The intern summarized key details from an internship document at LMTG:

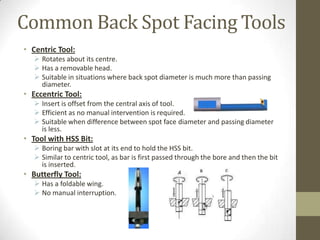

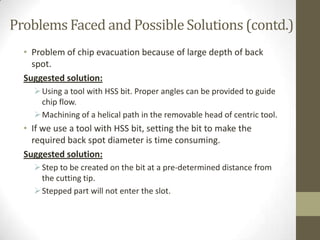

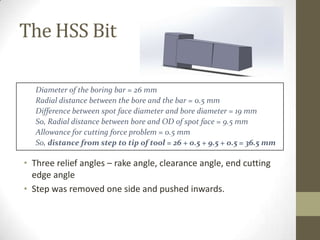

1. The intern conducted two projects - developing a specialized tool for back spot facing an ash lock, and analyzing surface finish obtained from a wiper cutter on a horizontal boring machine.

2. For the first project, the intern proposed and tested solutions to challenges like tool length and vibrations. This included a stepped shaft design.

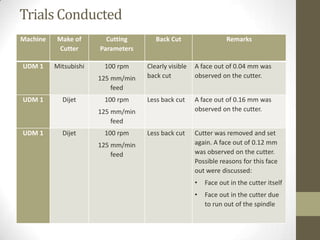

3. For the second project, the intern conducted trials varying machine, cutter, and parameters, finding spindle runout caused back cutting on one machine.