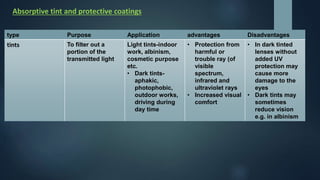

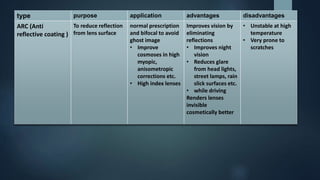

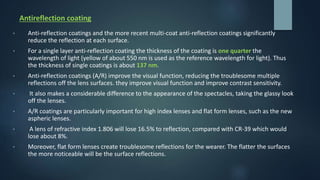

This document discusses various lens enhancements that can be applied to prescription lenses, including anti-reflection coatings, scratch-resistant coatings, and hydrophobic coatings. It provides details on how each type of coating works and is applied. Anti-reflection coatings reduce unwanted reflections using destructive interference of light waves. They are applied in very thin layers, with precise thickness needed. Scratch-resistant coatings increase the hardness and durability of plastic lenses through additional layers. Hydrophobic coatings create a high contact angle to allow water and oils to bead up and roll off the lens surface.

![ “When the absorption reaches the saturation point, the interfacial activator [within the

resin] changes water droplets into a thin outer layer of water.44” It is much more common

to find permanently applied antifog coatings in sport eyewear, such as swimming goggles.

Prescription lenses with an antifog coating are not always available.

When available they are limited to single vision lenses.

Fortunately, there are sprays and drops that can be applied to ordinary spectacle lenses

to reduce fogging, such as Zero-Fog lens treatment by OMS Opto Chemicals.

Although Zero-Fog claims to be compatible with AR coatings, not all antifog sprays or

drops are.](https://image.slidesharecdn.com/lensenhancement-consideringforprescribingfinal-200418124223/85/Lens-enhancement-considering-for-prescribing-25-320.jpg)