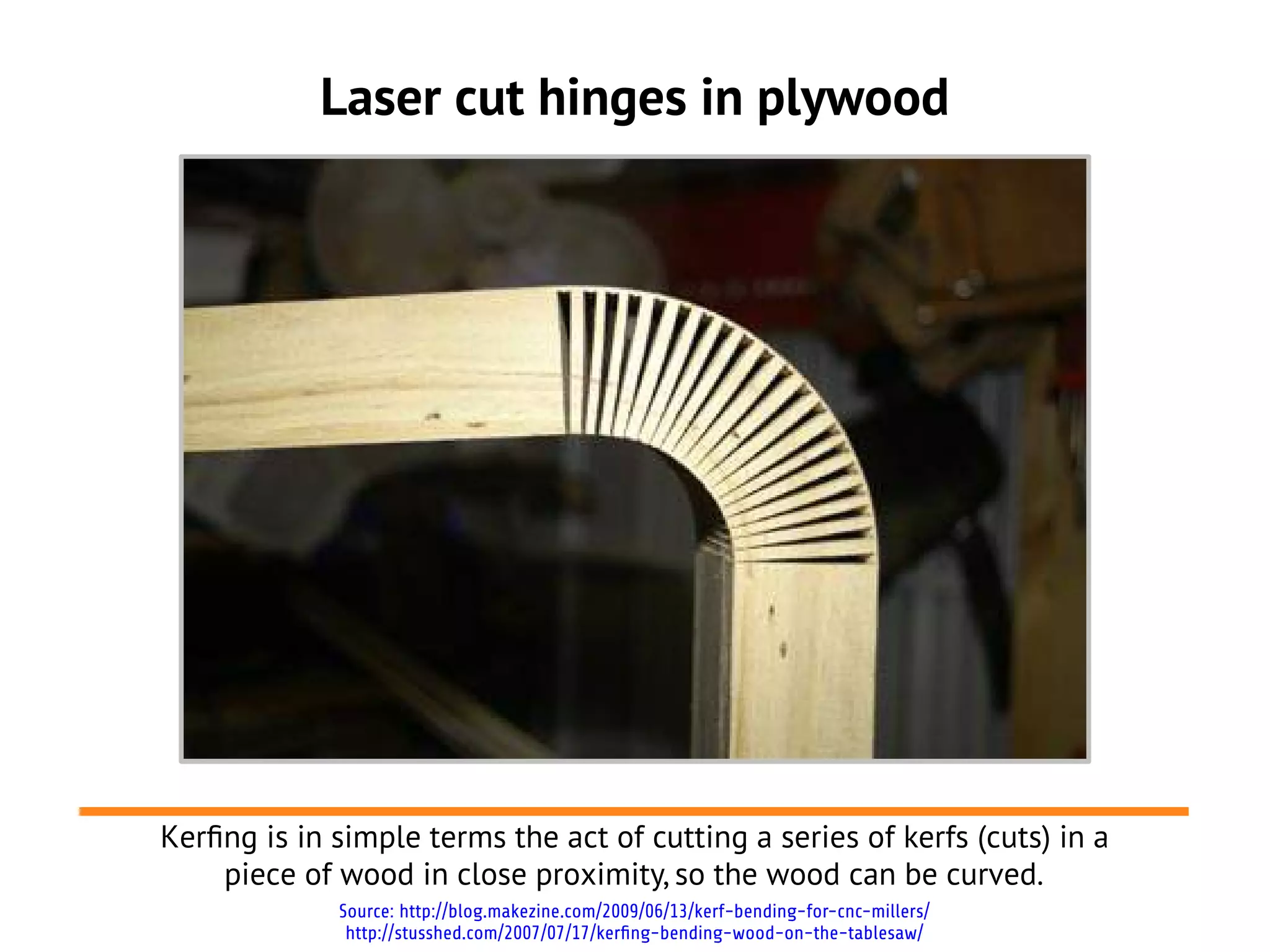

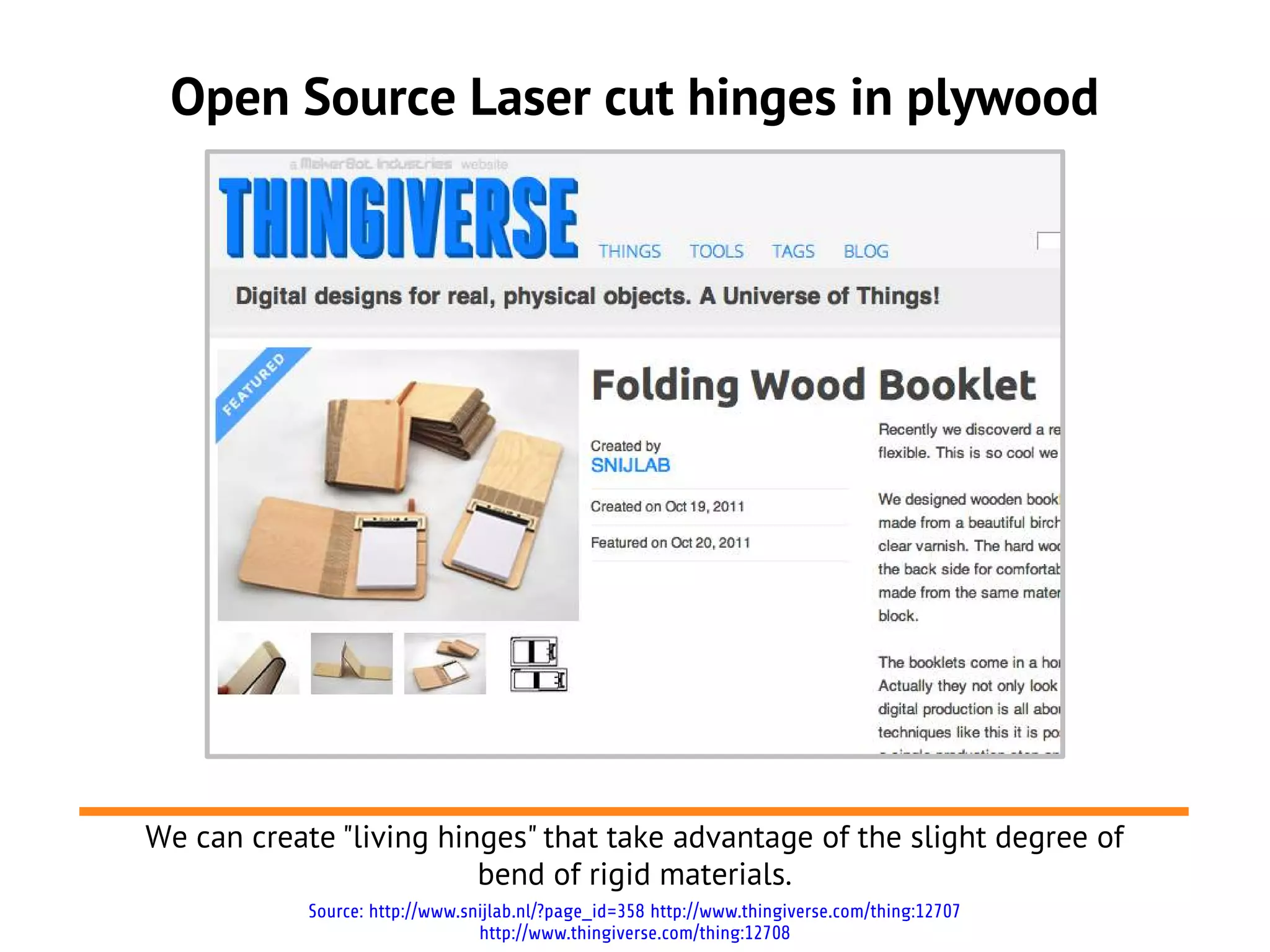

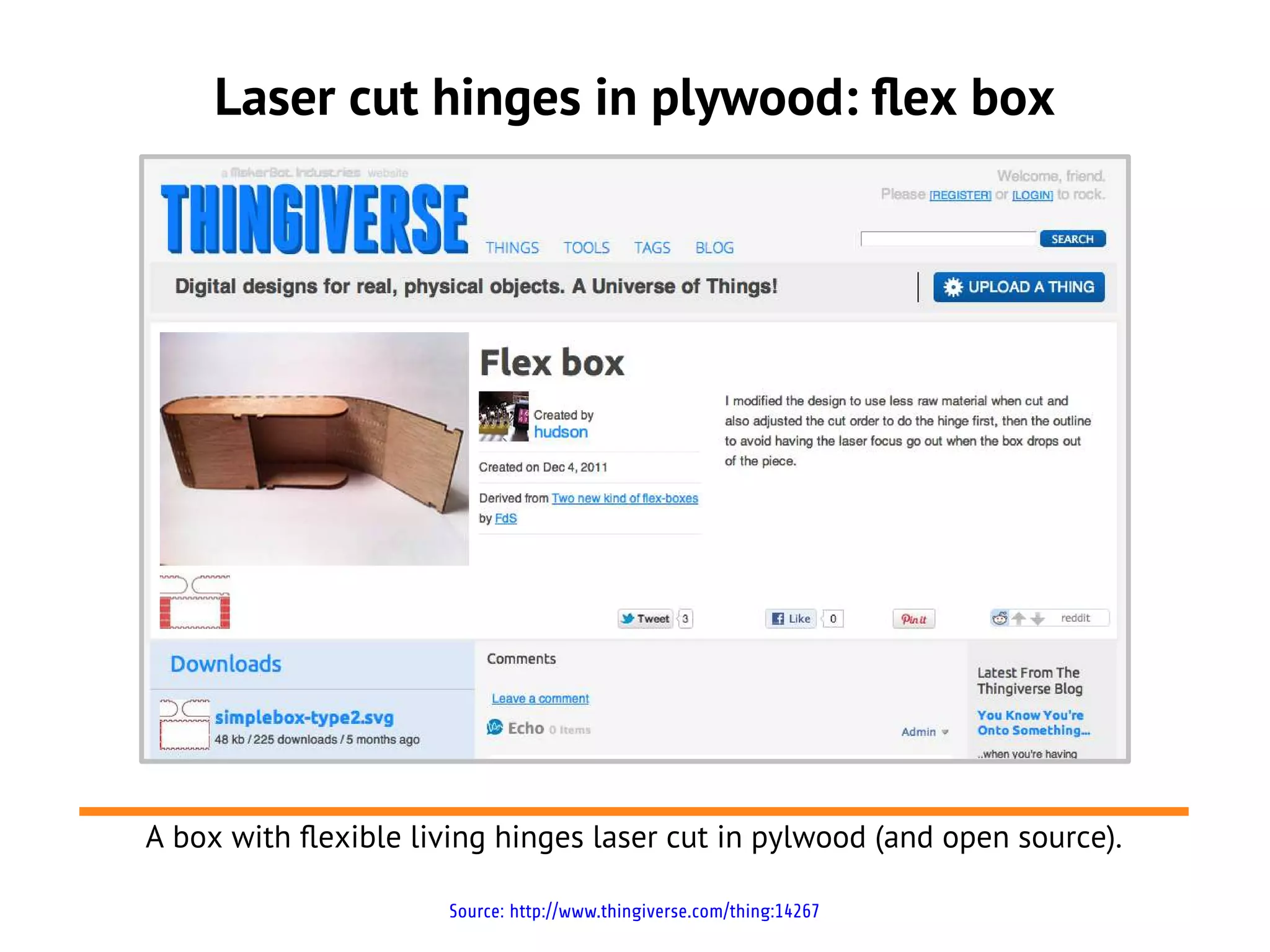

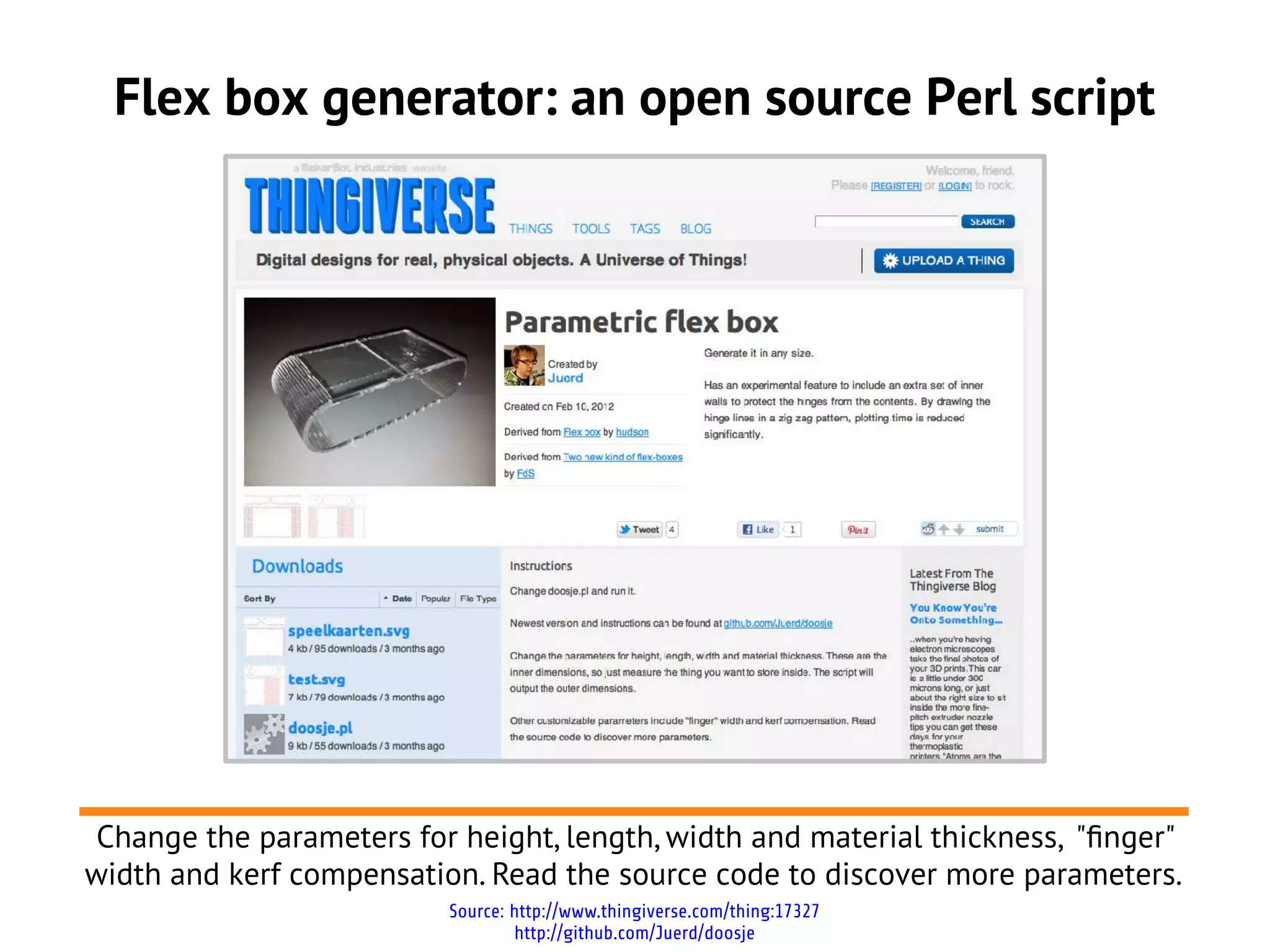

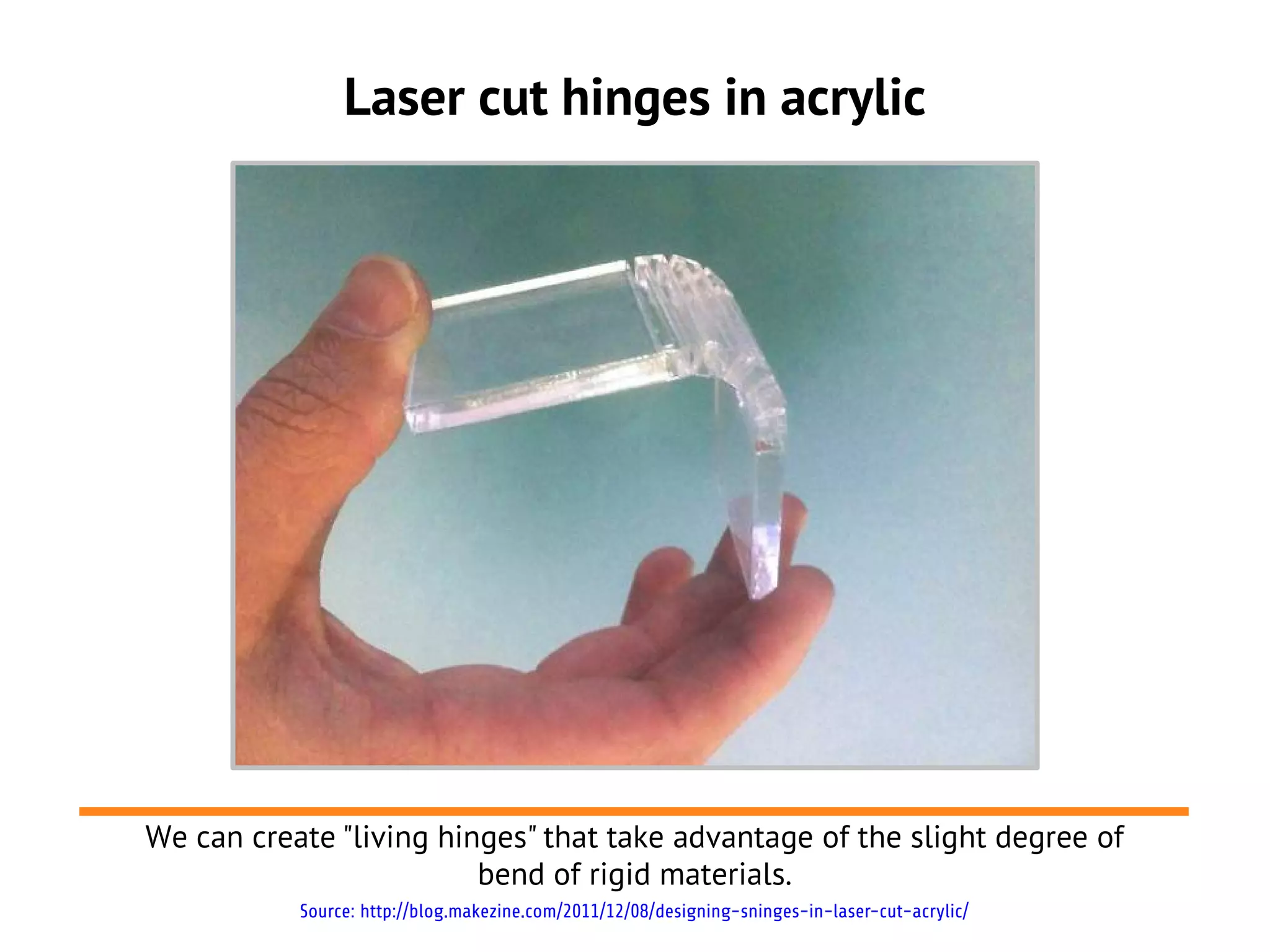

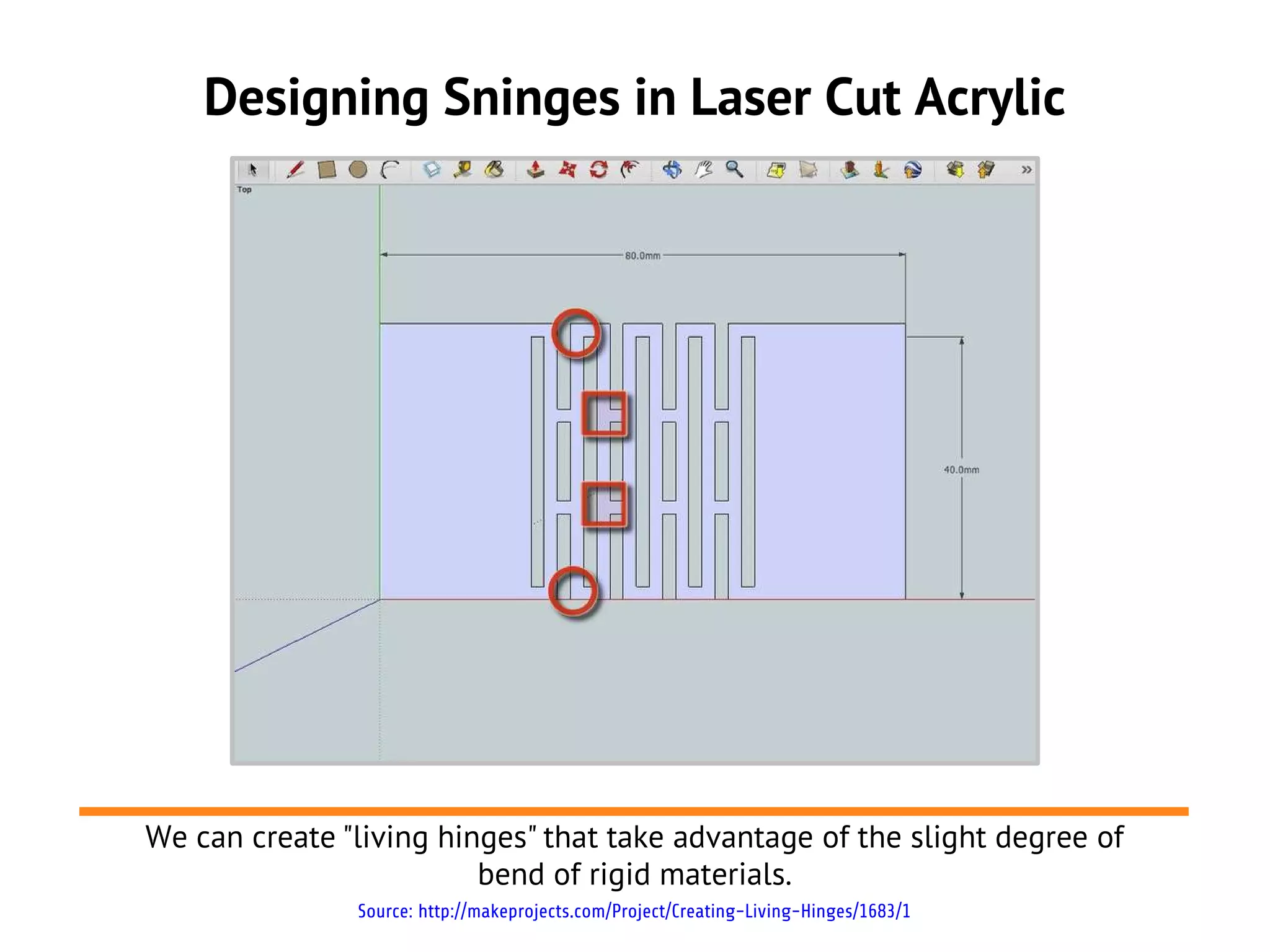

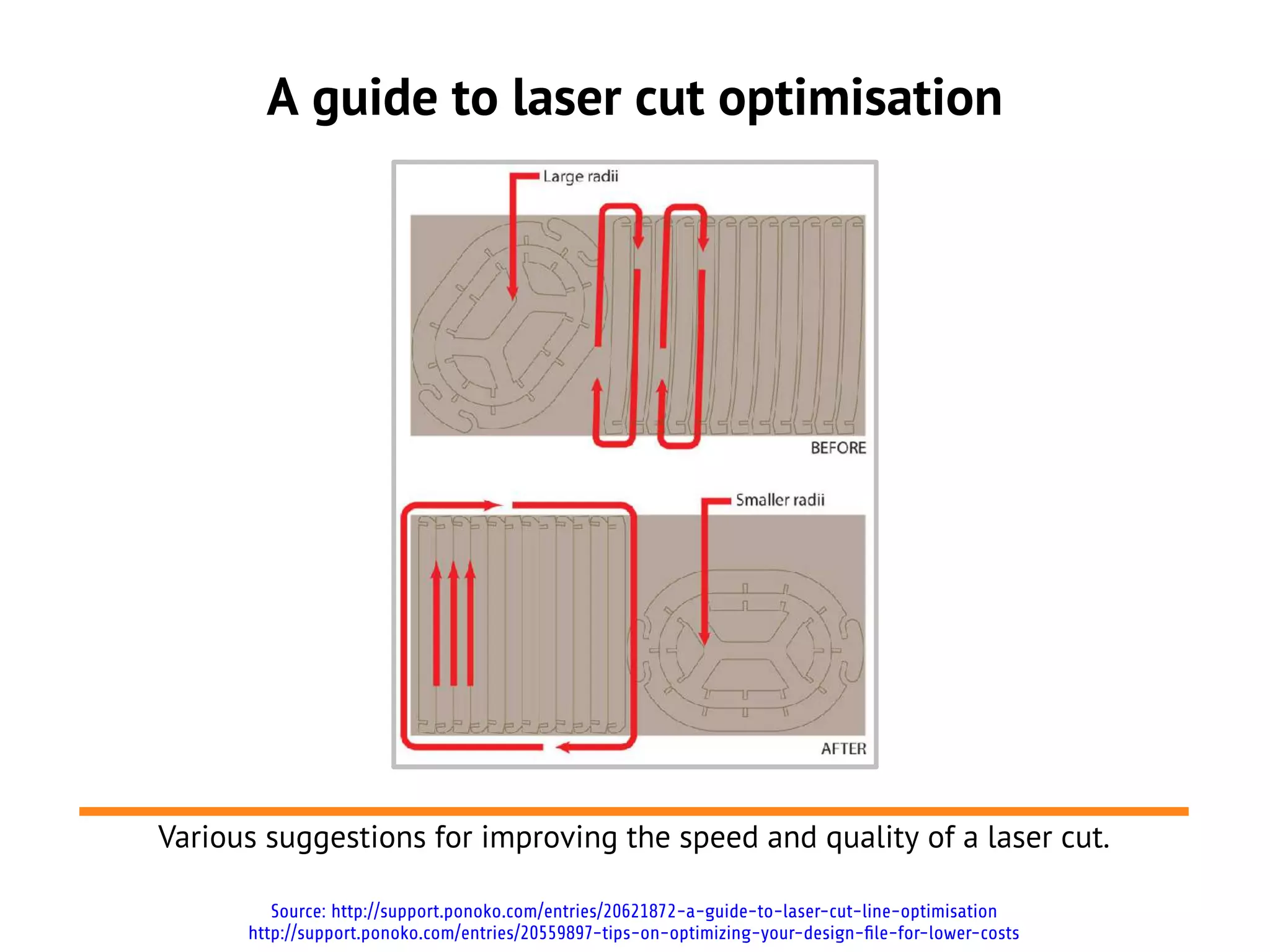

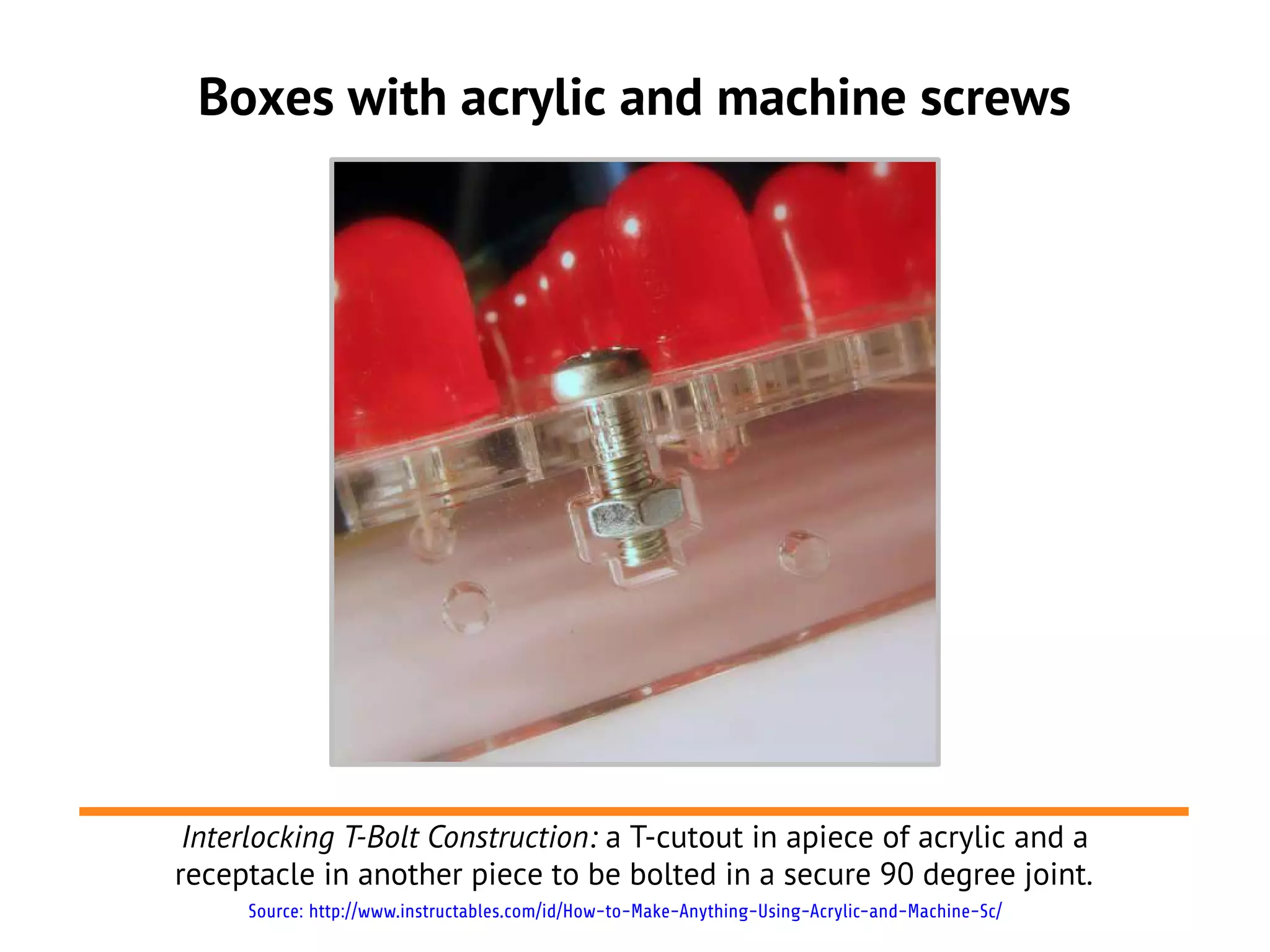

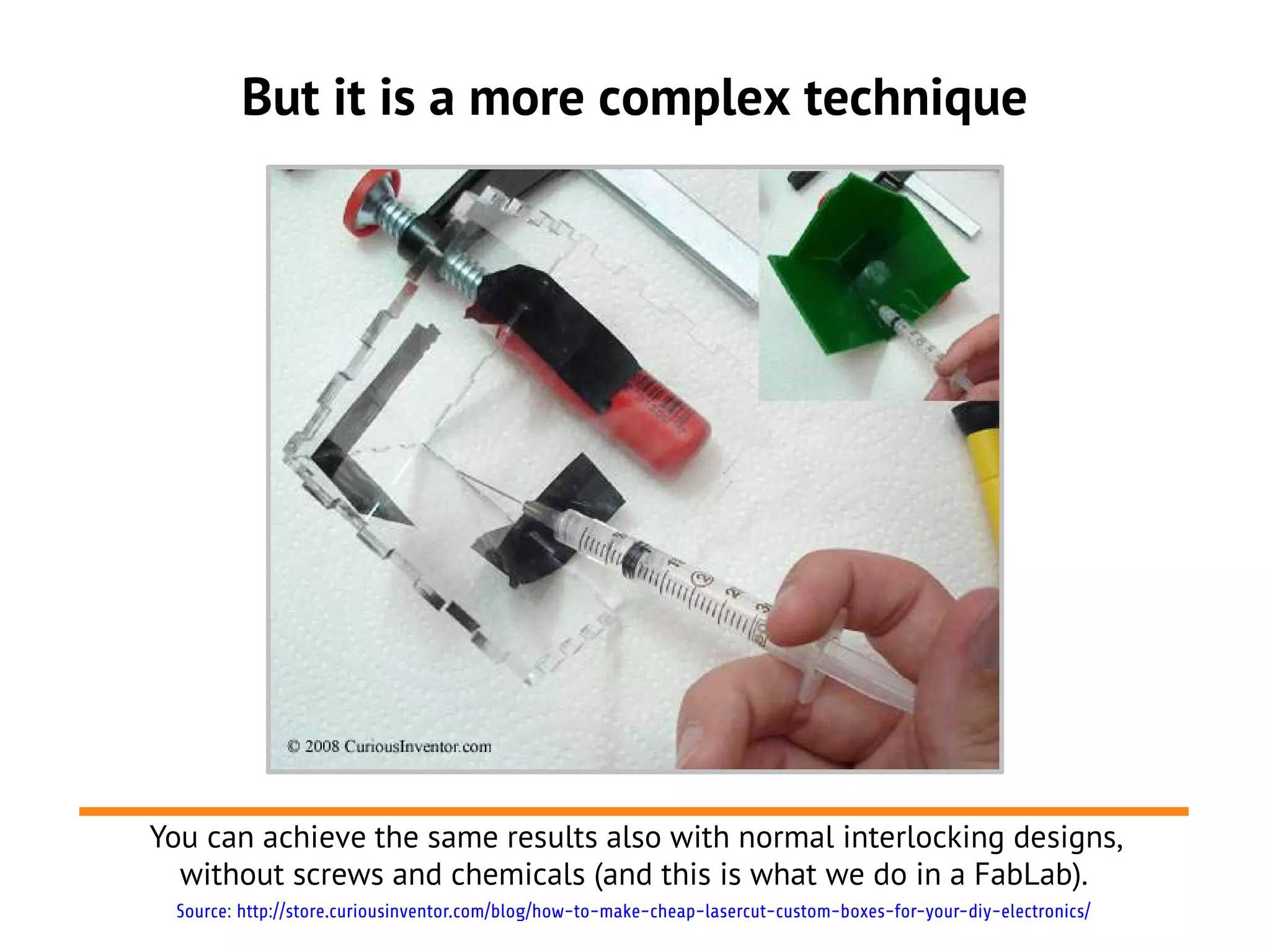

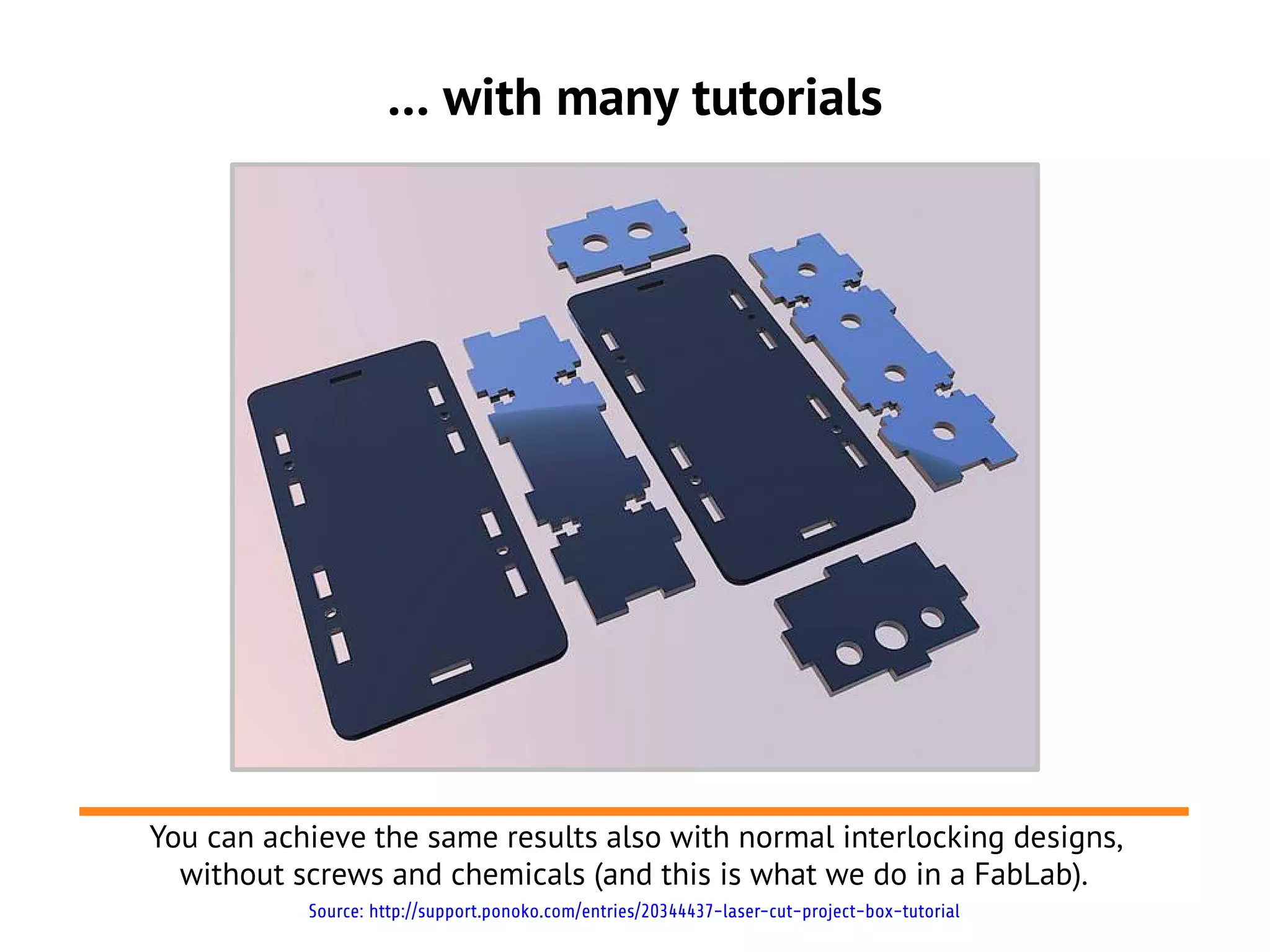

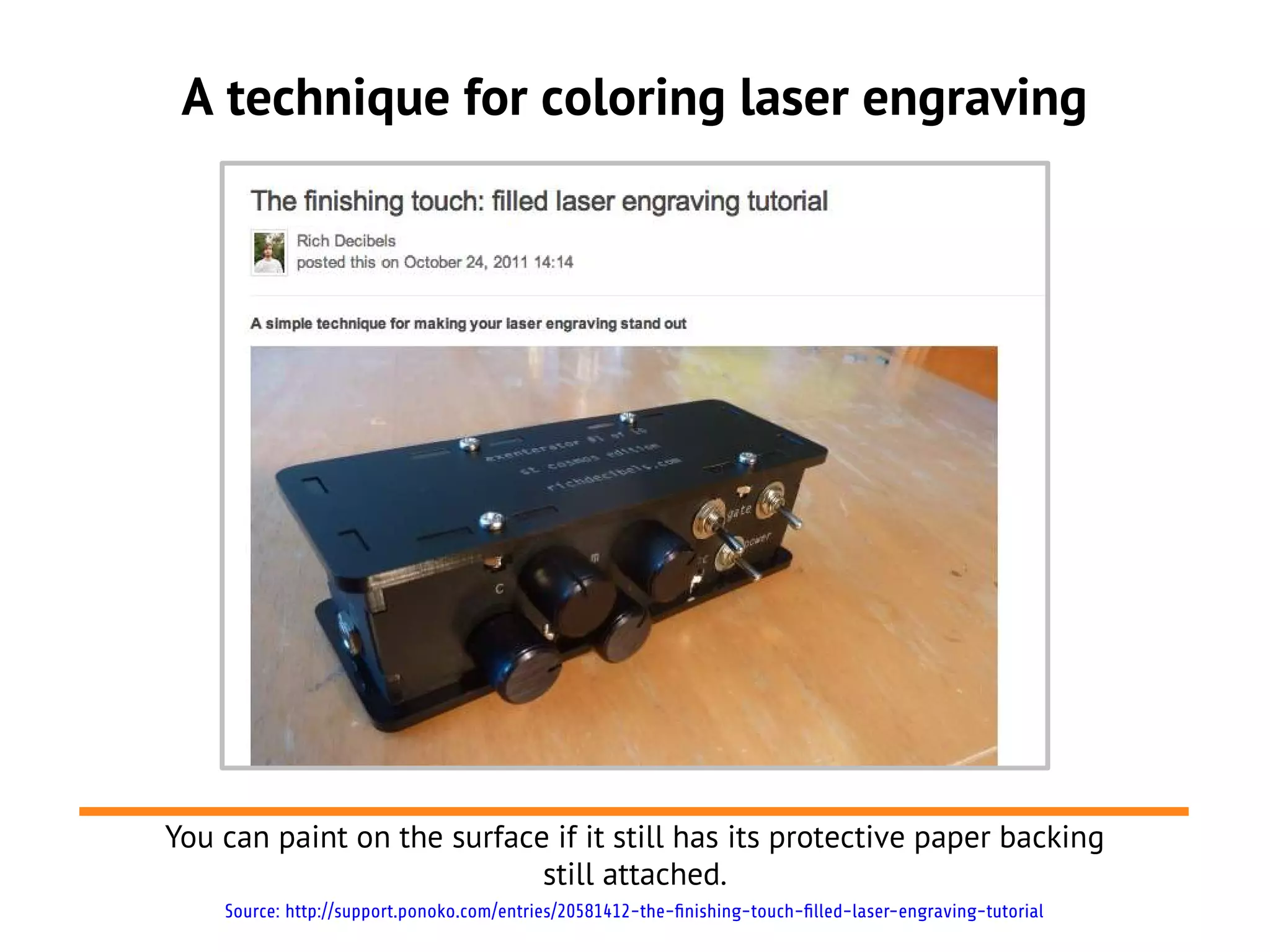

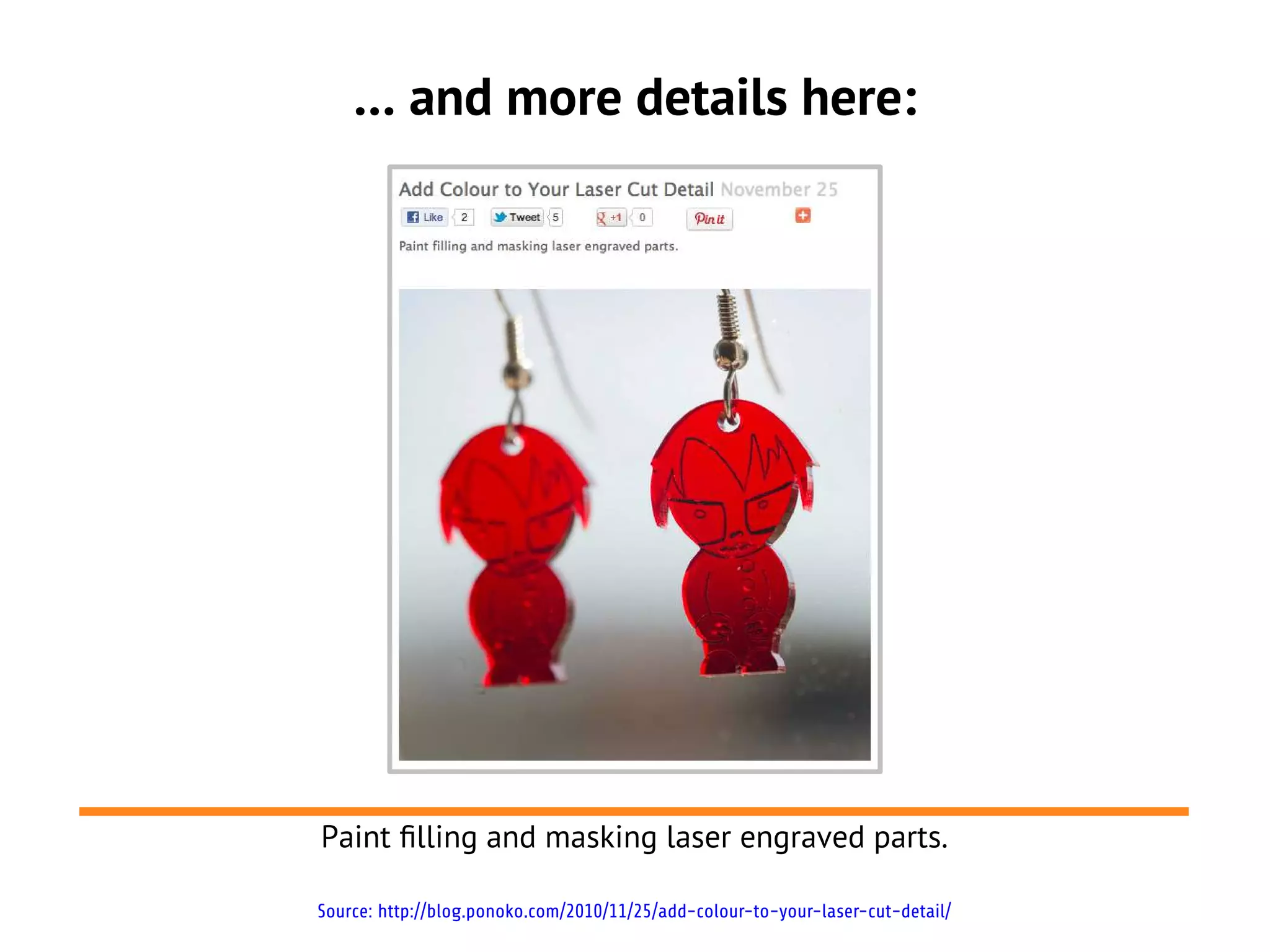

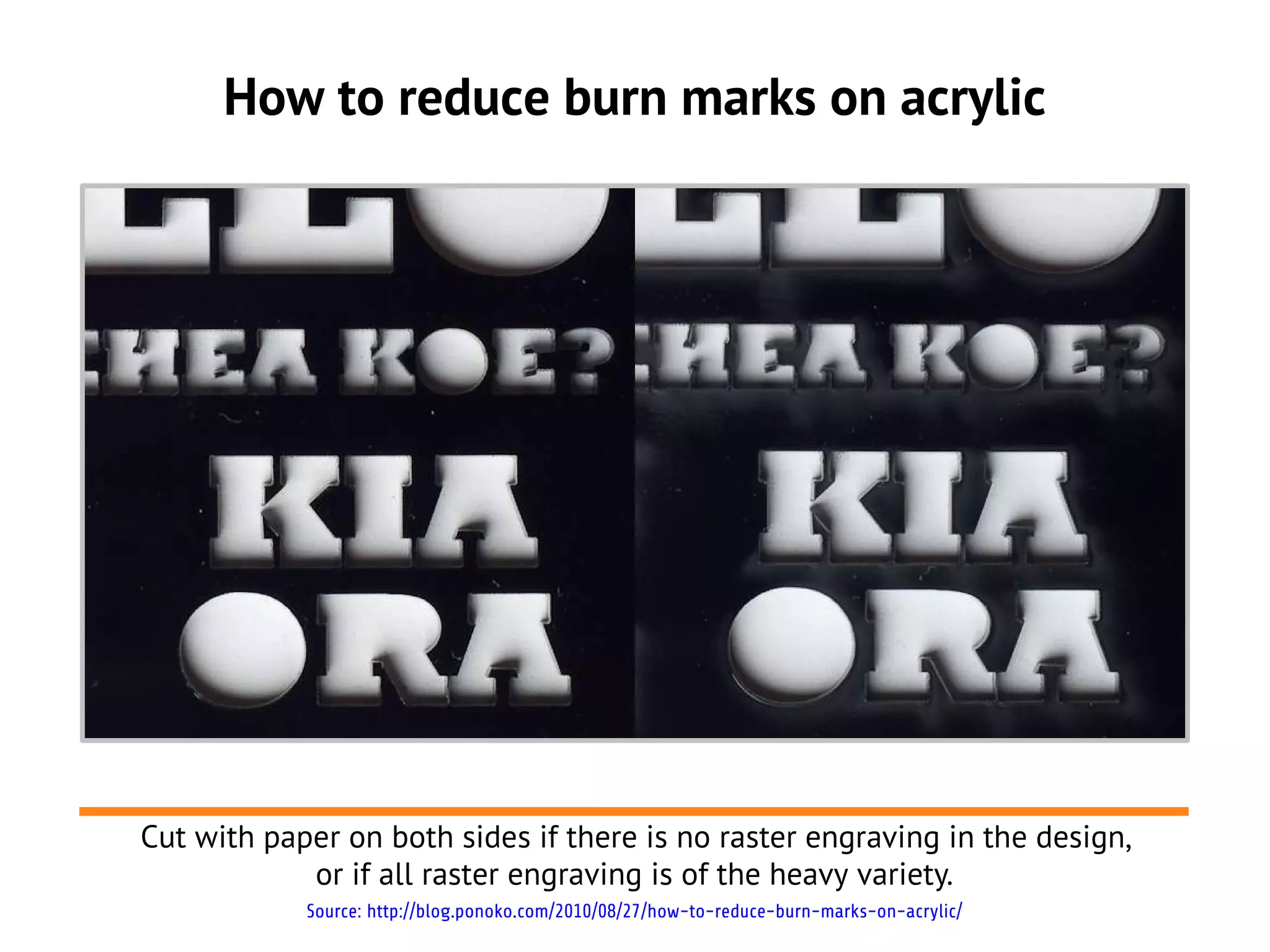

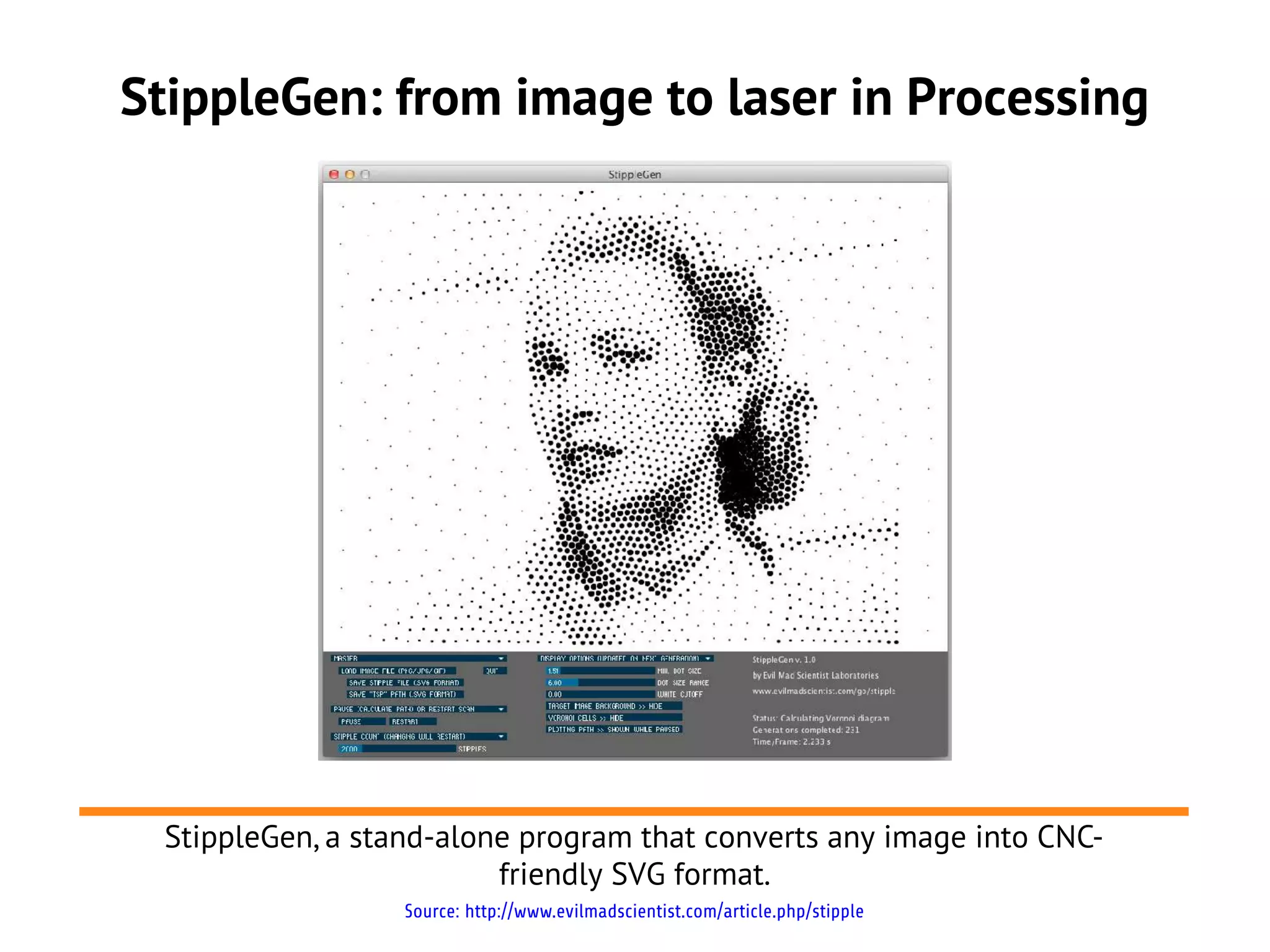

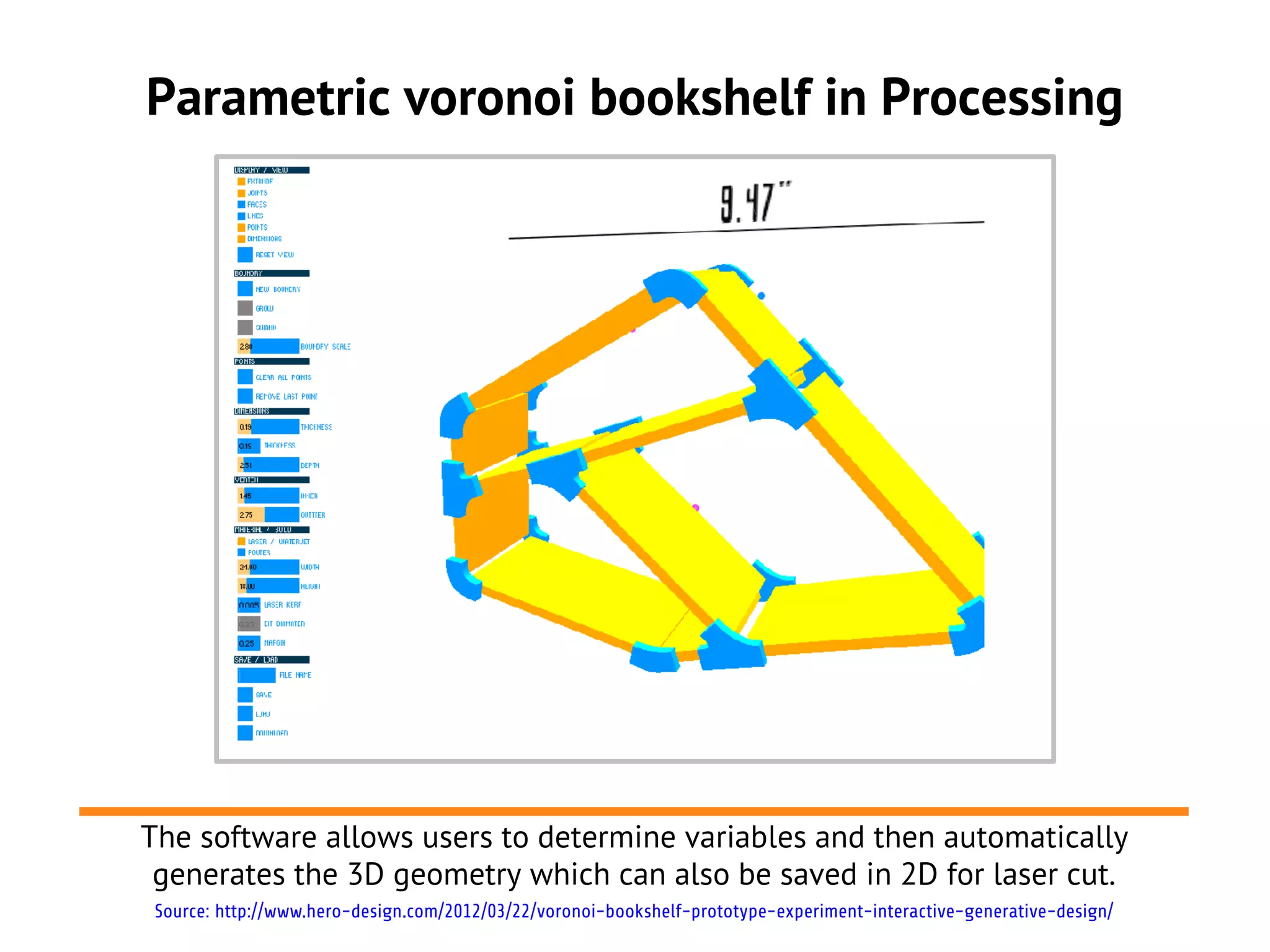

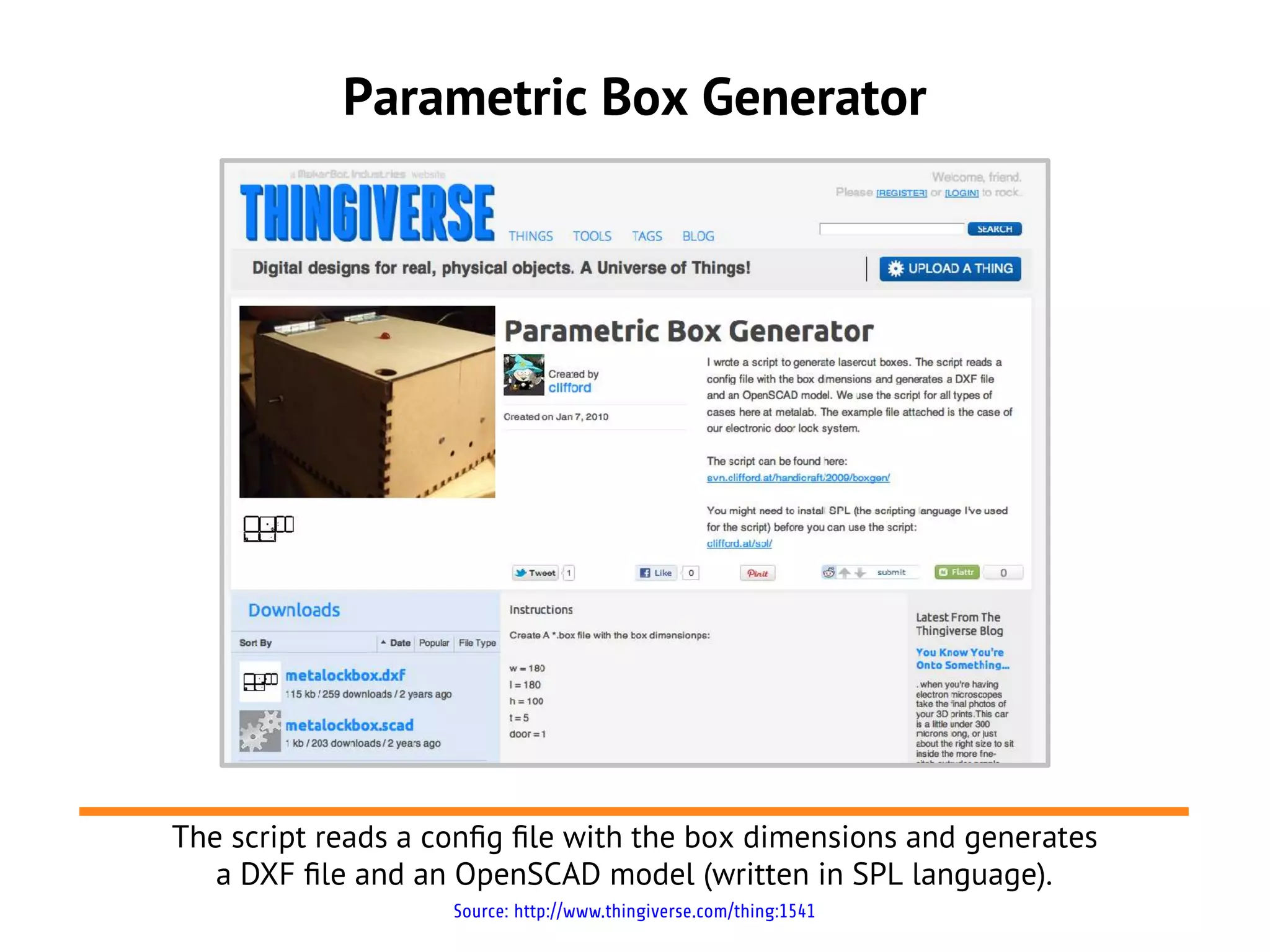

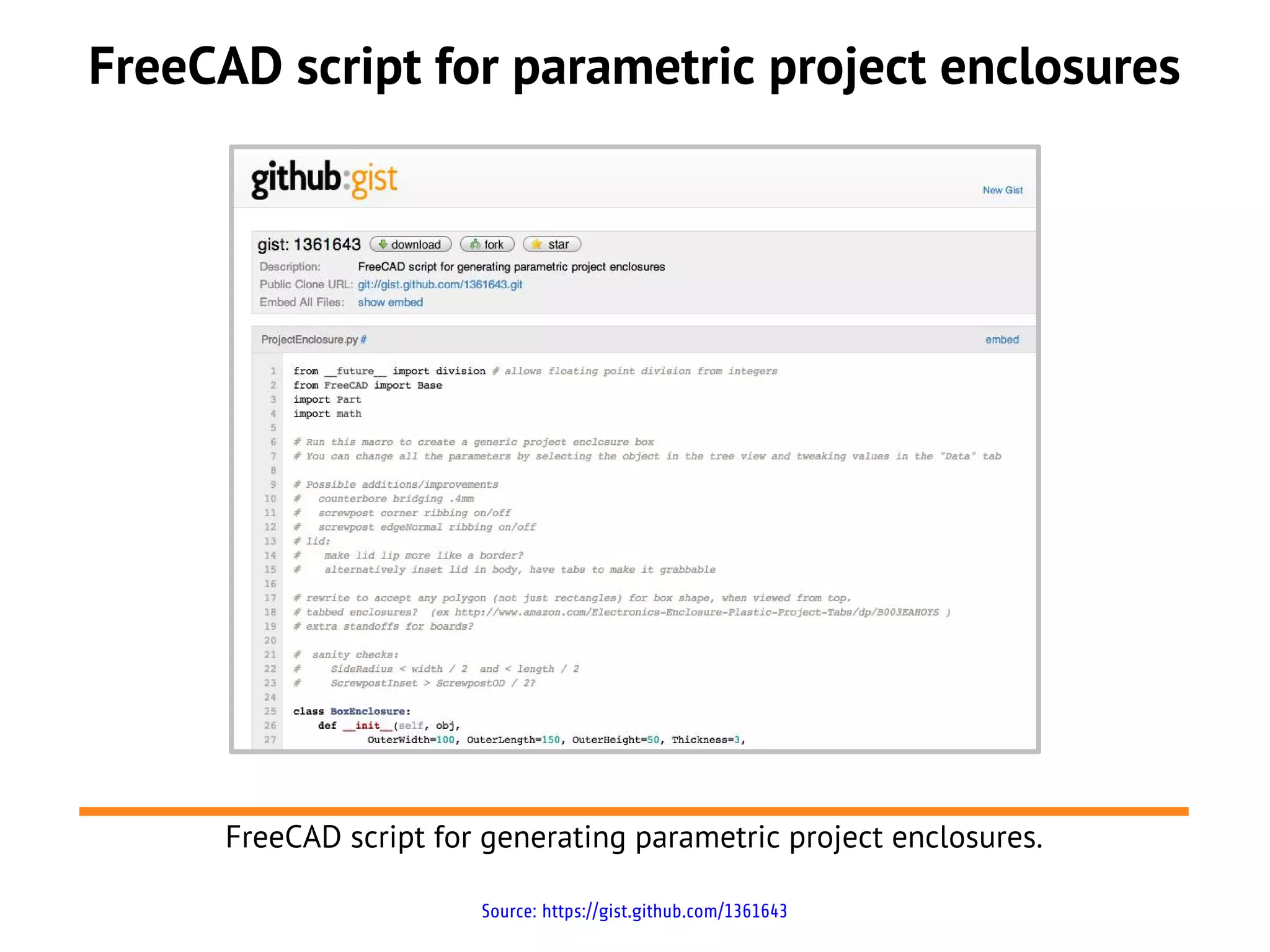

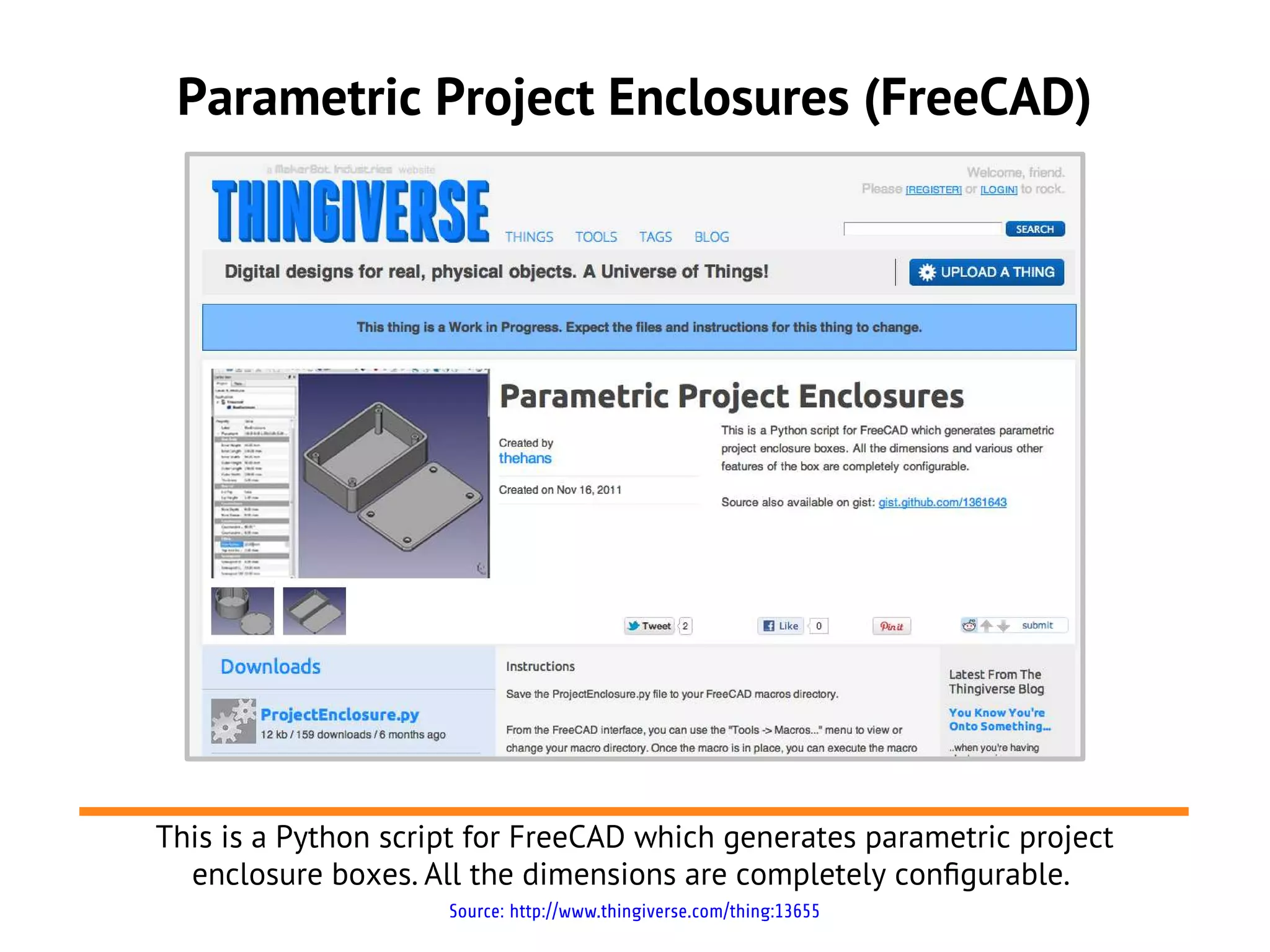

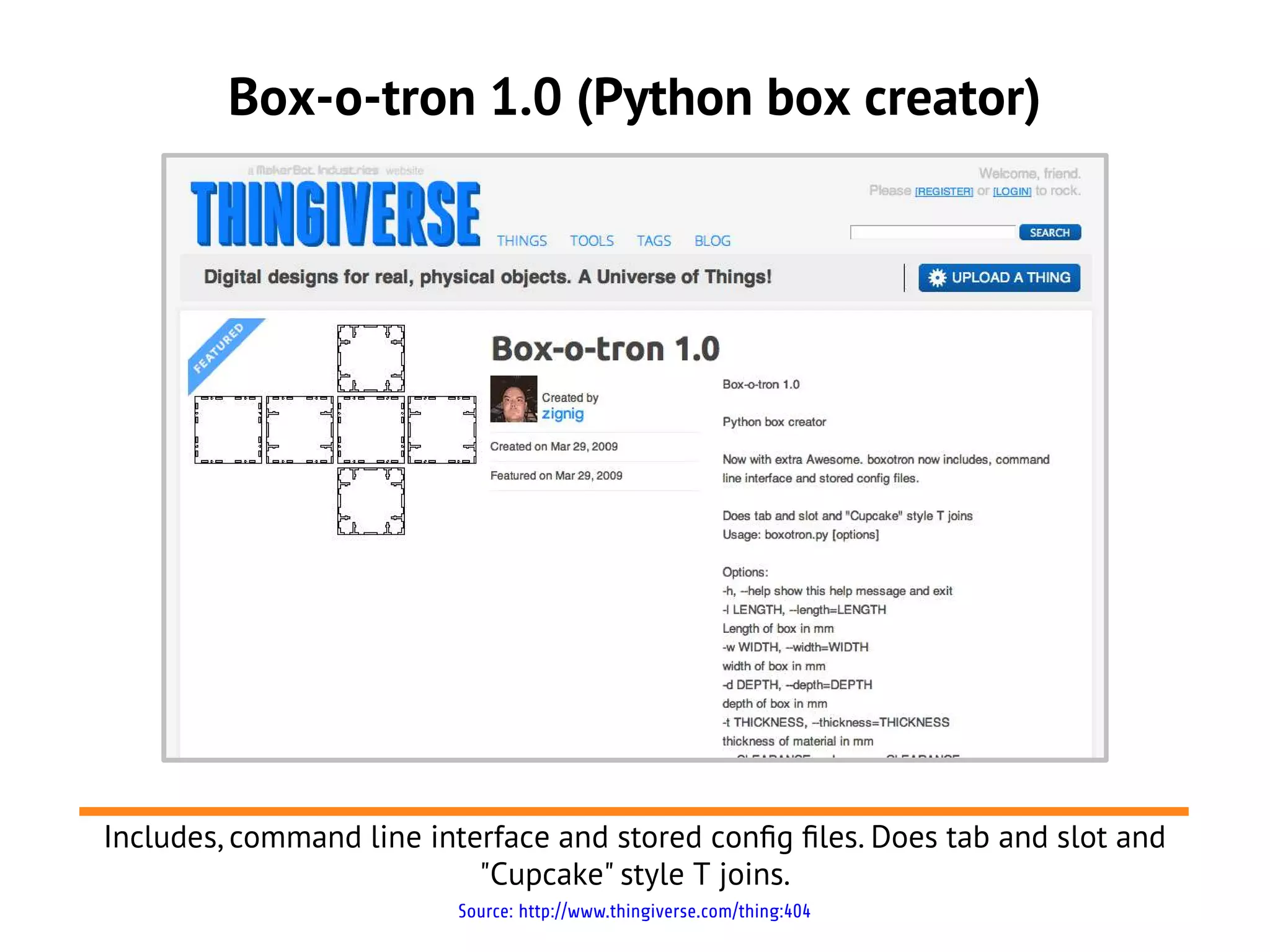

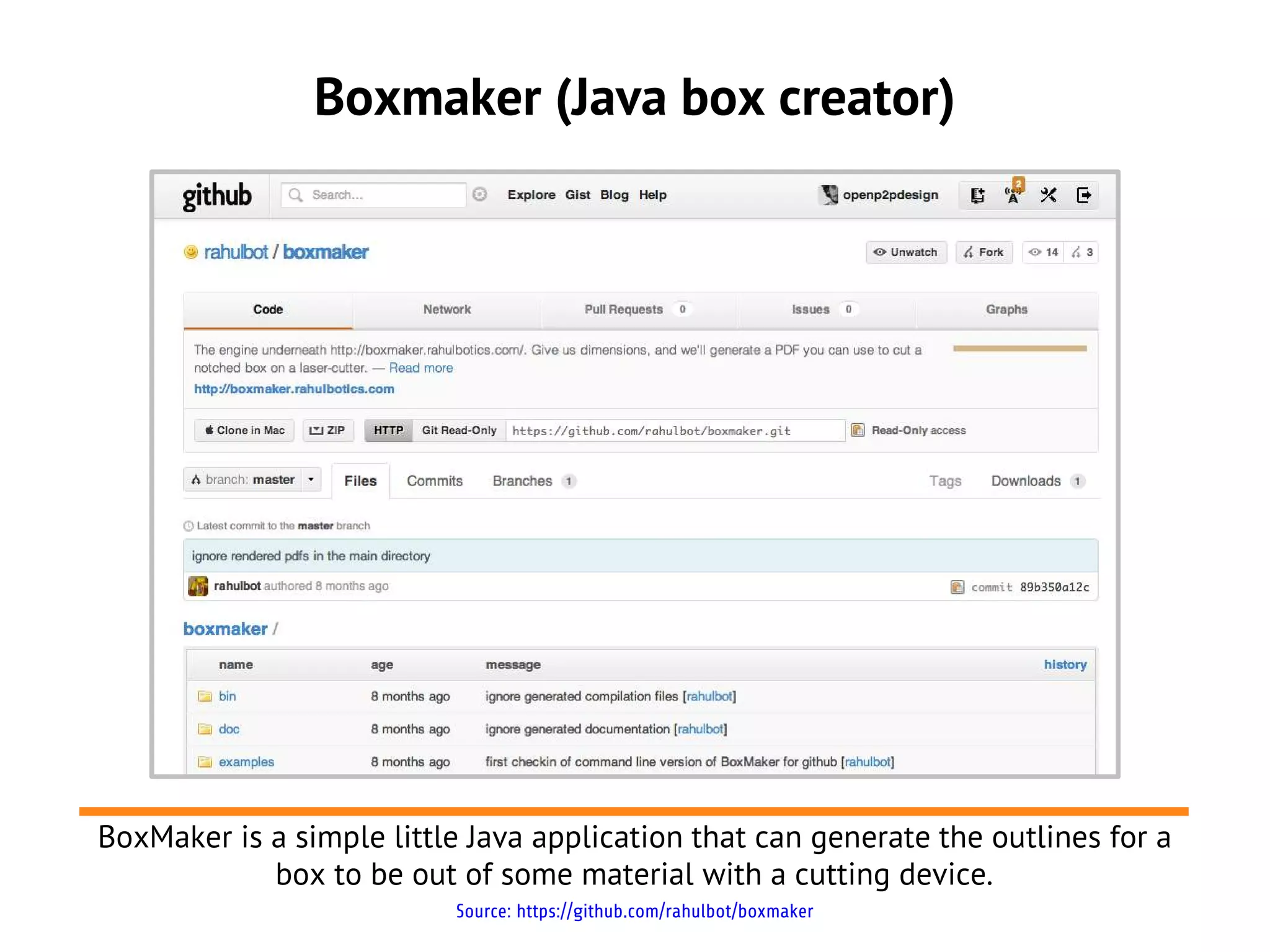

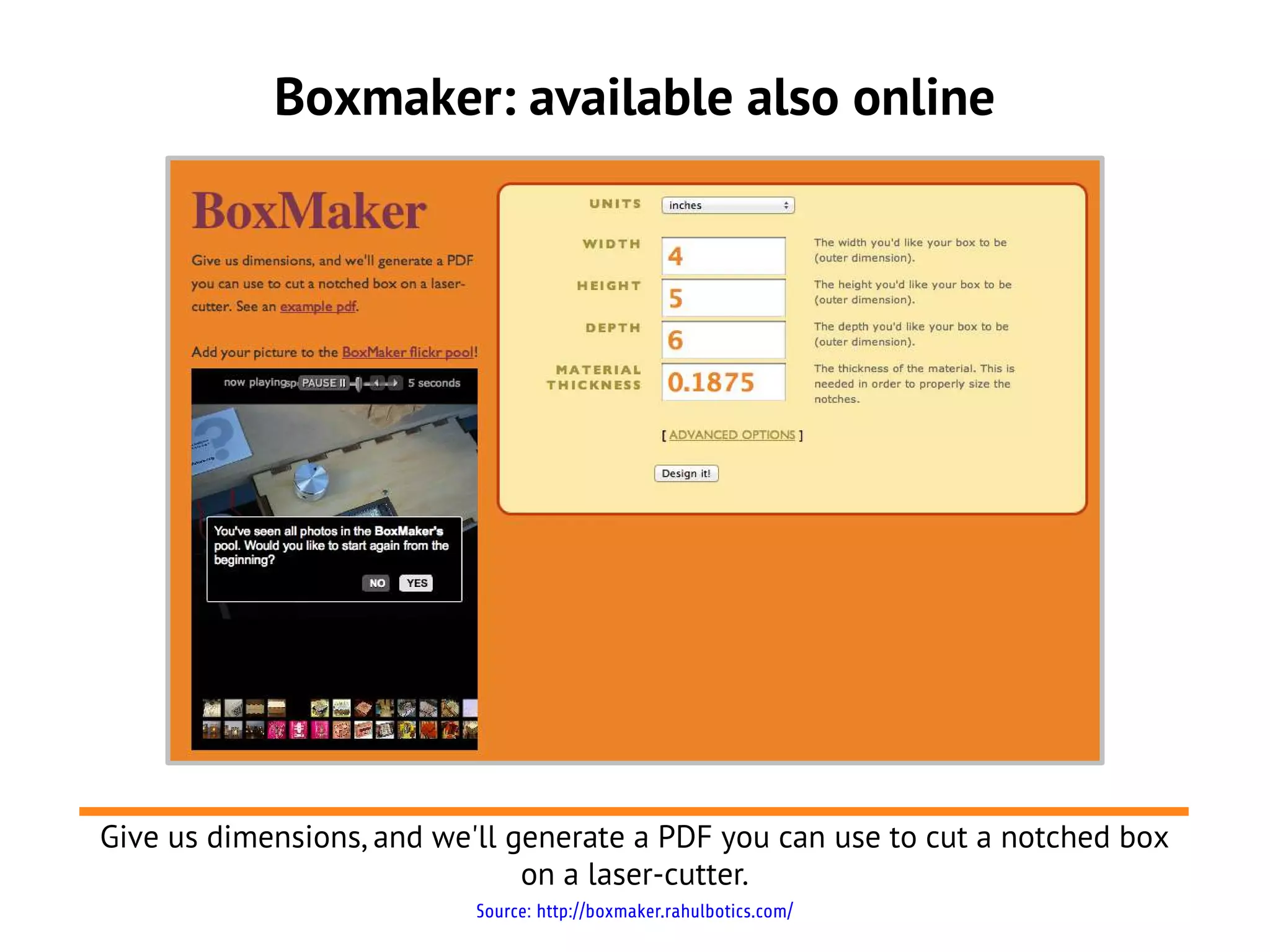

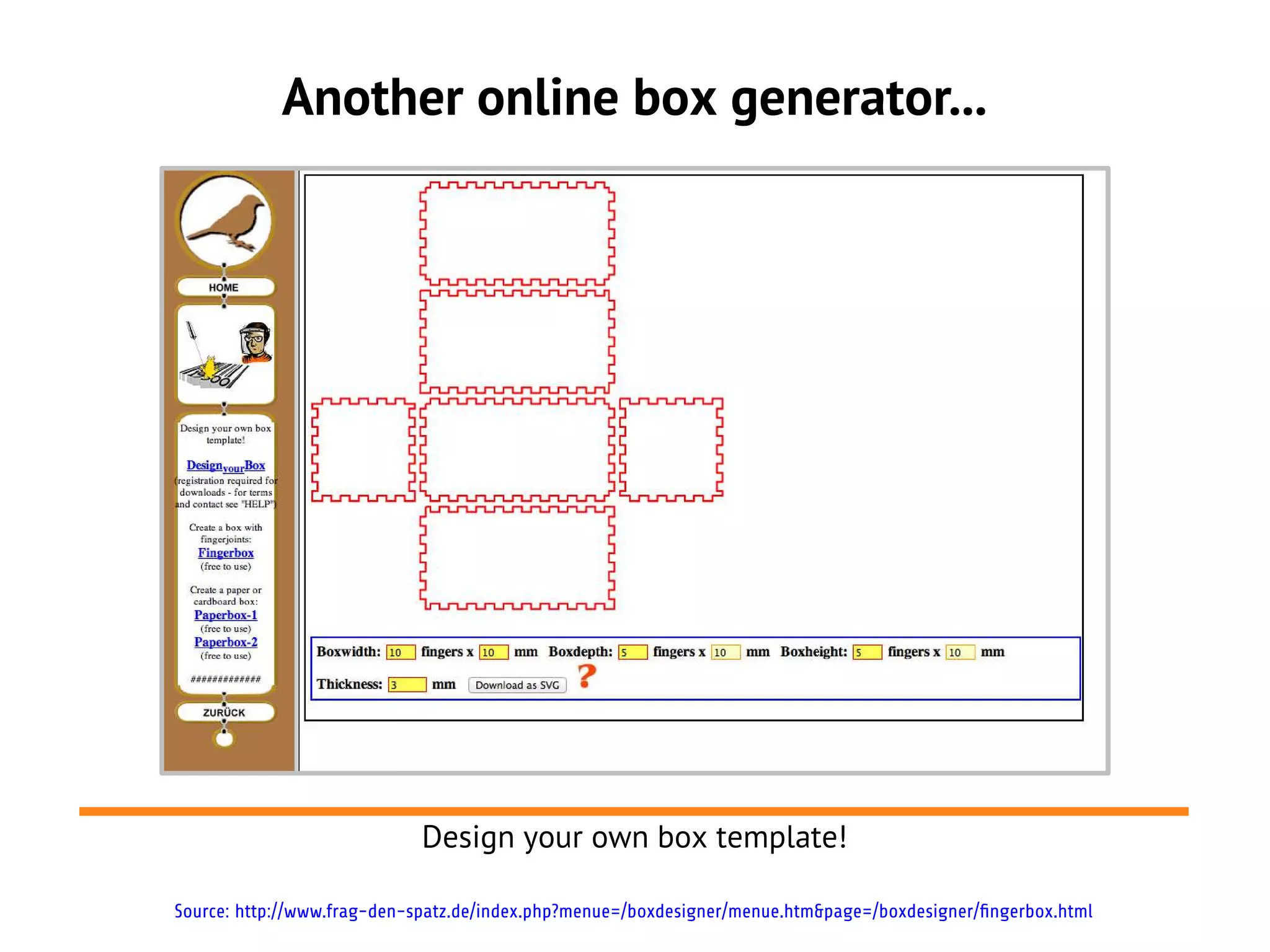

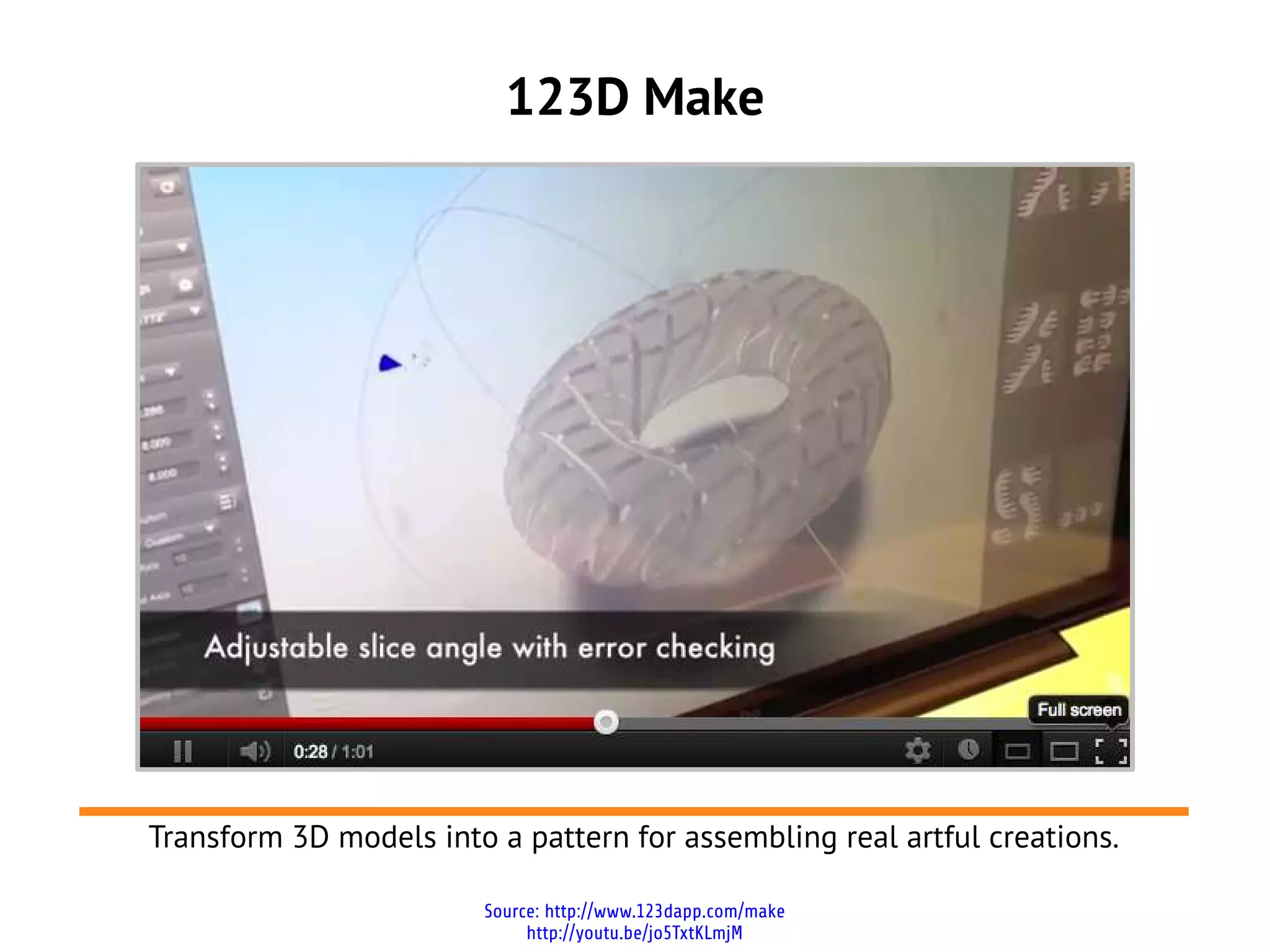

The document discusses laser cutting technology, its mechanisms, and various applications, including examples of projects produced with laser and vinyl cutters. It outlines technical considerations like material types, kerf measurement, and safety protocols when using such machines. Additionally, it highlights open-source innovations related to laser cutting and provides links to resources for further exploration.