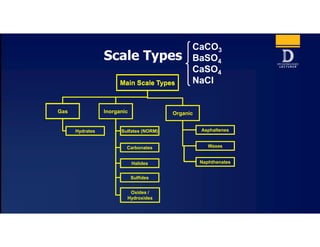

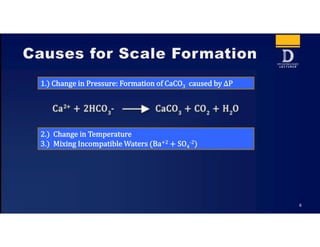

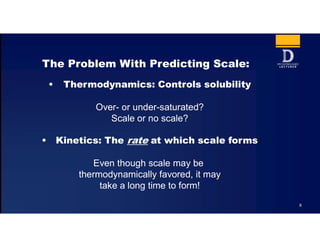

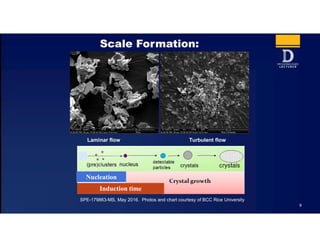

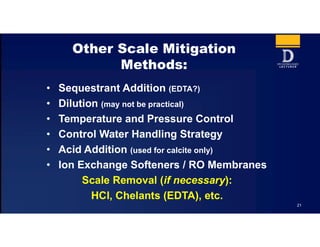

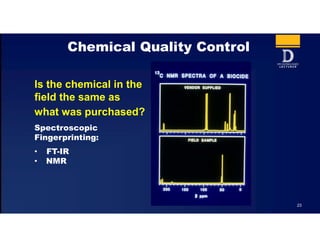

The document discusses a presentation on controlling scale deposition in oil fields. Primary funding for the Society of Petroleum Engineers Distinguished Lecturer Program comes from member donations and contributions from industry partners. The presentation covers topics like scale types, prediction, inhibition strategies, case studies, and chemical quality control. Preventing scale before it starts to form is emphasized as the most cost-effective approach to dealing with scale formation in oil and gas production.