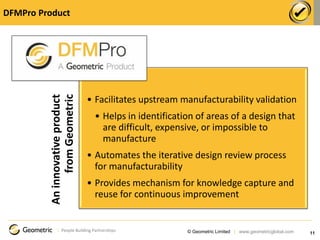

Geometric Limited, part of the Godrej Group, specializes in engineering solutions and technologies, providing services that enhance productivity in product design and manufacturing. Their key product, DFMPro, automates manufacturability checks during the design stage, significantly reducing time and costs associated with design revisions and production errors. The company has reported positive feedback from clients like Rockwell Automation and Motorola, who experienced substantial improvements in efficiency using DFMPro.

![We Provide Complete Engineering Solution

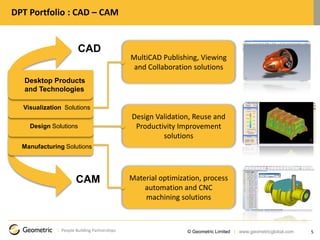

Software Solutions Engineering Solutions Products and Technologies

• Product Lifecycle • Product Engineering • Desktop Products for point

Management Solutions

• Manufacturing solutions

• Manufacturing IT Solutions Engineering • Technologies for building

• Software Product • Engineering Productivity solutions for Engineering

Engineering Solutions Productivity

Global presence

India USA

Mumbai Santa Clara, CA

[Corporate Head

Quarters] Scottsdale, AZ

Pune Houston, TX

Bangalore Troy, MI

Hyderabad Moline & Peoria, IL

Chennai Dublin, OH

Asia-Pacific Europe

Tokyo; Japan Stuttgart; Germany

St. Jean Bonnefonds;

Shanghai; China

France

Singapore Brasov; Romania

#1 Indian IT Product company in Engineering space

| People Building Partnerships © Geometric Limited | www.geometricglobal.com 4](https://image.slidesharecdn.com/dfmpro5may11-13054369325629-phpapp02-110515002536-phpapp02/85/CAD-integrated-automatic-DFM-analysis-4-320.jpg)