The document summarizes a project to create a mock wiring harness and data acquisition system for an IUPUI Motorsports Engineering MGB GT solo car. Key aspects include:

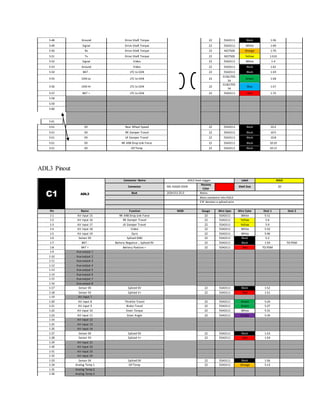

- Selection of Motec ADL3 dash logger and VIM expander to log data from selected sensors via CAN communication.

- Development of wiring harness in separate sections for different areas of the car, with heat shrink, boots, and connectors to protect wires.

- Selection of sensors for wheel speed, damper travel, spring force, and anti-roll bar drop link force.

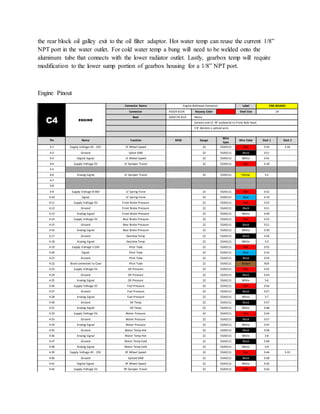

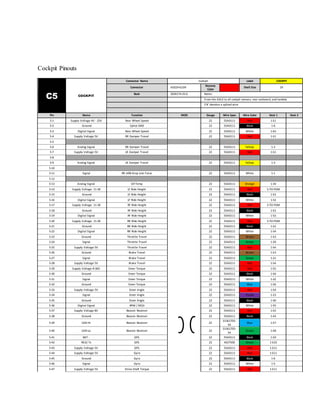

- Pinouts and connector details for wiring individual sensor sections and routing them back to the data loggers.

![Sources

1. Figure 1

ADL3 data logger [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.bimmerforums.com/forum/archive/index.php/t-1579010.html

2. Figure 8

ARB Drop Link Force [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.pistonheads.com/gassing/topic.asp?t=1131871

3. Figure 5

Damper Travel [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.fsae.com/forums/archive/index.php/t-

5776.html?s=2f4ac3793225a1cc9fb6f05198249449

4. Figure 3

Wheel Speed Sensor Mounting [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.aa1car.com/library/diagnosing_abs_wheels_speed_sensors.htm

5. Figure 4

Trigger Wheel and Hub [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.americanmuscle.com/mustang-frontwheel-hub-bearing-9404.html

6. Figure 6

Load Cell [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.raetech.com/Instrumentation/images/Coil-over-Installation-400x533.jpg

7. Figure 7

Load Cell [Digital image]. (n.d.). Retrieved October 11, 2016, from

http://www.interfaceforce.com/index.php?&mod=applications&show=24](https://image.slidesharecdn.com/mste330blackgroupproject1report-170325004018/85/Data-Acquisition-Project-Report-27-320.jpg)