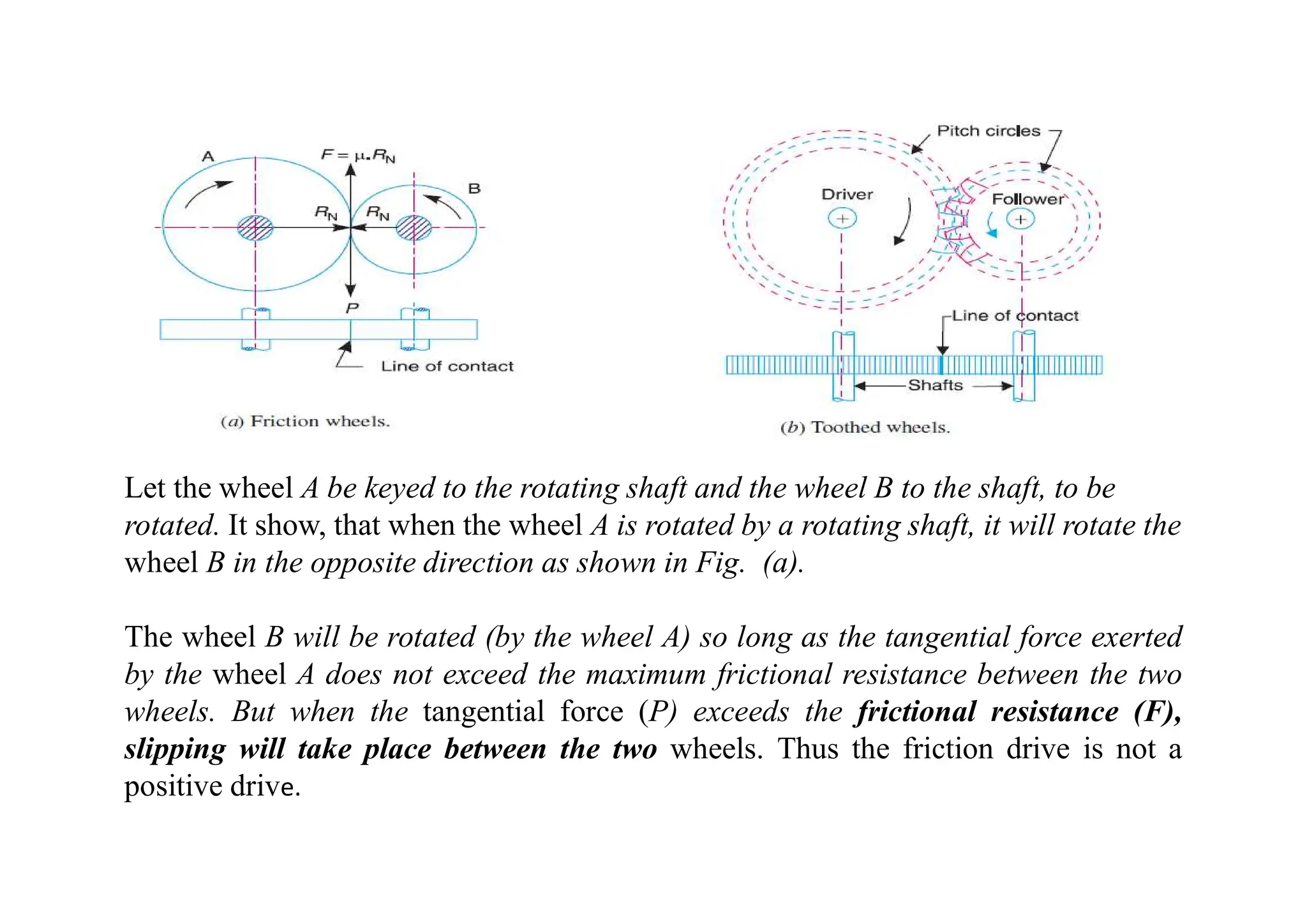

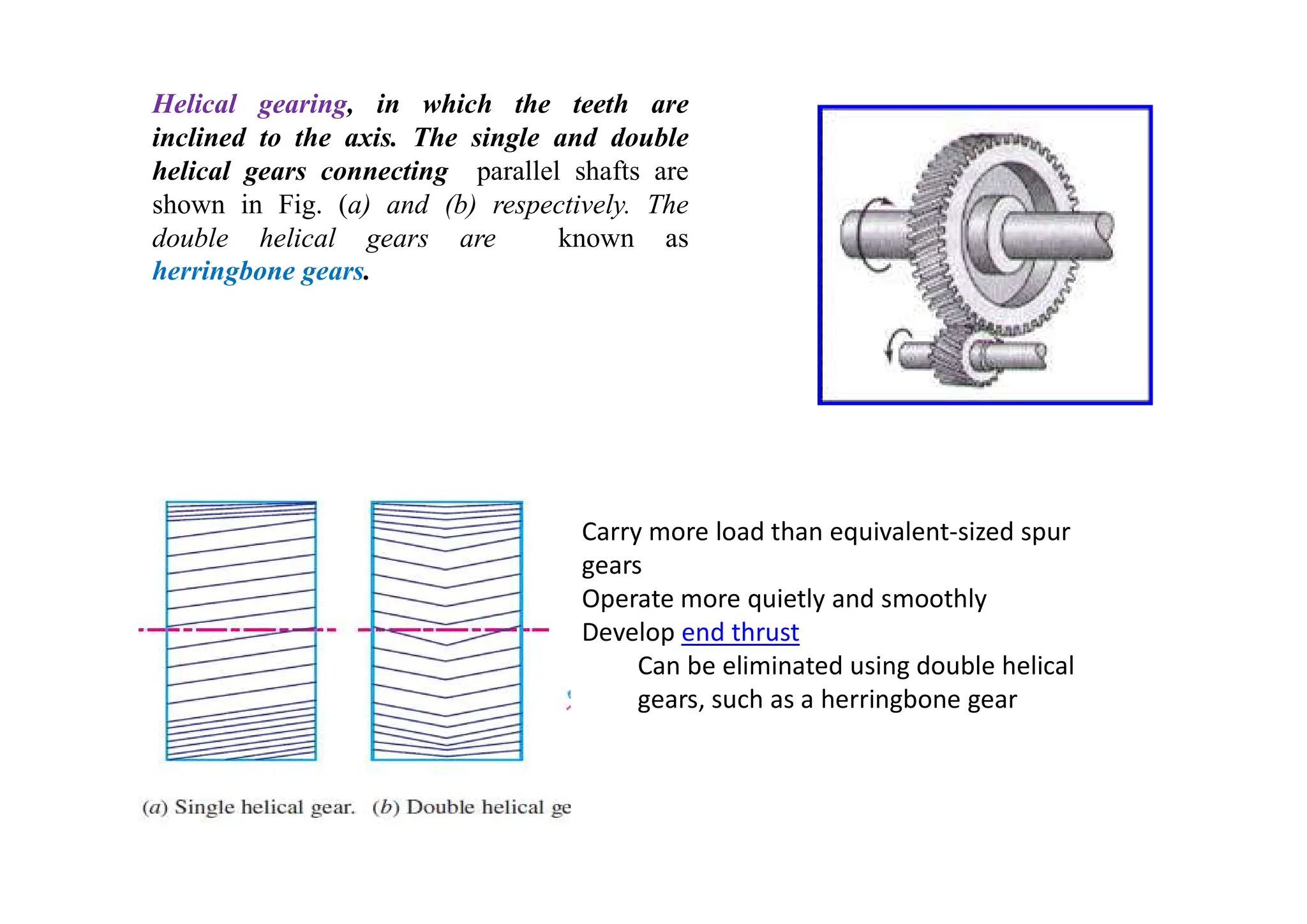

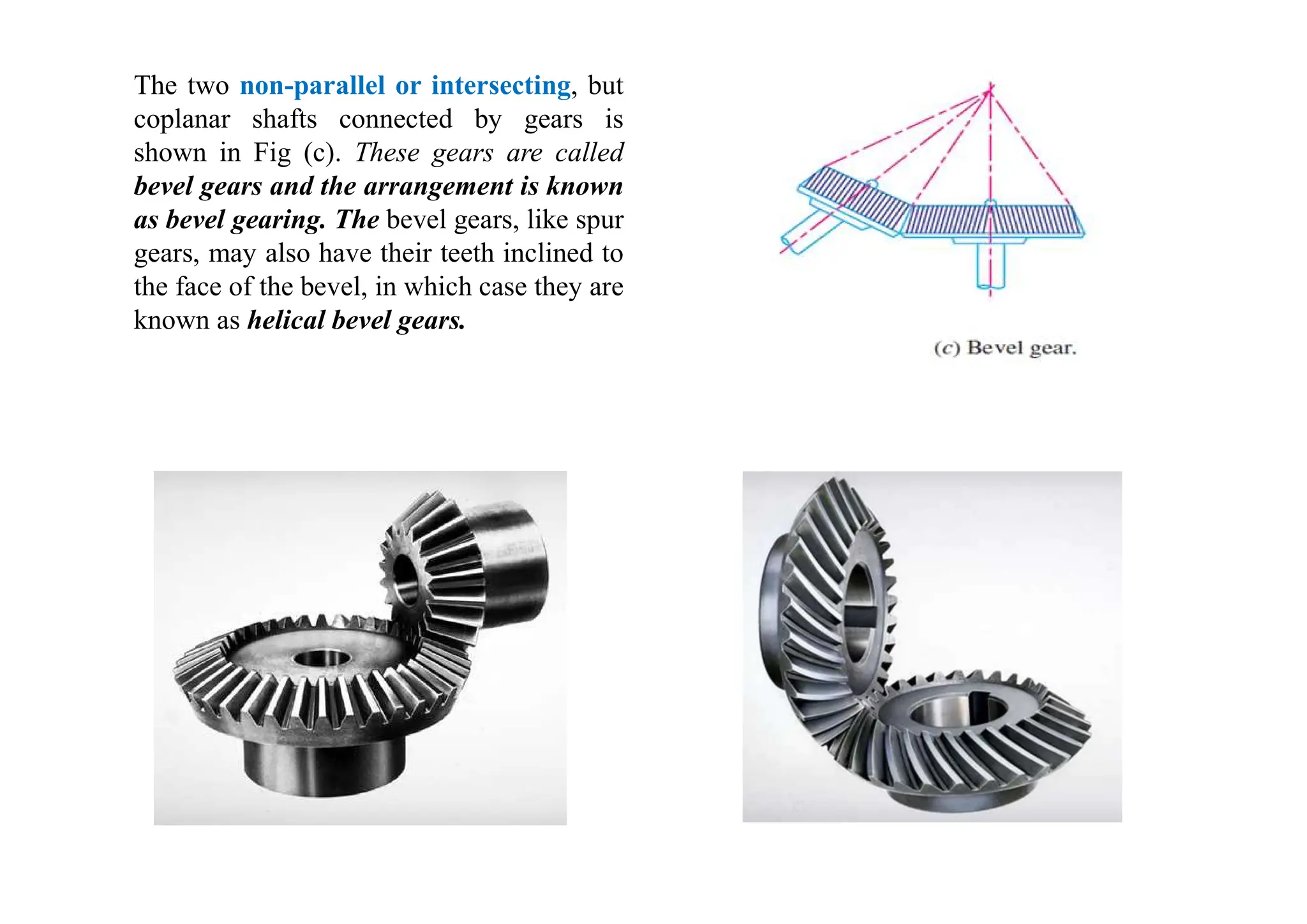

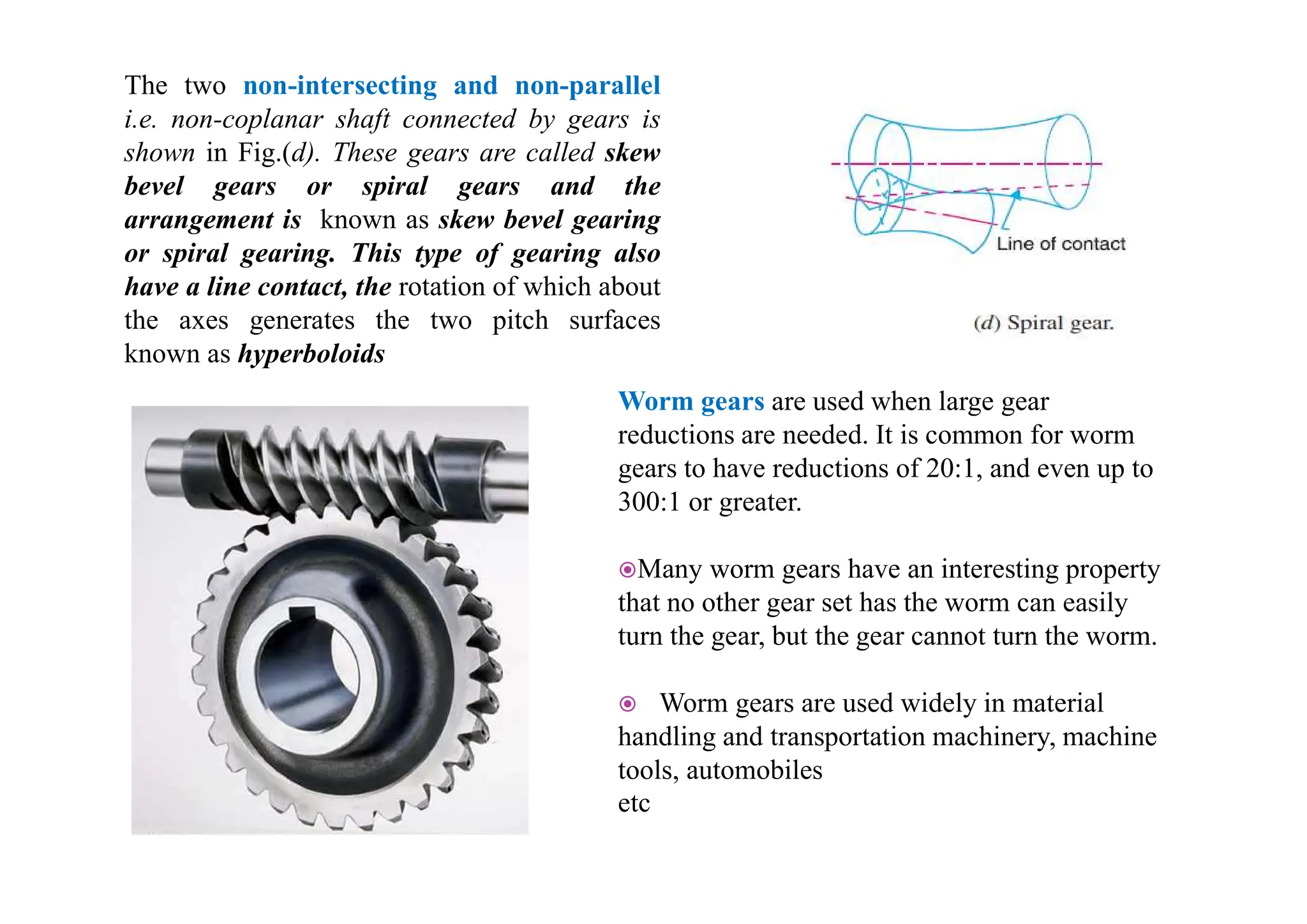

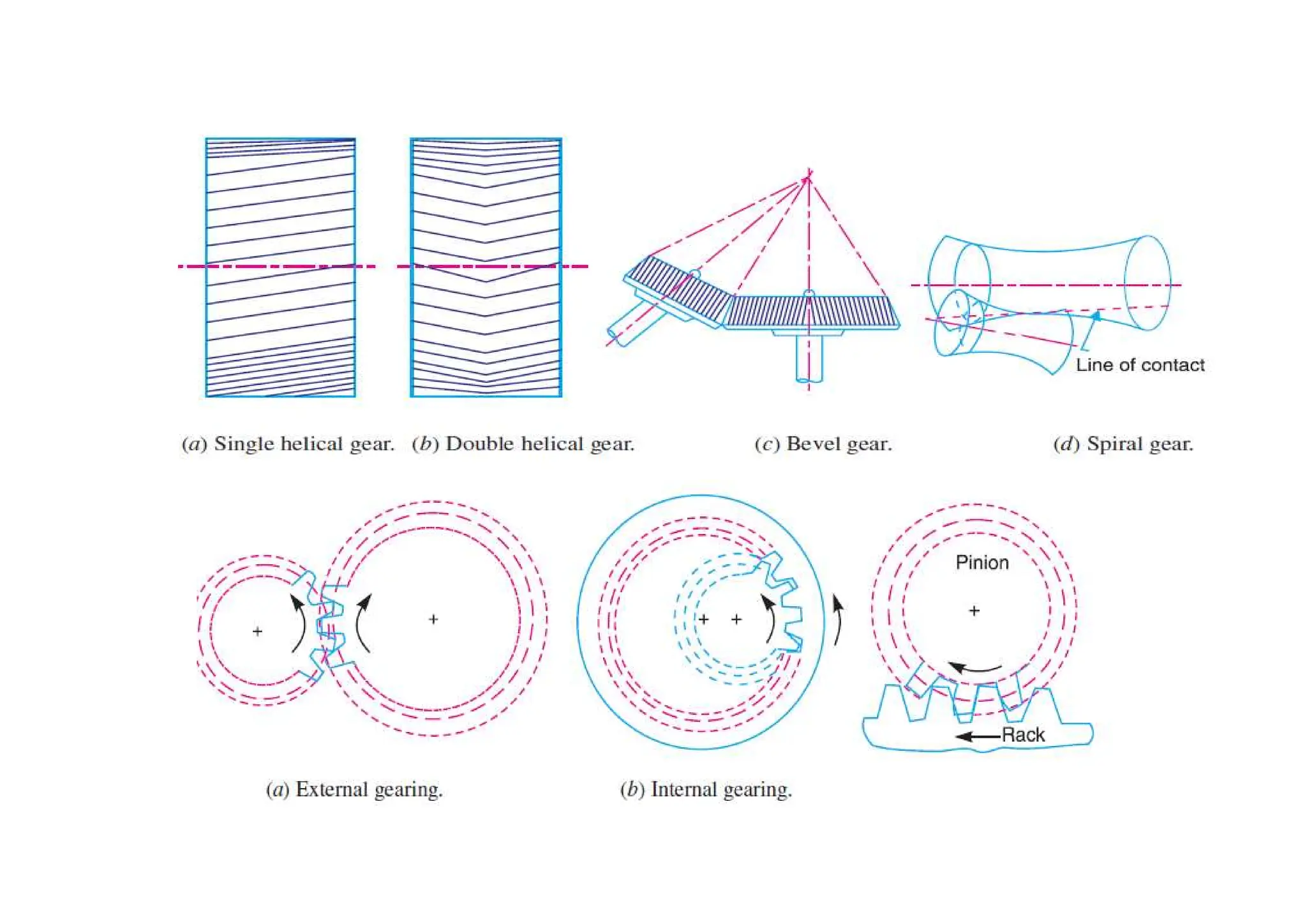

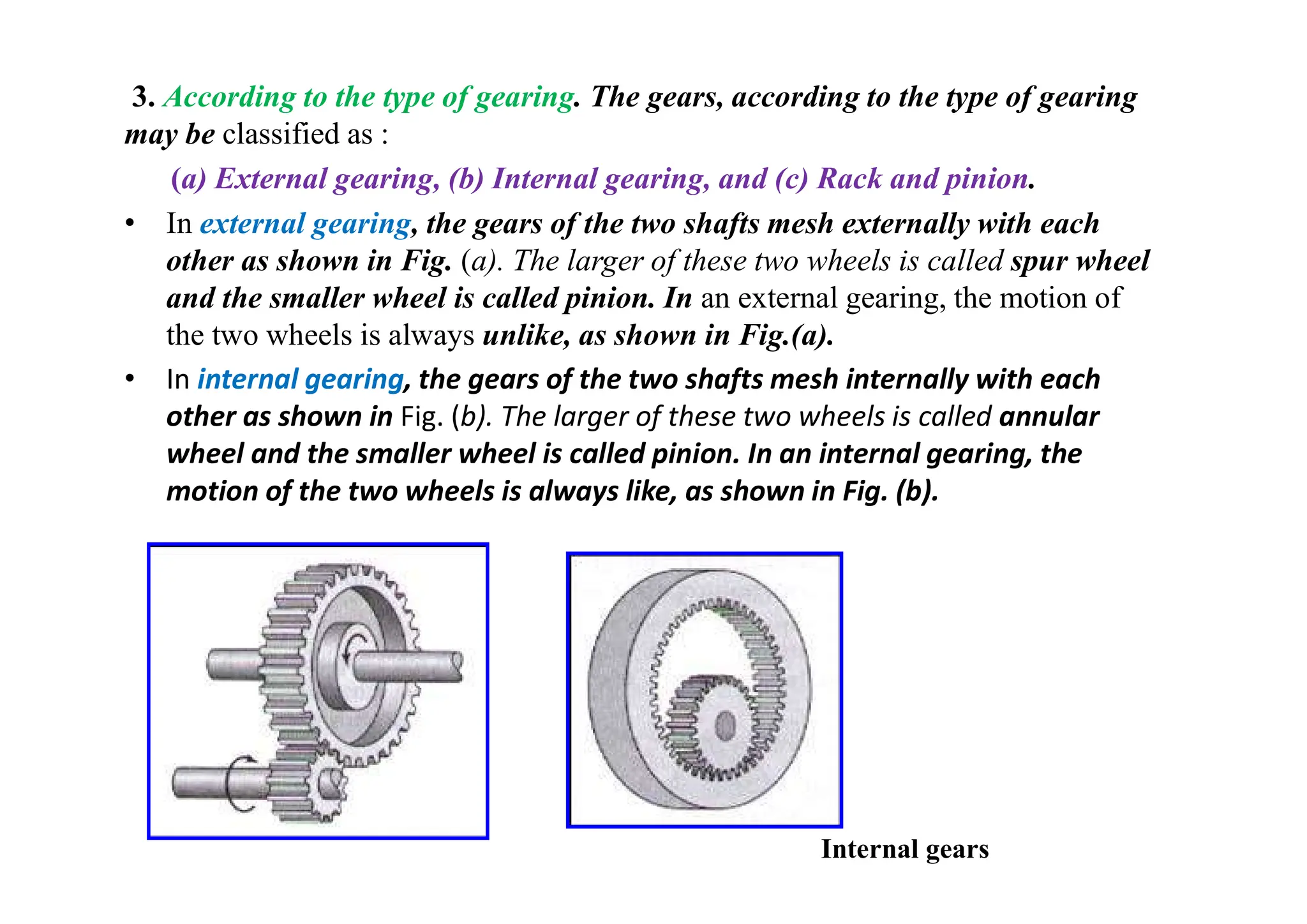

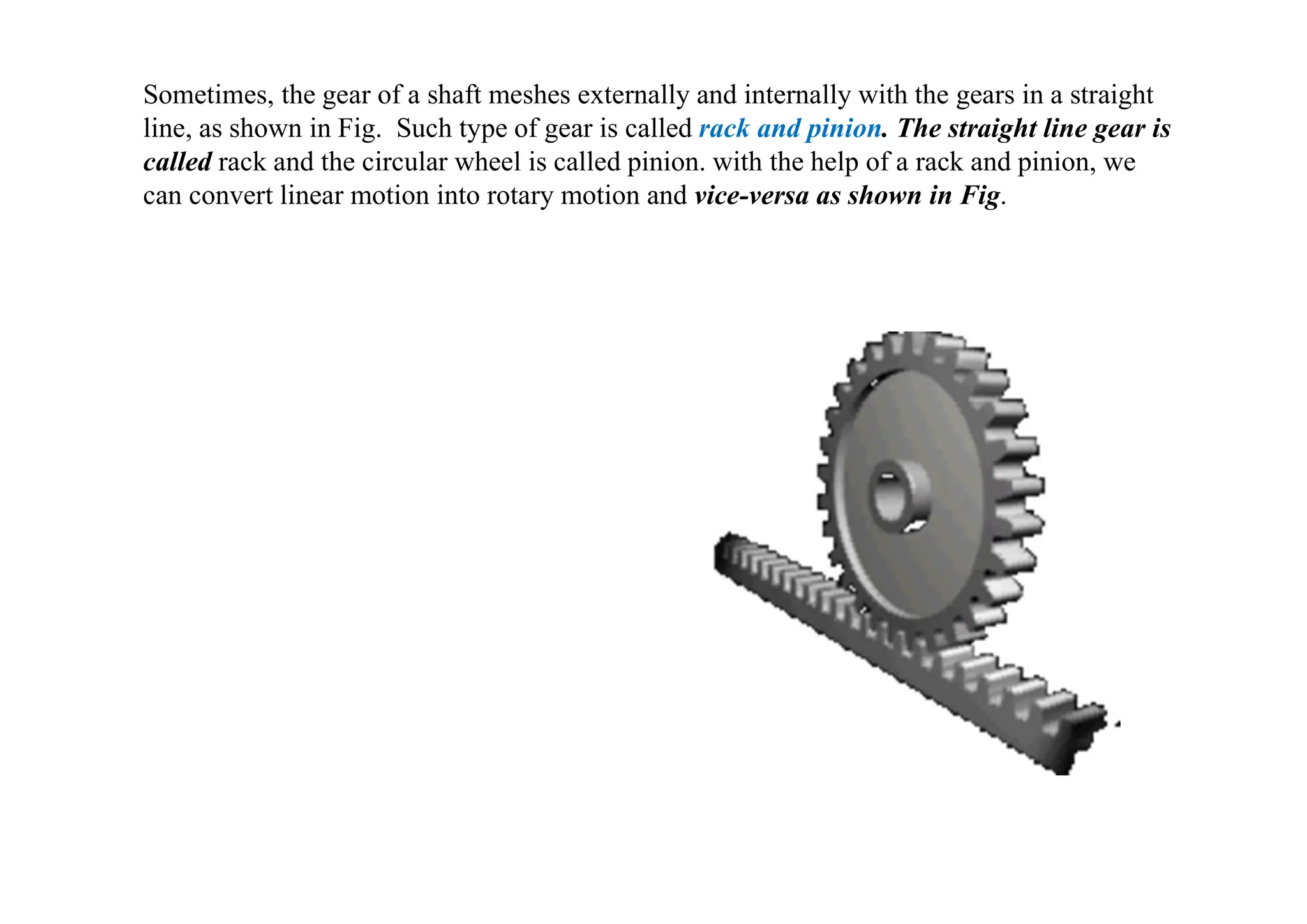

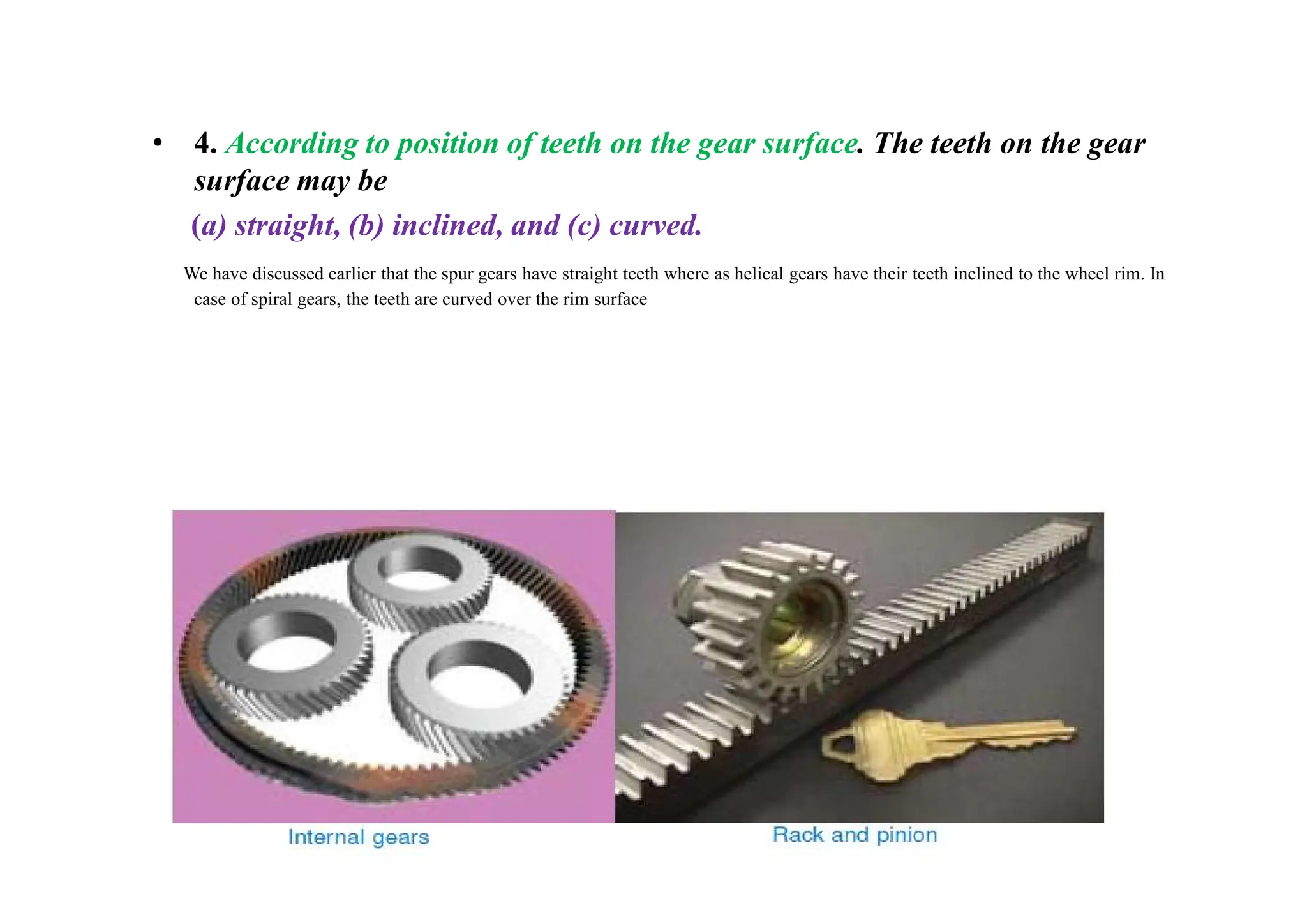

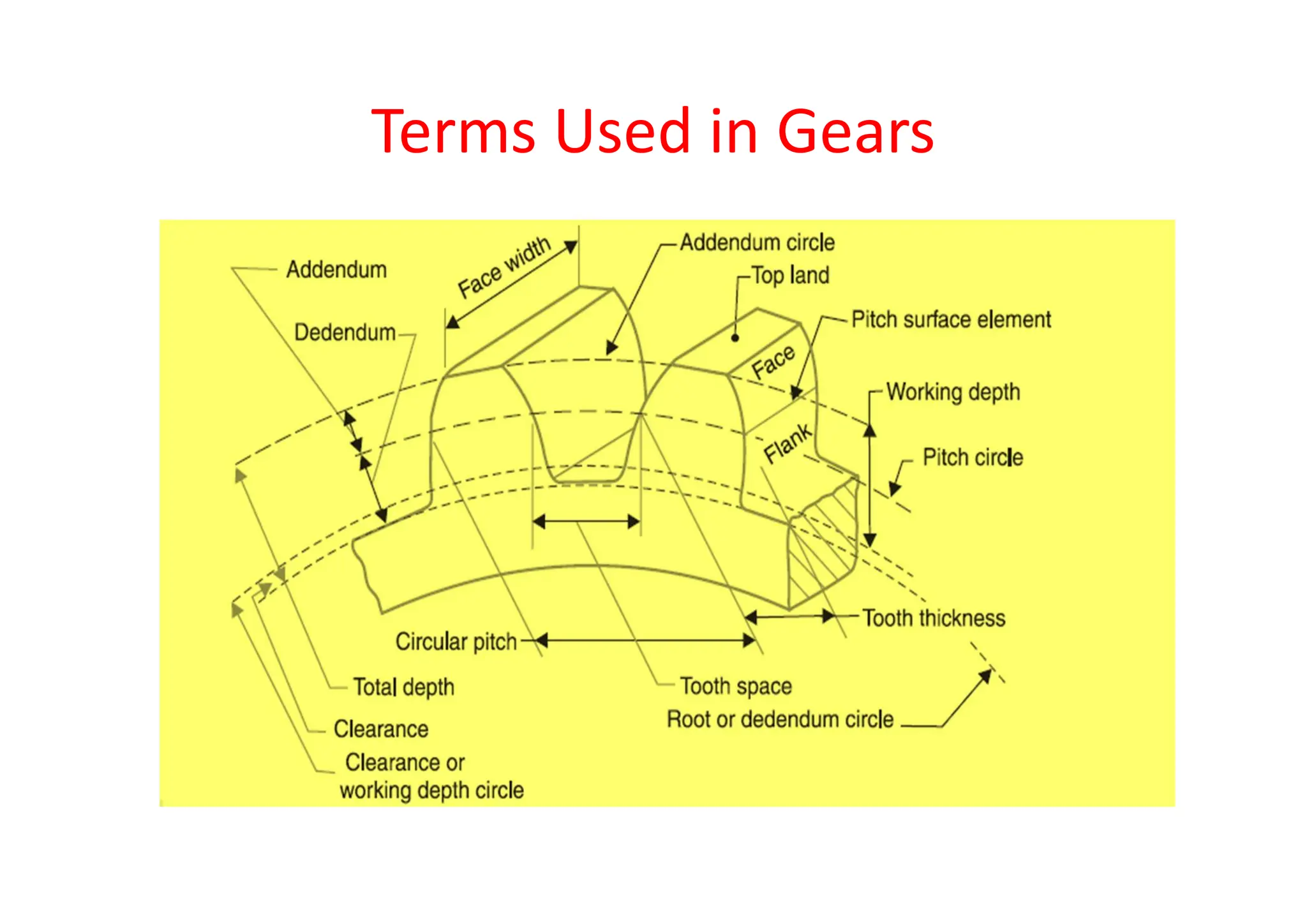

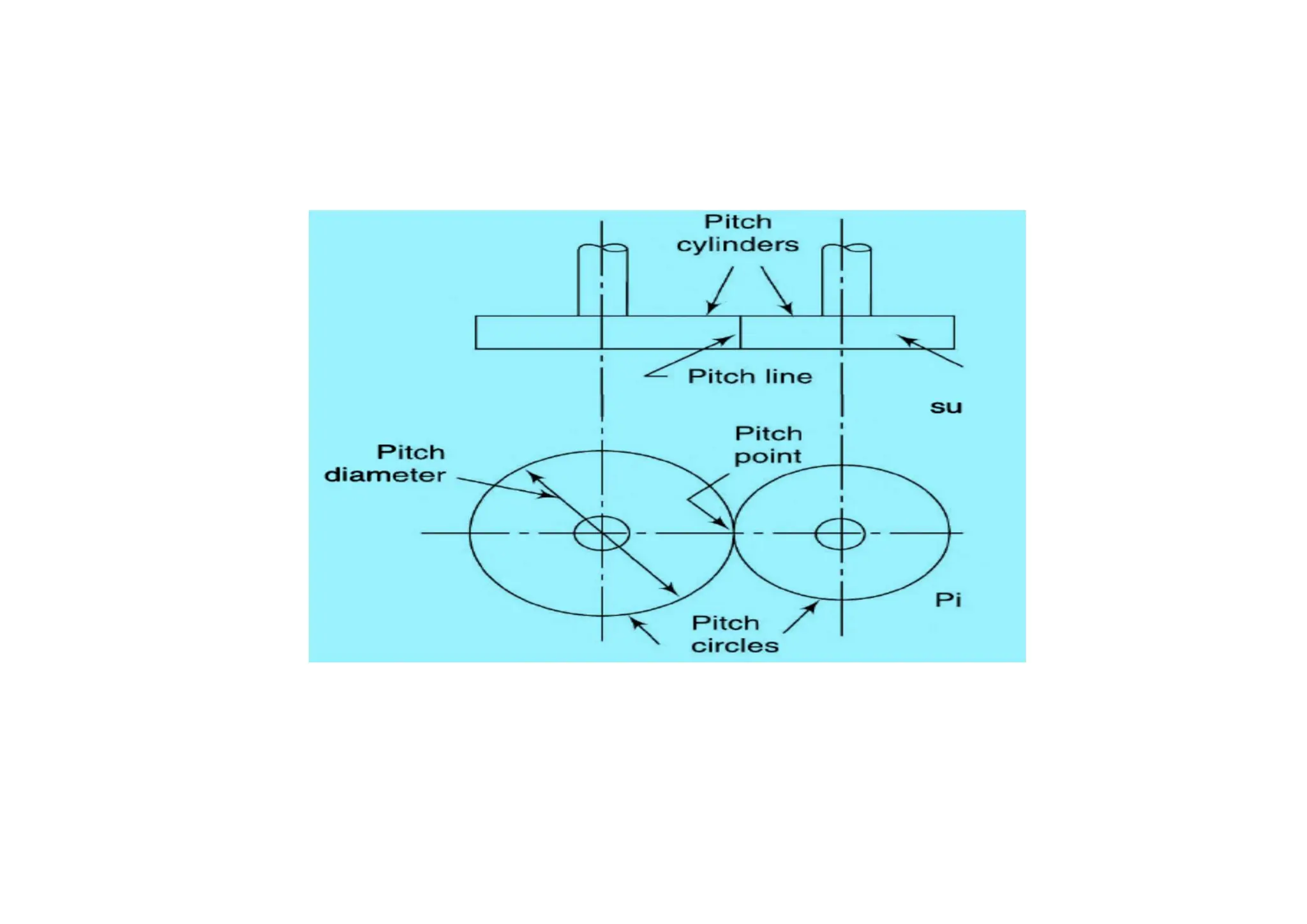

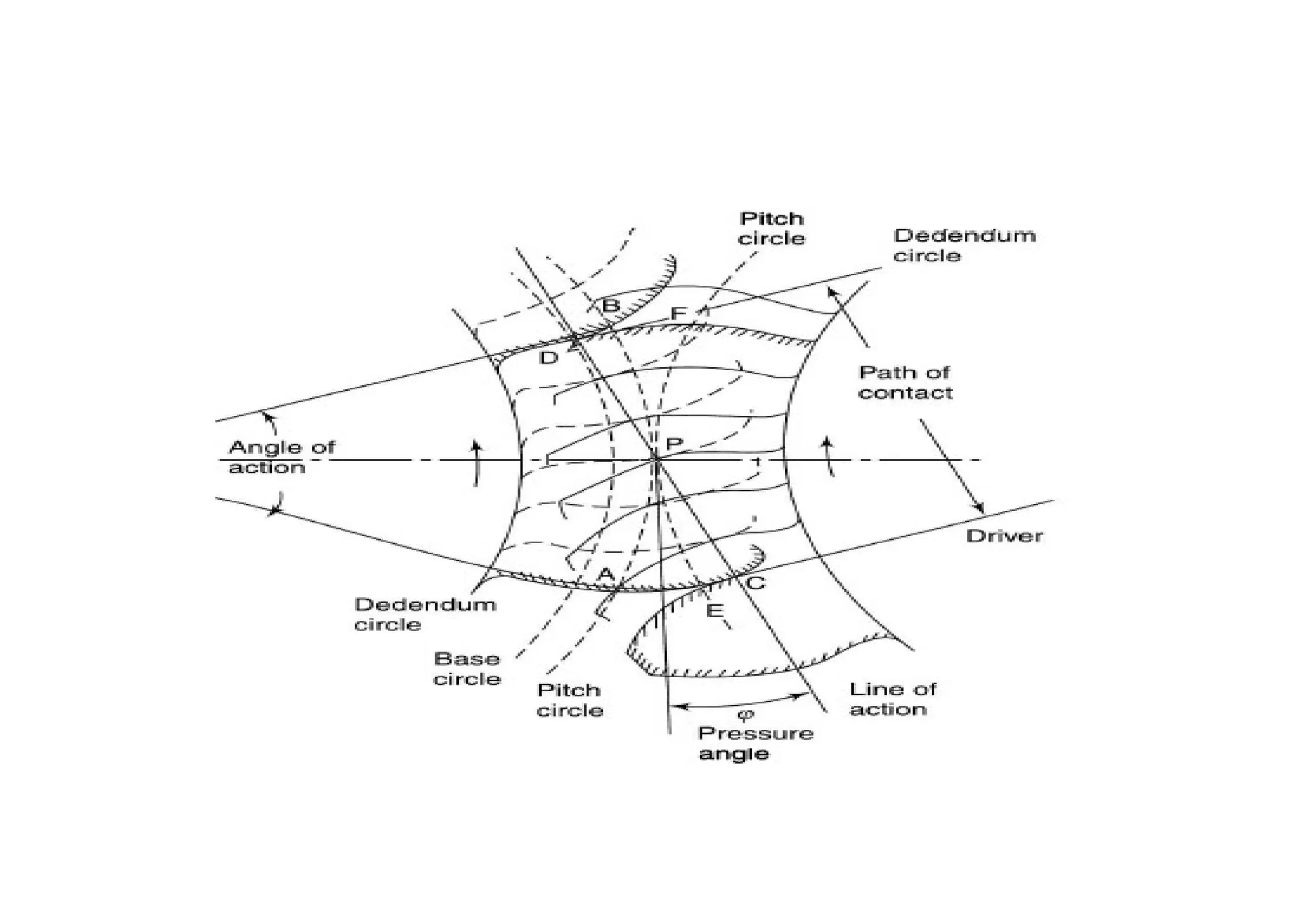

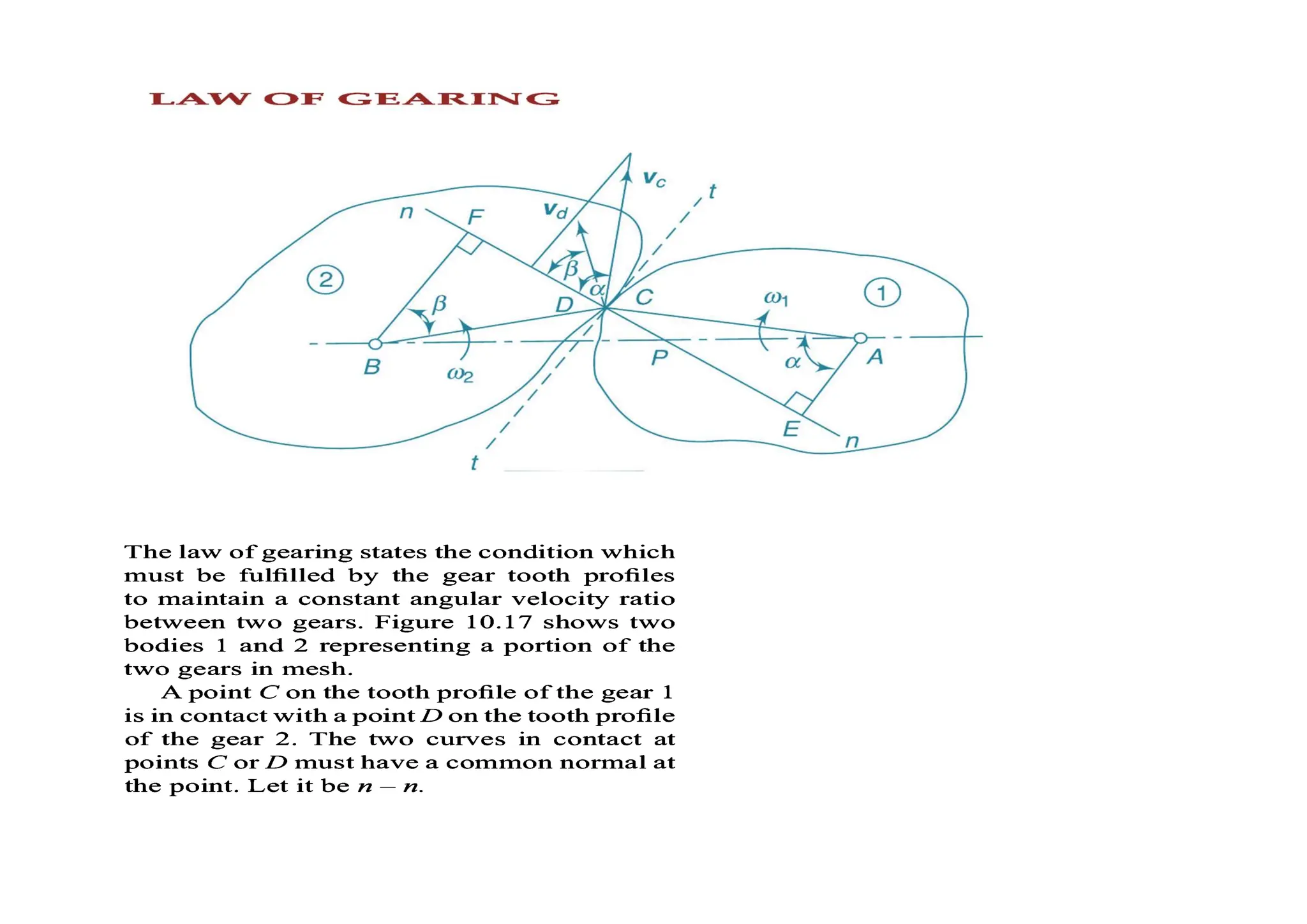

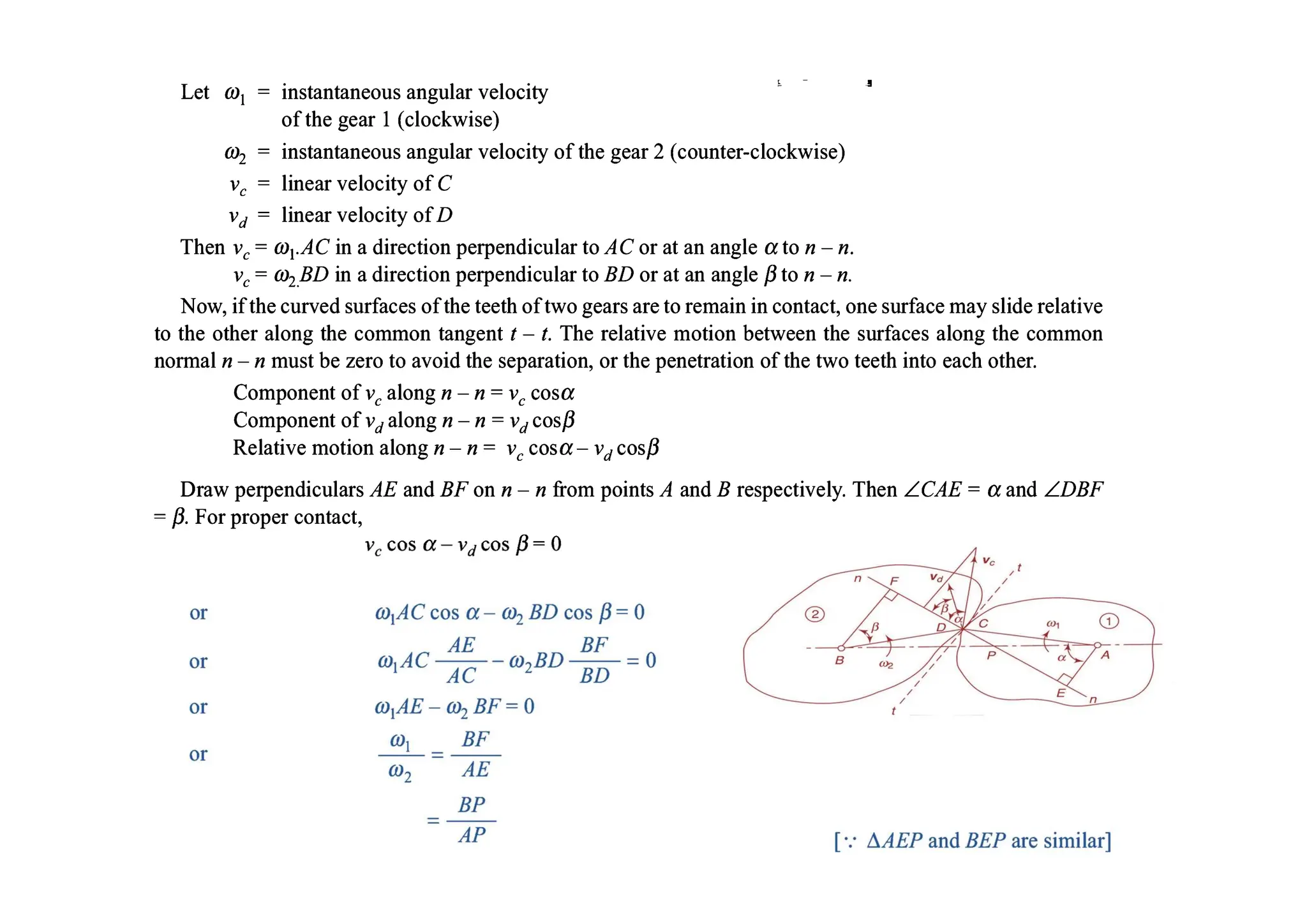

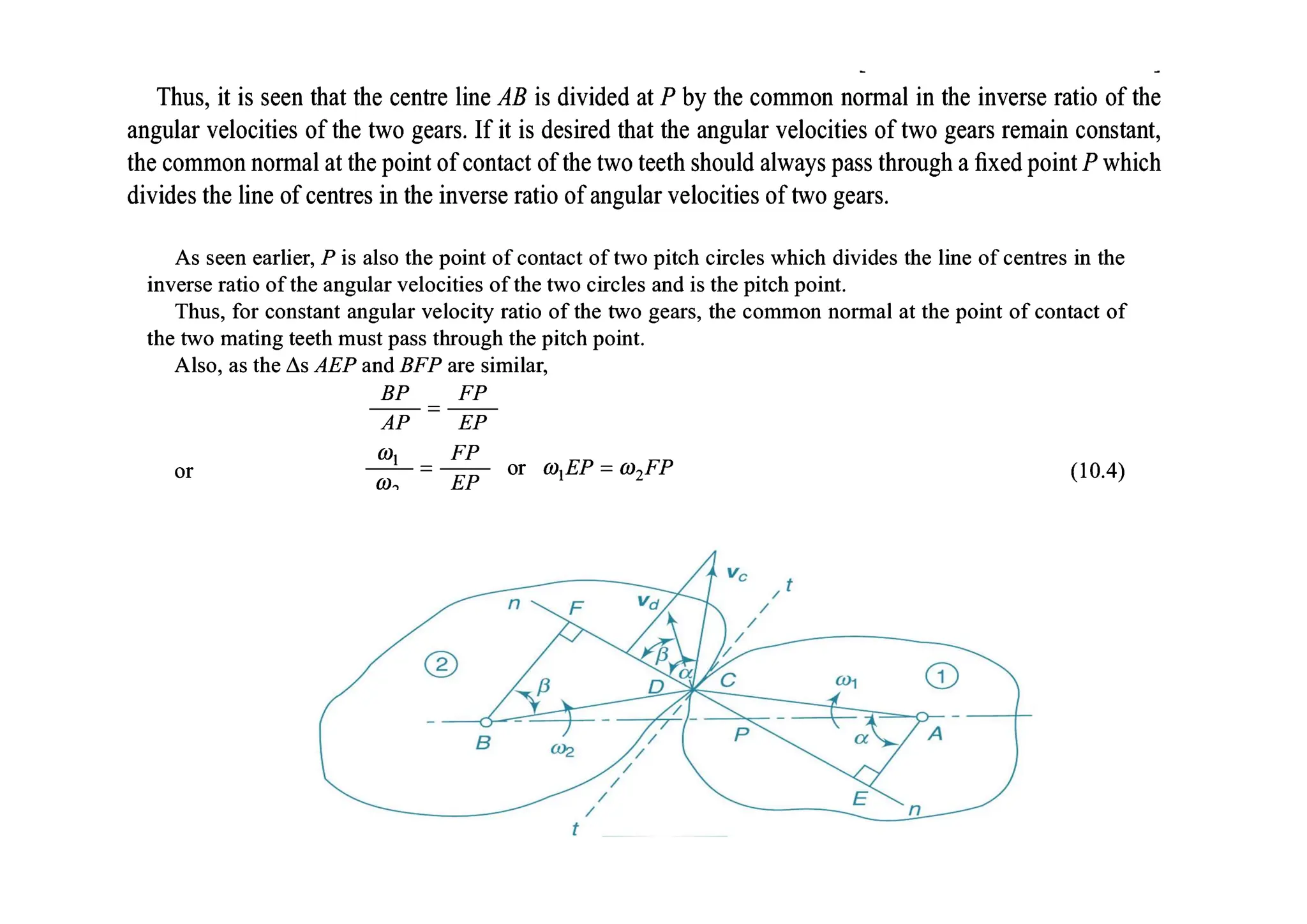

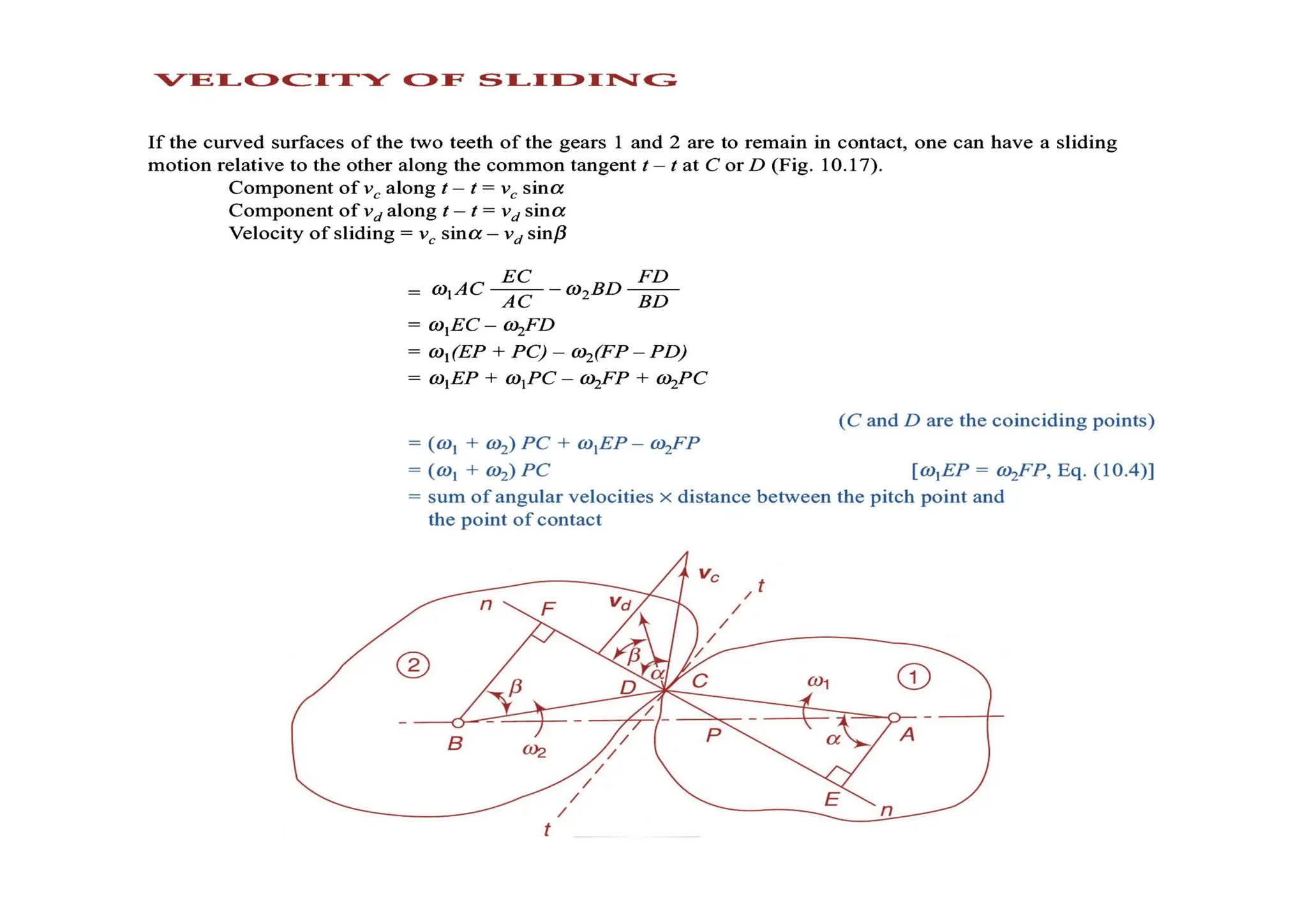

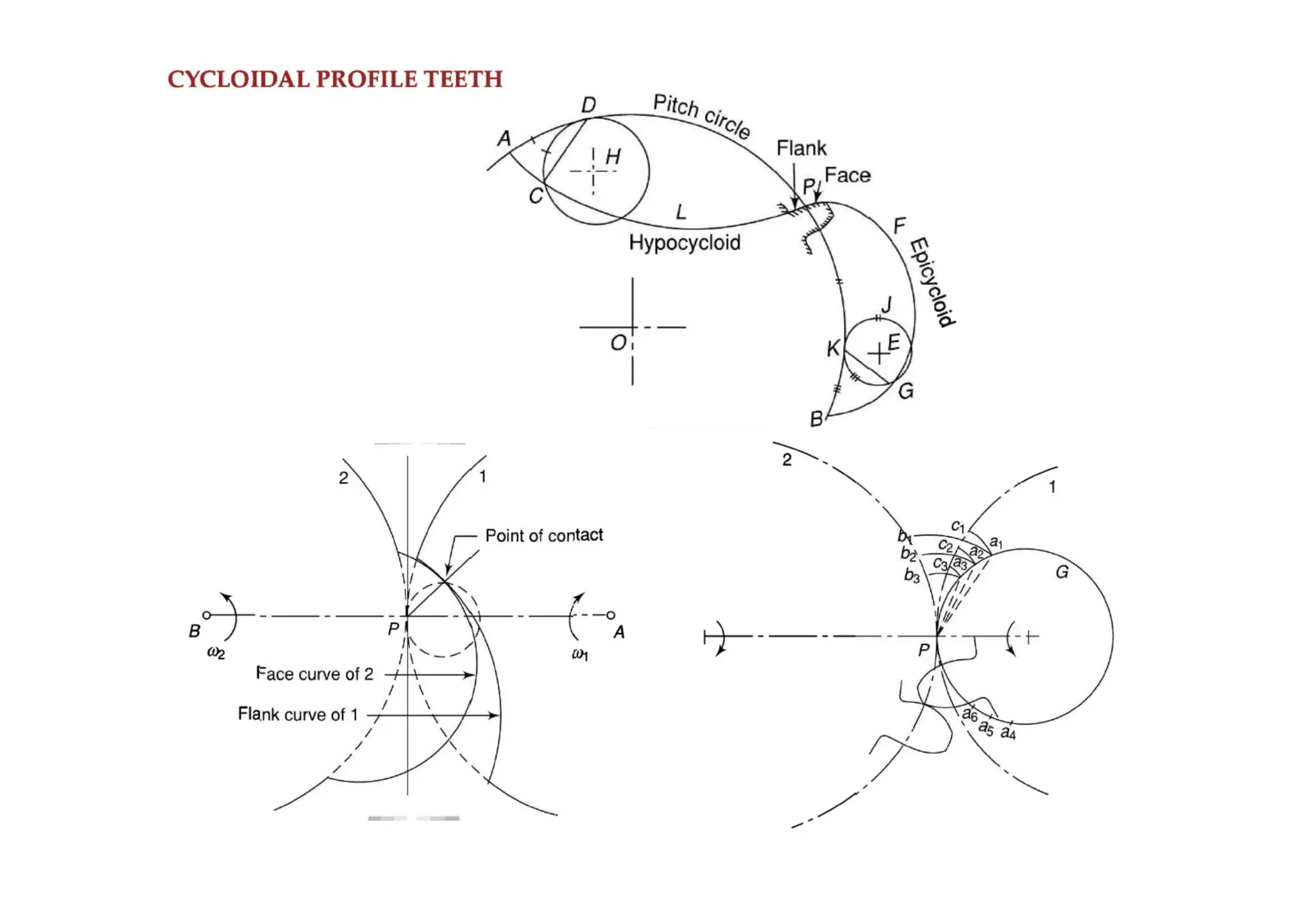

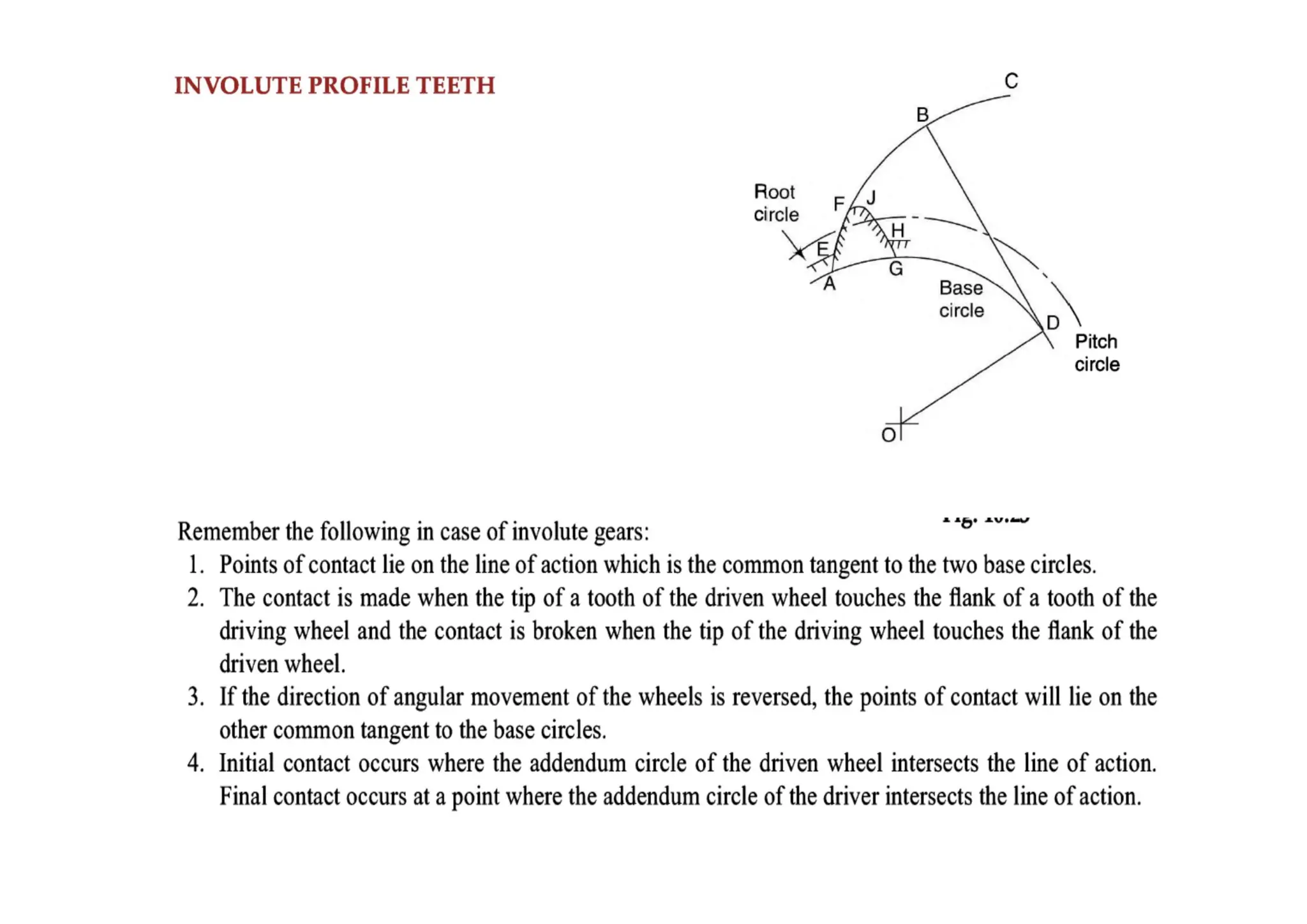

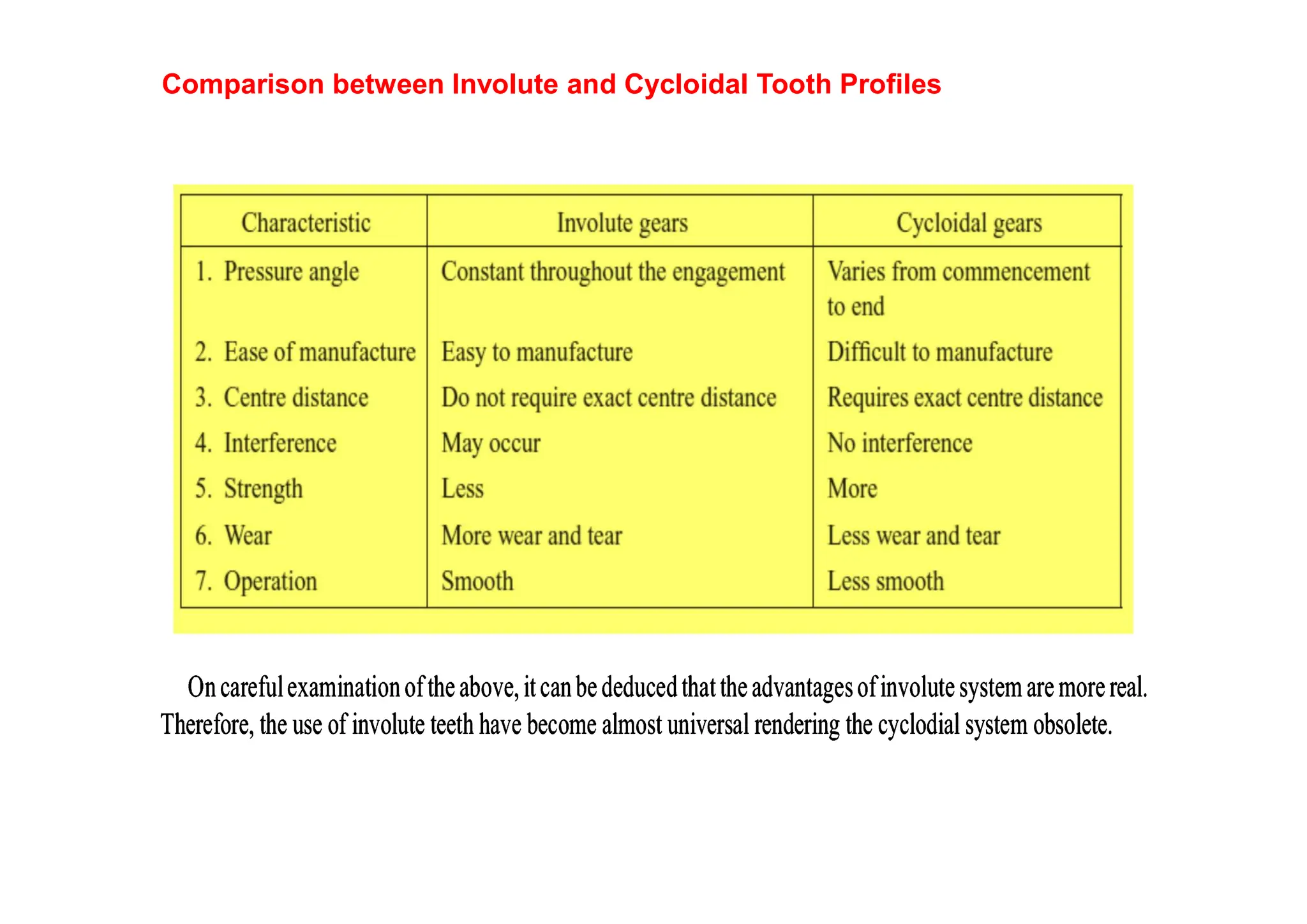

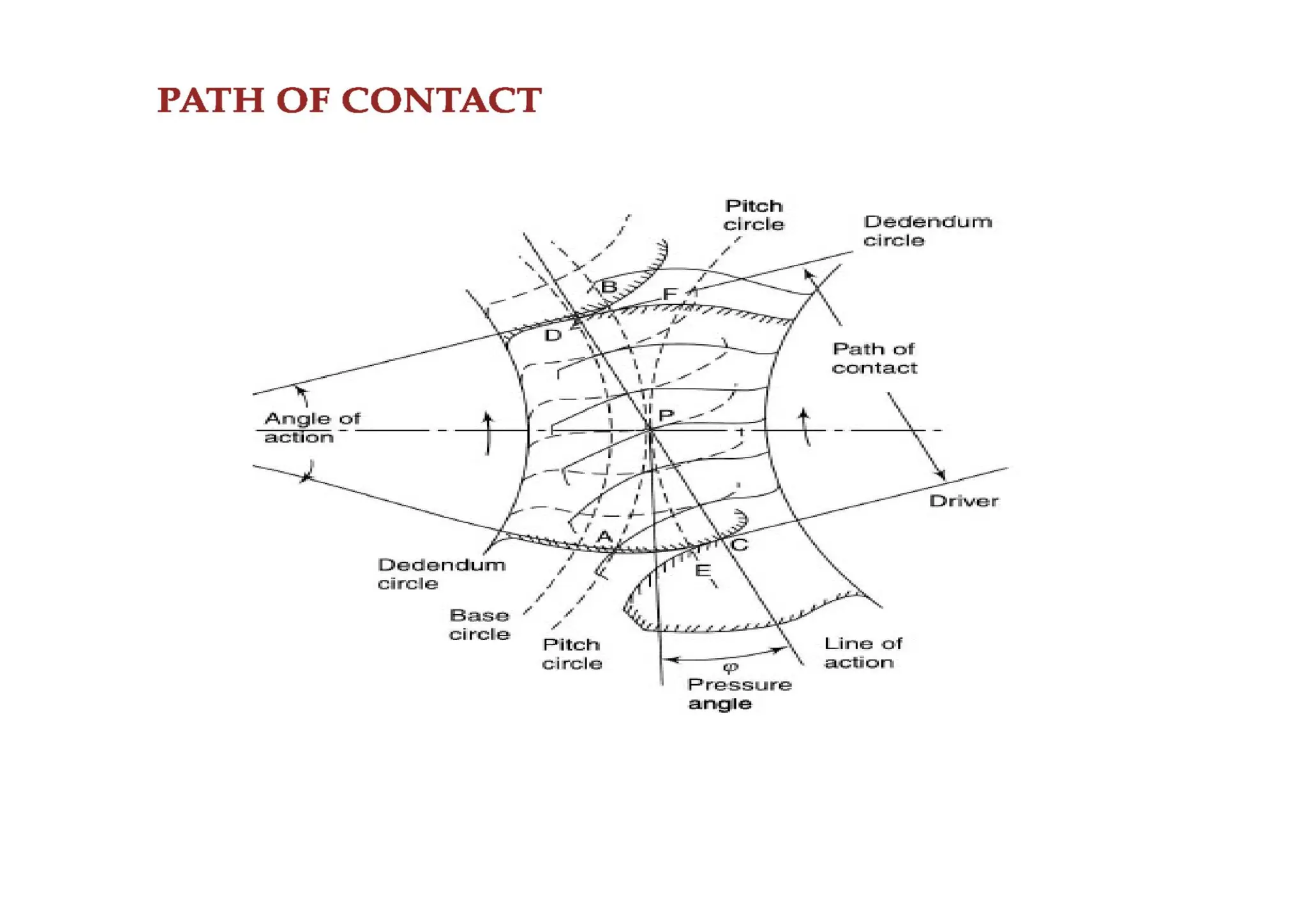

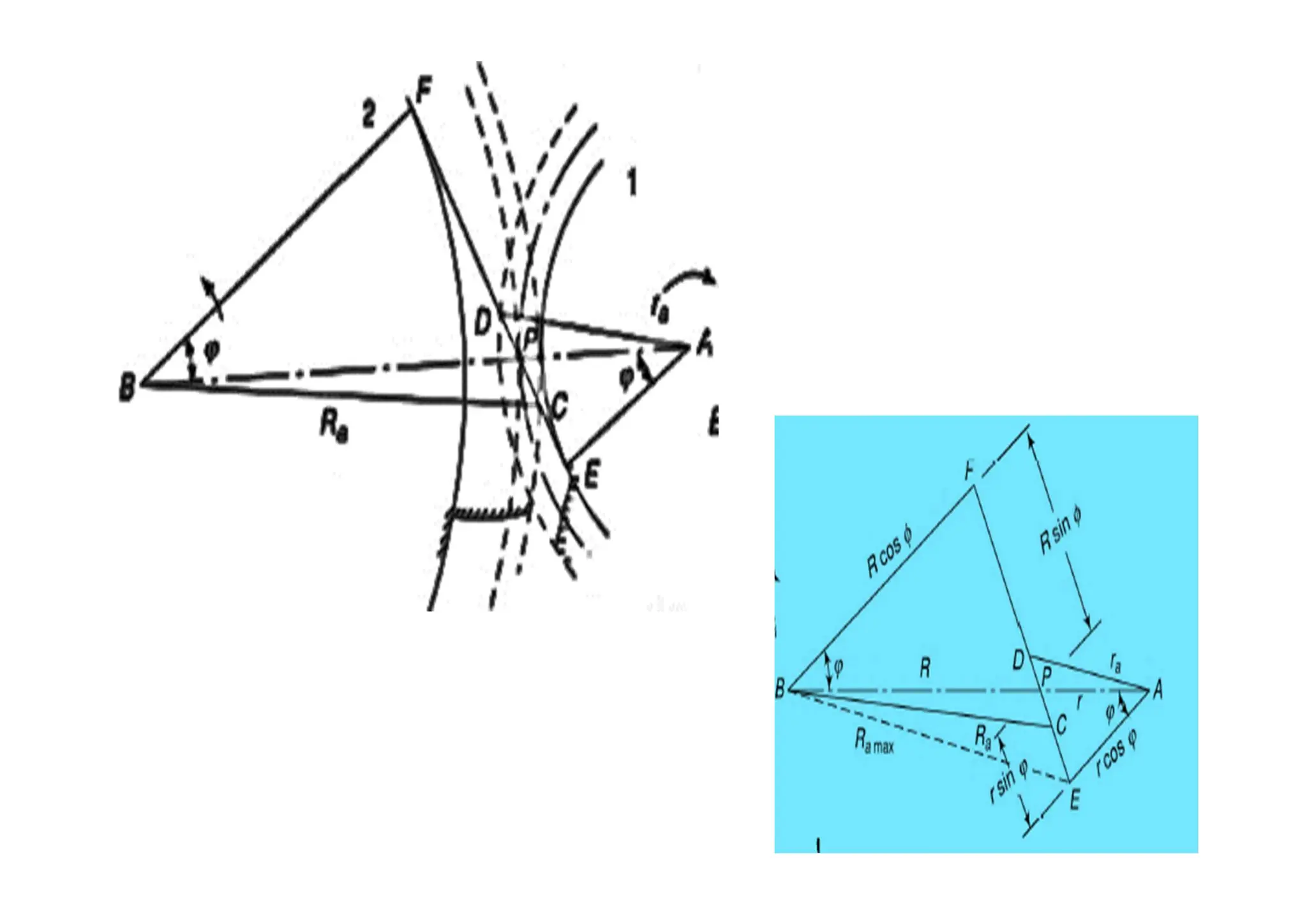

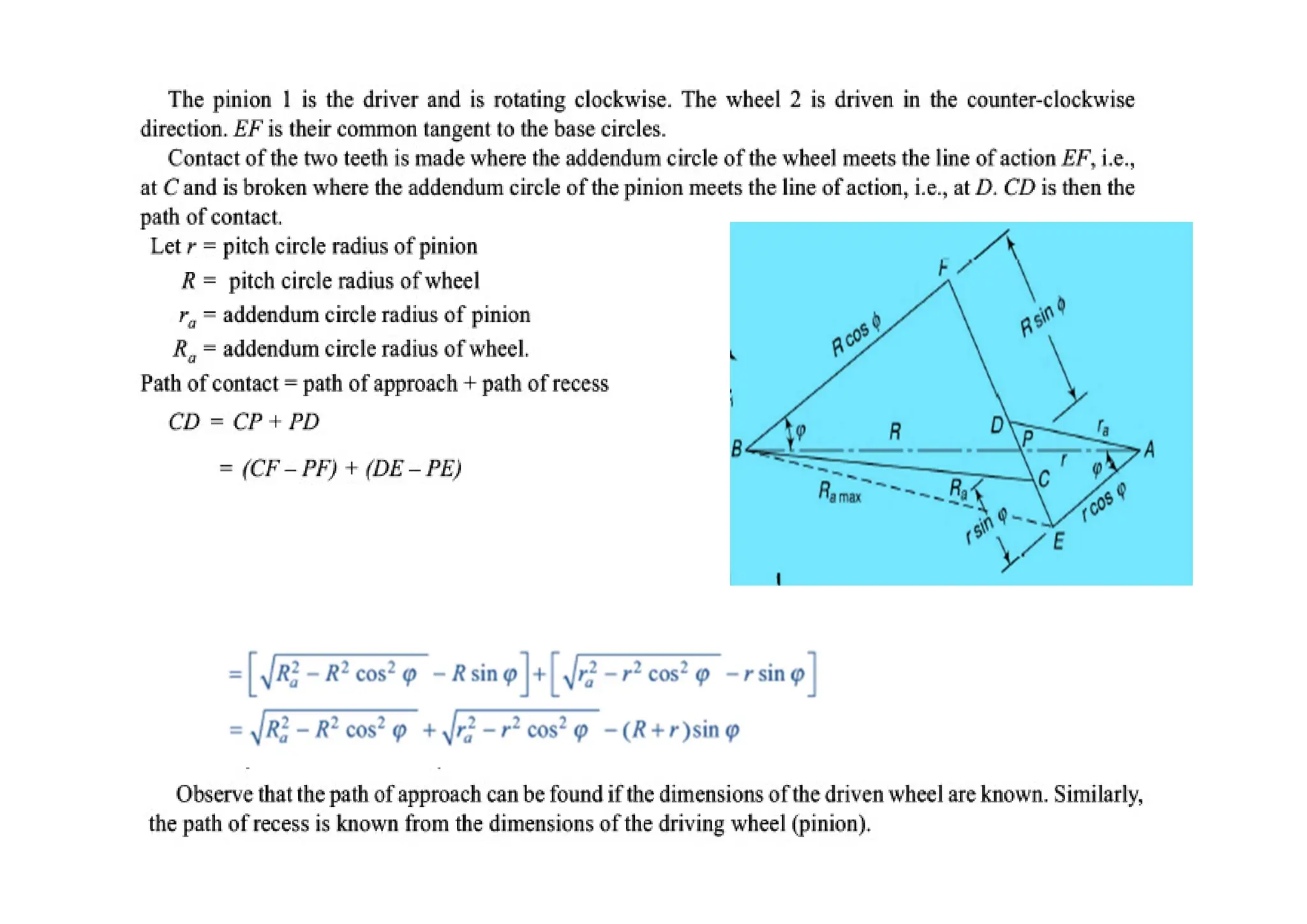

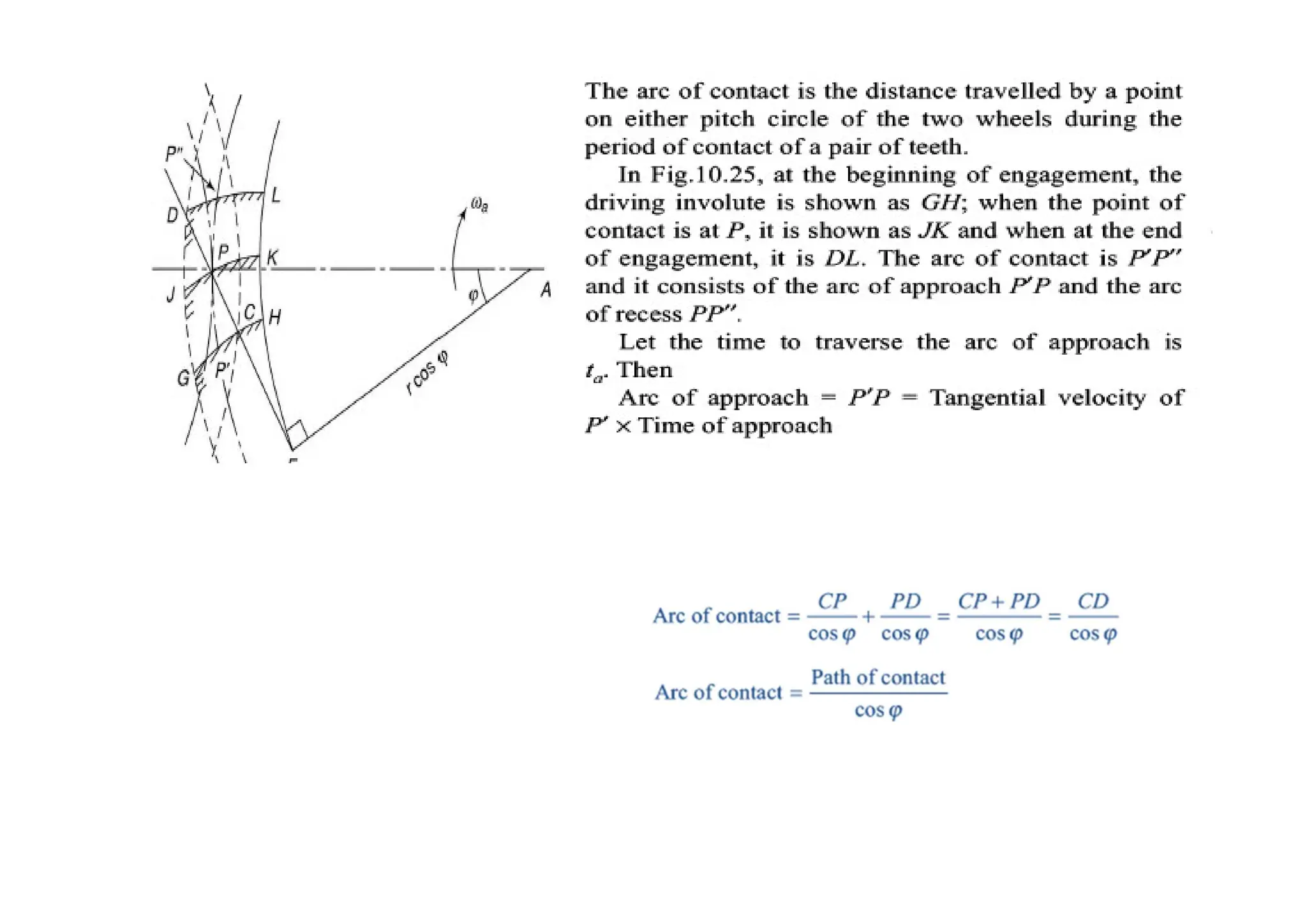

The document provides an introduction to gears, emphasizing their importance in transmitting motion and power without slipping, using toothed wheels or gears for precision applications. It covers the advantages and disadvantages of gears, classifications based on axes positions, peripheral velocity, types of gearing, and the terminology used in gear design and operation. Key terms include pitch circle, pressure angle, and addendum, which help describe the functionality and specifications of gears.