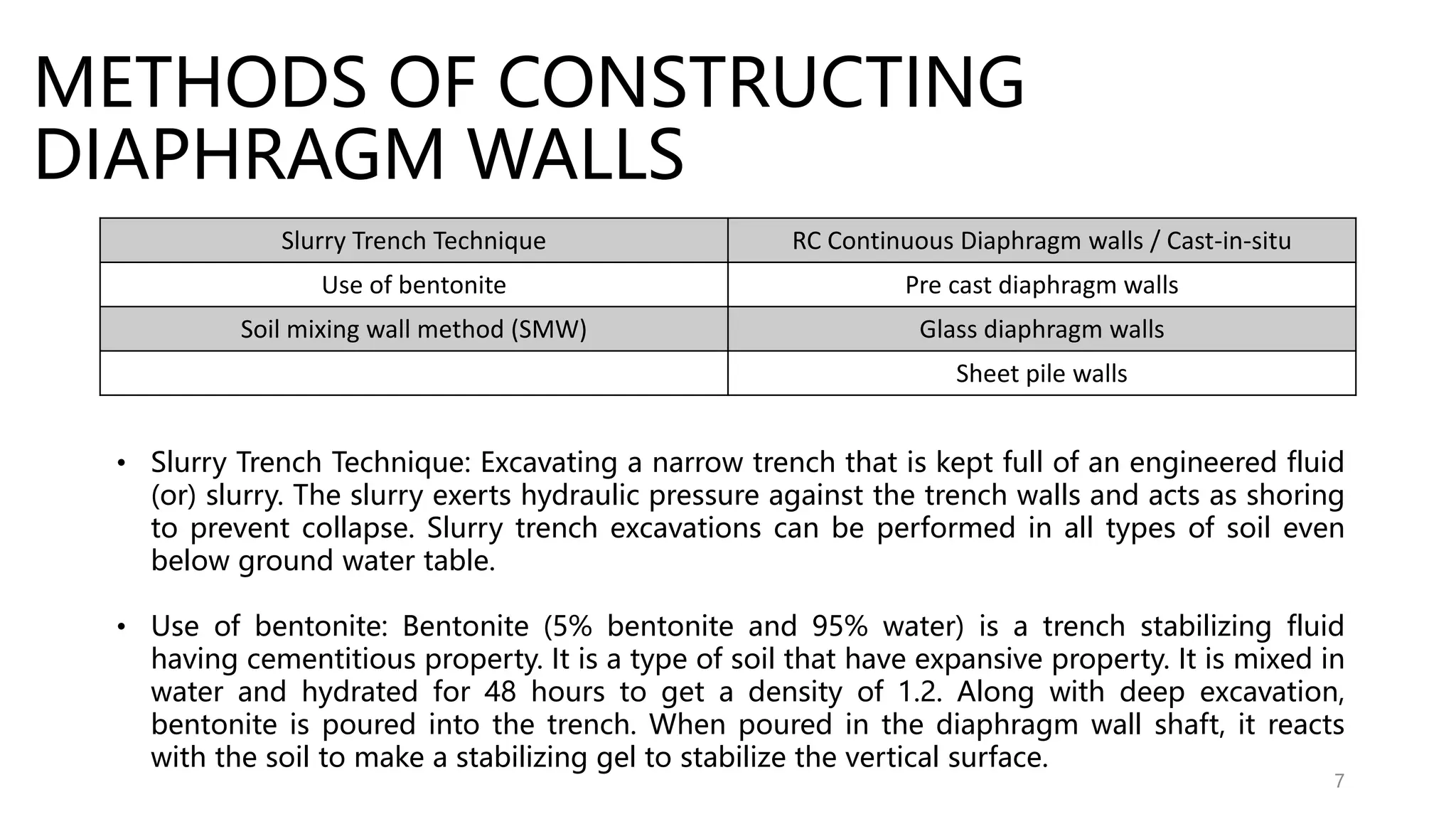

This document provides information on the construction of diaphragm walls. It begins by defining diaphragm walls as reinforced concrete structures constructed underground using the slurry wall technique. It then discusses how diaphragm walls are commonly used as retaining walls, cut-off walls for excavations, and foundations. The document goes on to describe the various methods used to construct diaphragm walls, including slurry trenching, soil mixing, and precast panels. It also outlines the materials, specifications, and general process for building diaphragm walls underground.