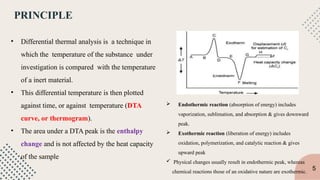

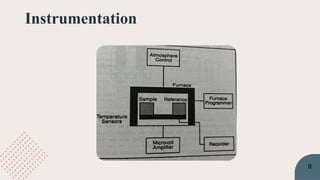

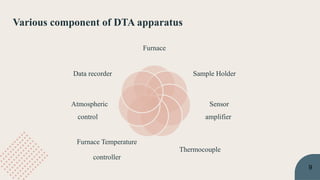

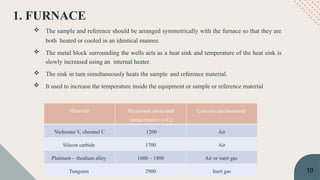

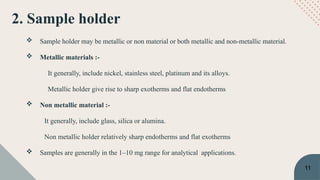

This presentation on differential thermal analysis (DTA) provides a comprehensive overview of its principles, instrumentation, factors affecting DTA curves, and key applications. It explains how DTA measures temperature differences between a sample and reference material, highlighting the role of thermocouples, furnaces, and sample holders. The presentation also discusses the impact of environmental and instrumental factors on DTA results and their applications in material science, polymer studies, and quality control.