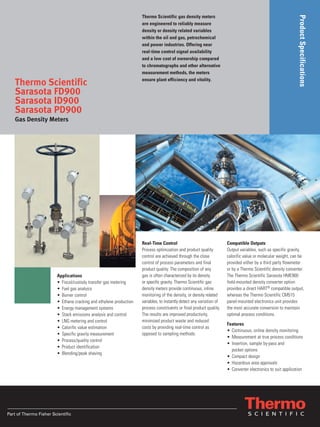

Thermo Scientific gas density meters provide continuous, inline monitoring of gas density or density-related variables to detect any variation in process constituents or product quality in real-time. The meters ensure plant efficiency and optimization through close process control. They offer various installation options like insertion, bypass, or pocket designs and hazardous area approvals. The meters achieve high accuracy and reliability through a vibrating cylinder design and temperature compensation.