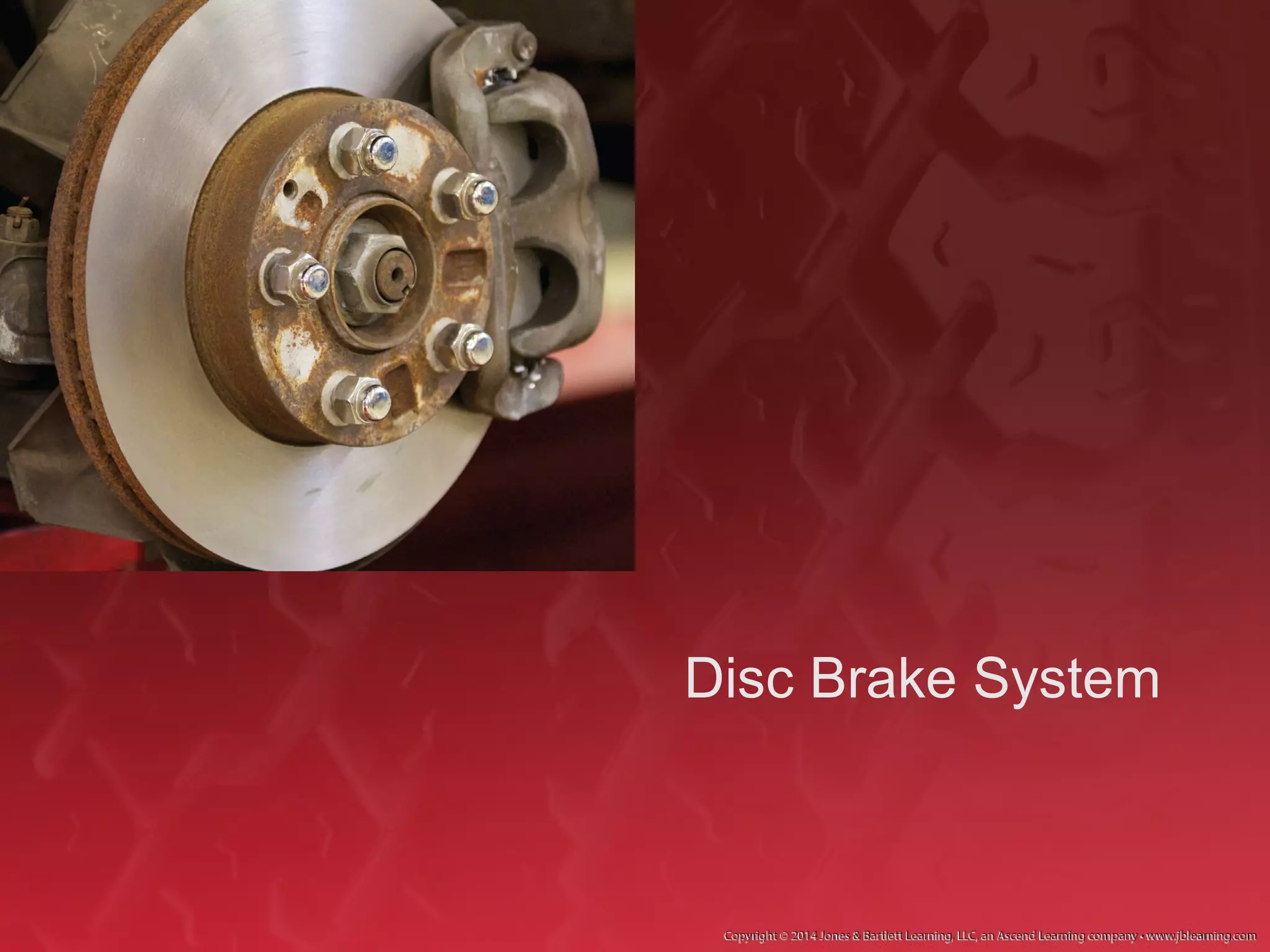

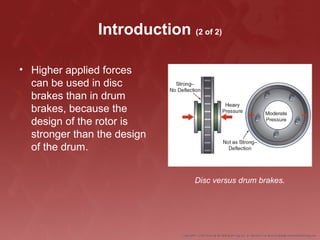

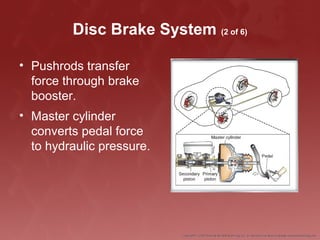

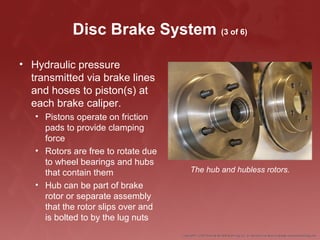

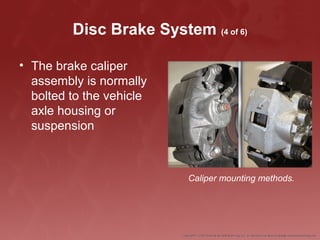

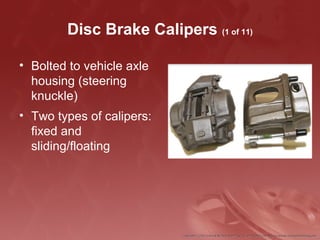

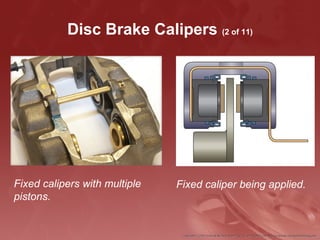

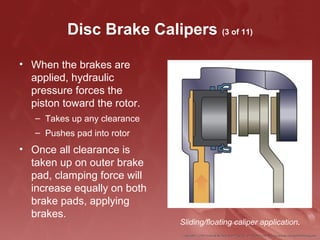

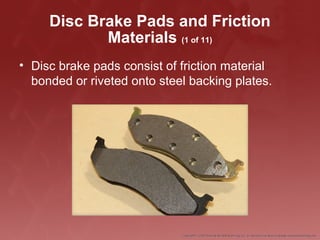

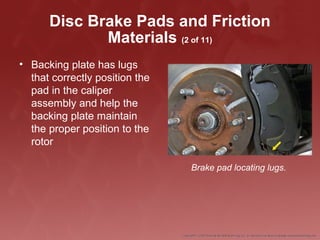

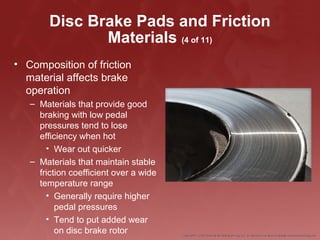

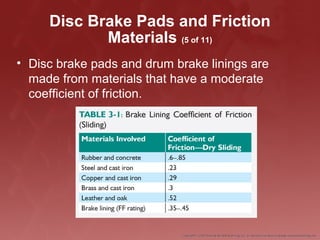

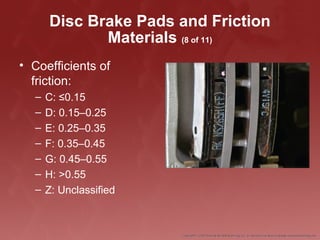

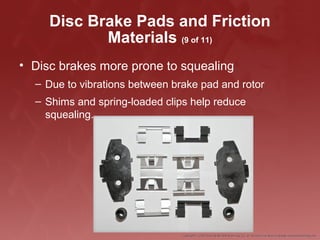

Disc brakes operate by applying friction between pads and a rotating disc, offering stronger braking forces compared to drum brakes. They are equipped with advanced components like calipers and hydraulic systems, providing advantages such as rapid cooling and ease of maintenance, while facing challenges like noise and warping. The performance of disc brake pads depends on their materials, which influence friction and efficiency across various temperature ranges.