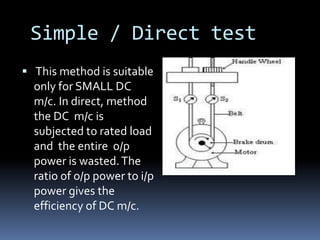

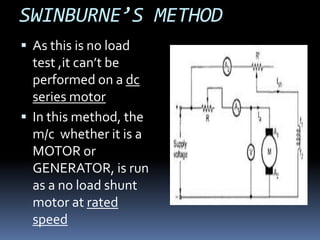

The document describes different testing methods for DC machines. It discusses the simple/direct test method, Swinburne's indirect test method, and Hopkinson's regenerative test method. The simple/direct test method calculates efficiency by directly loading the DC machine, but it is only suitable for small machines. Swinburne's method measures no-load losses to determine efficiency indirectly. Hopkinson's method couples two identical DC machines together to test them simultaneously, with one acting as a motor and the other as a generator.

![EFFICIENCY MOTOR

Motor o/p={ω(s1-s2)r× 9. 81}

Motor i/p= VtI.

ή(motor)={o/p}/{i/p}.

= [{ω(s1-s2)r× 9. 81}×100]/VtI

where; s1&s2 are the tension on the belt.

ω=2πn(motor speed in rad/sec

r=radius of pulley in meters(=1/2 out

side pulley dia+1/2 belt thickness)

Vt=terminal voltage & I=line current.](https://image.slidesharecdn.com/dcmc2-121009023055-phpapp01/85/testing-of-dc-machine-6-320.jpg)

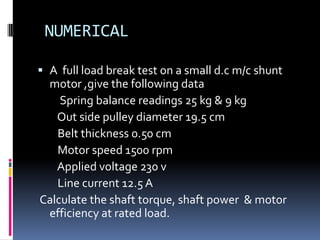

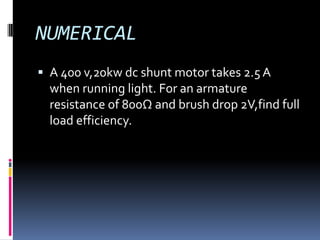

![SOLUTION

Shaft torque=(S1-S2)×Effective radius

=(25.9)[(19.5/2)+(0.5/2)]×(1/100)kg-m

=16×0.1×9.81 Nm=15.7 Nm

Shaft power=ω×Shaft torque

=[(2π×1500)/60]×15.7=2470w

Motor i/p=Vti=230×12.5=2875w

ή(motor efficiency at rated

load)=[2470/2875]×100=85.6%](https://image.slidesharecdn.com/dcmc2-121009023055-phpapp01/85/testing-of-dc-machine-8-320.jpg)

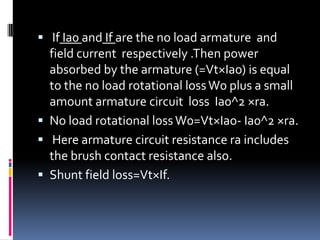

![ Let IL be the load current at which m/c

efficiency is required.

Generator efficiency

Generator o/p=Vt×IL

Armature current Ia=IL+If

Armature circuit loss= Ia^2×ra

ra=armature circuit resistance when hot.

Total loss=W0+ Ia^2×ra+Vt×If

ή(Generator)=[1-{(W0+

Ia^2×ra+Vt×If)}/{(Vt×IL+ W0+ Ia^2×ra+Vt×If)}]](https://image.slidesharecdn.com/dcmc2-121009023055-phpapp01/85/testing-of-dc-machine-13-320.jpg)

![ Motor efficiency

When m/c is working as a motor then

Ia=IL-If

Motor i/p=Vt×IL

ή(motor efficiency)=[1-

{(W0+Ia^2×ra+If×Vt)}/{(Vt×IL)}]](https://image.slidesharecdn.com/dcmc2-121009023055-phpapp01/85/testing-of-dc-machine-14-320.jpg)

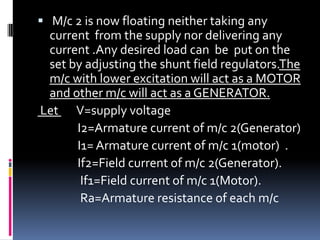

![EFFICIENCY

Armature circuit loss in Generator =I2^2×ra .

Armature circuit loss in Motor=I1^2×ra .

Power drawn from supply= V×I.

No load rotational loss in two m/c=W0=

V×I-ra(I1^2+I2^2) .

No load rotational loss for each m/c=W0/2 .

Generator o/p= I2^2×ra.

Generator loss=Wg=(W0/2)+V×If2+ I2^2×ra.

ή(g)=[1-(Wg)/(V×I2+Wg)]](https://image.slidesharecdn.com/dcmc2-121009023055-phpapp01/85/testing-of-dc-machine-25-320.jpg)

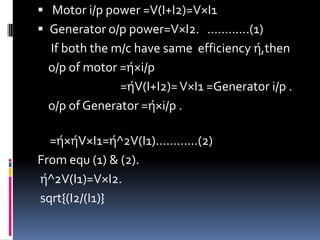

![ Motor i/p=V(I1+If1)

Total motor losses Wm=(W0/2)+ V×If1

+I1^2×ra .

ή( Motor)=[1-(Wm)/V(I1+If2)]](https://image.slidesharecdn.com/dcmc2-121009023055-phpapp01/85/testing-of-dc-machine-26-320.jpg)