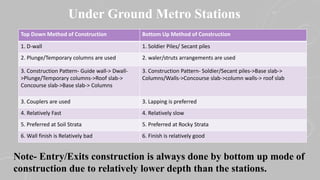

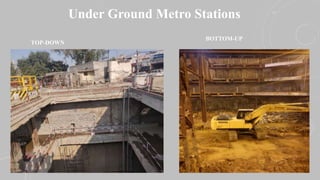

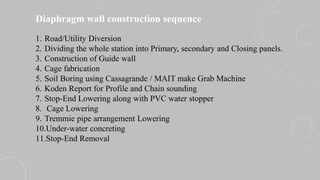

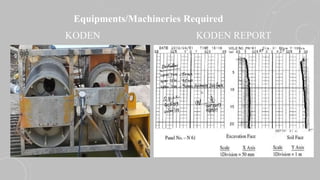

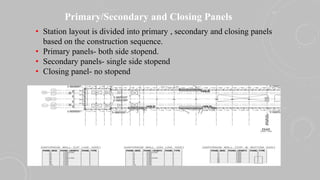

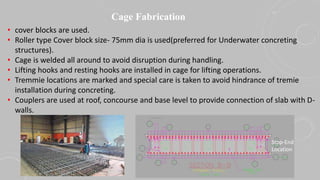

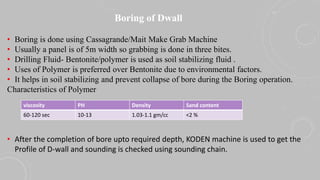

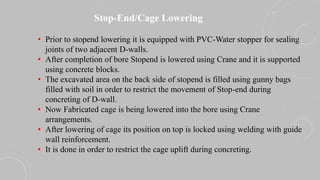

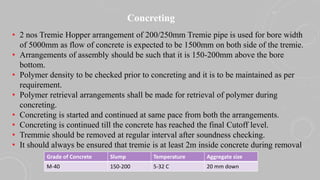

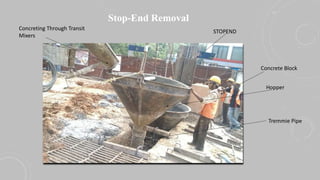

The document describes two methods for constructing underground metro stations - the top-down and bottom-up methods. The top-down method involves constructing diaphragm walls using guide walls, plunge columns, and concreting in stages from the roof down. The bottom-up method uses soldier piles and secant piles with base slabs constructed before walls and columns. Diaphragm wall construction involves dividing the station into panels, installing guide walls, soil boring, cage fabrication, lowering the cage and stop-ends, and concreting through tremie pipes in stages. Equipment used includes grab machines, Koden for profiling, cranes, stop-ends, and transit mixers.