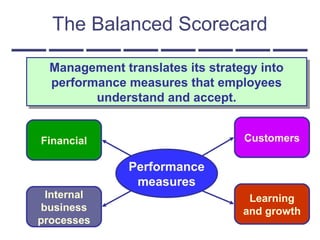

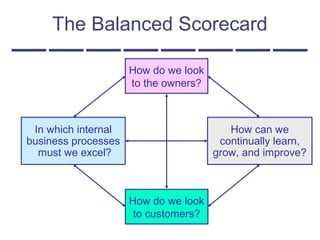

The Balanced Scorecard is a strategic planning and management system used to translate an organization's mission and strategy into a comprehensive set of performance measures. It provides managers with a fast and comprehensive view of the organization from four important perspectives: financial, customer, internal business processes, and learning and growth. The four perspectives are interconnected, with internal business processes affecting customer satisfaction, customer satisfaction affecting financial outcomes, and continuous learning and improvement affecting all areas.