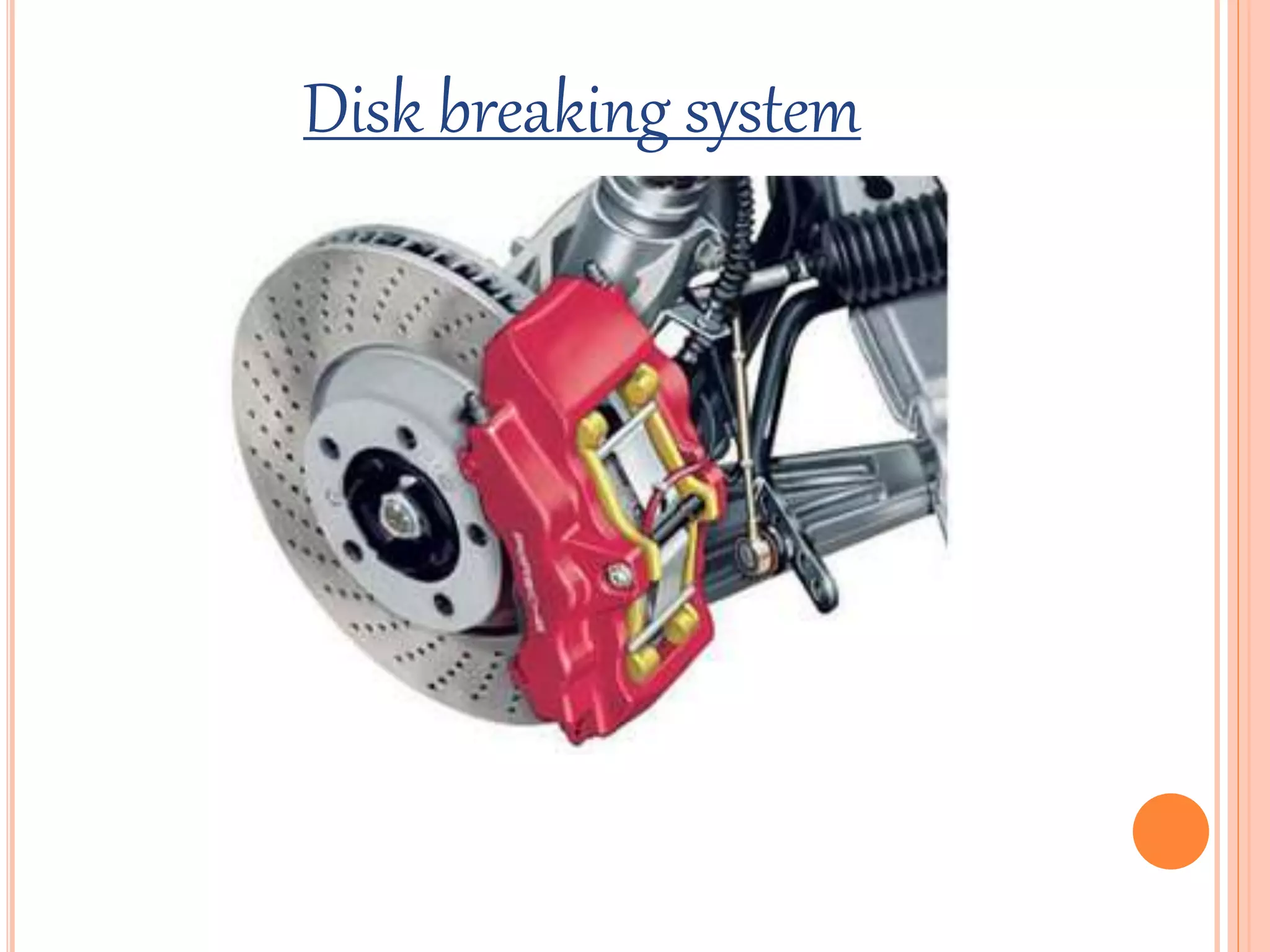

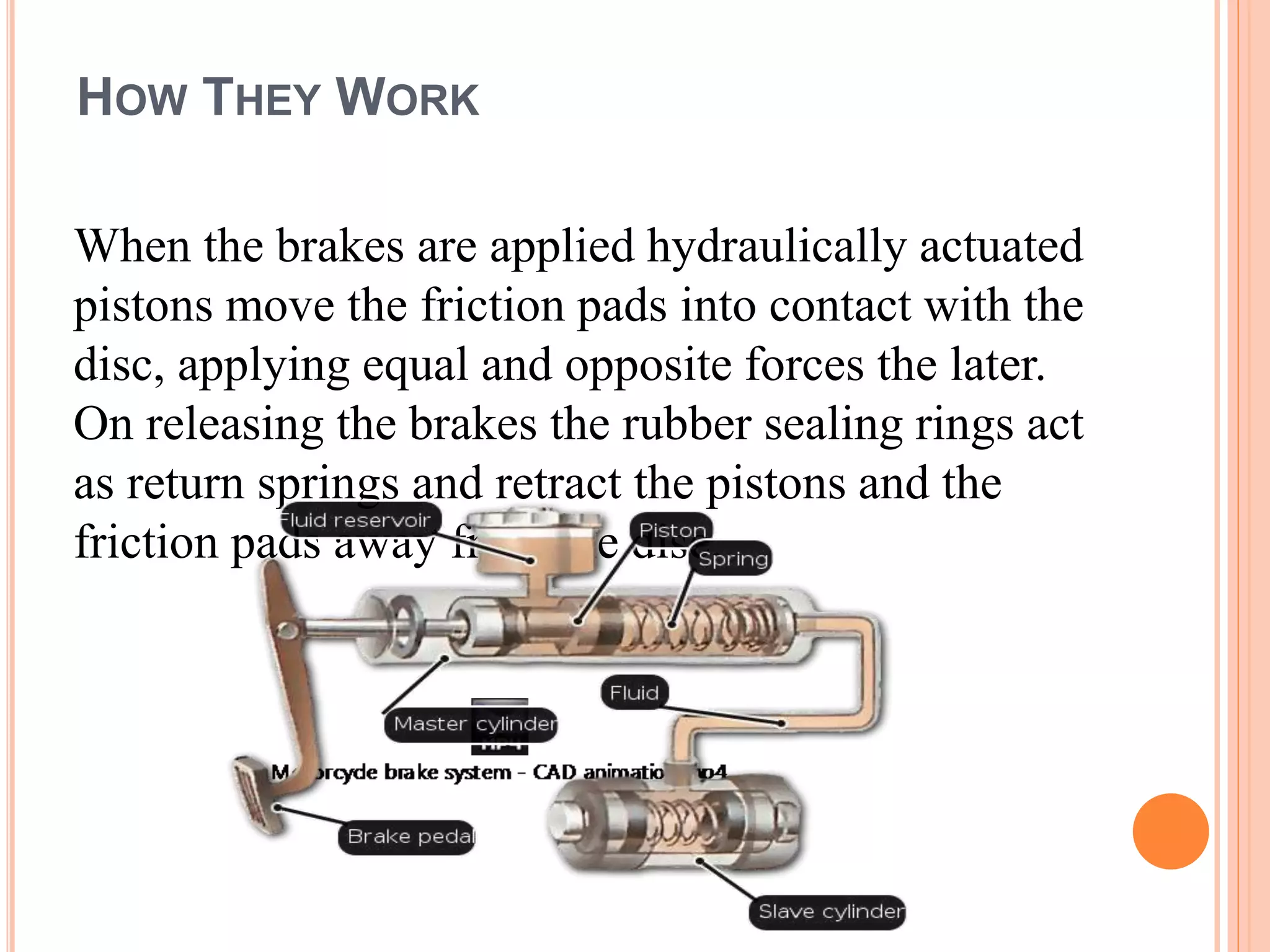

This document discusses disk brakes, including their history, types, advantages, and how they work. Disk brakes use friction pads that squeeze a metal disk attached to the wheel hub to slow rotation. There are two main types - opposed piston brakes, which use pistons on both sides of the disk for even pressure, and floating caliper brakes, which use a piston on the inner side to push the caliper and outer pad against the disk. Disk brakes are more efficient than drum brakes as they dissipate heat better and maintain performance longer under stress.