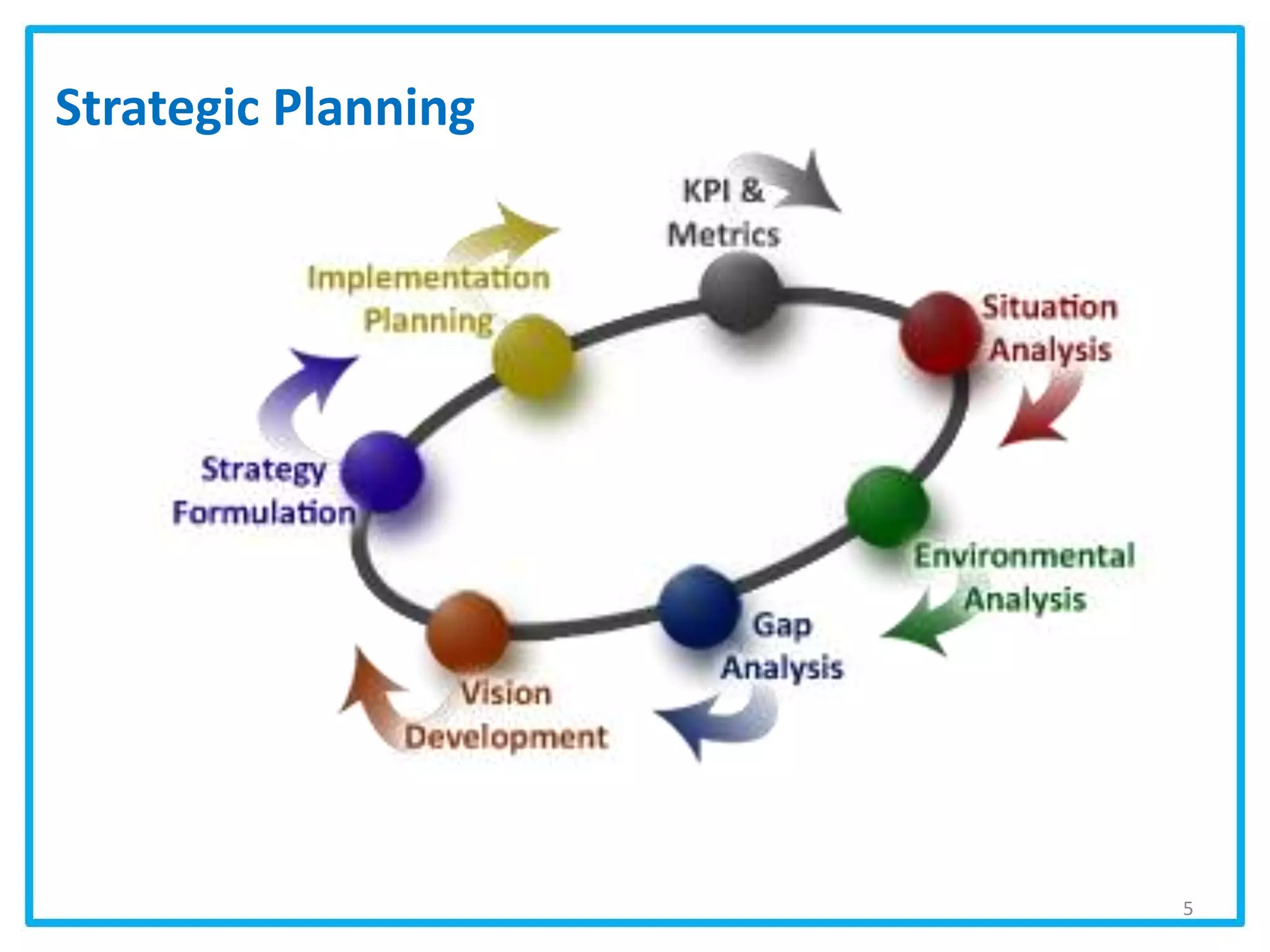

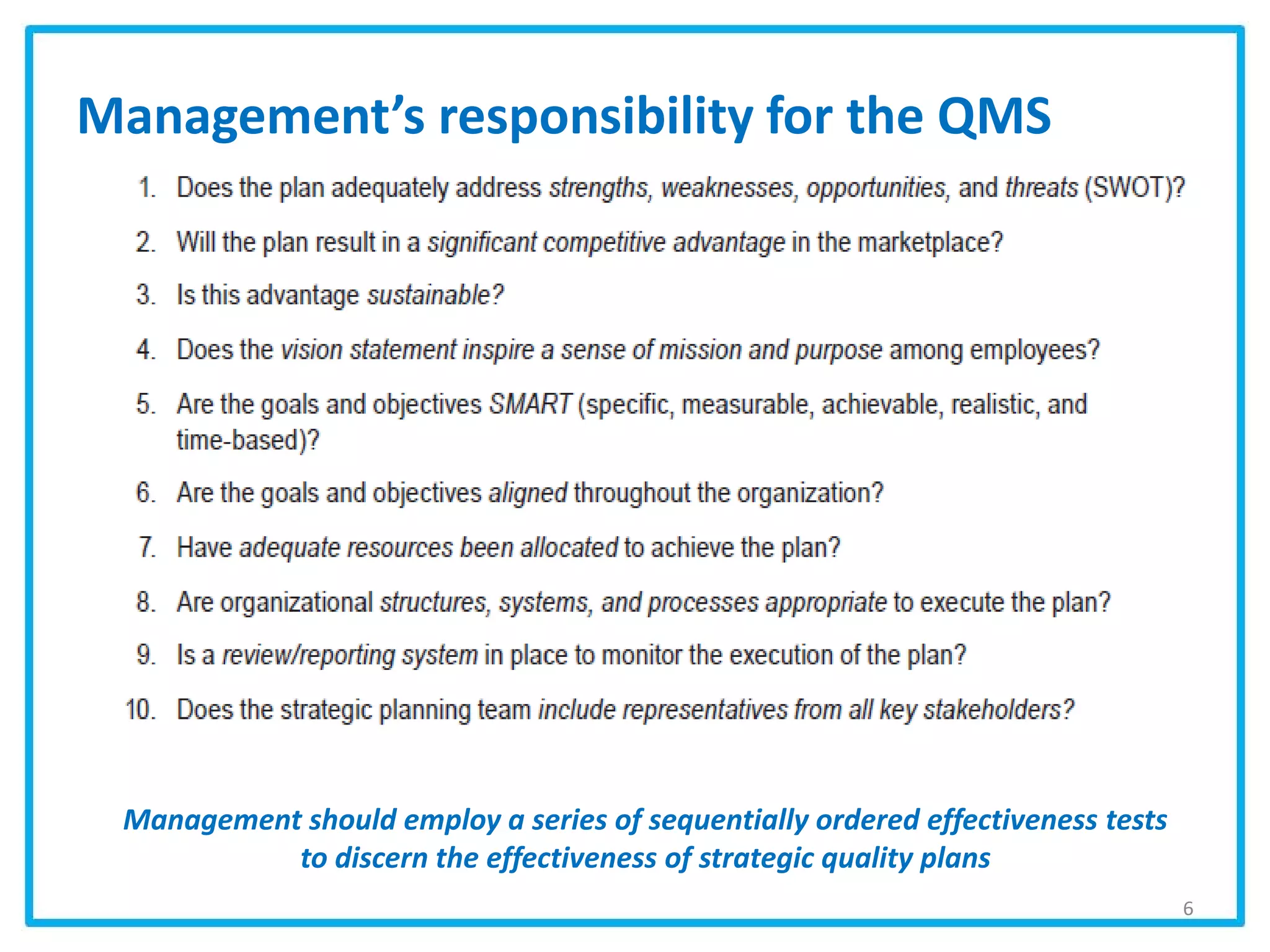

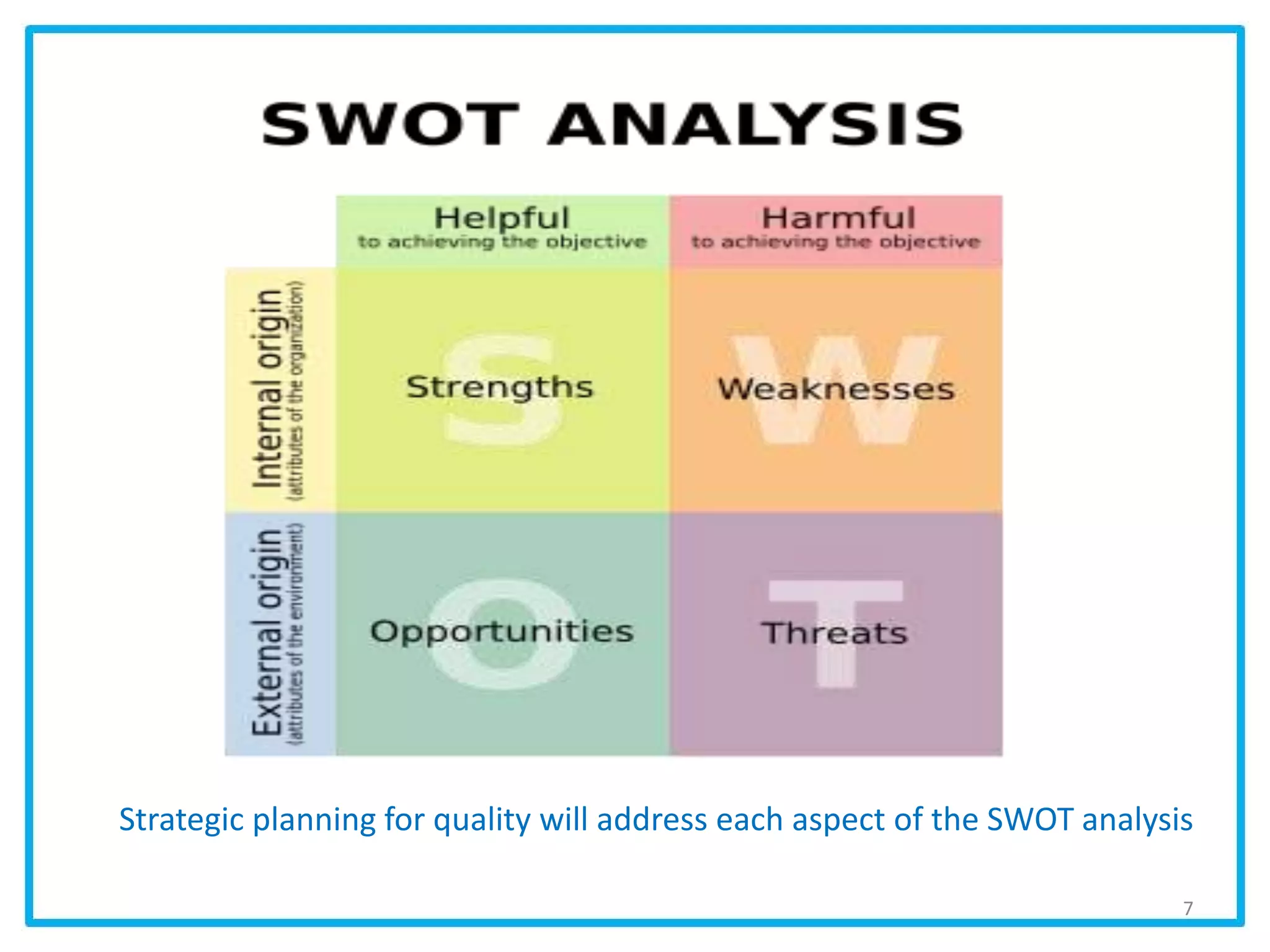

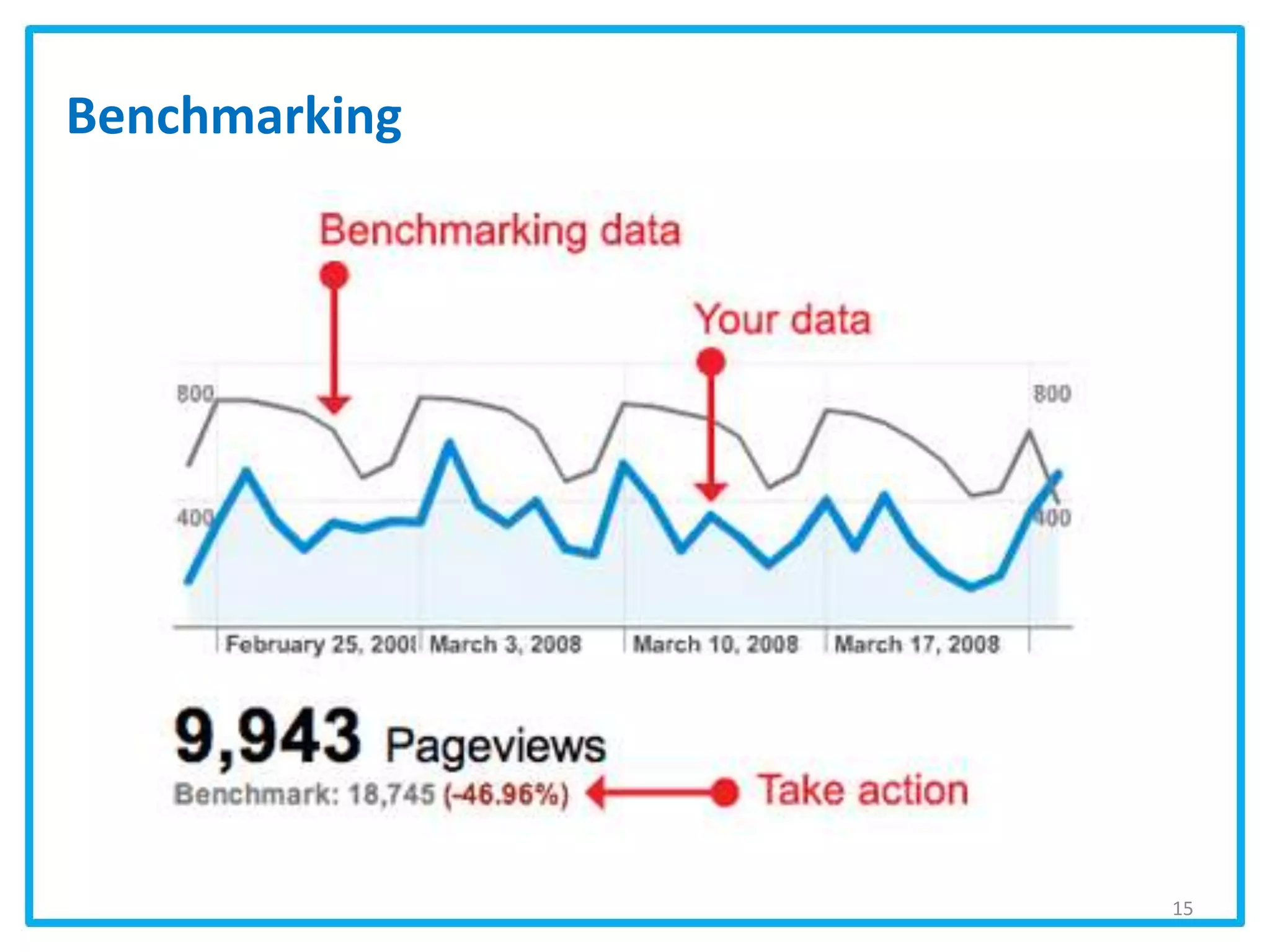

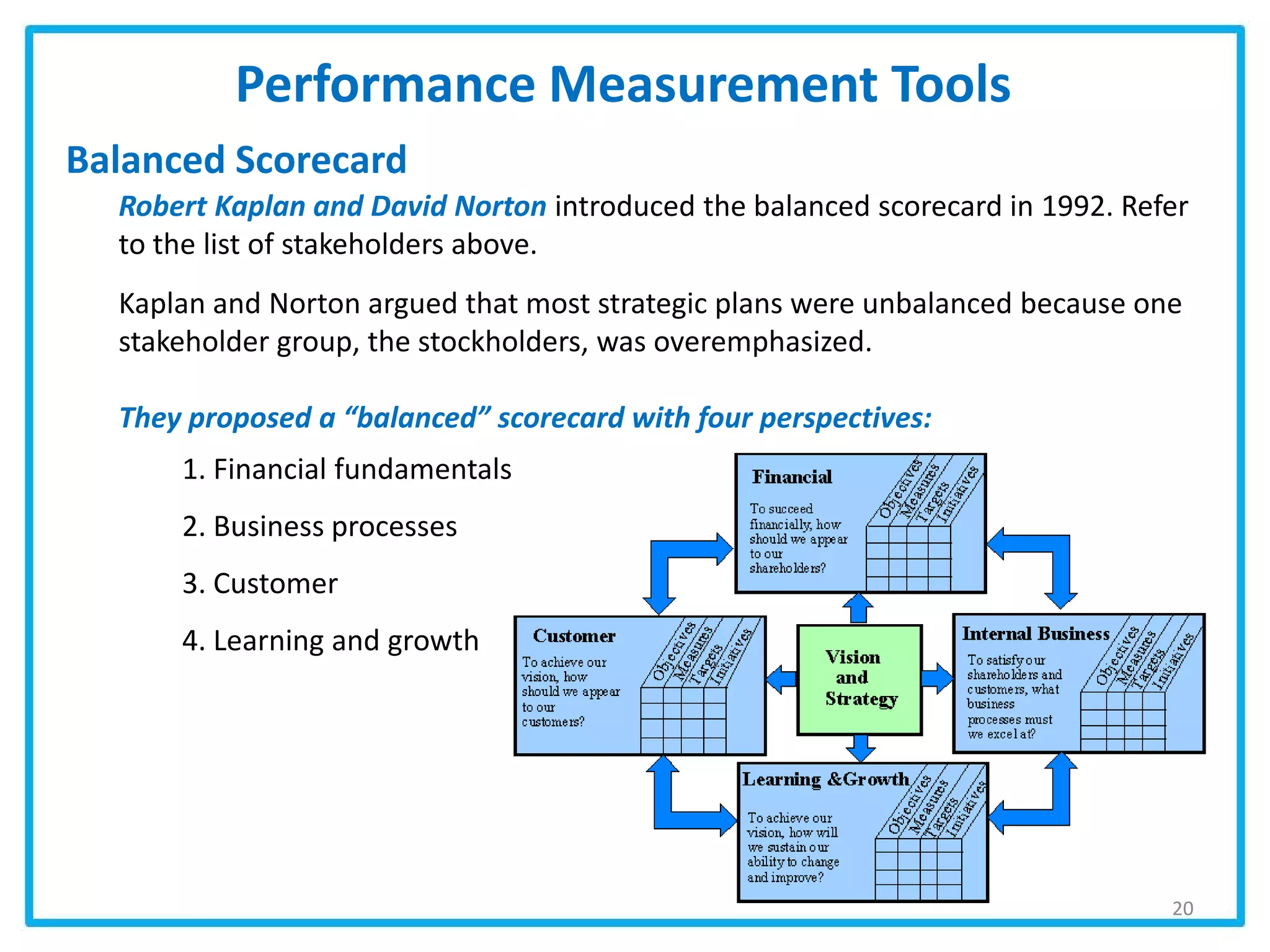

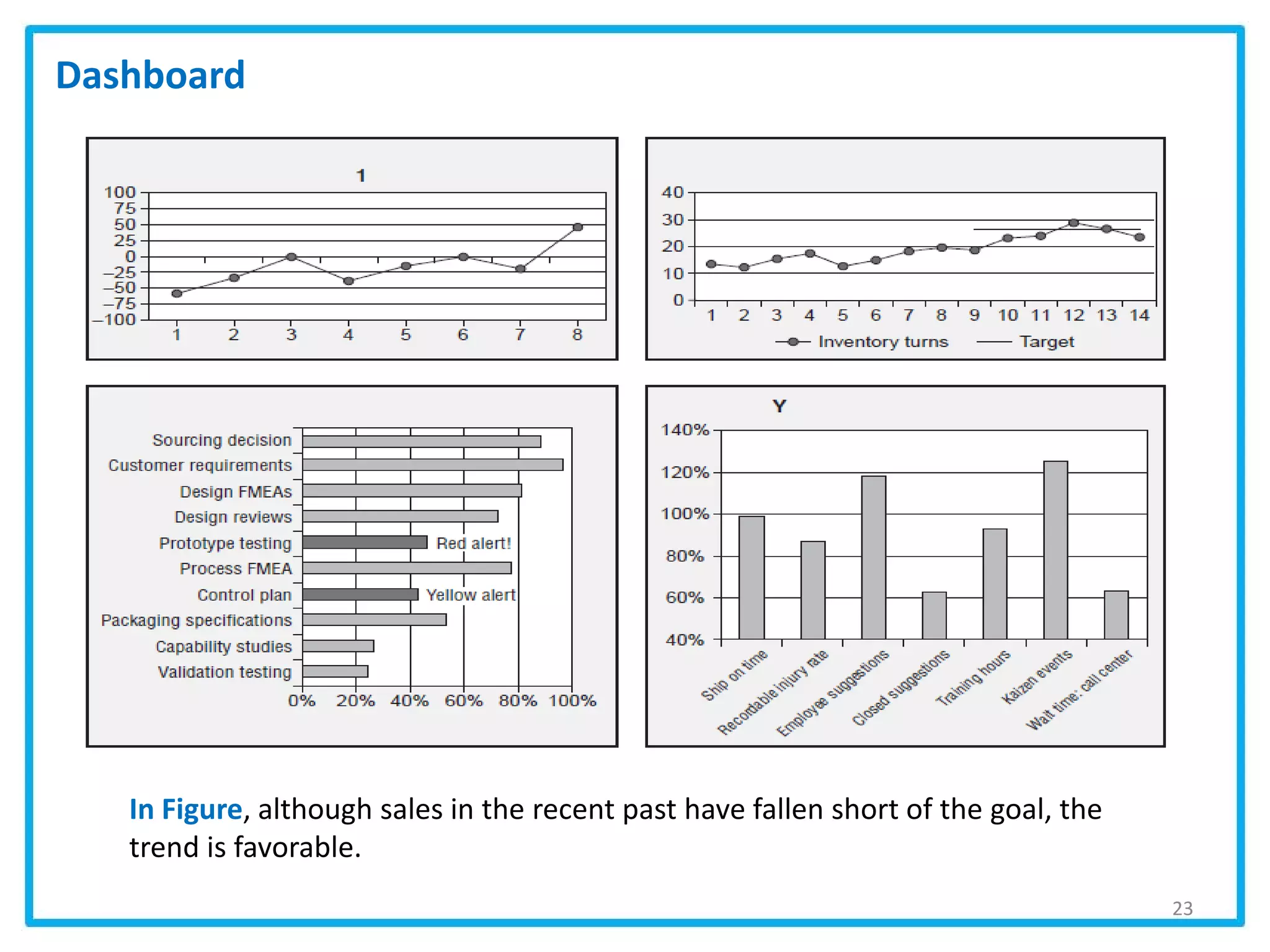

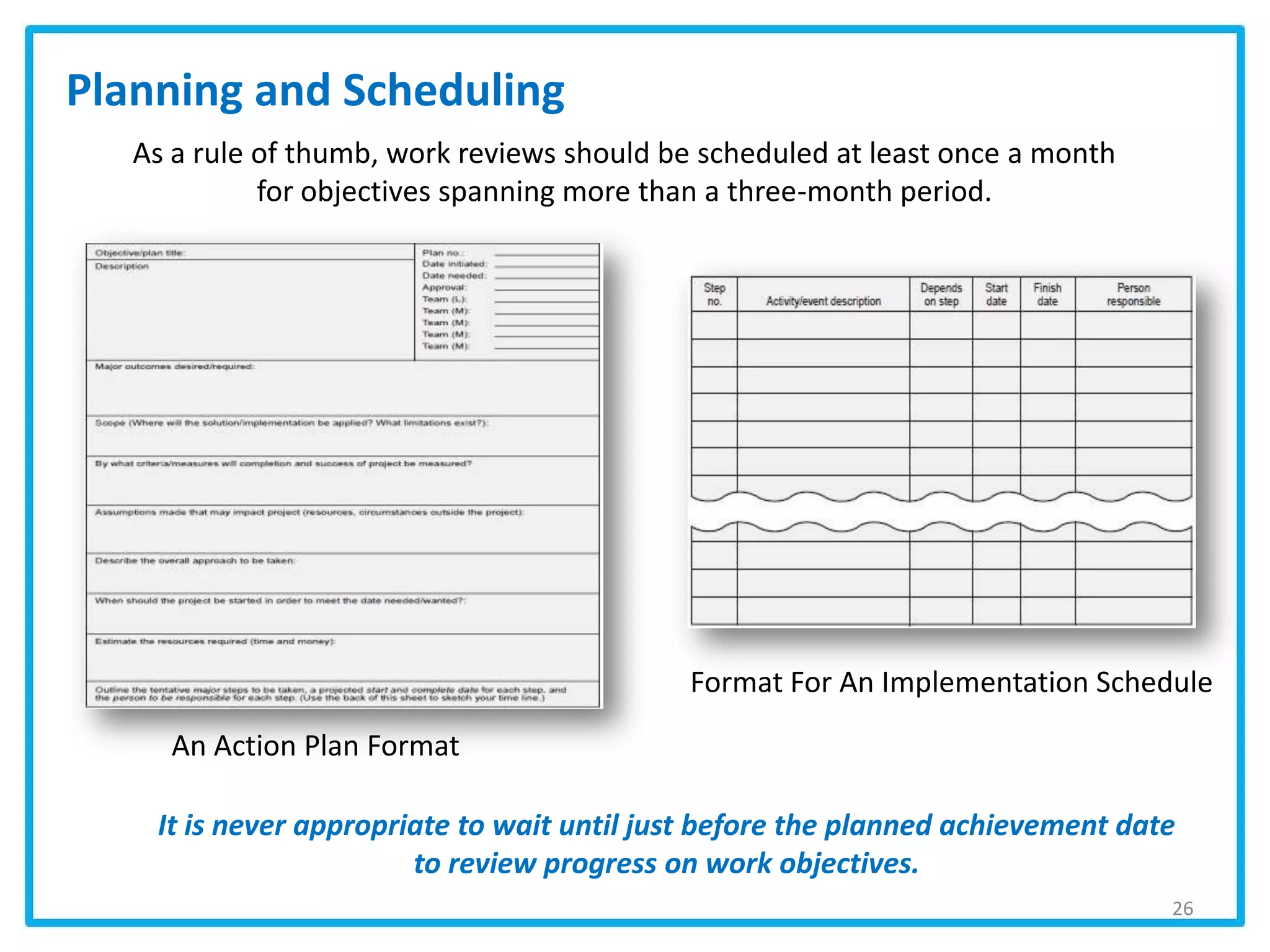

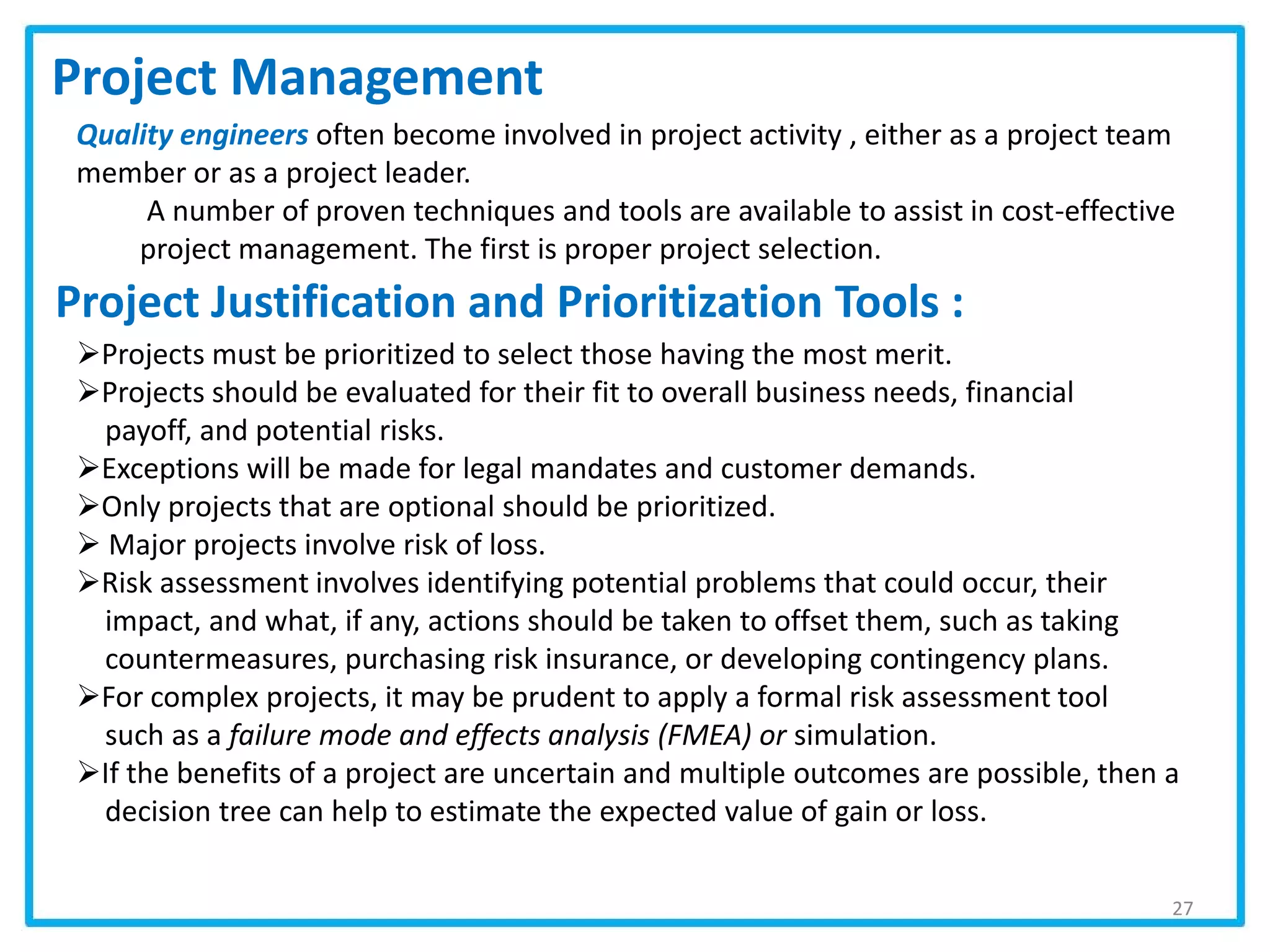

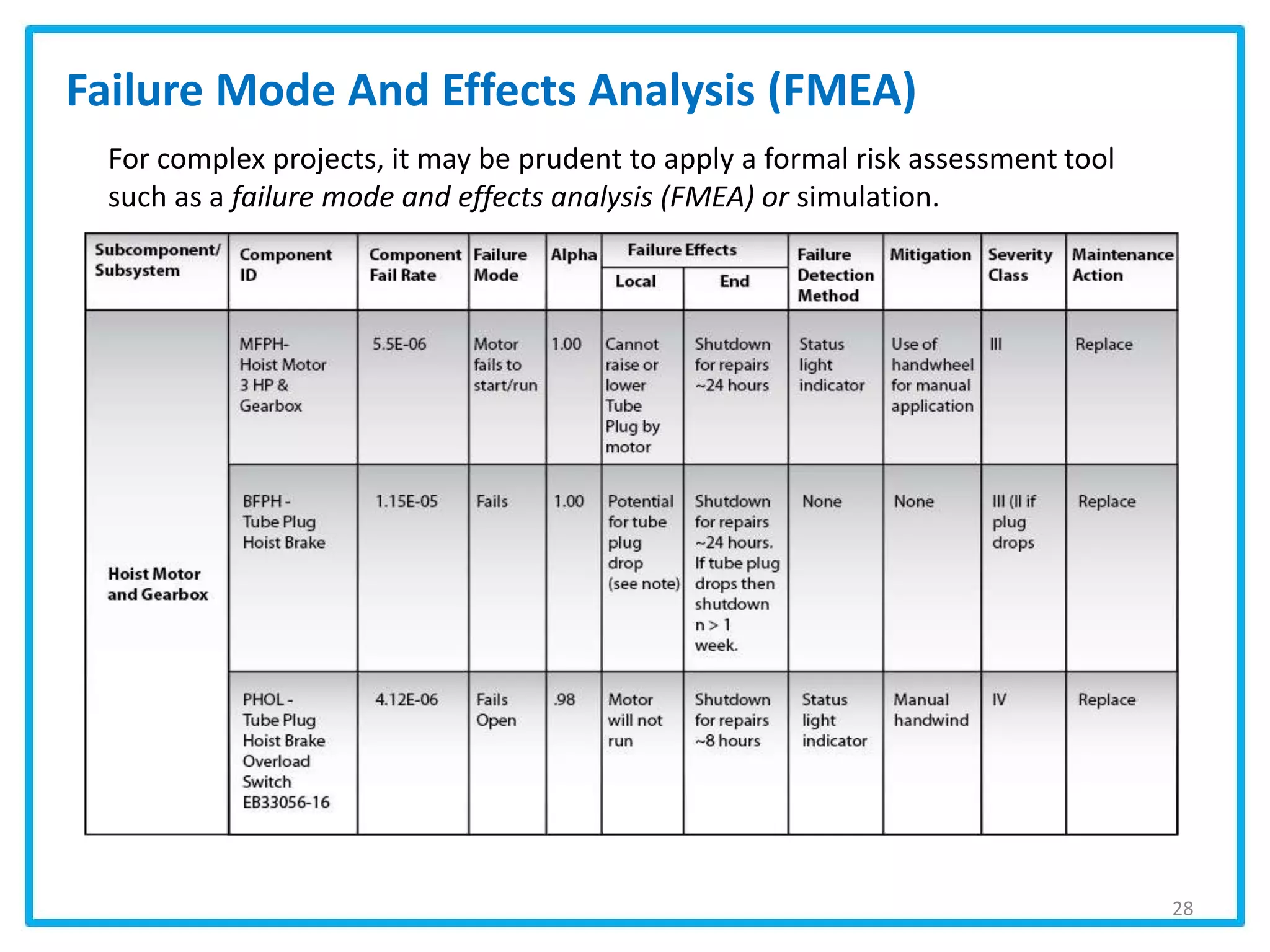

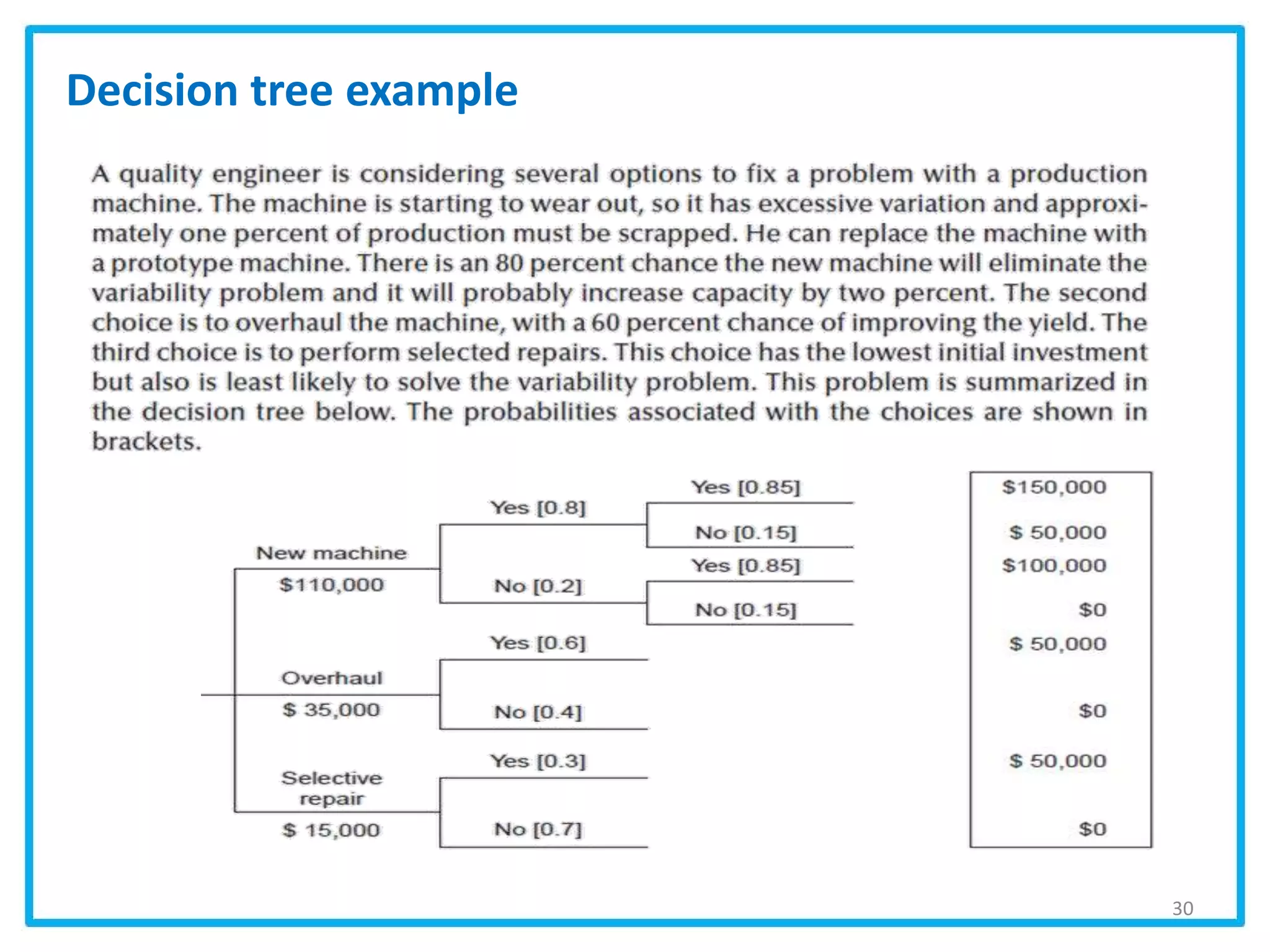

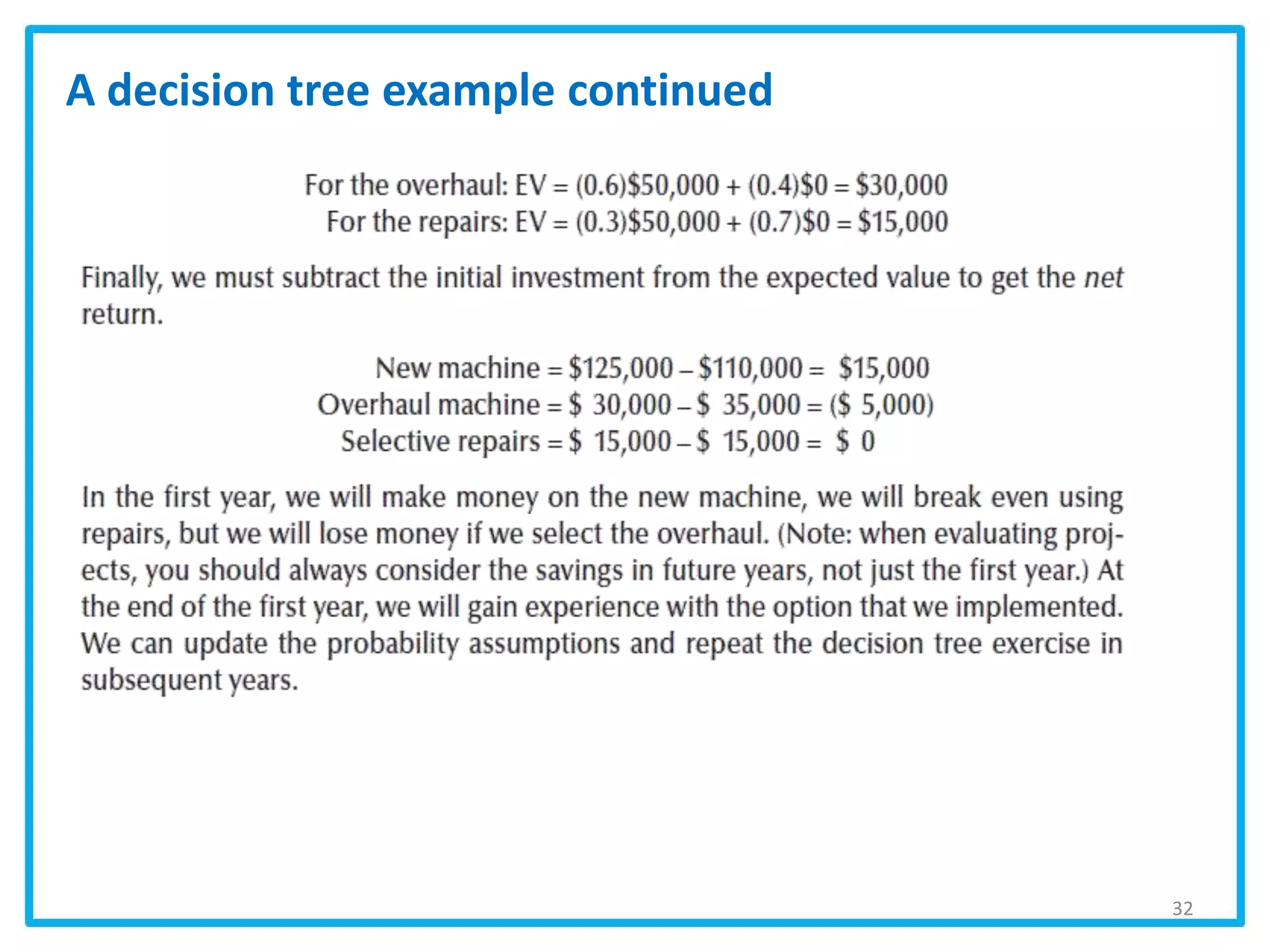

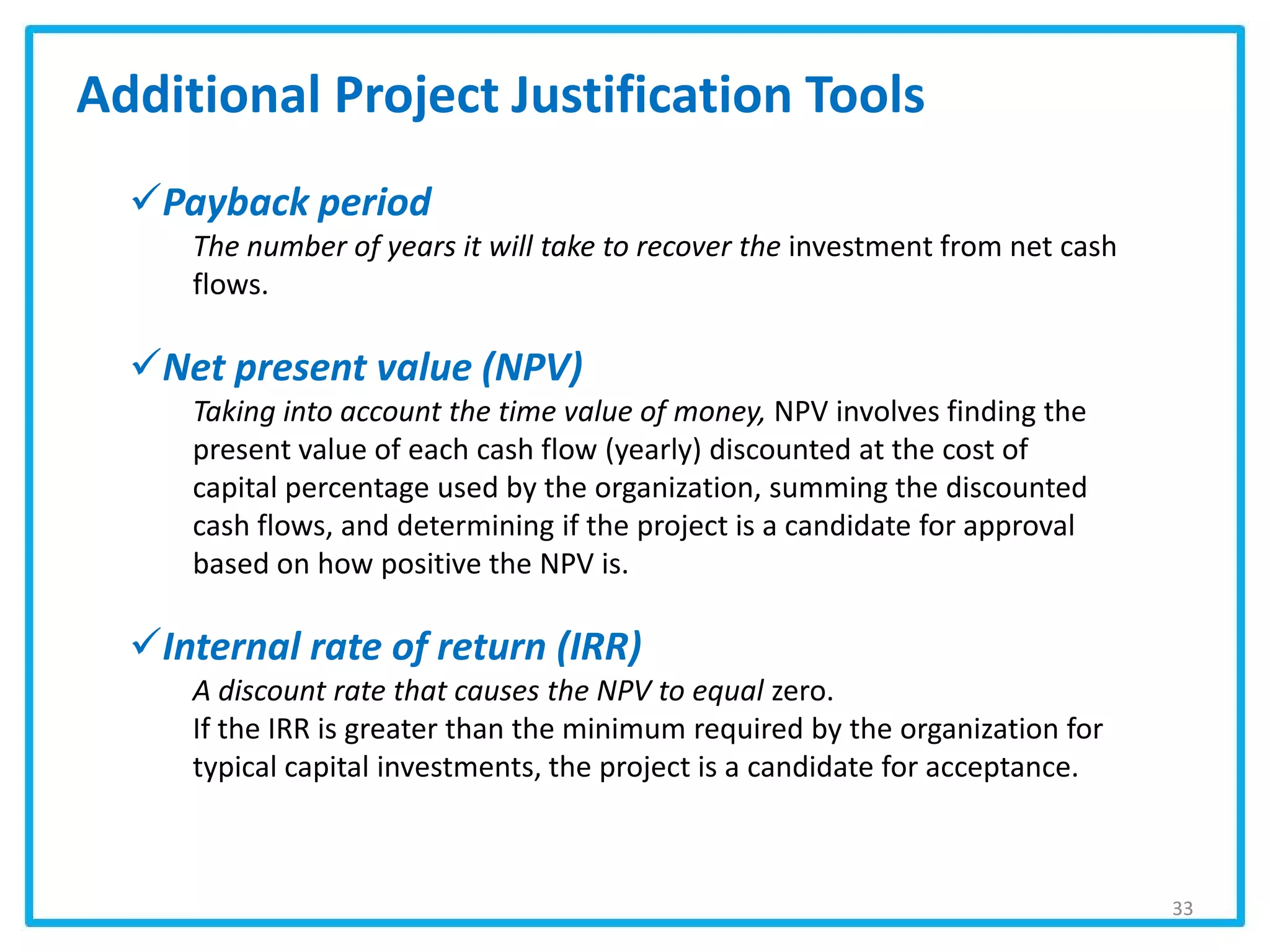

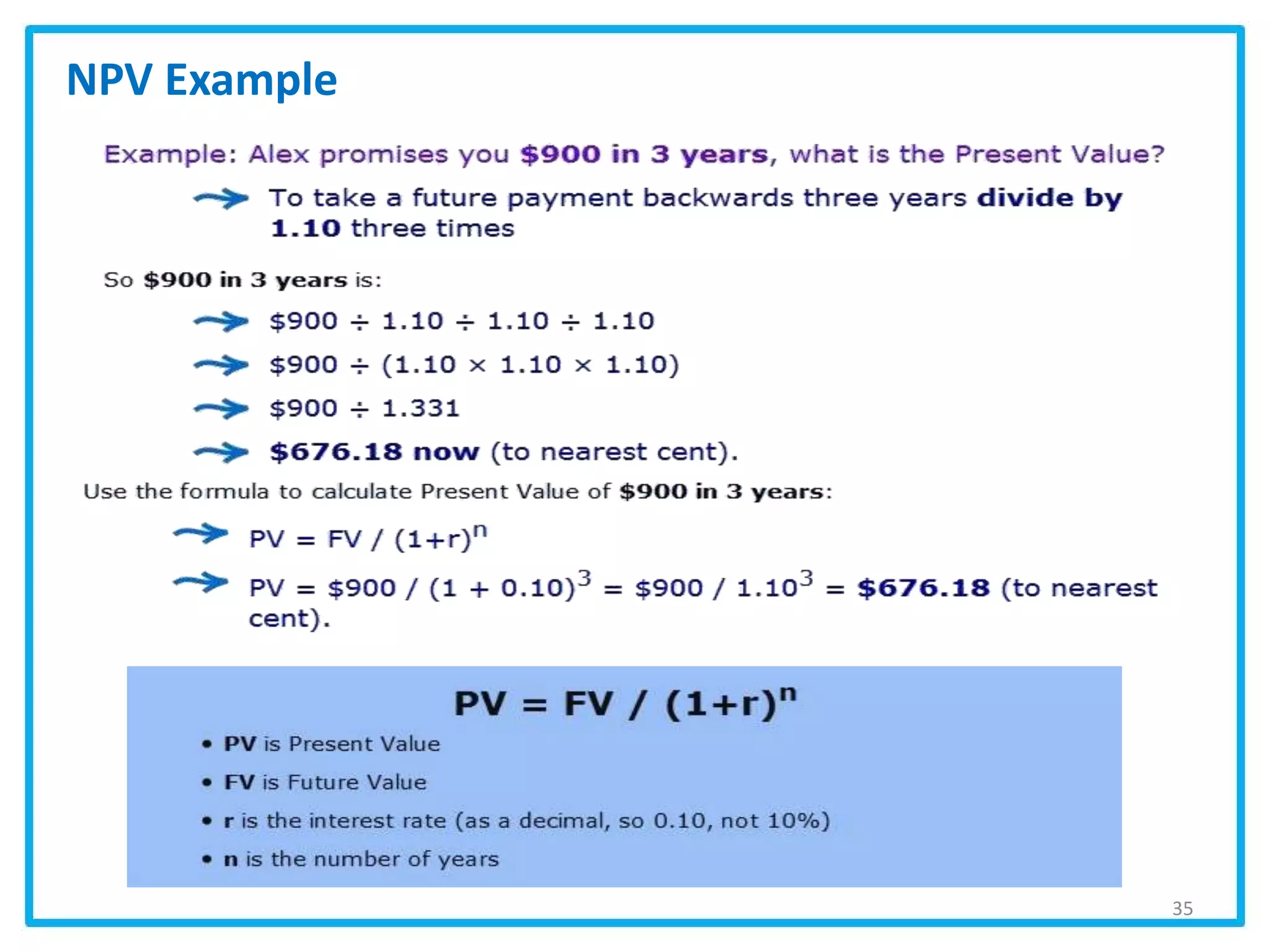

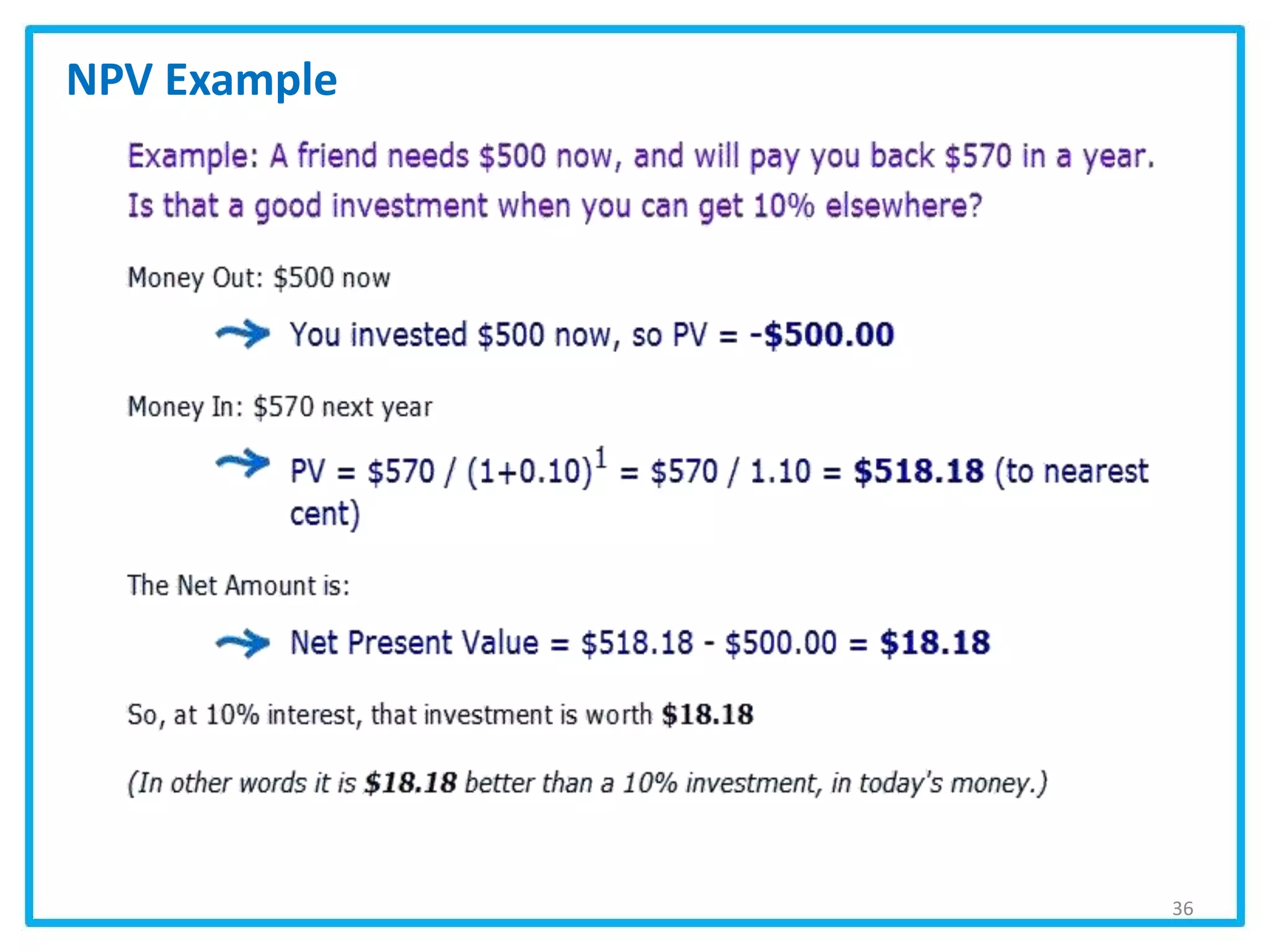

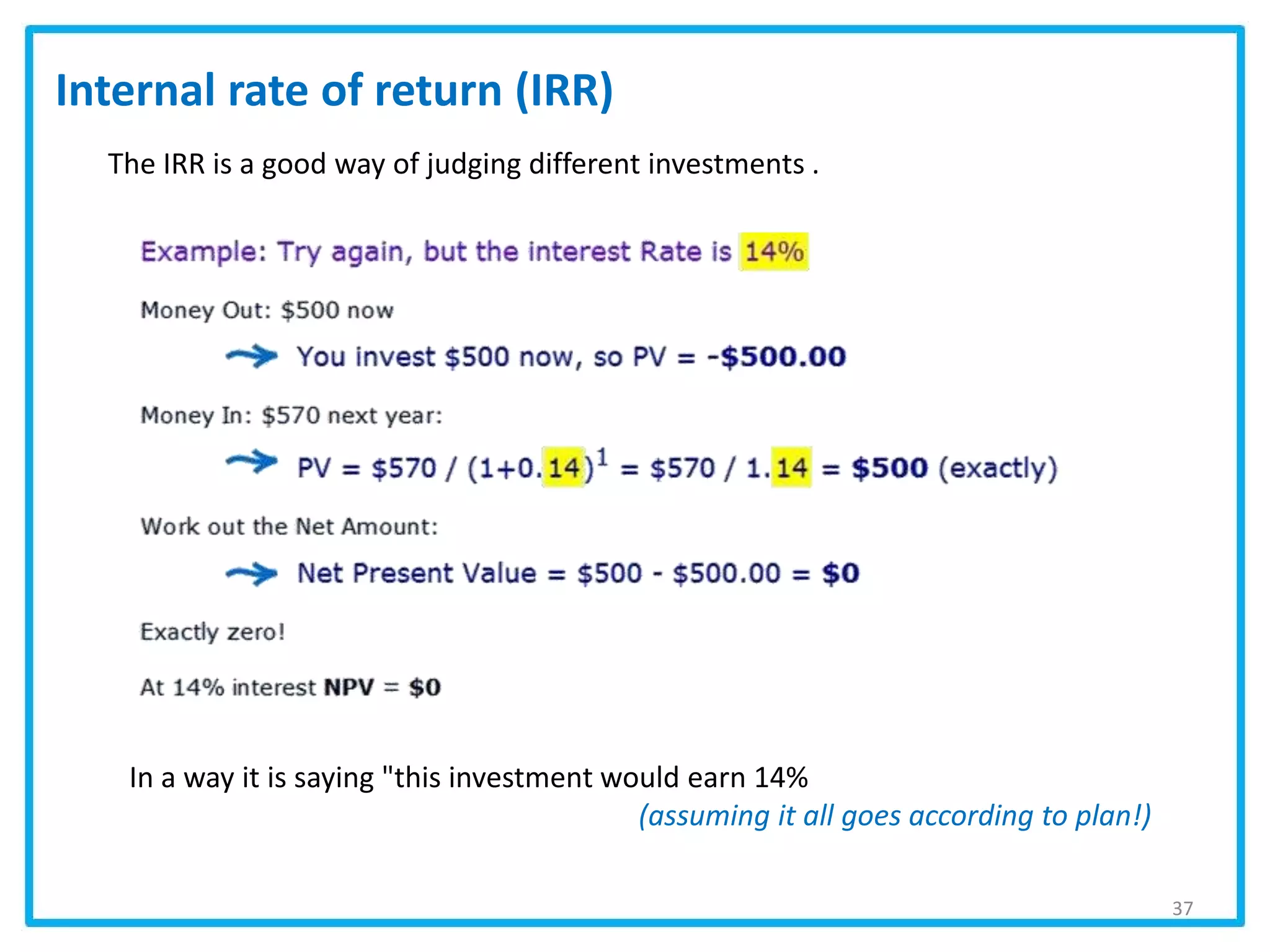

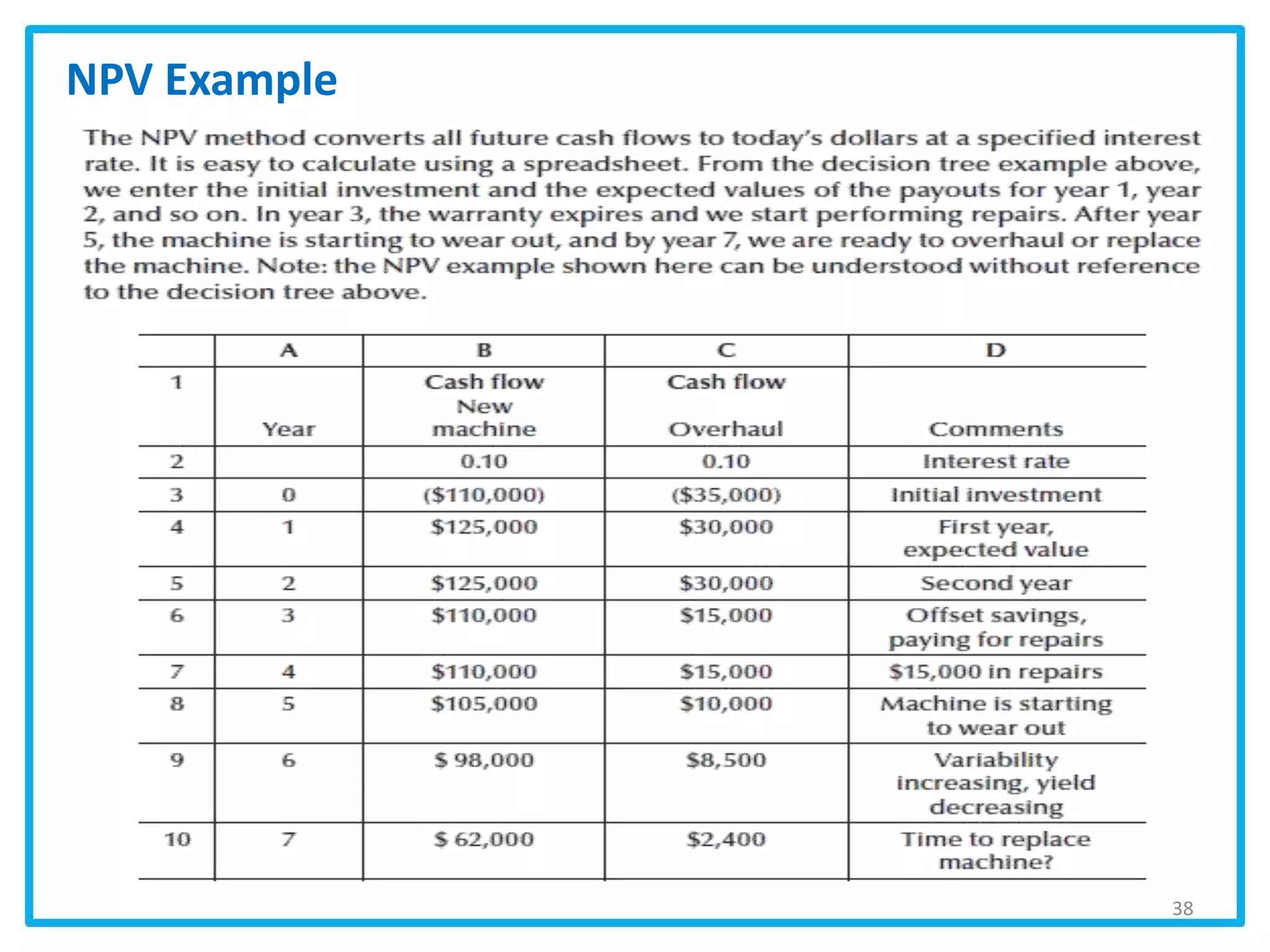

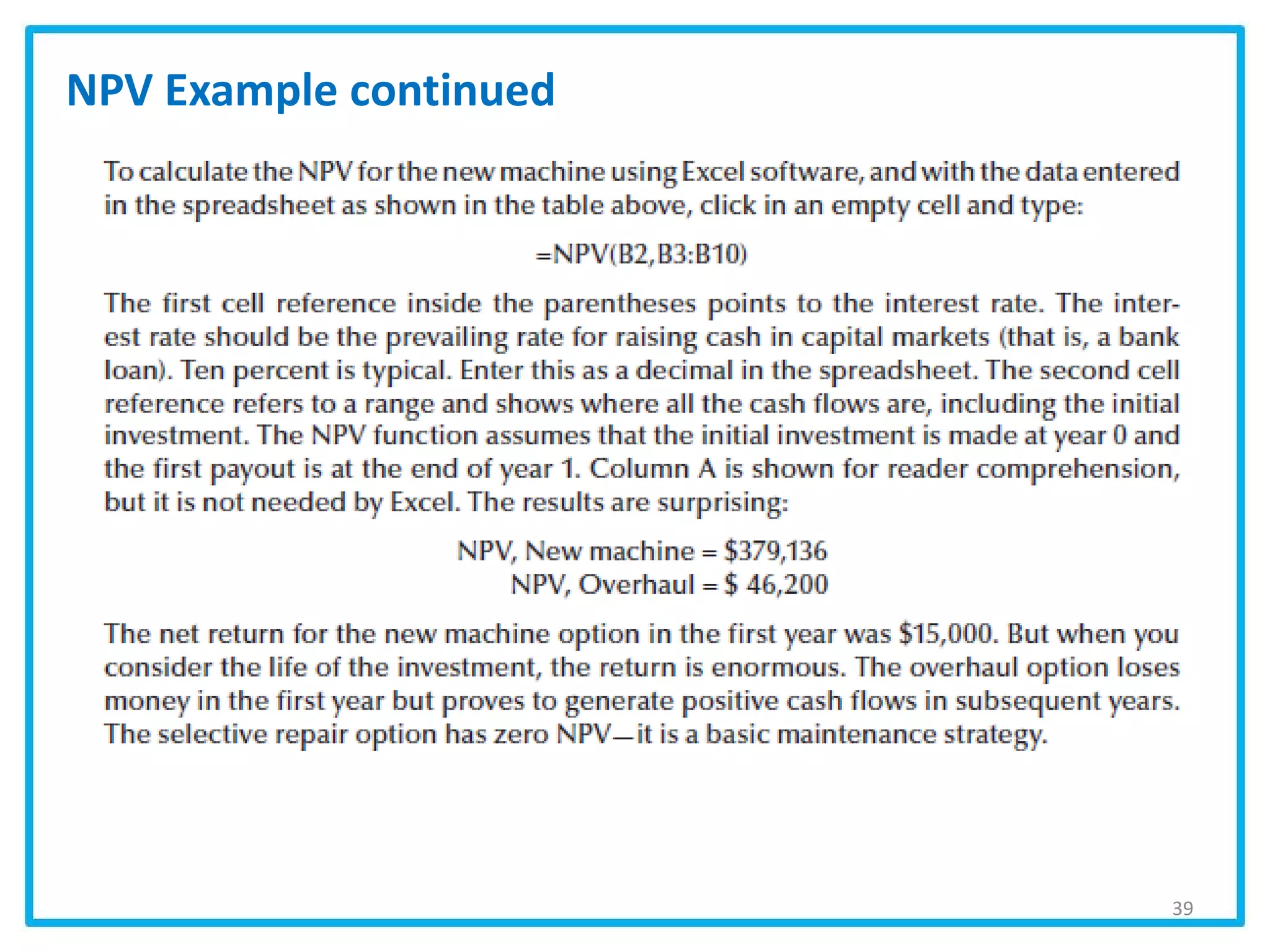

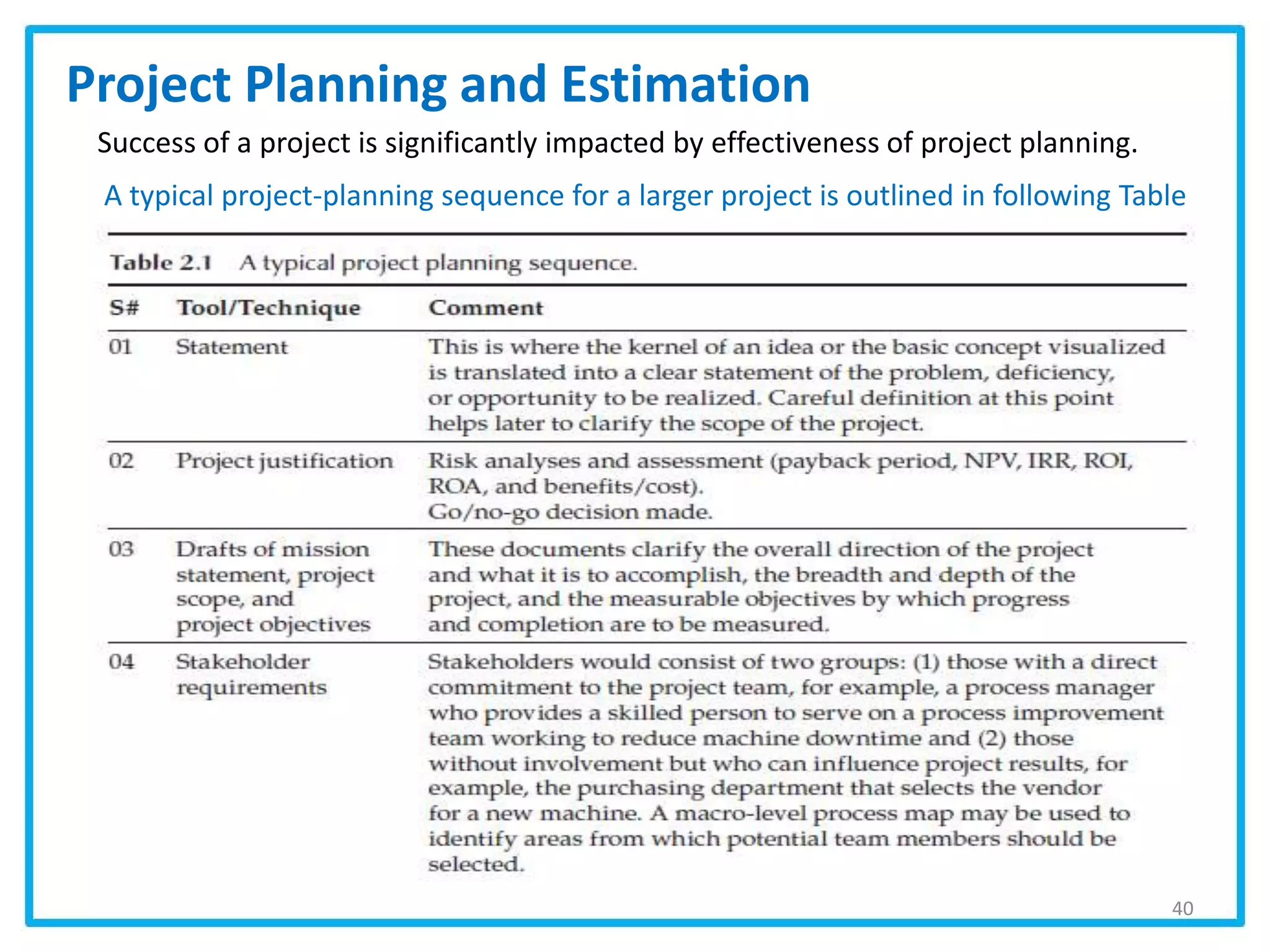

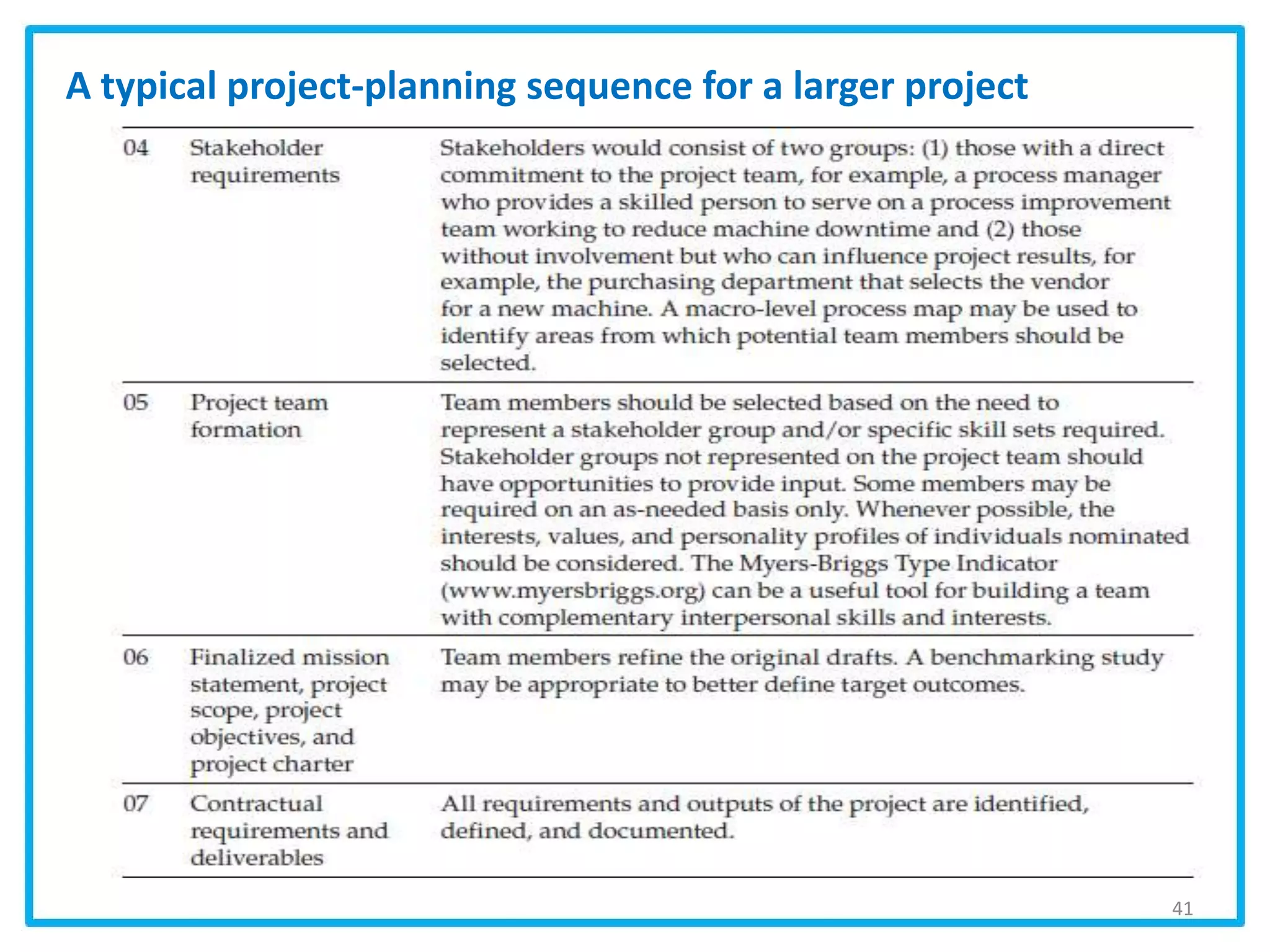

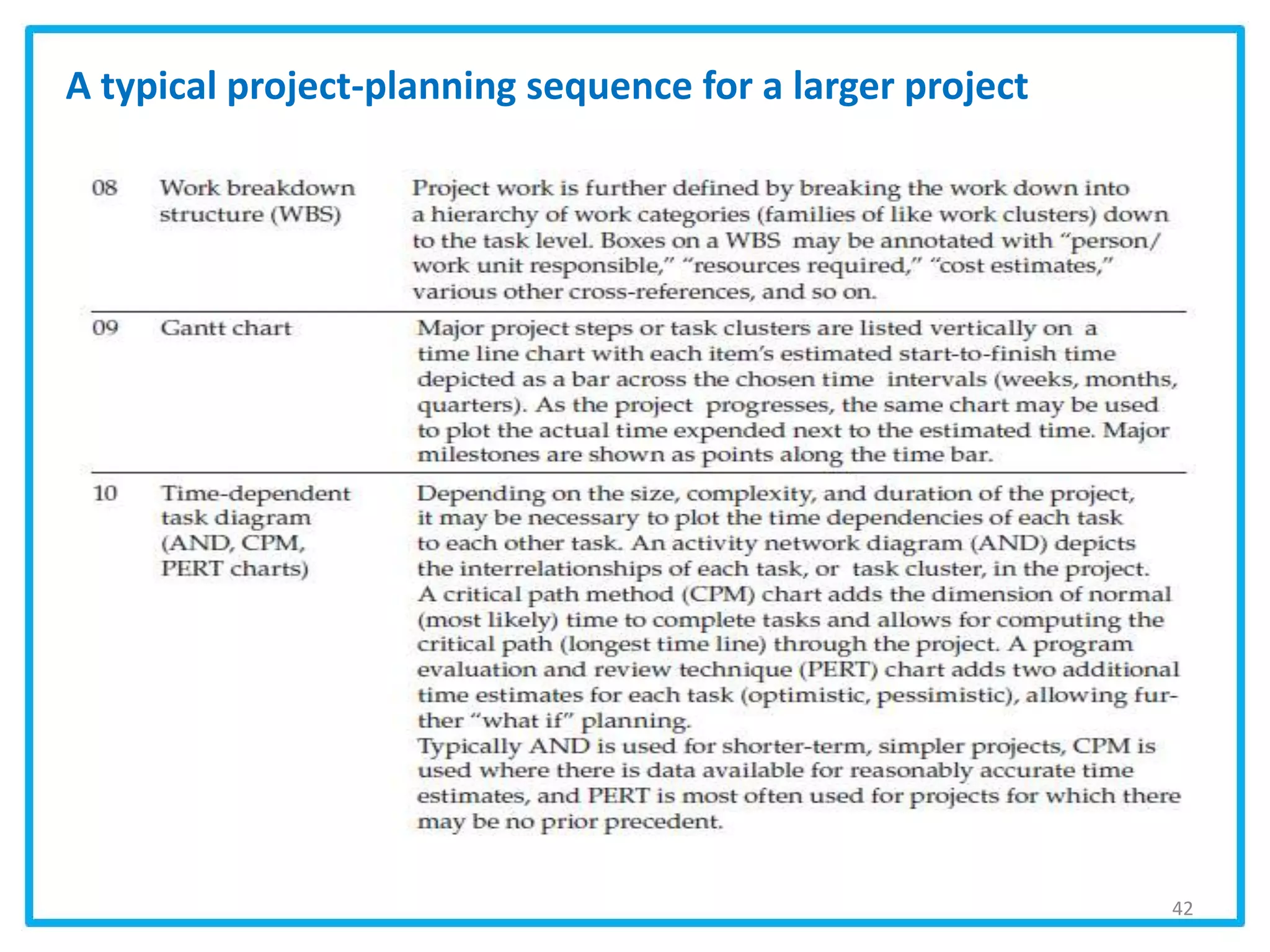

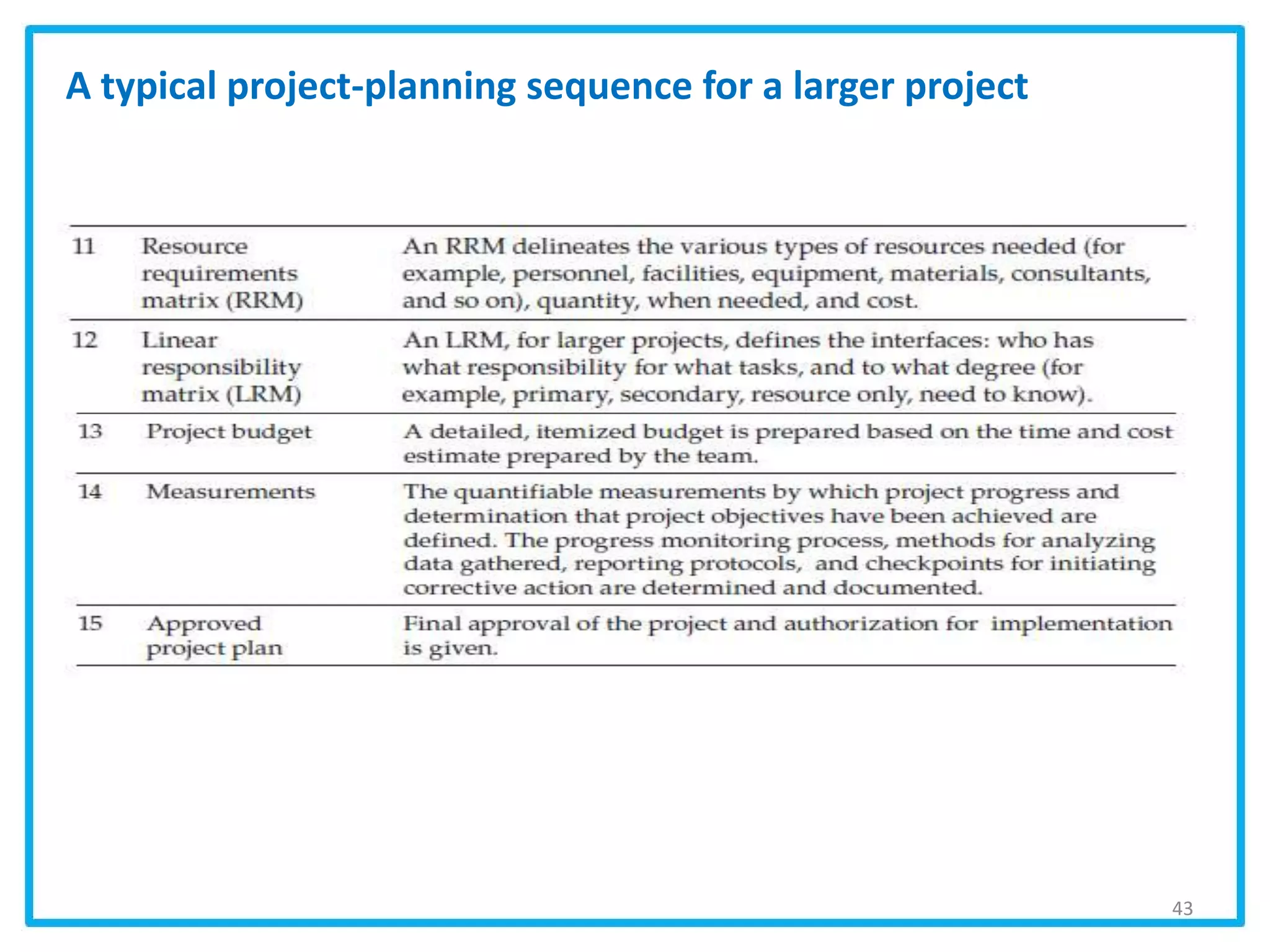

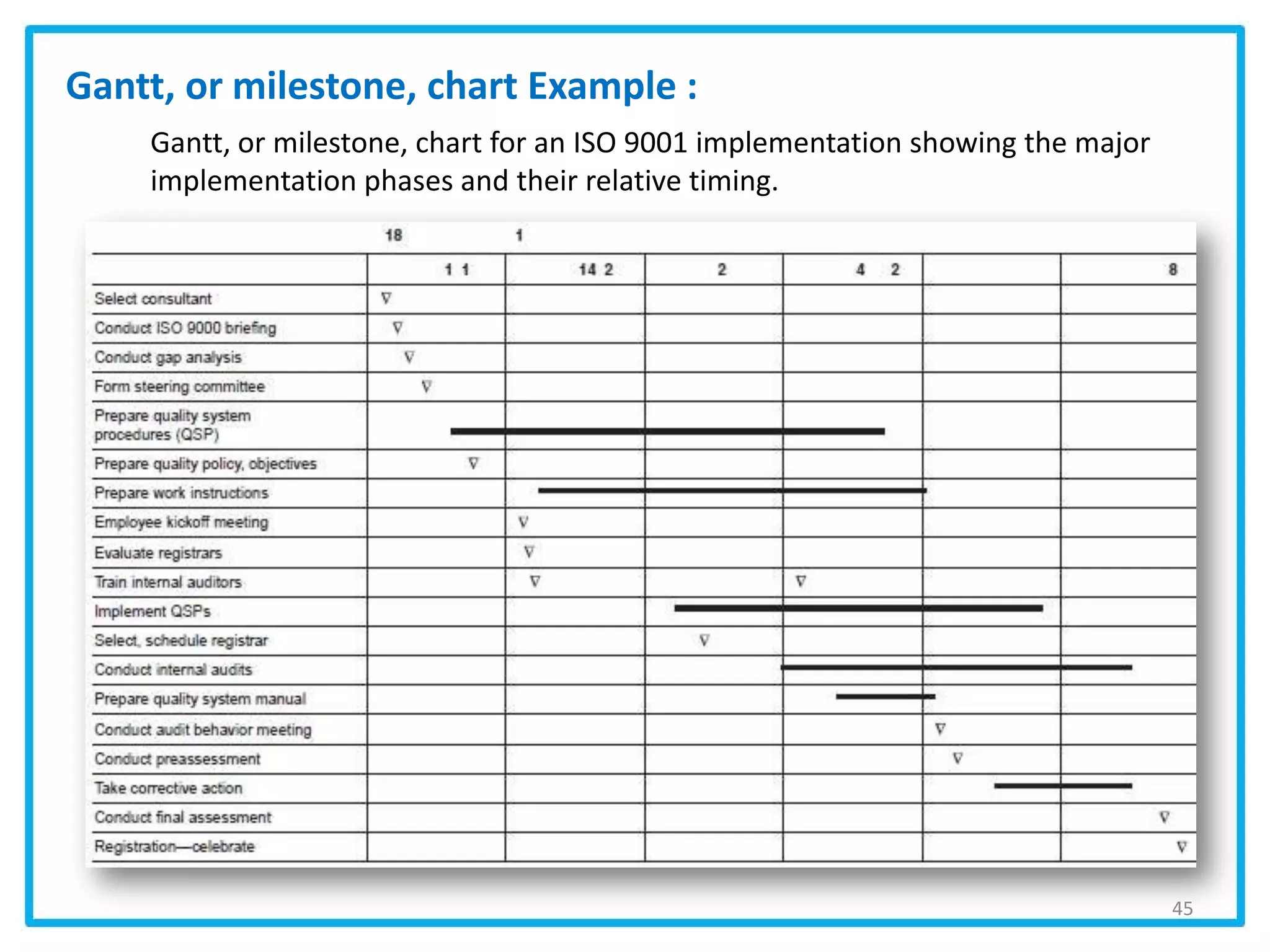

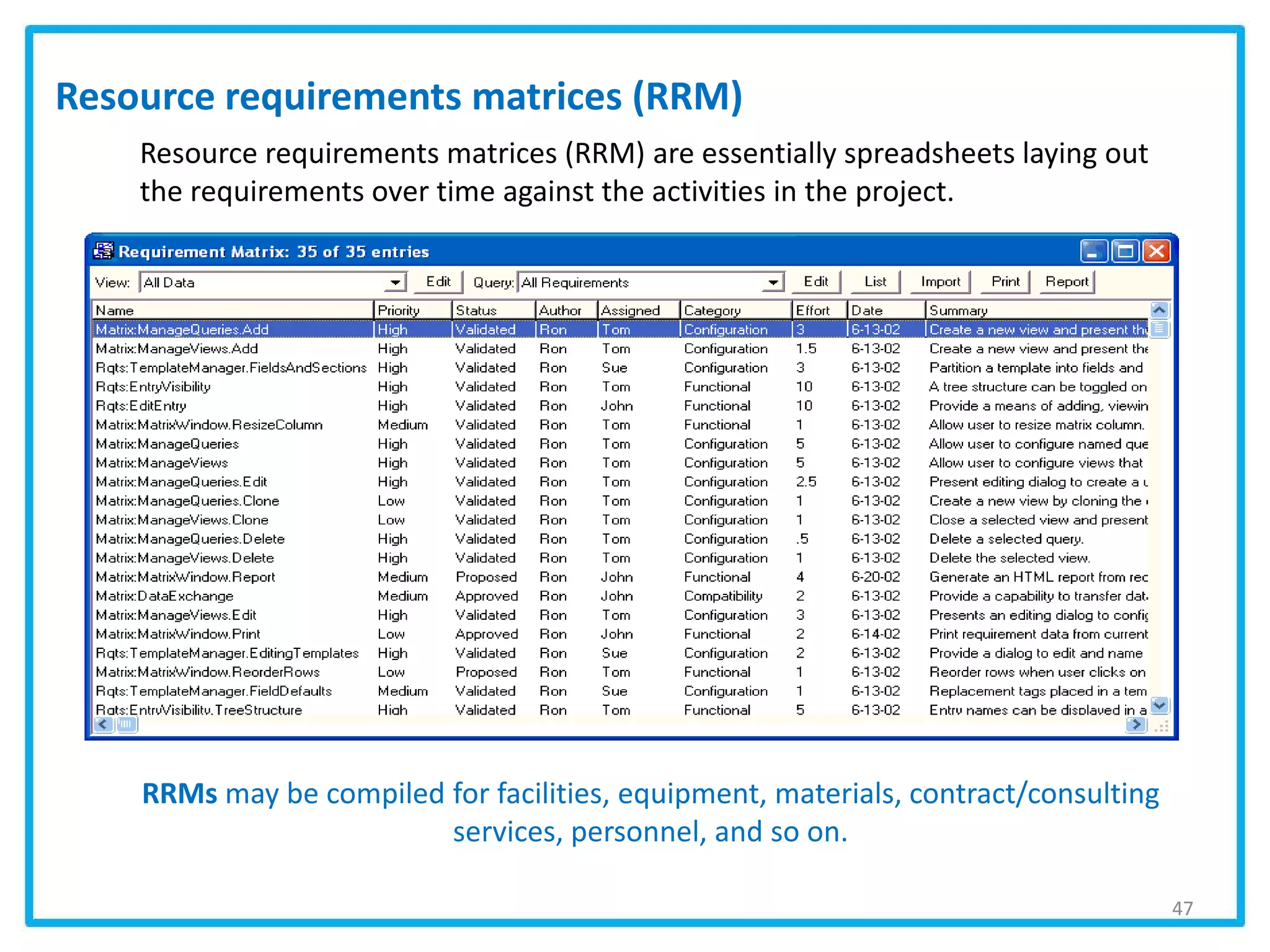

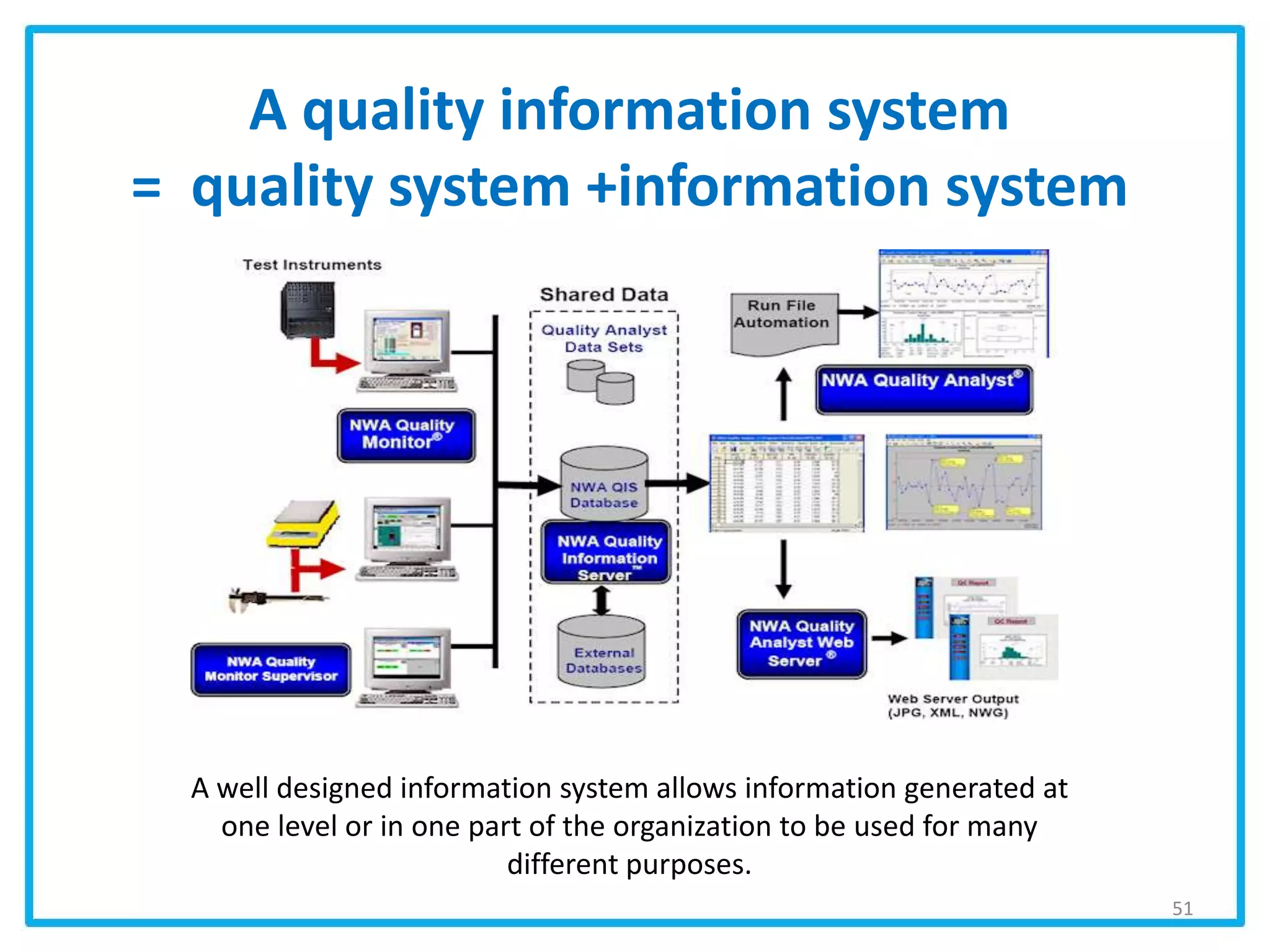

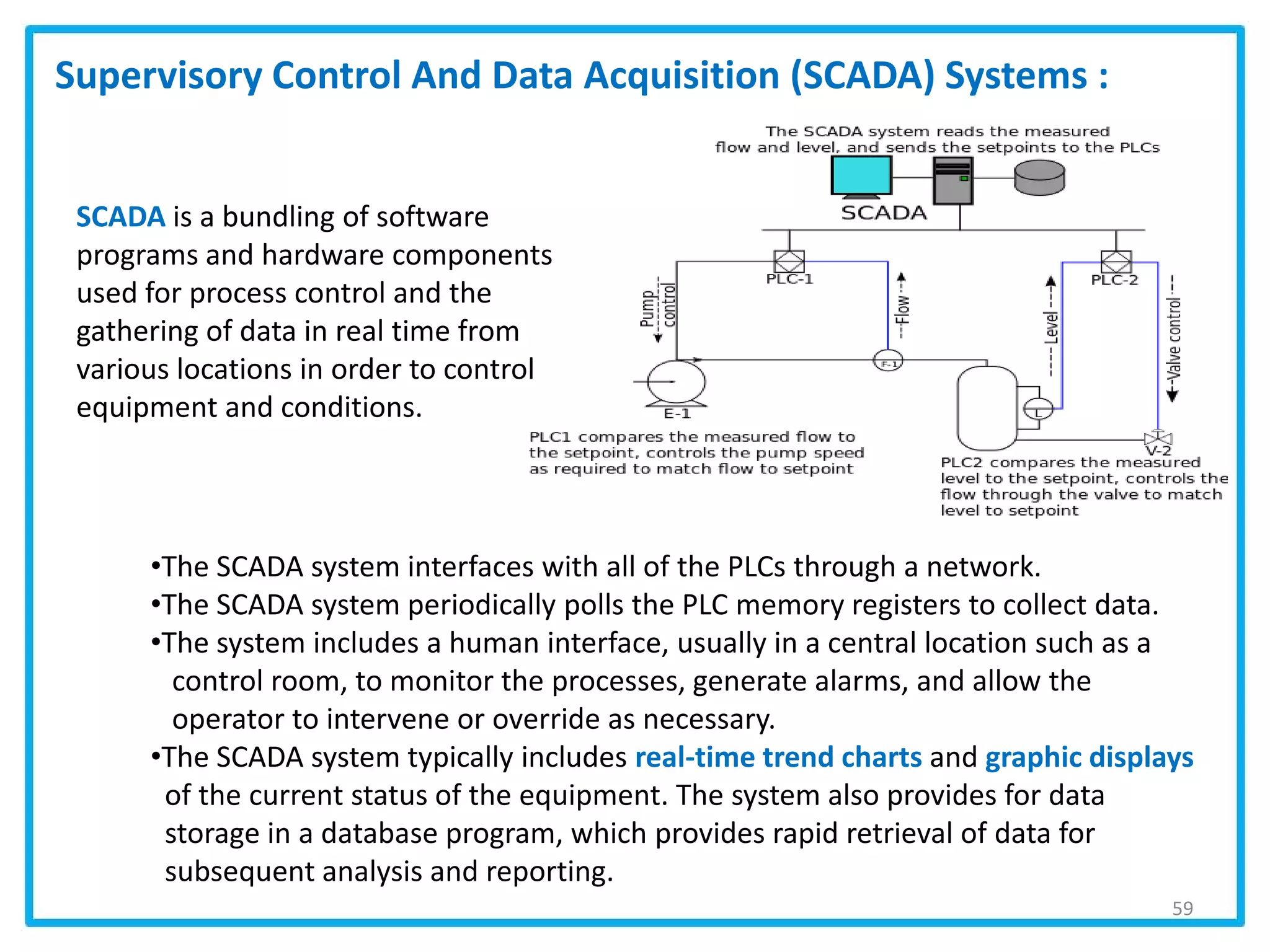

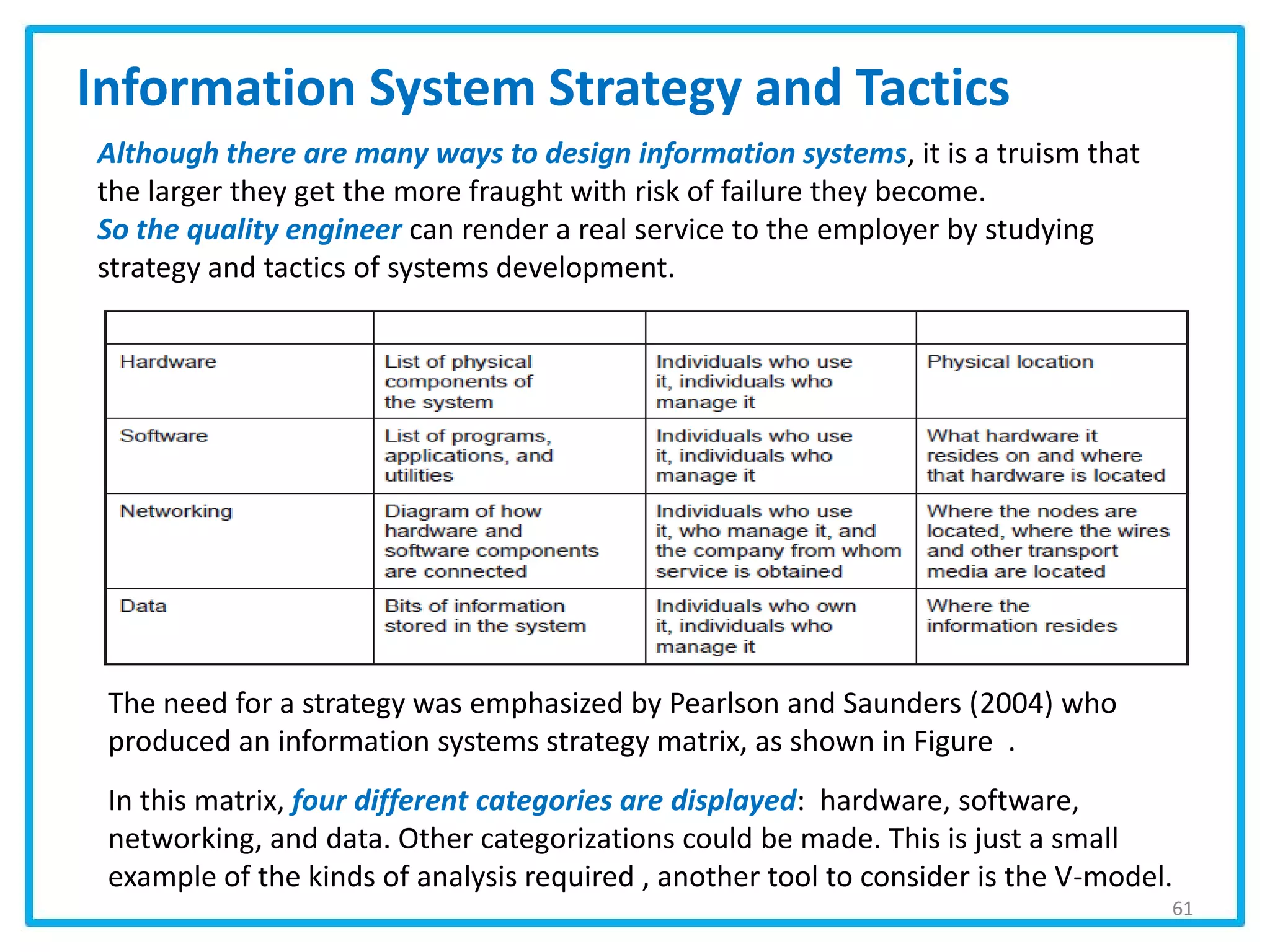

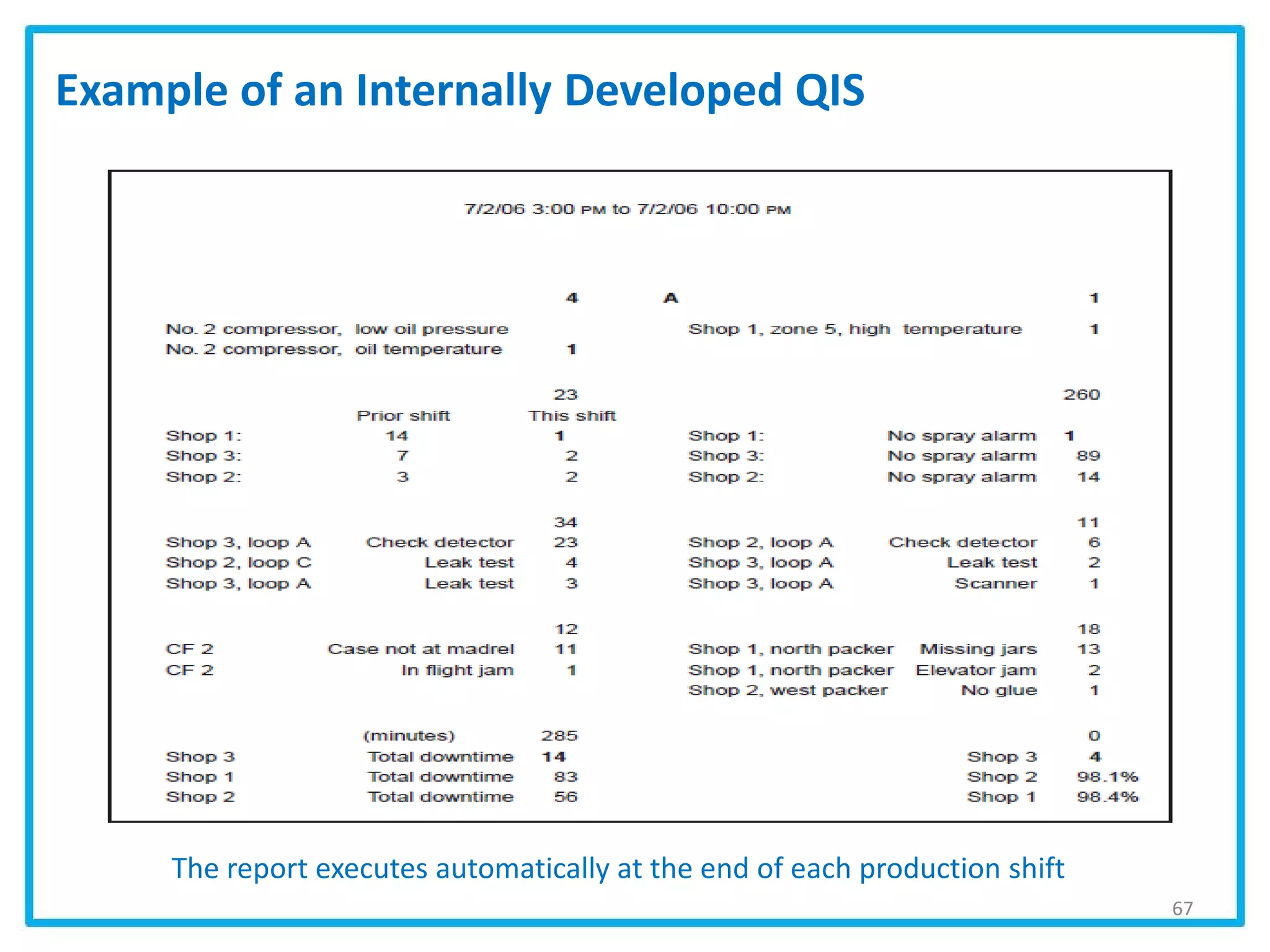

The document outlines a course on quality examination preparation focusing on management and leadership principles, emphasizing the importance of a quality management system (QMS) and strategic planning. It covers topics such as stakeholder analysis, performance measurement tools like balanced scorecards, and project management techniques including risk assessment and benchmarking. Additionally, it highlights the integral role of quality information systems in enhancing operational efficiency and improving overall quality management.