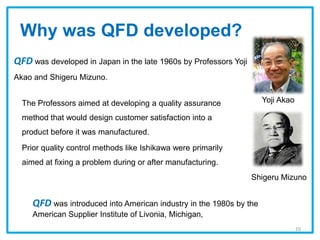

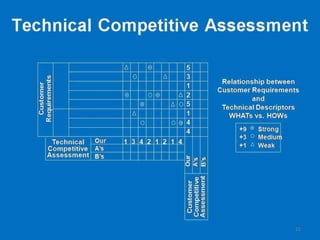

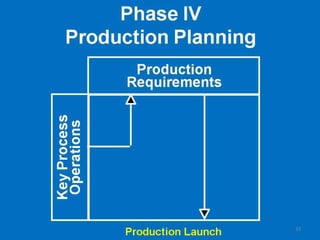

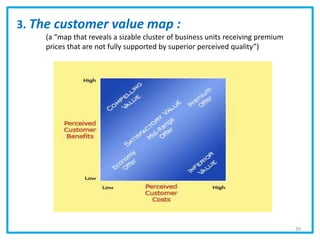

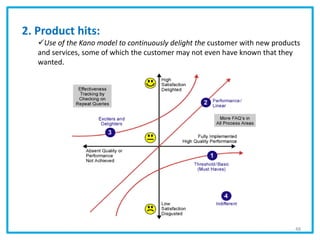

The document is a preparation course for the CQE exam focusing on management and leadership, particularly in quality engineering and customer relations. It discusses various aspects of quality management, the importance of understanding customer needs versus wants, and the methodologies like Quality Function Deployment (QFD) to improve customer satisfaction. Key takeaways include the necessity of continuous customer engagement and proactive quality planning to anticipate customer demands.