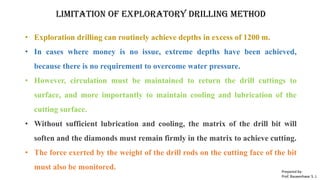

The document discusses the importance of geological investigations in civil engineering projects, emphasizing the need for engineers to understand the geological conditions to avoid costly structural failures. It outlines the main objectives of geological investigations, various methods for surface and subsurface exploration, and techniques for core logging and preservation. Additionally, it highlights the limitations of exploratory drilling methods and the critical nature of accurate data collection for geotechnical analysis.

![Objects

The main objects of geological investigations

for most engineering projects are to determine:

• The geological structure of the area;

[Topography]

• The lithology of the area;

[Type of rocks and properties]

• The ground water conditions in the region;

[Water table]

• The seismicity of the region;

[Earthquake and settlement parameters]

Prepared by-

Prof. Basweshwar S. J.](https://image.slidesharecdn.com/module-4eg-220404085914/85/MODULE-4-EG-pdf-3-320.jpg)