The document provides a 18 step procedure for removing the MGB engine:

1) Disconnect the battery, drain fluids, and elevate the car on jack stands.

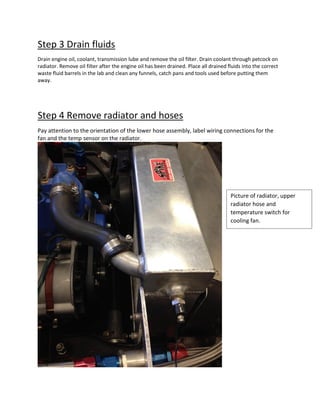

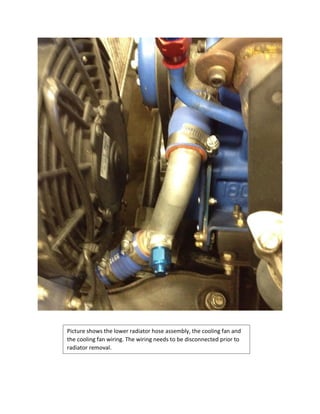

2) Remove the radiator, fuel lines, carburetors, intake manifold, and alternator.

3) Take out the rear exhaust, header, driveshaft, and clutch slave cylinder while disconnecting wiring.

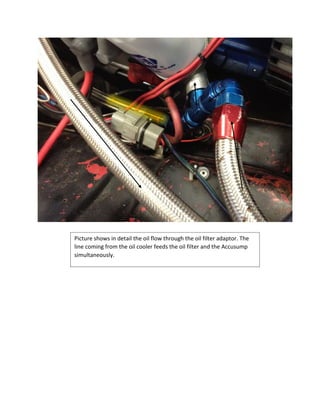

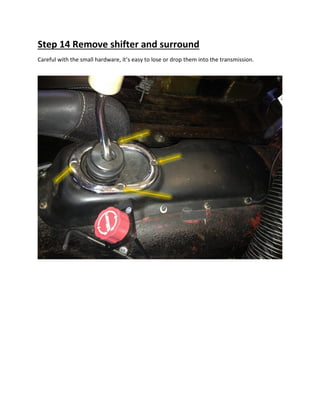

4) Detach the oil lines, crankcase vent, shifter, and connect an engine hoist before removing the front mounts and transmission mount to lift the engine out.