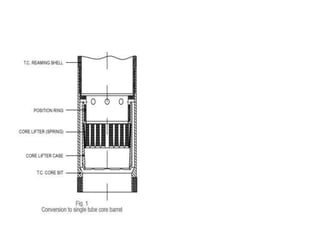

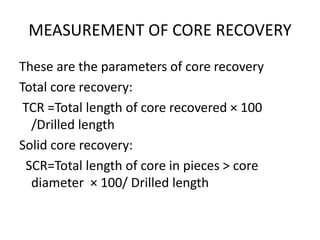

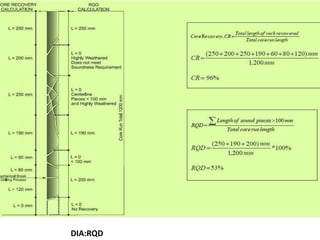

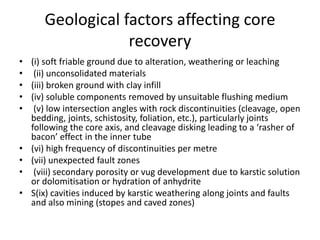

This document discusses core recovery methods used in drilling. It describes rotary core drilling where a tube with teeth is rotated to cut a cylindrical core sample from rock. Parameters for measuring core recovery include total core recovery and solid core recovery. Rock Quality Designation (RQD) is also discussed, which evaluates core pieces over 100mm in length. Technical factors like bent drilling equipment and geological factors like soft or fractured rock can negatively impact core recovery.