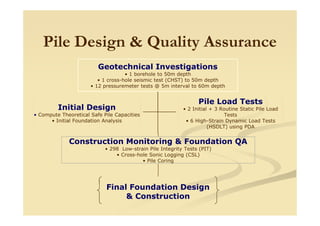

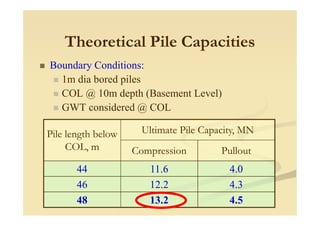

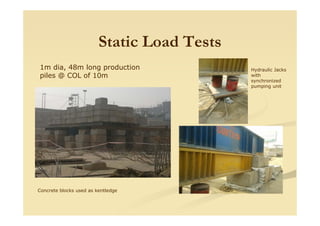

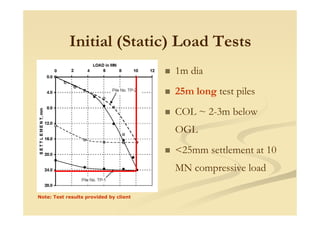

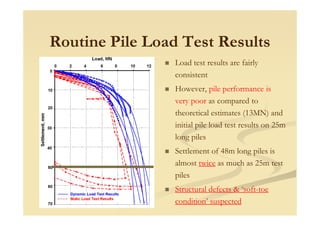

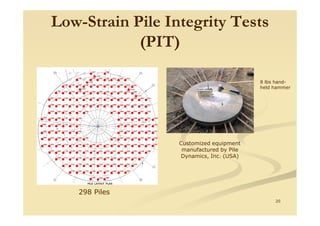

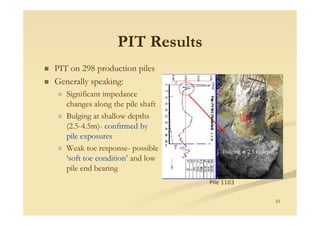

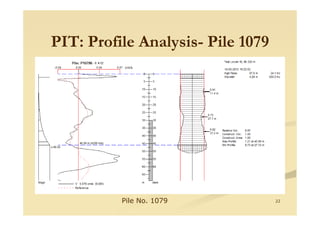

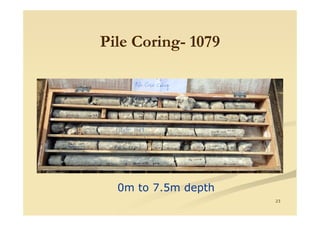

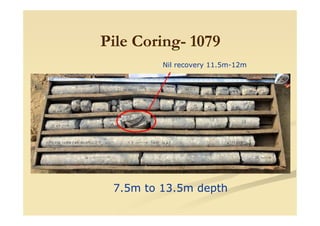

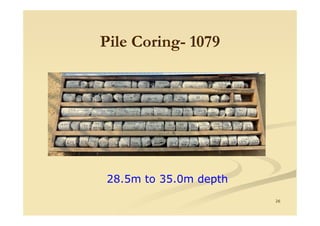

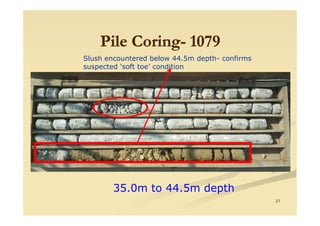

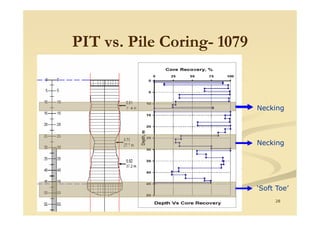

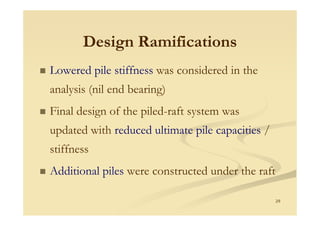

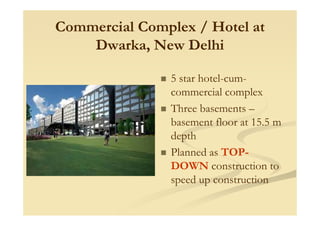

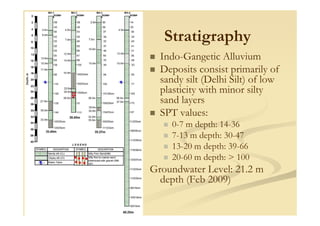

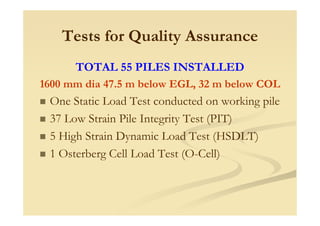

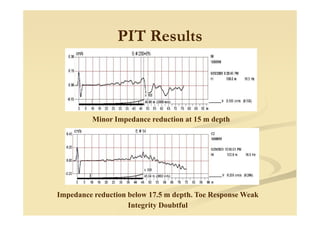

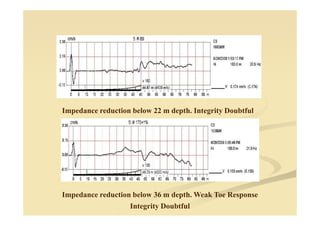

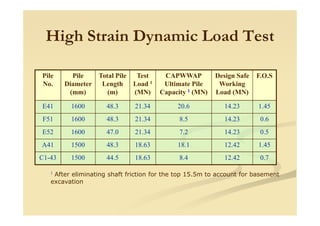

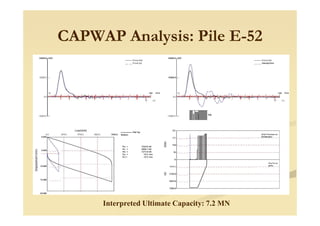

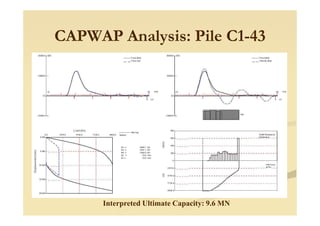

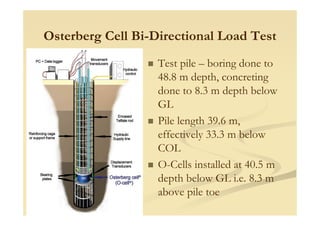

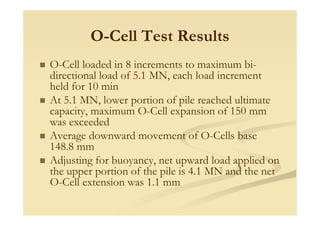

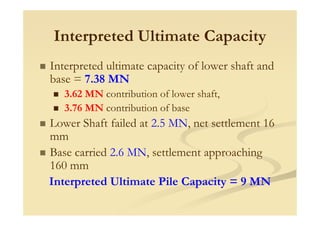

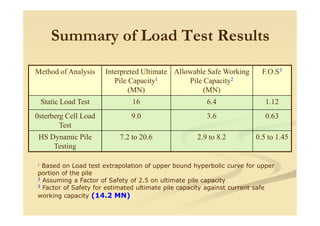

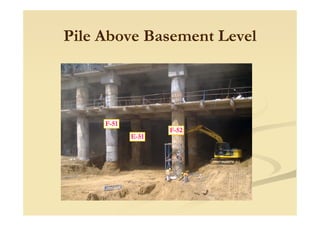

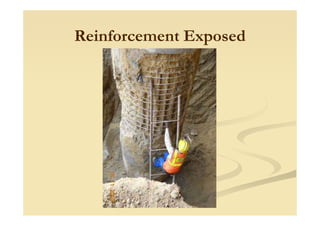

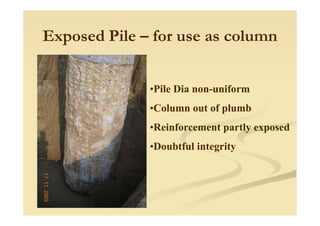

This document discusses using quality assurance tests to identify defects in large diameter bored piles for two construction projects. For the first project, pile load tests, integrity tests, and coring identified necking, bulging, and a weak pile toe, likely due to a "soft toe" condition. The pile capacities were reduced and additional piles were added. For the second project, integrity and load tests found impedance reductions and doubtful pile integrity below certain depths. Load capacities were de-rated based on the test results. The conclusion emphasizes the importance of a comprehensive quality assurance program to ensure foundation safety and performance.