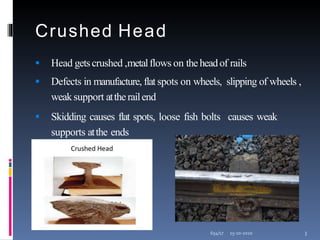

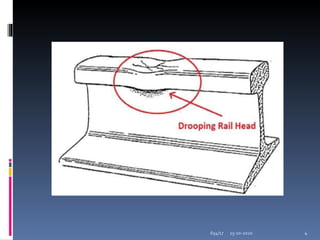

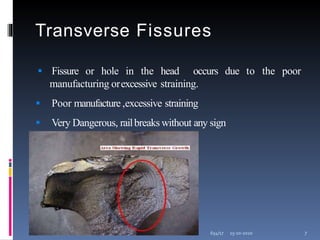

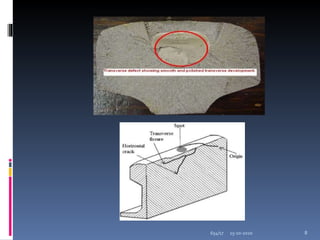

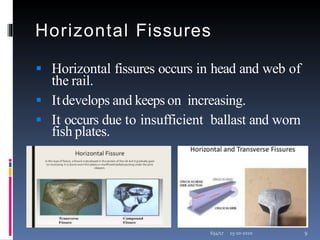

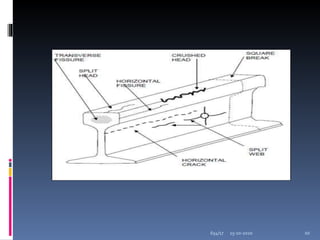

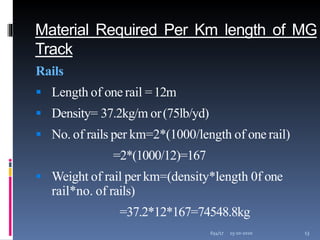

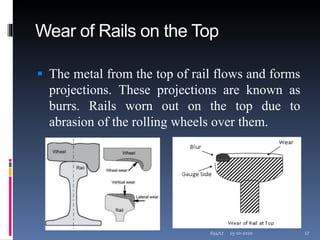

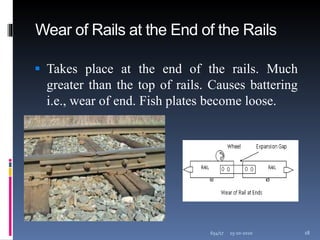

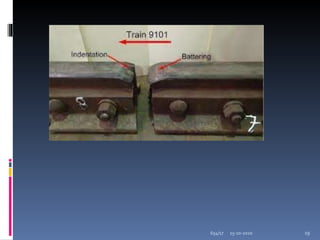

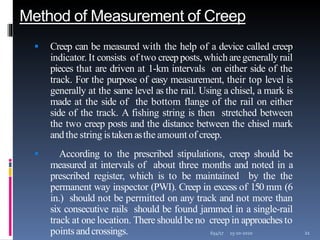

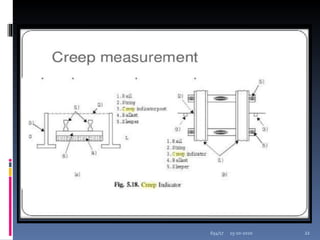

This document discusses different types of rail failures and rail wear that can occur on train tracks. It outlines six main types of rail failures: crushed head, split head, transverse fissure, horizontal fissure, and square and angular breaks. It also describes three main types of rail wear: wear on the top of rails, wear at the ends of rails known as battering, and wear on the sides of rails which is most destructive. The document provides details on measuring creep, which is the gradual movement of rails due to stress, using creep indicators installed at 1 km intervals along the tracks.