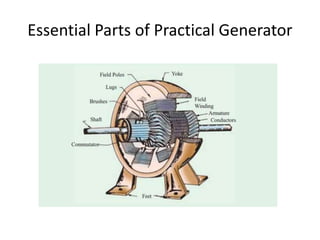

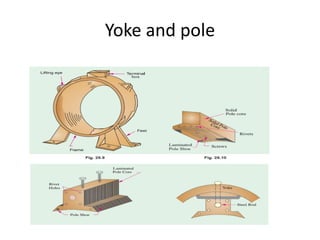

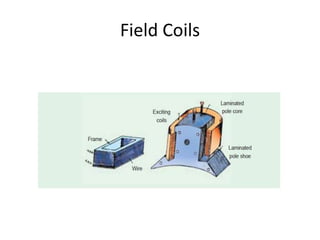

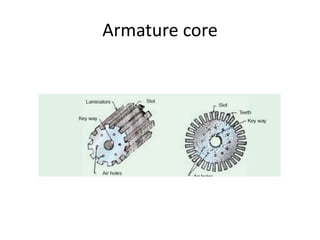

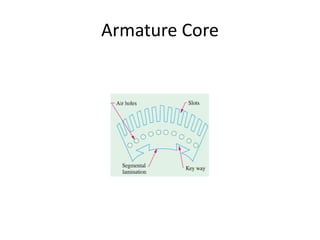

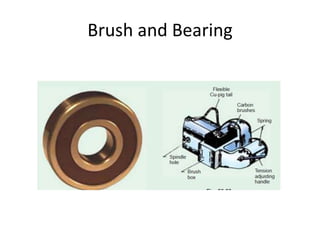

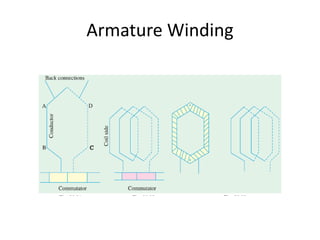

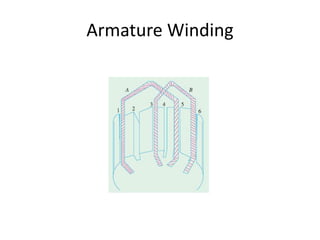

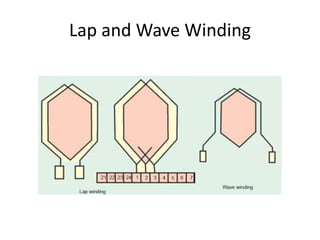

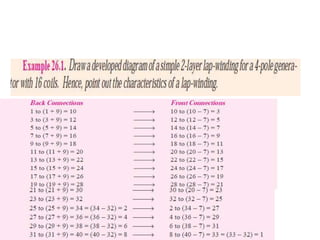

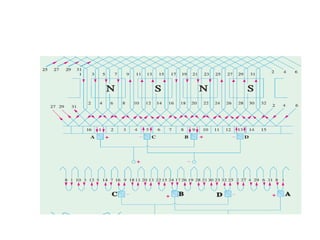

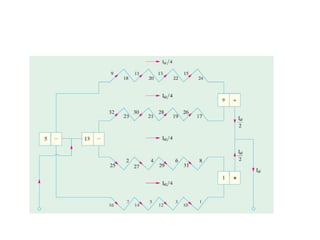

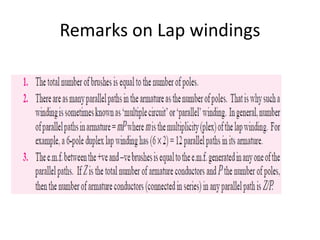

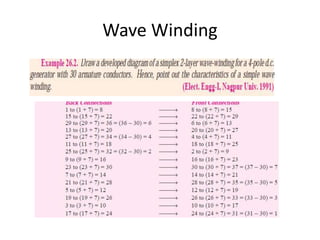

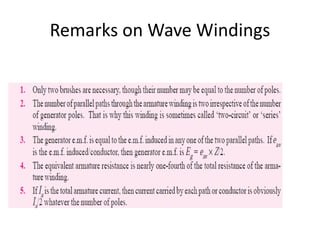

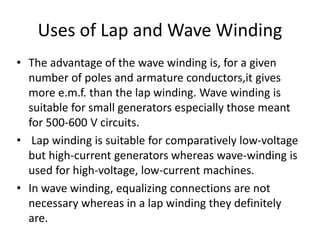

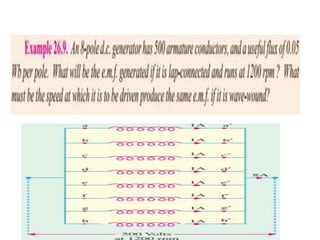

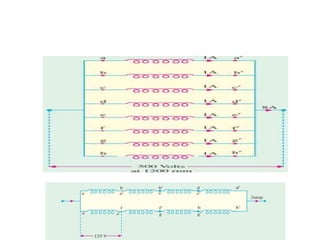

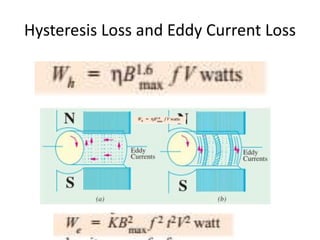

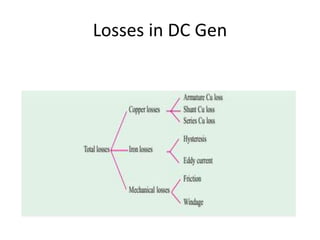

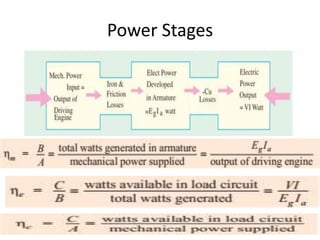

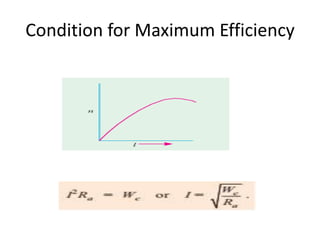

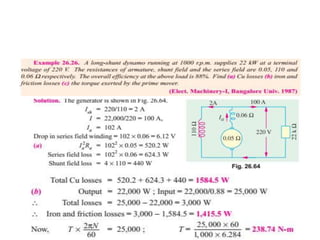

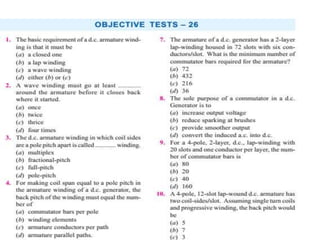

This document discusses the key components and operating principles of DC generators. It describes the essential parts of a practical generator including the magnetic frame, pole cores, field coils, armature core, armature windings, commutator, brushes and bearings. It also covers different types of armature windings such as lap and wave windings. Finally, it discusses losses that occur in DC generators and conditions for maximum efficiency.