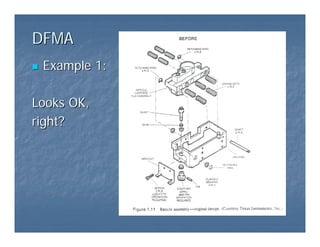

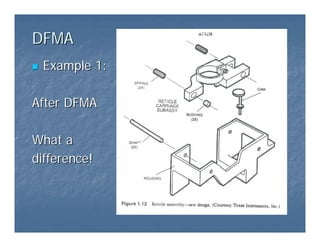

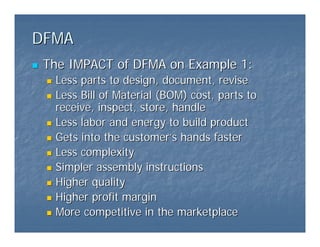

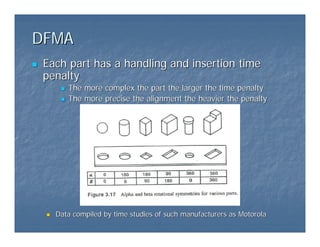

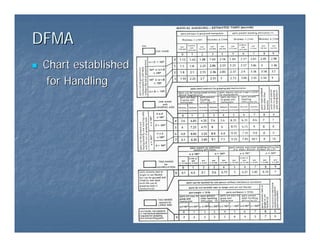

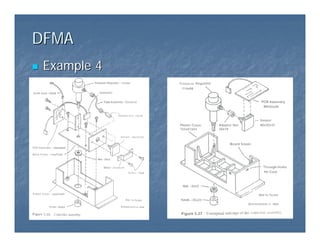

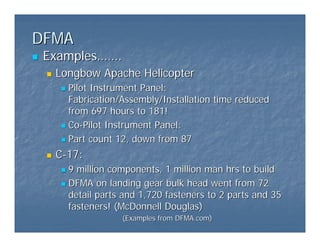

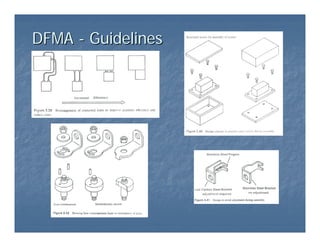

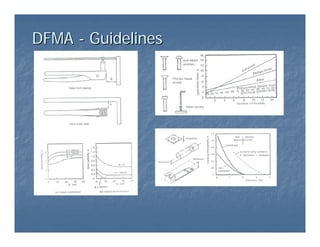

This document provides an overview of Design for Manufacturing and Assembly (DFMA). It begins with the presenter's background and then defines DFMA. Examples are given that show how DFMA principles can significantly reduce part counts and assembly times. Guidelines for designing parts for ease of manufacturing and assembly are presented. The benefits of applying DFMA include lower costs, faster production, higher quality, and increased competitiveness. DFMA analysis techniques allow quantitative evaluation of design alternatives.