1) Injection molding is an important manufacturing process that is used to produce plastic parts in large quantities. It is important to design parts for injection molding considering manufacturing guidelines to ensure quality parts and reduce costs.

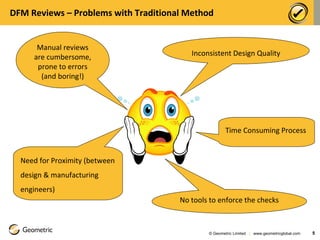

2) Traditional DFM reviews are time-consuming and inconsistent. A new software called DFMPro automates DFM checks for injection molded parts using predefined rules.

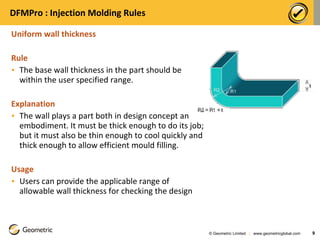

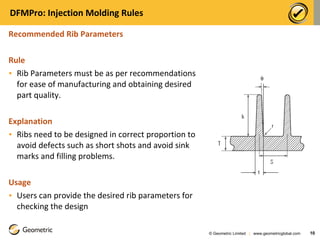

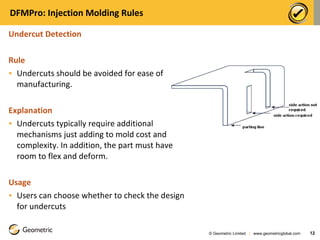

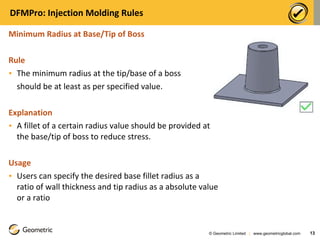

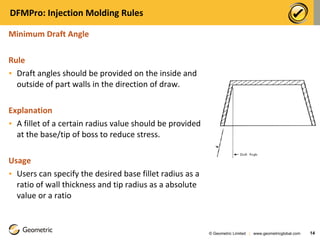

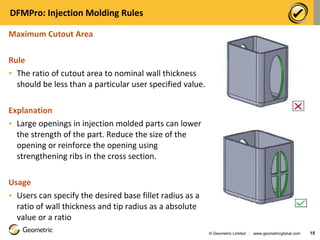

3) DFMPro includes rules for injection molded parts related to wall thickness, draft angles, ribs, bosses, and undercuts that help improve manufacturability and part quality. Users can customize rules and the software enforces checks.

![THANK YOU © Geometric Limited | www.geometricglobal.com The copyrights/ trademarks of all products referenced herein, are held by their respective companies. http://dfmpro.geometricglobal.com For any queries: [email_address]](https://image.slidesharecdn.com/dfmproforinjectionmoldingoct09-12565778038602-phpapp02/85/DFMPro-For-Injection-Molding-Oct09-16-320.jpg)