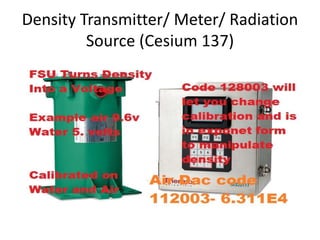

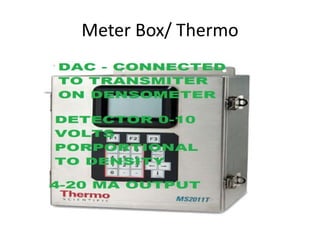

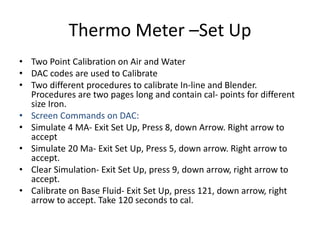

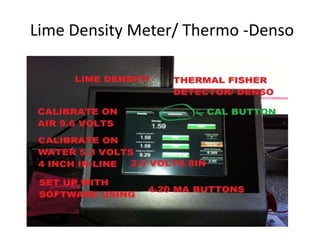

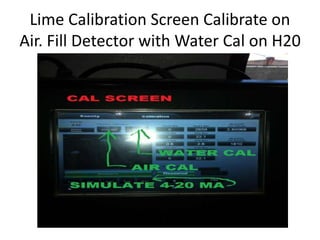

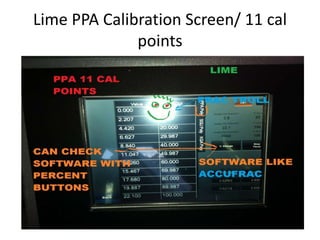

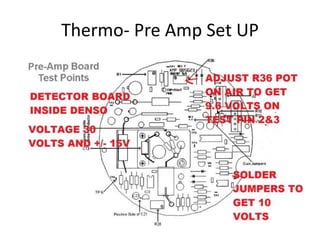

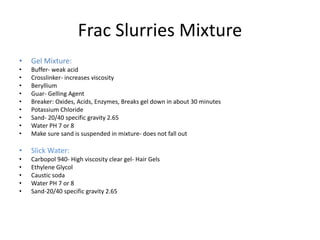

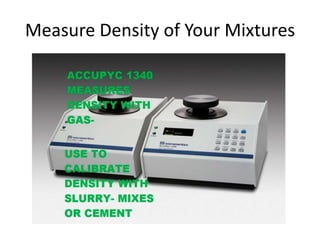

This document provides instructions for calibrating a density meter and summarizes procedures for testing density measurement systems using frac slurry mixtures. It outlines a two-point calibration process using air and water, recording calibration results for restoring meter settings, and calibrating on different fluid types. It also describes preparing frac slurry mixtures with various additives to achieve different densities, measuring the true densities of the mixtures, and using the mixtures to calibrate or test a densometer by taking pressure readings and comparing to known densities. The goal is to practice density measurement techniques and calibrate equipment.