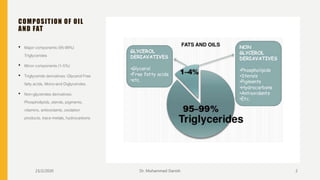

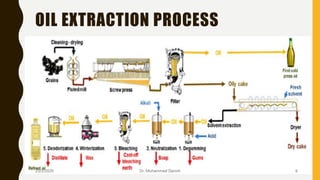

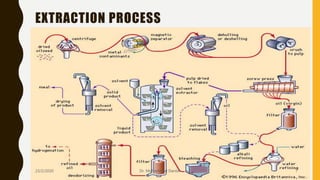

This document discusses the processing of edible oils, specifically palm oil. It describes the extraction of lipids from natural sources through either chemical extraction using solvents or physical extraction through mechanical crushing. It then outlines the refining process used to produce edible oil from crude oil, including degumming, bleaching, and deodorization. Additional processing methods like hydrogenation, fractionation, and interesterification are also summarized.