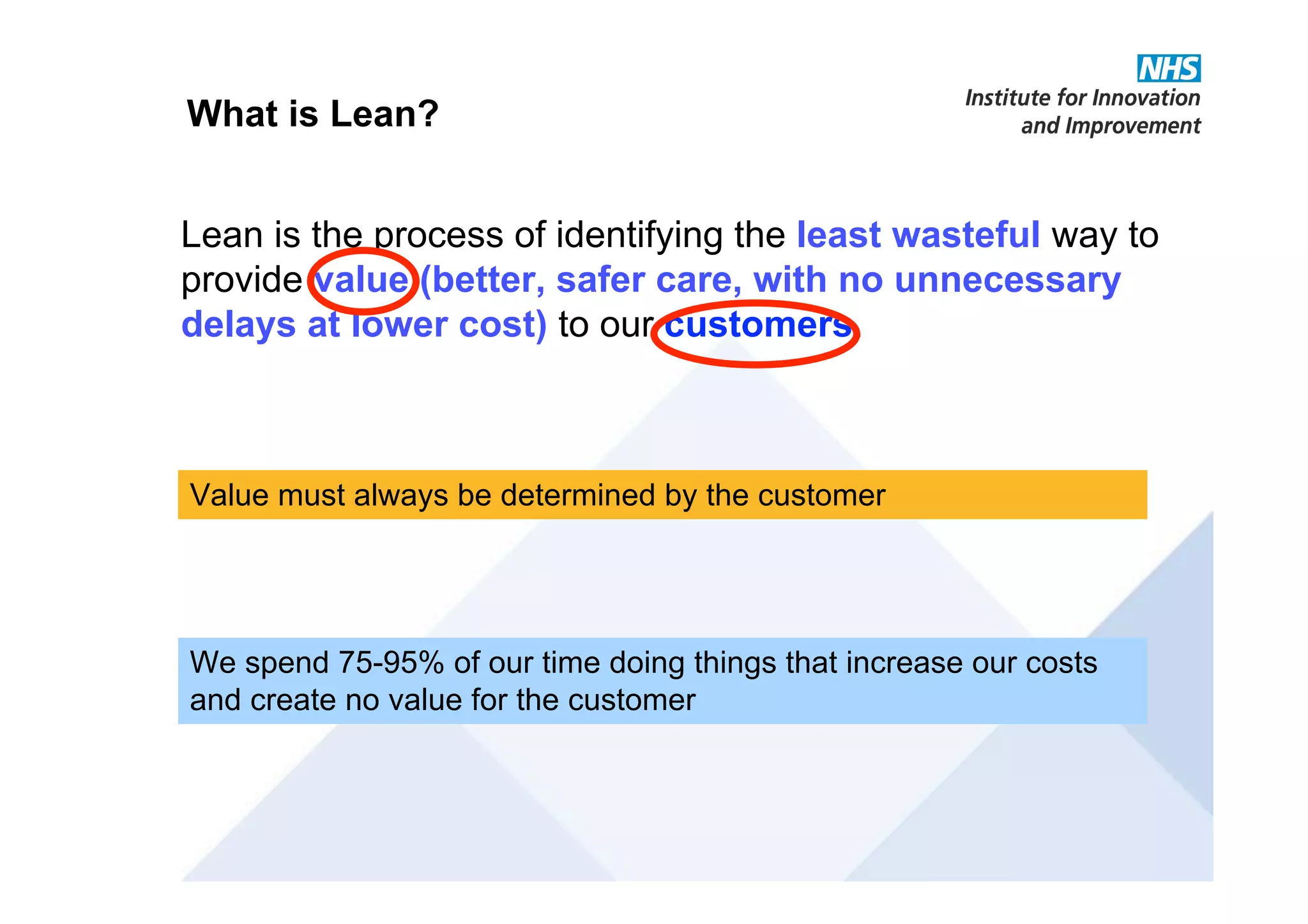

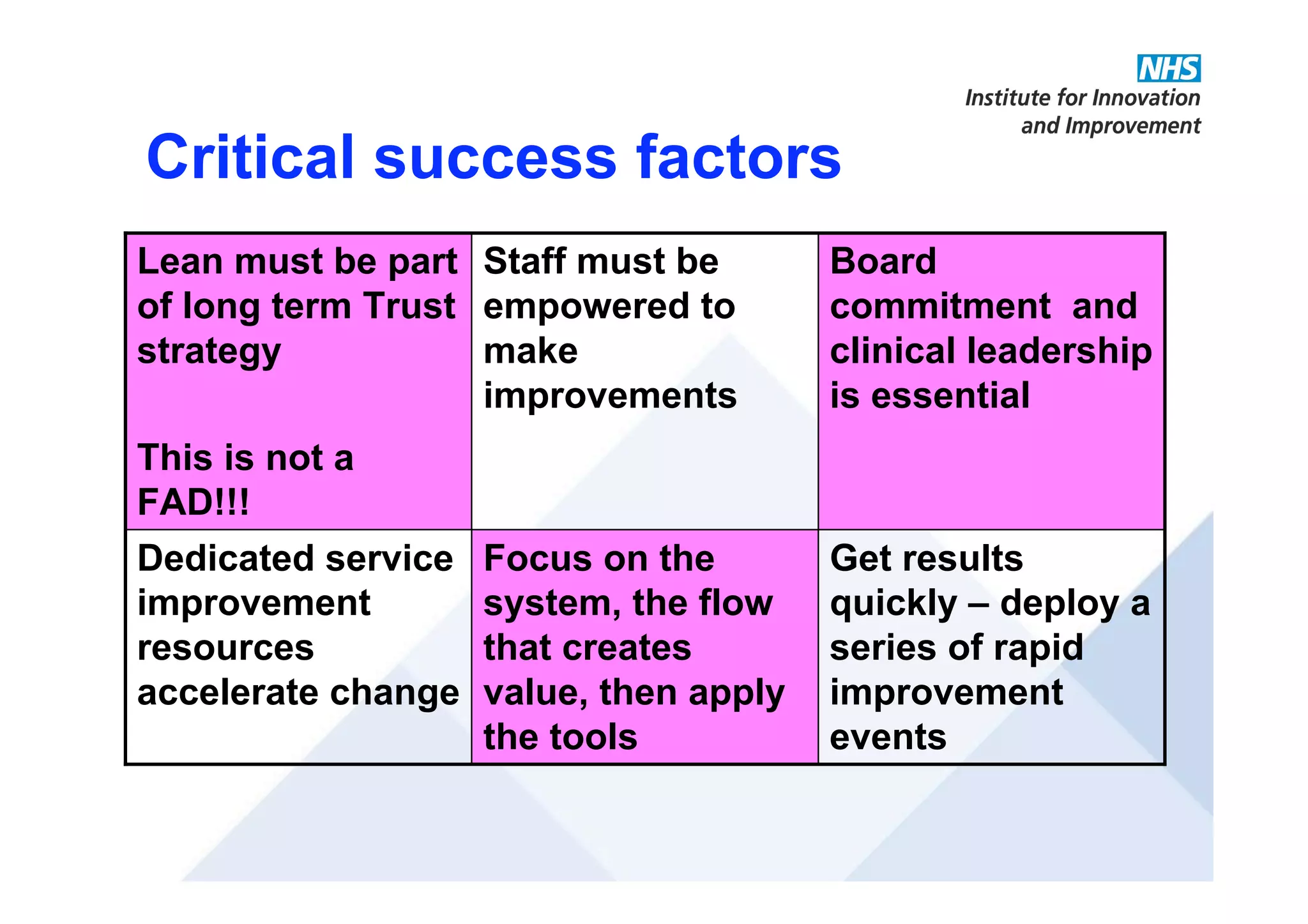

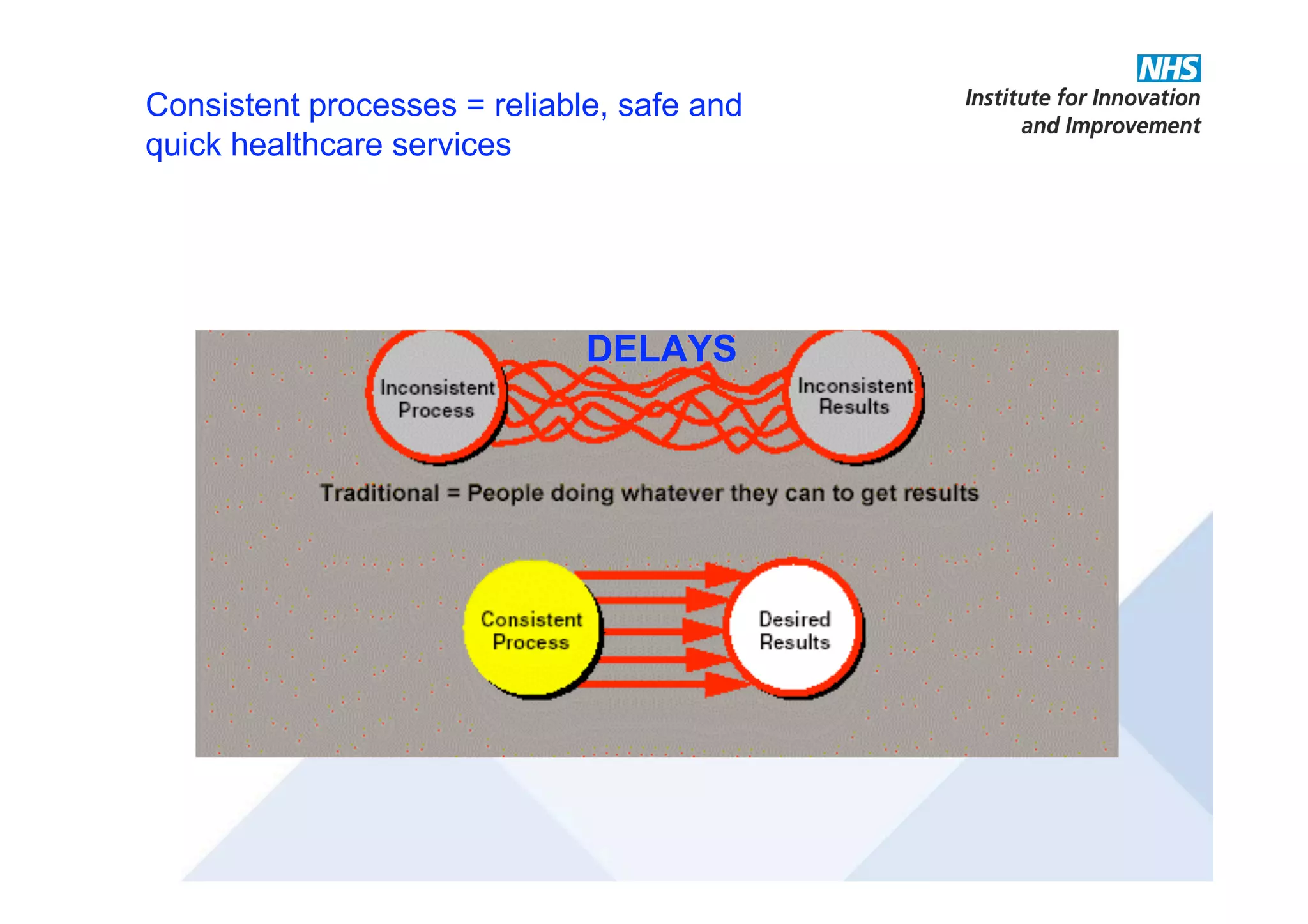

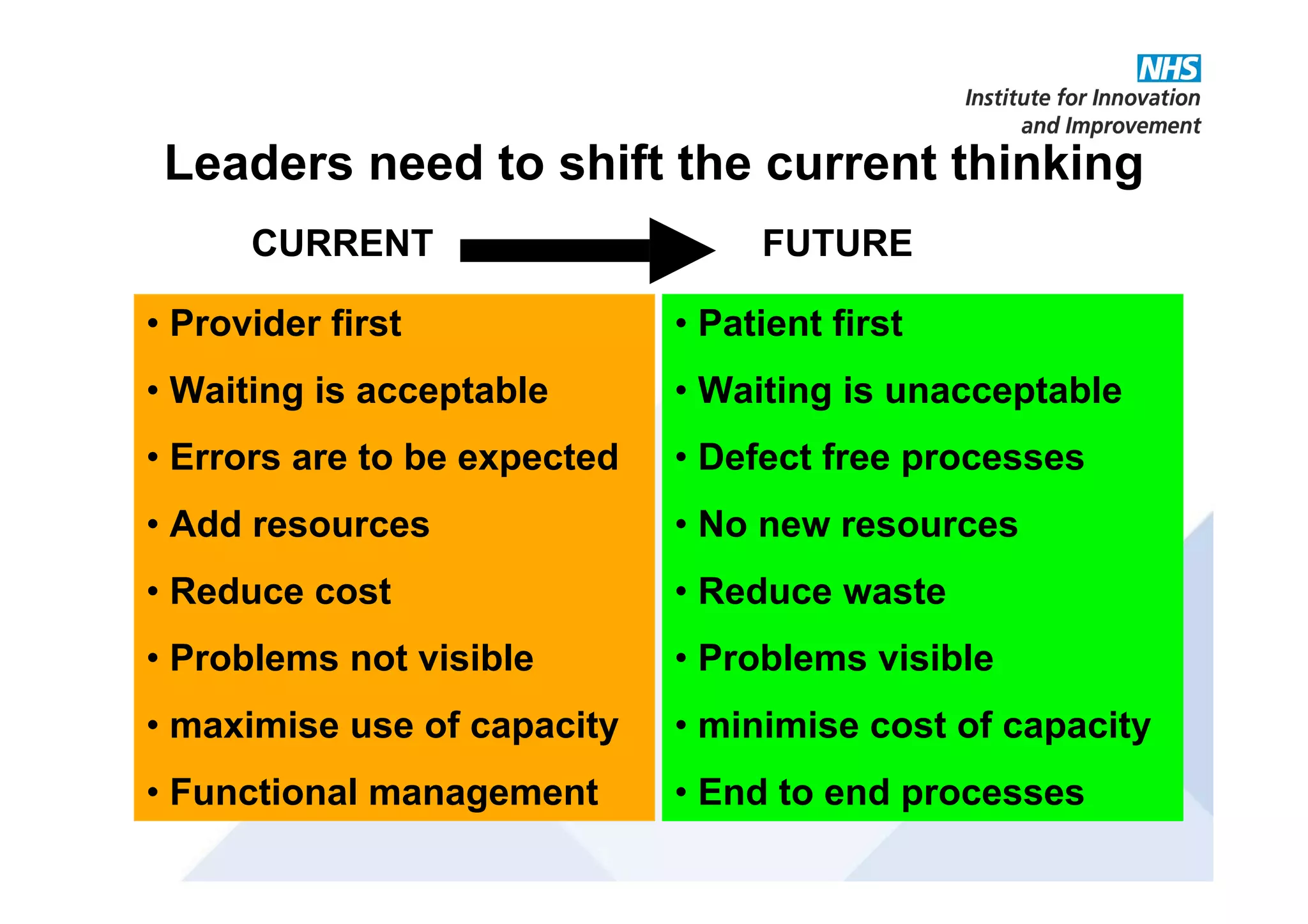

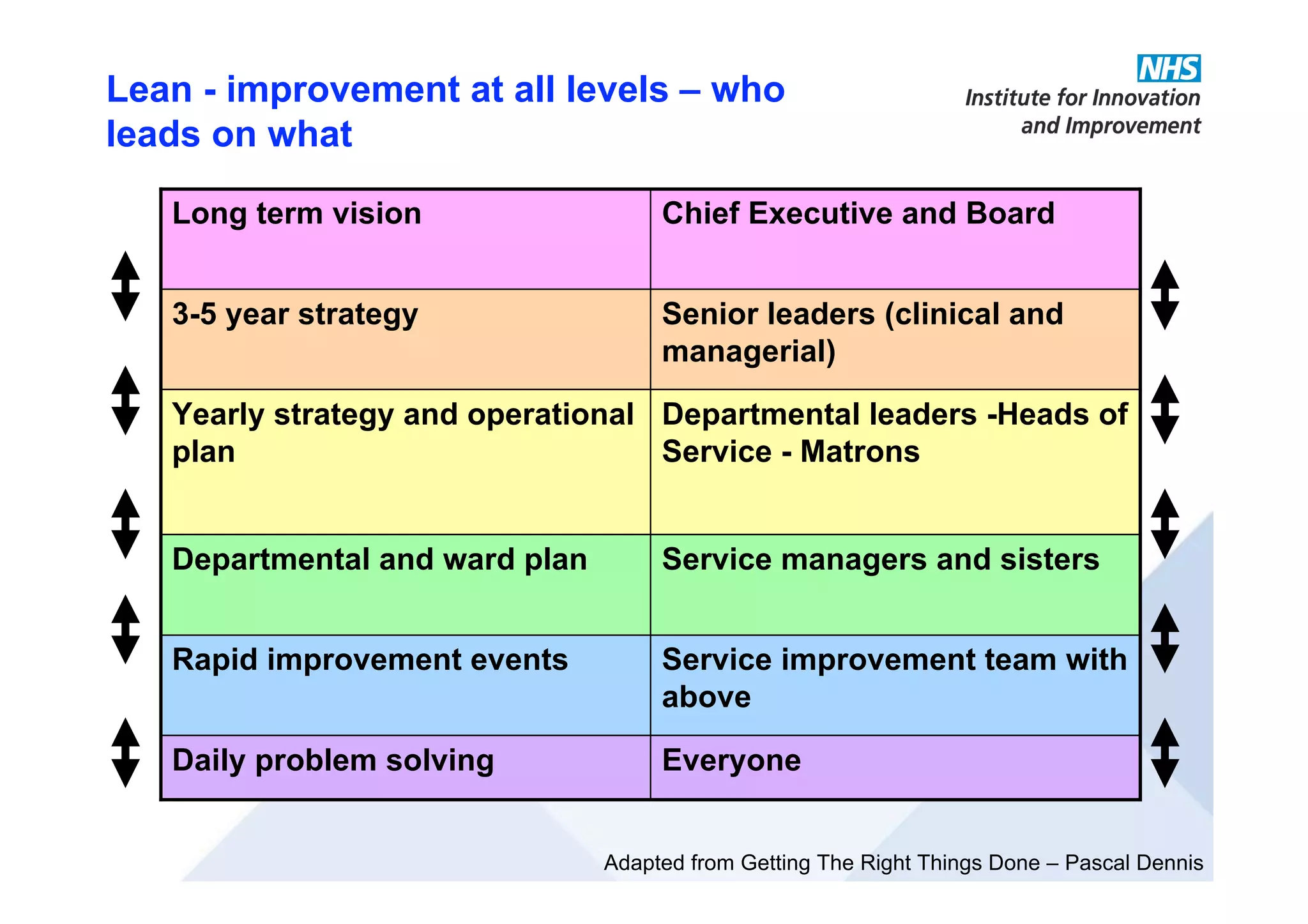

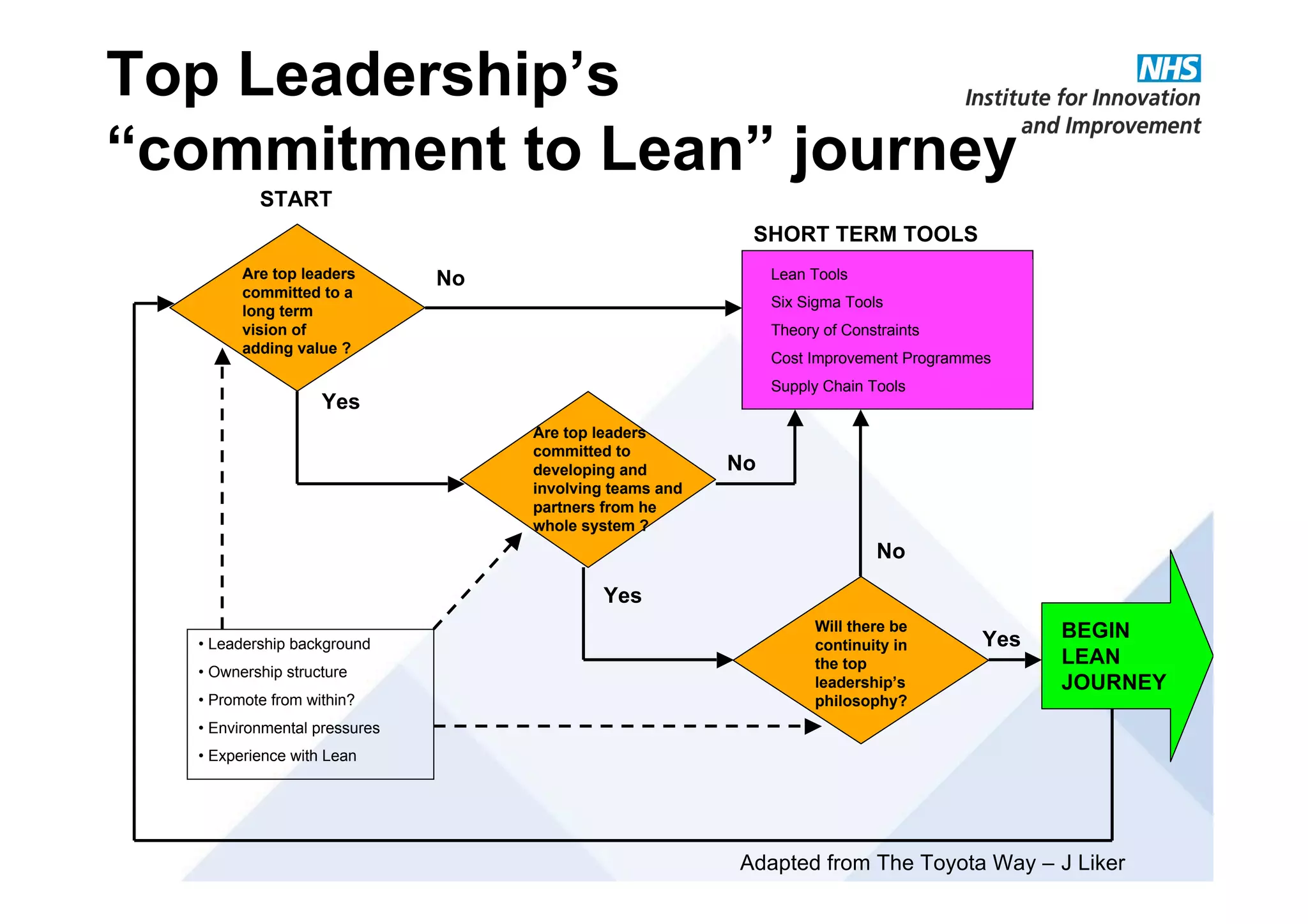

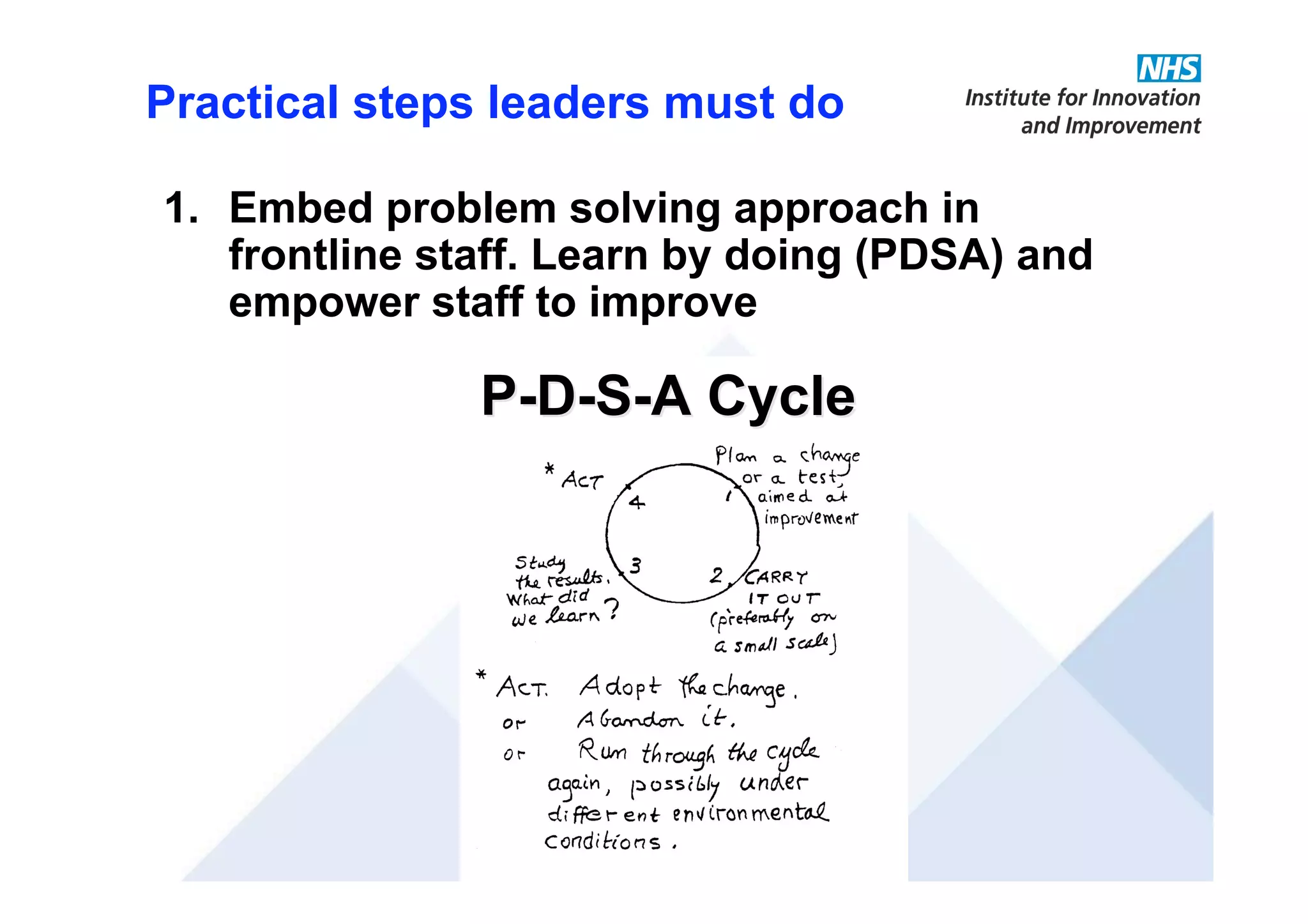

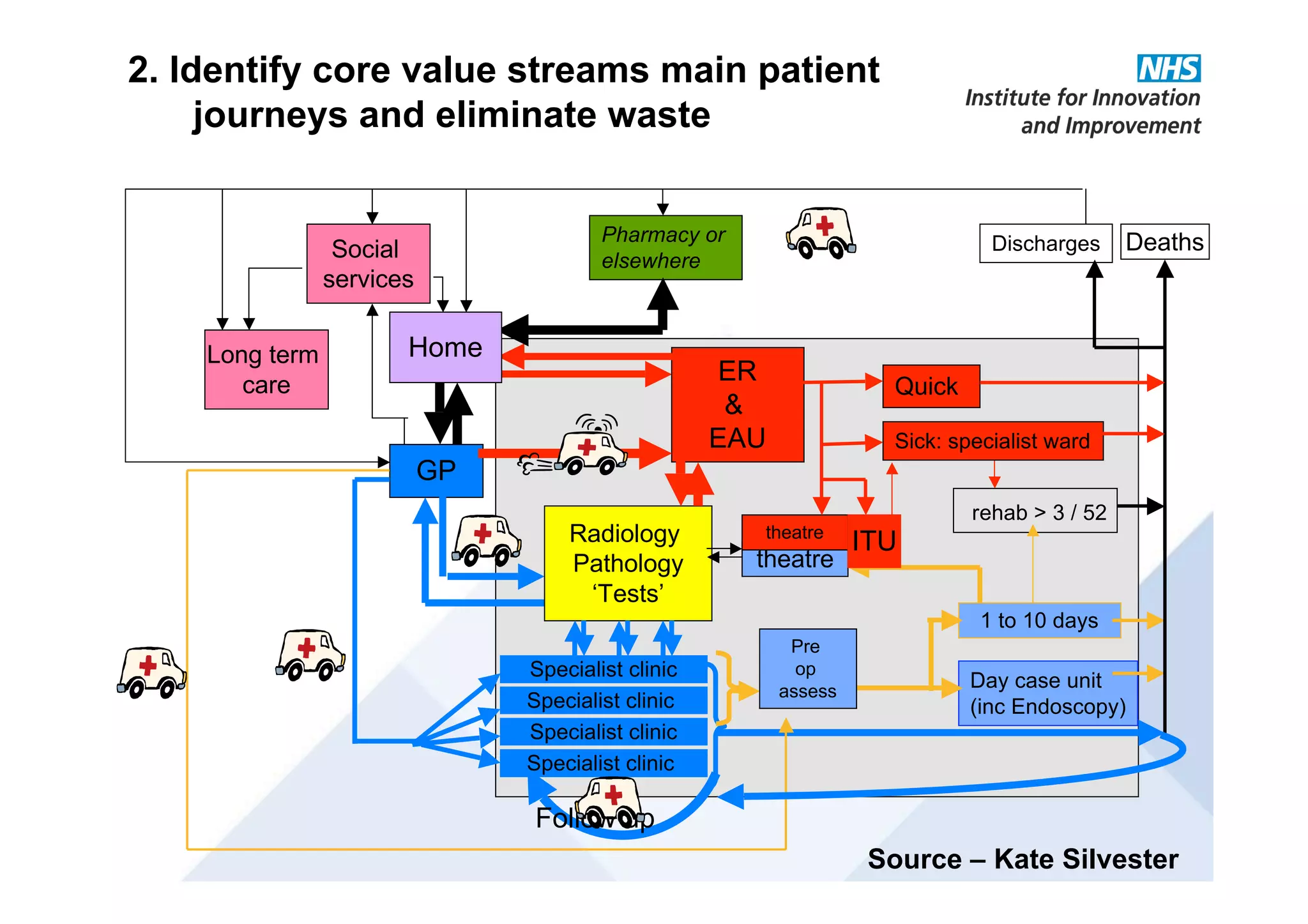

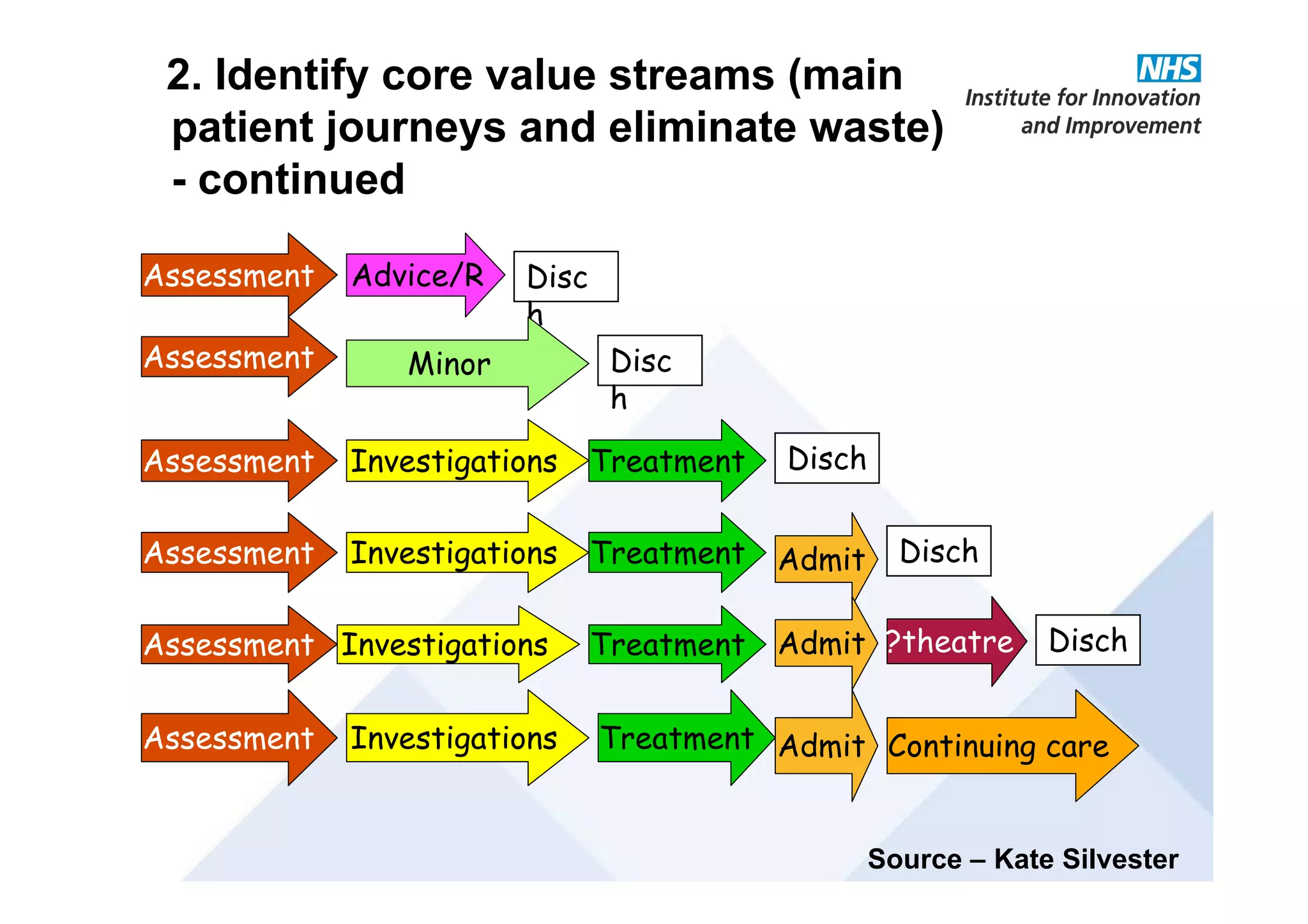

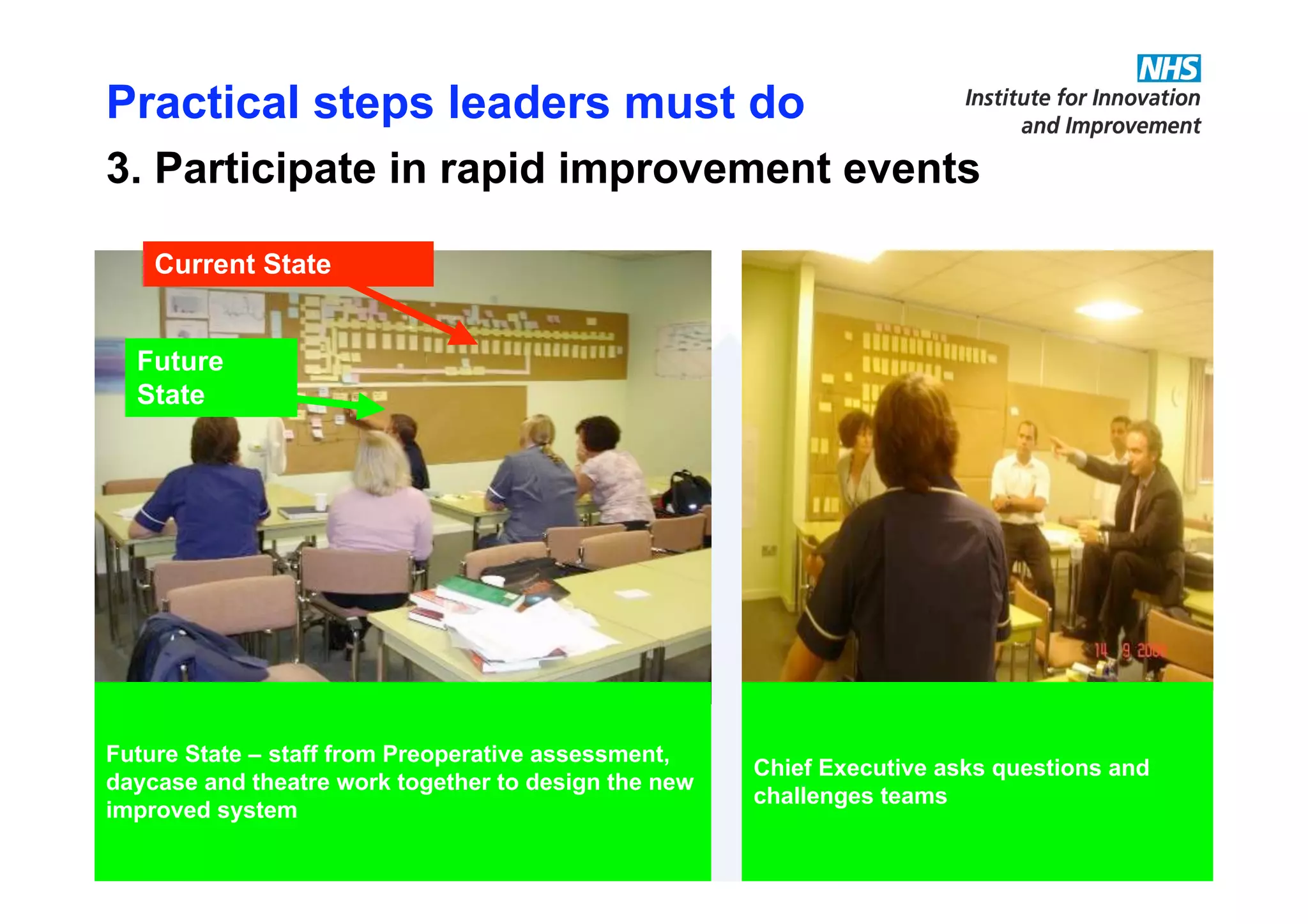

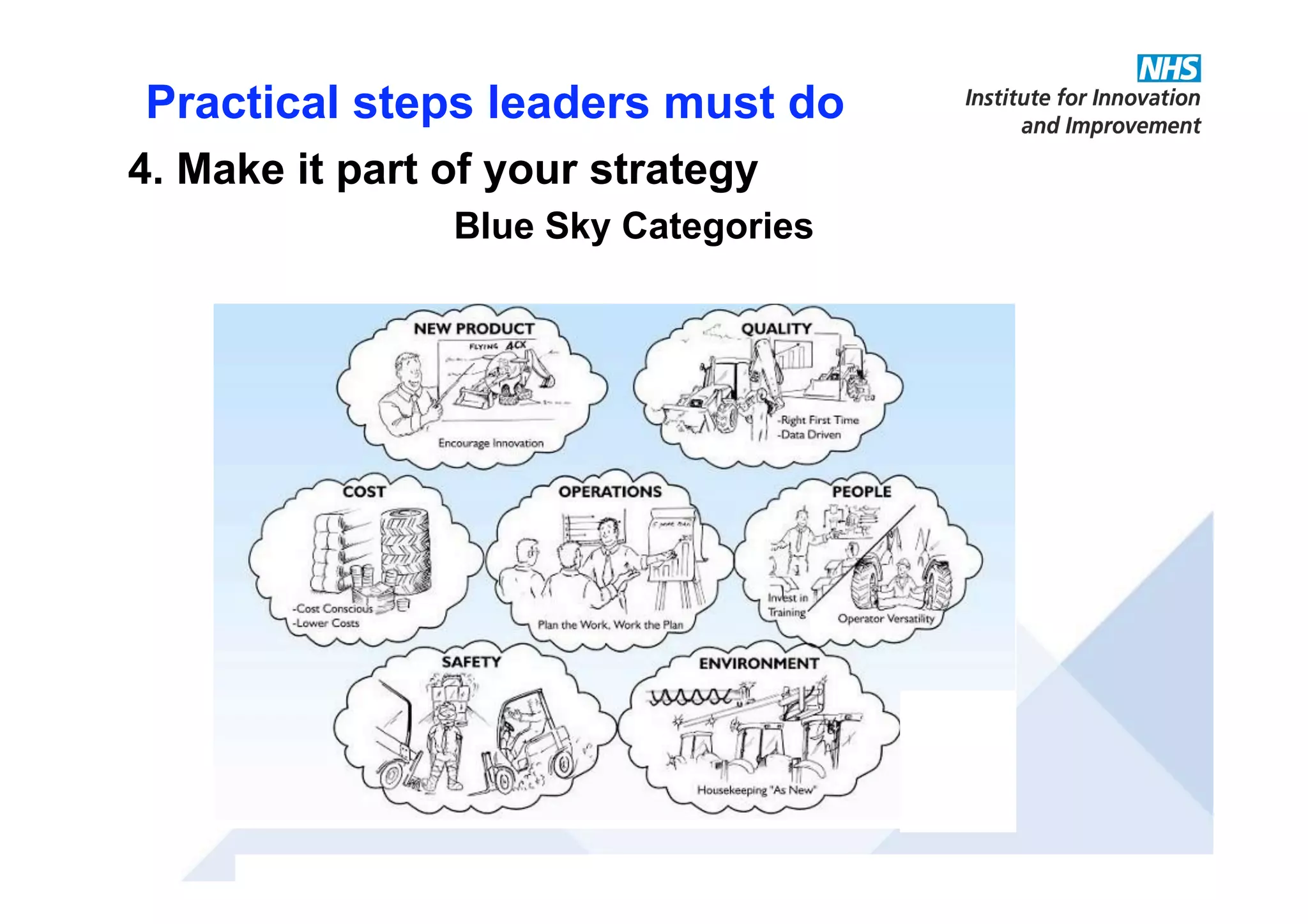

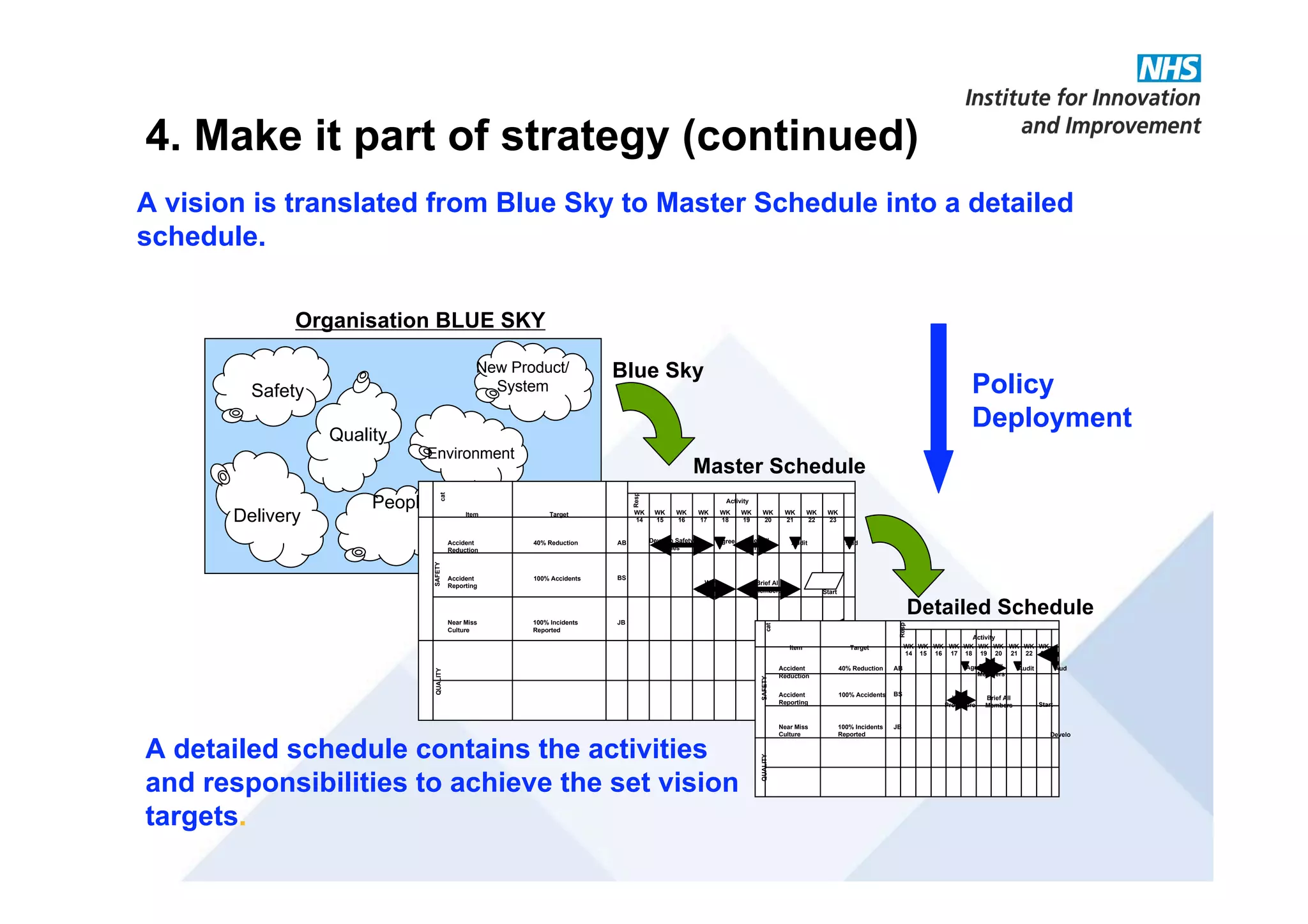

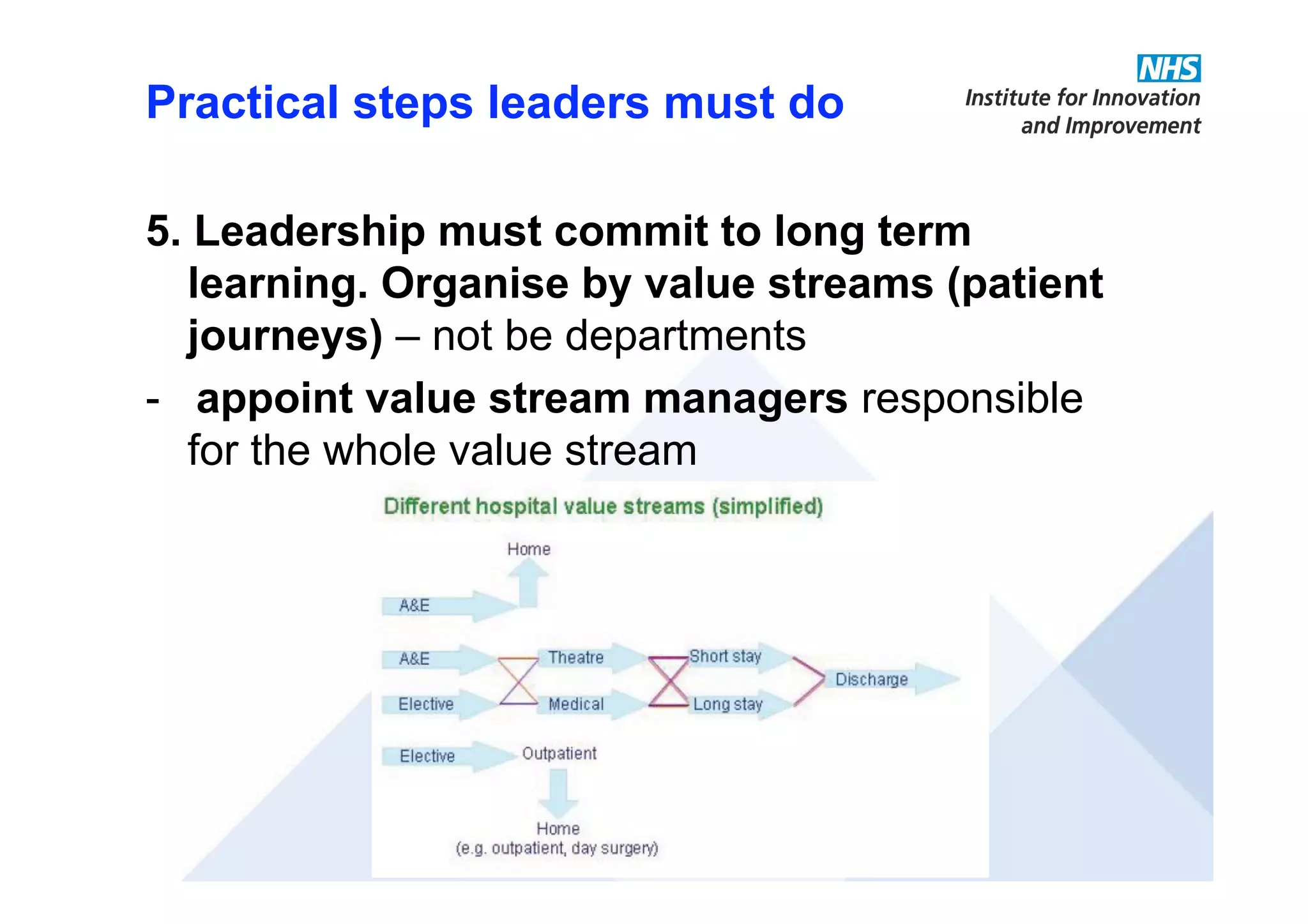

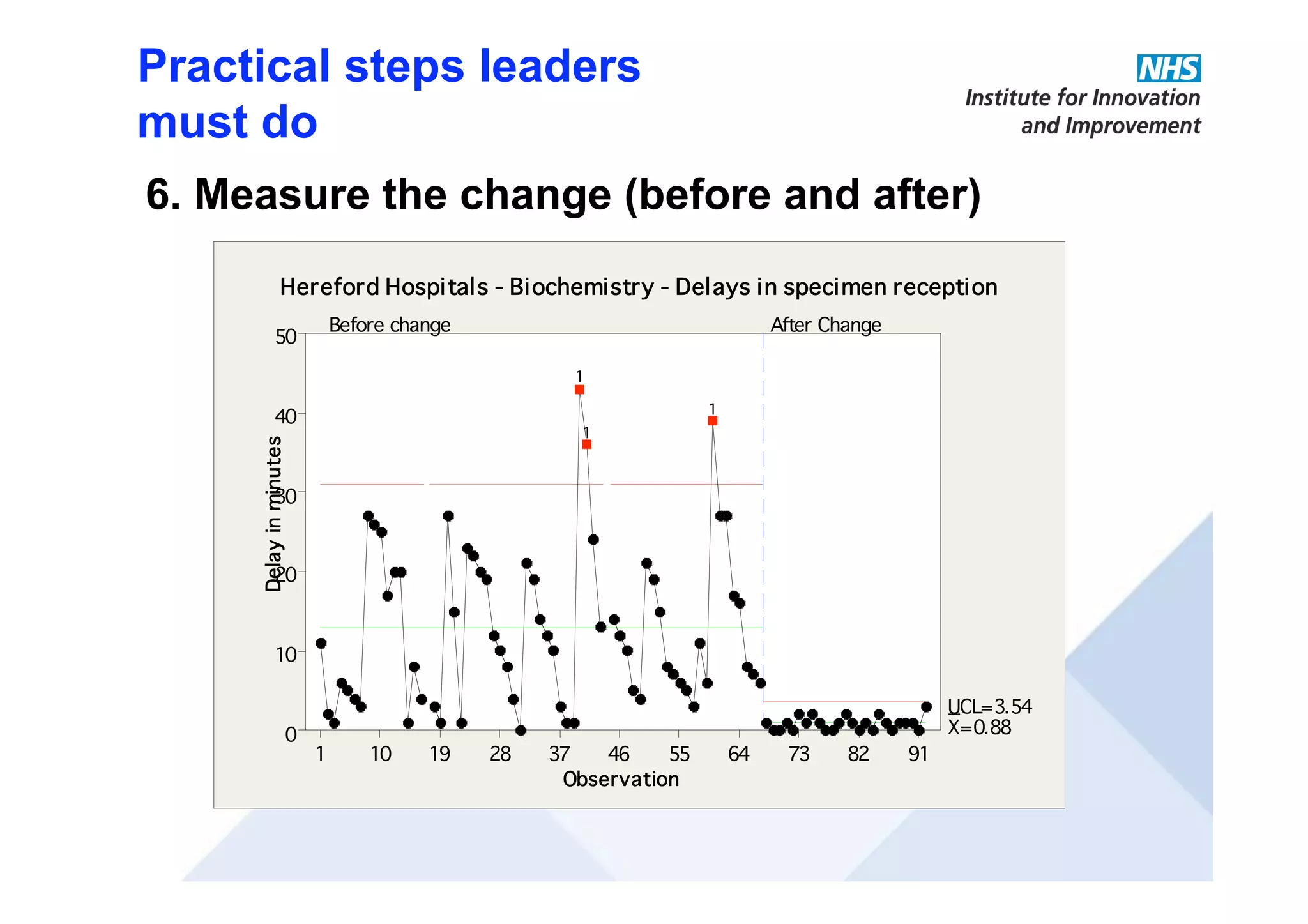

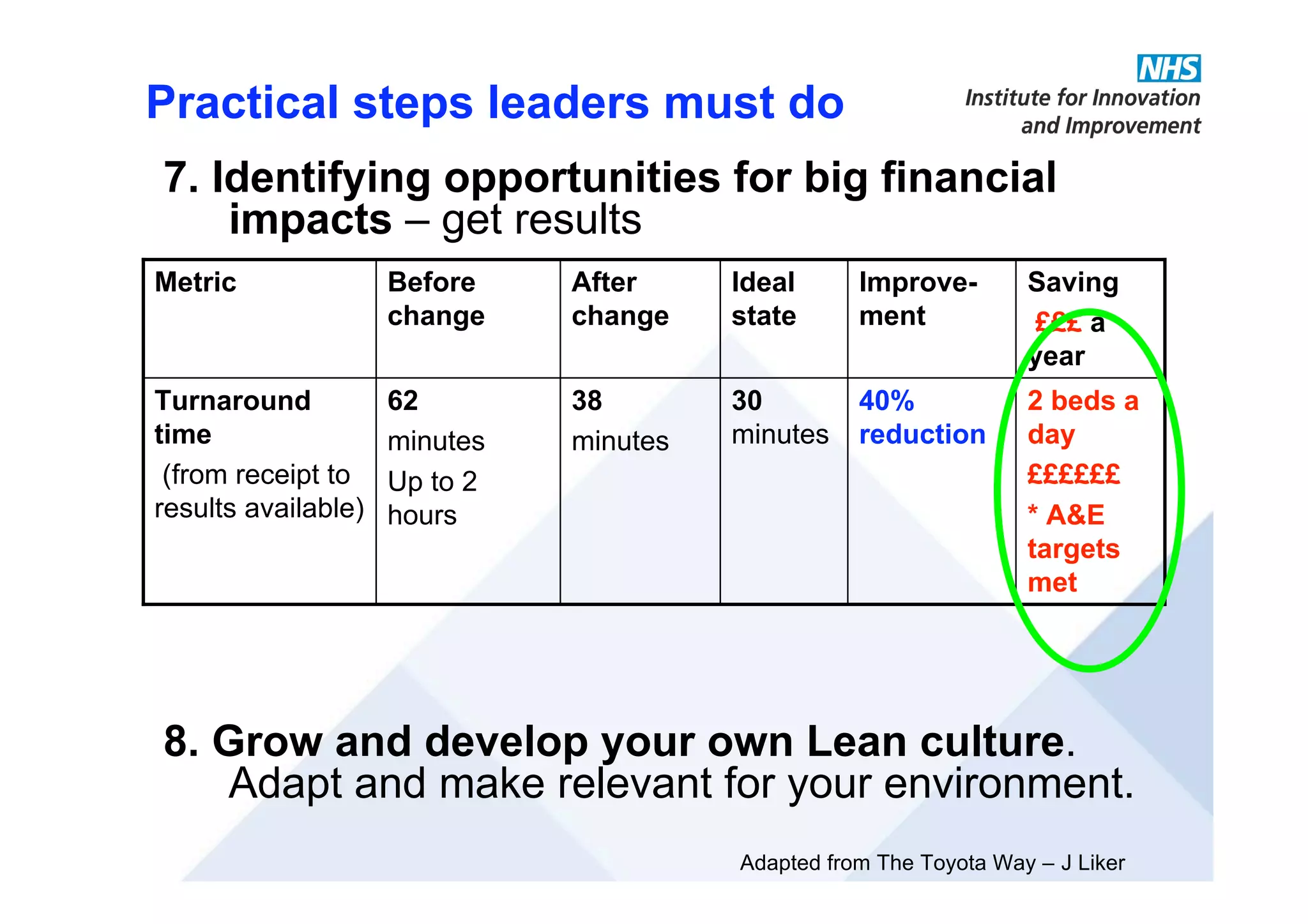

Lean leaders need to commit to a long-term vision of adding value for customers by eliminating waste, participate in rapid improvement events to generate quick results, and make Lean part of their organization's overall strategy in order to successfully implement and sustain Lean practices.