CV CBK 2015 N

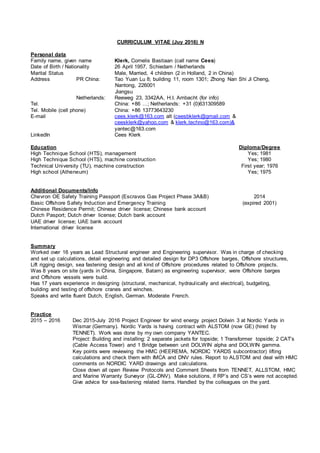

- 1. CURRICULUM VITAE (Juy 2016) N Personal data Family name, given name Klerk, Cornelis Bastiaan (call name Cees) Date of Birth / Nationality 26 April 1957, Schiedam / Netherlands Marital Status Male, Married, 4 children (2 in Holland, 2 in China) Address PR China: Tao Yuan Lu 8; building 11, room 1301; Zhong Nan Shi Ji Cheng, Nantong, 226001 Jiangsu Netherlands: Reeweg 23, 3342AA, H.I. Ambacht (for info) Tel. China: +86 …; Netherlands: +31 (0)631309589 Tel. Mobile (cell phone) China: +86 13773643230 E-mail cees.klerk@163.com alt (ceesbklerk@gmail.com & ceesklerk@yahoo.com & klerk.techno@163.com)& yantec@163.com LinkedIn Cees Klerk Education Diploma/Degree High Technique School (HTS), management Yes; 1981 High Technique School (HTS), machine construction Yes; 1980 Technical University (TU), machine construction First year; 1976 High school (Atheneum) Yes; 1975 Additional Documents/Info Chevron OE Safety Training Passport (Escravos Gas Project Phase 3A&B) 2014 Basic Offshore Safety Induction and Emergency Training (expired 2001) Chinese Residence Permit; Chinese driver license; Chinese bank account Dutch Pasport; Dutch driver license; Dutch bank account UAE driver license; UAE bank account International driver license Summary Worked over 16 years as Lead Structural engineer and Engineering supervisor. Was in charge of checking and set up calculations, detail engineering and detailed design for DP3 Offshore barges, Offshore structures, Lift rigging design, sea fastening design and all kind of Offshore procedures related to Offshore projects. Was 8 years on site (yards in China, Singapore, Batam) as engineering supervisor, were Offshore barges and Offshore vessels were build. Has 17 years experience in designing (structural, mechanical, hydraulically and electrical), budgeting, building and testing of offshore cranes and winches. Speaks and write fluent Dutch, English, German. Moderate French. Practice 2015 – 2016 Dec 2015-July 2016 Project Engineer for wind energy project Dolwin 3 at Nordic Yards in Wismar (Germany). Nordic Yards is having contract with ALSTOM (now GE) (hired by TENNET). Work was done by my own company YANTEC. Project: Building and installing: 2 separate jackets for topside; 1 Transformer topside; 2 CAT’s (Cable Access Tower) and 1 Bridge between unit DOLWIN alpha and DOLWIN gamma. Key points were reviewing the HMC (HEEREMA, NORDIC YARDS subcontractor) lifting calculations and check them with IMCA and DNV rules. Report to ALSTOM and deal with HMC comments on NORDIC YARD drawings and calculations. Close down all open Review Protocols and Comment Sheets from TENNET, ALLSTOM, HMC and Marine Warranty Surveyor (GL-DNV). Make solutions, if RP’s and CS’s were not accepted. Give advice for sea-fastening related items. Handled by the colleagues on the yard.

- 2. 2013 - 2015 April 2013 May 2015 Lead Structural Engineer at West African Ventures WAVENTURES (WAV) in Lagos, Nigeria. WAV is 100% Nigerian Offshore company and has the same owner as STG and CPL. WAV is related to STG in Lagos; STG in Sharjah; STG in Rotterdam. Initiate / design / check all Engineering in- and output (calculations, drawings and procedures), most related to lift rigging, hoisting devices, sea fastening, load out plans for all kinds of structures on vessels required for all of the Projects/Tenders in hands by WAV. -Modification of Stinger J30 for EGP3A; -Delta South: Jacket and topside installation: Design install and test 8 pt mooring system on J25, New winches, fairleads, load measuring system, centralized control cabin, HPU’s, cooling system and integrate with electric/hydraulic system on vessel. Manage all hoisting, sea- fastening and load out arrangements for jacket, topside modules and bridge. -ERHA NORTH phase 2: Engineering Supervisor. Manage all hoisting, sea-fastening and load out arrangements for Suction pile and Manifold installation at 1000 m depth with J31. Redesign Gangway landing platform on FPSO. This all with direct contact with Project Management, Construction- and Engineering department. Also involved in new building projects of STG in Singapore and CPL in China. 2010 - 2013 April 2010 Lead Structural Engineer at STG in Sharjah, United Arab Emirates. Manage the calculations and drawings, most related to lift rigging, hoisting devices, sea fastening, load out plans for all kinds of structures on vessels, required for upgrade/design our DP3 Crane/Pipe lay/Construction and Accommodation Offshore vessels (J18, J25, J28, J30, J31, J34) to make them suitable for jobs asked for by clients. Review the original designs to lower the costs on maintenance. Upgrade and manage our existing DP3 vessel drawings (Hull, Mechanic and Electric) with all upgrades done (or required) by vessel or Class. Make/design the calculations needed for tenders and projects on all hoisting /rigging /sea fastening/ load out related items. Cooperate with whole tender/project team, how hoisting related items can be solved/proposed (based on firm hoisting (crane design) background) 2008 - 2010 July 2008- At Engineering & Design Department (EDD) of STG / CPL in Shanghai: Make structural calculations and drawings for J25, J34, DP3 Pipe lay/Crane Barges. Structural engineering for J18 & J35. DP3 Deepwater Pipe lay/Construction Ships. 2006 - 2008 Feb 2006 Engineering Supervisor for CPL. Onsite Batam: set up own draft team and supervise external engineering’s companies JASCON28. Engineering Supervisor & Deputy Project Manager. Build complete accommodation block for 460 persons onshore and roll on to vessel by 4 SPMT’s. Completely outfit and commissioning this DP3 Crane/Accommodation barge. Design and fabricate Gangway landing platform. JASCON38. Project Manager & Engineering Supervisor. Upgrade this deck cargo barge. JASCON33. Project Manager & Engineering Supervisor. Convert this deck cargo barge to an accommodation barge with 8 point Mooring system. Check stability calculations and strength calculations made by third parties. In charge of procurement of all equipment. June 2007 In Nantong for CPL: JASCON37: Set up preliminary specification and GA to convert this deck cargo barge to an accommodation barge. JASCON25: Make sea fastening arrangements for unmanned tow. Oct 2007 – June 2008. In Singapore for CPL: JASCON28. Engineering Supervisor at Dry Dock World Singapore. Conversion of vessel. Install extra Galley, Messroom, Cold stores, Accommodation, HVAC plant, 280t and 32 t Offshore deck cranes and Telescopic Offshore gangway. Install 3rd Generator set 2 additional side Thrusters and mid aft retractable Thruster. Put 2 existing thruster HPU’s to below deck. Design 8 point Mooring system in addition to DP3 system. 2004 - 2008 Quality control and Project management for TMS (Dutch engineering company) in China. Supervise at “Yatai” (in Nantong) the fabrication of crawler crane parts designed and assembled in Holland. This during time not directly working for CPL or STG. 2005: Inspector for Dutch company “Concordia” building vessels (basic hull) in China. Advice Chinese yards how to boost up their QA and QC to be accepted by foreign companies. Sept 2005 - Jan 2006 Project Engineer for Global Industries Ltd. Conversion of DLB Hercules in China. Function: Mechanical Equipment Supervisor (Overhaul pipe laying equipment and all Cranes)

- 3. 2004 Apr till Aug: On site (for CPL) design, engineering and inspections of modification “JASCON5” in Singapore & Batam. Main items: new forecastle deck with new winches, extra ventilation, drag brake cooling system, several piping systems, installation of new offshore crane. Design and review of hydraulic piping systems for the winches. 2000 - 2004 From Oct 2000 till Apr 2004 Assist on site in China the project management of “Consolidated Projects Ltd” (CPL is part of Seatrucksgroup (STG)) in building DP3 pipe lay/crane barge “JASCON5” (Later on renamed C-Master). Inspections of yard work, engineering support, supervise all yard production drawings, make sea fastening arrangements and keep contact with classification authority ABS. 1998 - 2000 Owner & Senior Mechanical Engineer at “Klerk Engineering” - Project engineer ROV A-frame design 14 Ton SWL for Noordhoek Diving and HAM - Project engineer at “BAILY” crane division. Redesign Traveling, revolving and luffing Grab crane for ENCI, line up of specifications, design: manuals, test protocols and transport plan. -"Cargo securing plan (DNV)" for supply ship Maxita (Saipem). - Bluewater FPSO conversion - Glas Dowr. Several support constructions. - Design Cable Carousel Seaspider (“de Hoop”) - Design gangway for SAIPEM7000 - At “IHC GUSTO Engineering” and “HUISMAN/ITREC”: line up technical specifications for cranes, winches, gearboxes and el./hydr. systems for pipe lay vessel CSO Deep Blue. - For consortium “HAM” and “Noordhoek”: Hydraulic/mechanic/structural engineering of trencher/ROV (SEAJET2000) for 2500m water depth. Included purchasing and testing. Design el./hydr. system for Umbilical winch and multi functional el./hydr Powerpack. Testing of all on POLAR PRINCE in Norwegian waters. - At IHC GUSTO Engineering: Structural and Mechanical engineer of the main- (20.000 ton) and auxiliary hoist system for platform removing vessel "Excalibur" (structural, skid system, hoisting blocks, reeving, power and performance, min. and max. cable force, etc.). Later on design was changed to “Pieter Schelte”/”Pioneering Spirit”. 1987 - 1998 Vice president at “Buitendijk Techniek BV” (BT) Offshore- onshore cranes, brand name “SHF”. Project engineering, price calculation, mechanical & structural engineering of cranes, winches and machines, develop the el. and hydr. systems, manuals, contact with classification authorities, testing and delivery. Continue the same as from 1981-1987. 1985 - 2005 Owner of company “C.B. Klerk BV”. In 1998 “Klerk Engineering”. 1981 - 1987 Senior Mechanical-/ Structural-/Project engineer at Schiedamse Hijswerktuigen Fabriek (SHF). Designing Offshore&onshore cranes. Special deck cranes (hoisting, luffing, slewing, traveling) for dredging ships, rigs and pipe laying vessels. Traveling on or inside rails by boogies and “rack pinion” drive. Luffing by cylinder or winches. Gearboxes hydraulic or electric driven. Electric driven most of the time by frequency control systems. Designing less electric power consuming systems and “stored power” systems. Cranes were totally internal designed including electric and hydraulic systems and controls. Also fabrication in own hand. From 1983 –1985 Vice president and from 1985 President (Technical). In 1987 Company bought by “Buitendijk Techniek BV” Skills: - Review, line up offers and inquiries for mechanical/electrical equipment. - Design, review, redesign, estimate and calculate all kind of cranes (Offshore- and Onshore cranes, (traveling, slewing, luffing, knuckle boom), standard and explosion proof). - Review of all existing designs for structural, mechanical, electric systems for cranes and machinery, to have less downtime, less maintenance and less power consumption. Also improve the safety for employees working with the equipment. Come out with “out of the box” solutions. Try to optimize and standardize the stock of spare parts needed for equipment. - Check or make Calculations, Drawings, most related to lift rigging and cranes, sea fastening, all kinds of structures on vessels and related to hoisting devices. - Design of special material handling and marine equipment (special cranes, winches, drilling equipment, pipe handling equipment, gangways, ramps and hatches) - Design, review, estimate and calculate el. and hydr. systems for transport equipment and all kinds of mechanical equipment (also "explosion proof"). - Design of controls and safety devices for transport equipment and all kinds of mechanical equipment. - Coordination the assembly of all main structural items and commissioning the el. and hydr. systems. - Design Structural Fire protection drawings and Fire Control & Safety plan drawings for Vessels.

- 4. Line up of technical specifications and commissioning: - External technical specifications for client - Internal technical specifications for drawing/engineering department - Internal technical specifications for purchase of lift rigging, mechanical- electrical- and hydraulical components or systems - Offshore procedures - Maintenance- and instruction manuals - Commissioning and Test protocols for cranes, mechanical equipment, hydraulic systems and ships systems etc. and coordination of the tests Developing technical calculation programs (Mathcad, Excel) for: - The “basic design” of cranes, mechanical equipment, lift rigging and sea fastening - The mechanical components (winches, gearboxes, slewing bearings, rigging, bearings) - The hydr. components (pumps, motors, overcentre valves, control valves, piping) - Weight- and COG control programs for ships and structures. Review technical calculations and drawings from third parties and own draft/engineering team for cranes, lift rigging, transport equipment, seafastening and load out, mechanical equipment, Hull and Accommodation, vessel systems (ballast, bilge, FiFi, Black and Grey water, drainage, Fresh water, Fuel Oil, hydraulics, AC & Ventilation), Fire Protection & Safety plans. Maintain the contacts with classification authorities (Lloyd's, DNV, BV, ABS) and clients concerning the above mentioned reviews. Inspections (structural and mechanical) on onshore- & offshore constructions, cranes and ships, according A-cad drawings and technical specifications. Make on-site solutions and A-cad drawings in case of deviations. Discus the drawings of vessels and equipment with classification authorities (Lloyd's, DNV, BV, ABS) Skilled in: Autocad (above average). Word and Excel (above average) Mathcad, Microsoft Project. Judging the results of FEM calculations (e.g. ANSYS, SACS). Coordination of Naval, Structural & Mechanical Engineering on yard (fabrication) and office Installation and Commissioning. Assist Project Management. Strengths: Communications skills. Not afraid to 'get hands dirty' and be on the spot whenever needed. Willing to relocate. Used to work worldwide with people from all over the world.