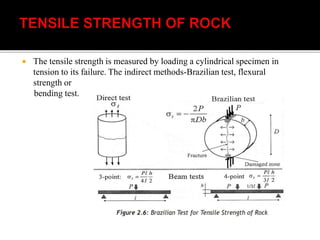

The document discusses rock mechanics engineering, focusing on the mechanical properties of rock and their application in engineering problems related to mining and excavation. It highlights the importance of proper blasting techniques, stability analysis of underground structures, and the design of pillars and stopes to ensure safety and efficiency in mining operations. Key factors such as rock stress, material properties, and environmental considerations are crucial for successful mining feasibility studies and structural designs.