This document describes a contouring control method for CNC machine tools using a linear parameter-varying (LPV) controller. It involves transforming the axis coordinates into a task frame defined by the toolpath direction and velocity. An LPV feedback controller is designed as a function of the toolpath trajectory direction and velocity to minimize estimated contouring error while suppressing vibration. Weighting functions in the controller design are tuned to improve contouring accuracy and bandwidth by adjusting parameters like gains and crossover frequencies.

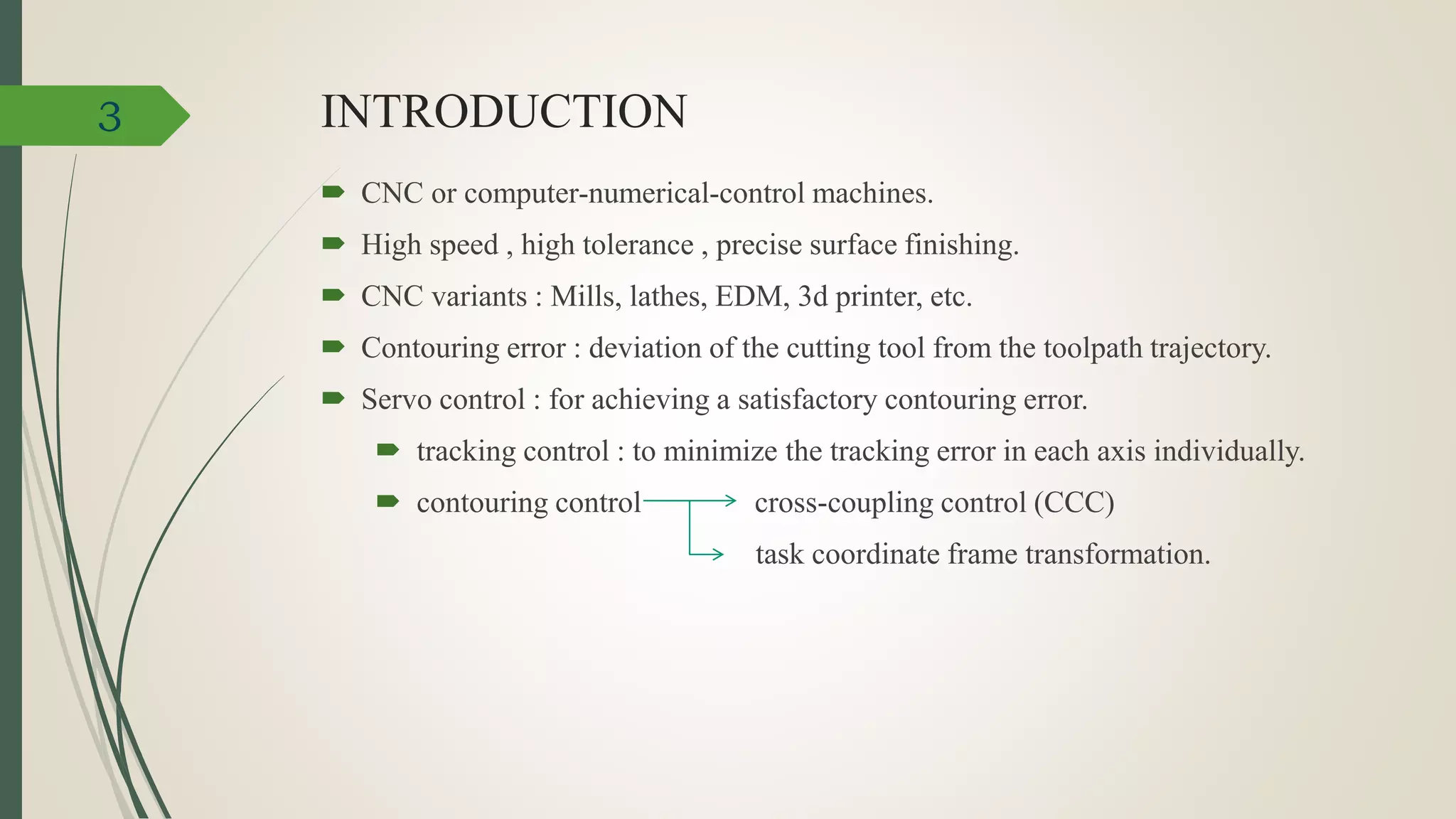

![ Table with workpiece mass : move in x and y directions.

Table with machining tool : displaces in z direction.

Three ball-screw feed-drive systems connected with DC motors for movement.

Applied voltages current amplifiers DC motors

(𝑣 𝑥, 𝑣 𝑦 and 𝑣𝑧 [V]) (send current commands) (torques generated)

Torque to the screws : linear displacements (positions) of the tables 𝑝 𝑥, 𝑝 𝑦 and 𝑝 𝑧.

The positions measurement : linear encoders in real-time for feedback control.

External forces 𝑓𝑥, 𝑓𝑦 and 𝑓𝑧 [N] : the resultant component of the cutting forces

and friction along the three axes.

7](https://image.slidesharecdn.com/jj-171119154152/75/Contouring-Control-of-CNC-Machine-Tools-7-2048.jpg)

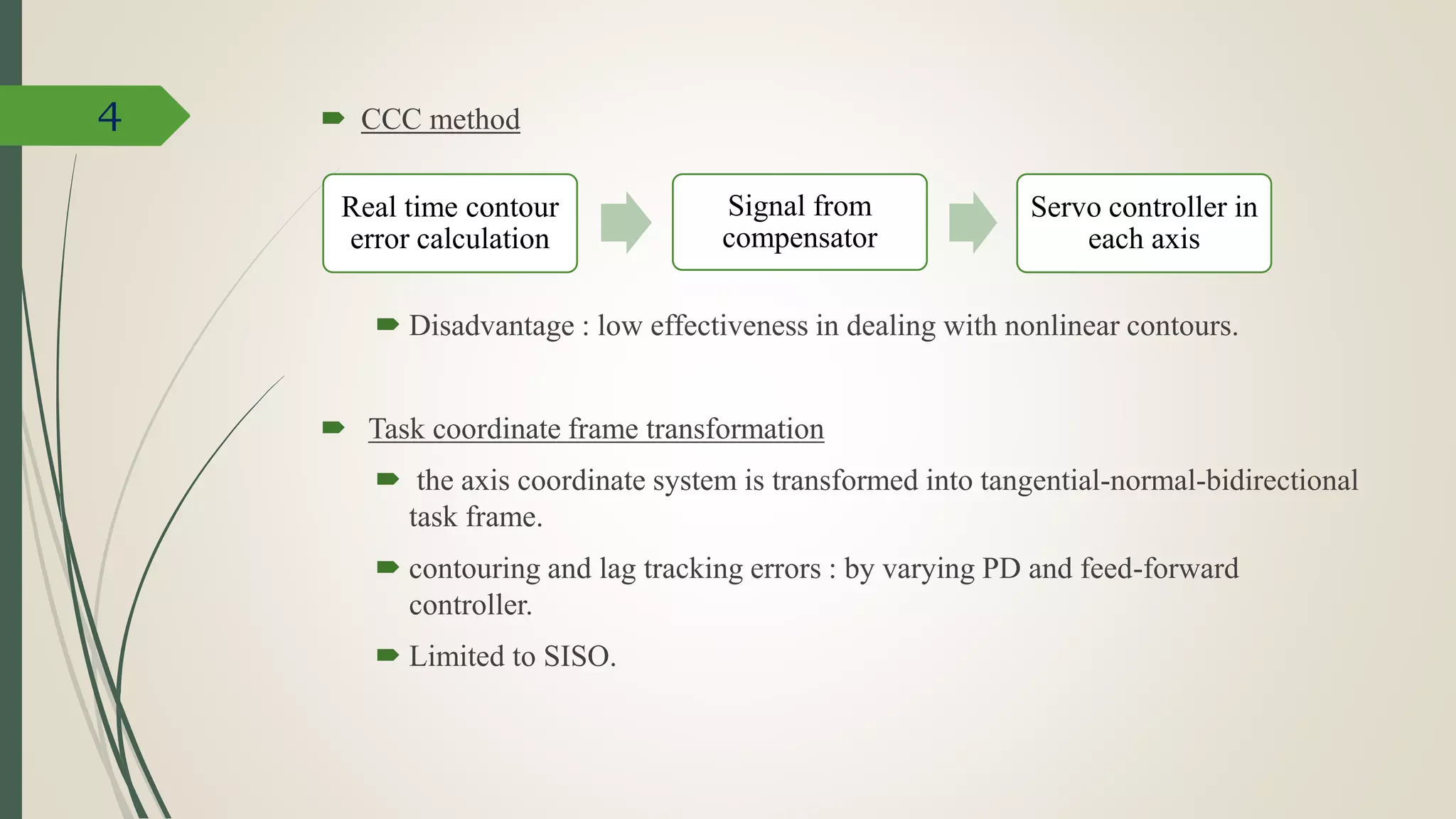

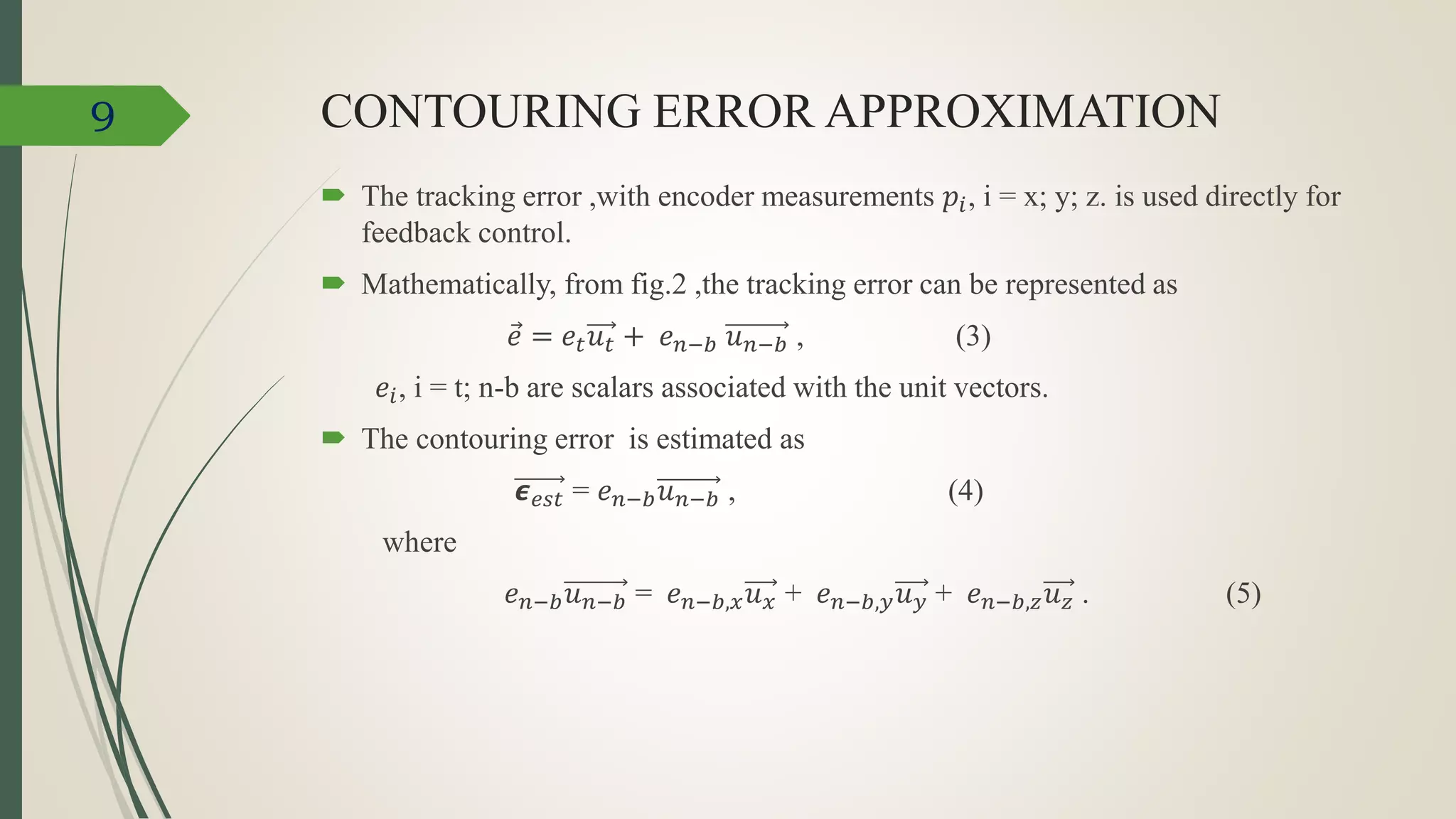

![TRACKING AND CONTOURING ERROR

The tracking error : difference between the

table position and its reference in each axis at

each time instant t:

𝑒 𝑡 = 𝑟 𝑡 − 𝑝 𝑡 (1)

In 3 dimension,

𝑟 𝑡 = [𝑟𝑥(𝑡), 𝑟𝑦(𝑡), 𝑟𝑧(𝑡)] 𝑇

𝑝 𝑡 = [𝑝 𝑥(𝑡), 𝑝 𝑦(𝑡), 𝑝 𝑧(𝑡)] 𝑇 (2)

where 𝑟𝑖, i = x; y; z are the reference signals

in x, y and z directions.

The contouring error : difference between the

displacement at each time instant and the

shortest-distance point on the reference

trajectory.

Fig. 2: Tracking error and

contouring error in 3axis CNC

machine

8](https://image.slidesharecdn.com/jj-171119154152/75/Contouring-Control-of-CNC-Machine-Tools-8-2048.jpg)

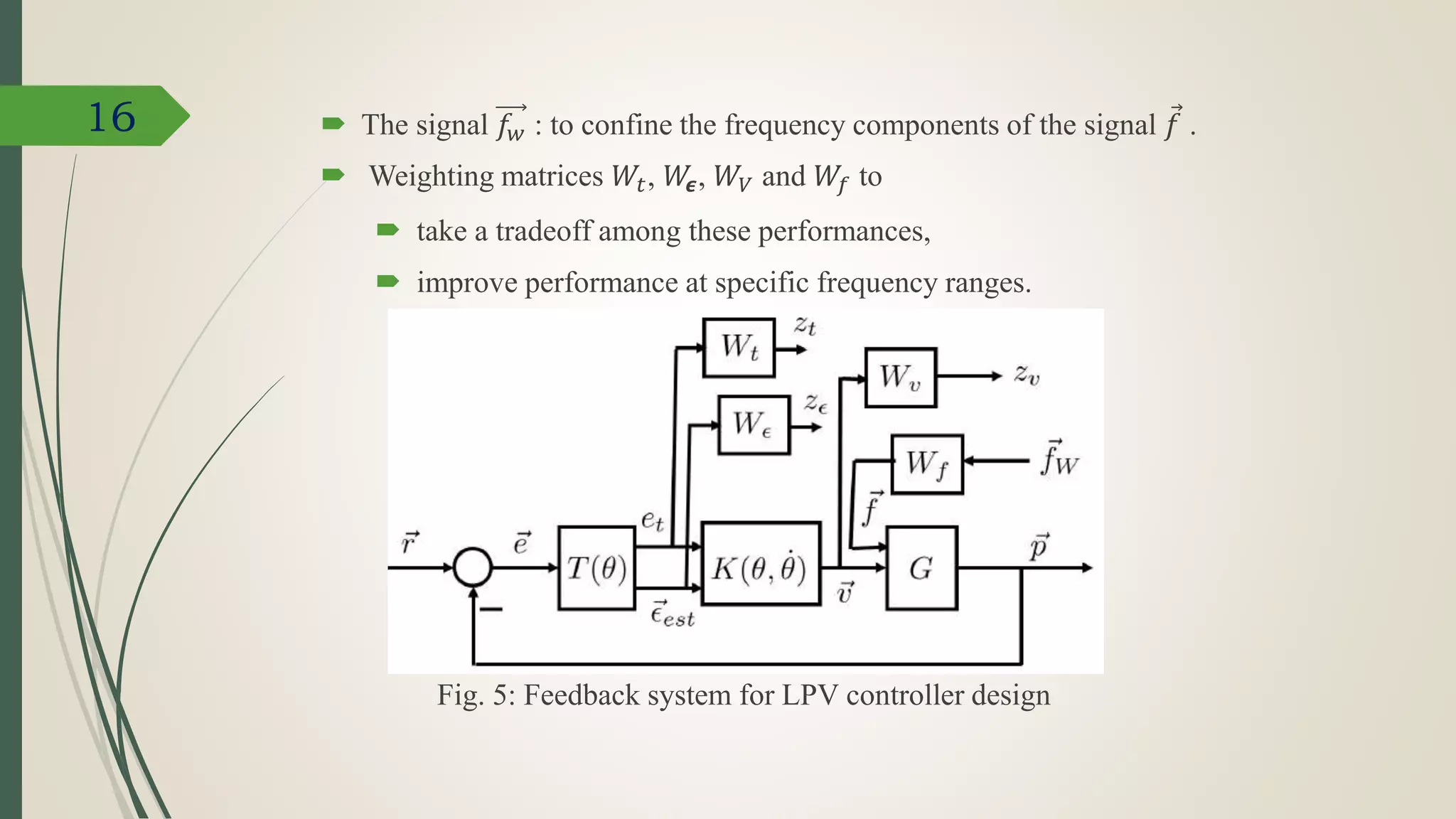

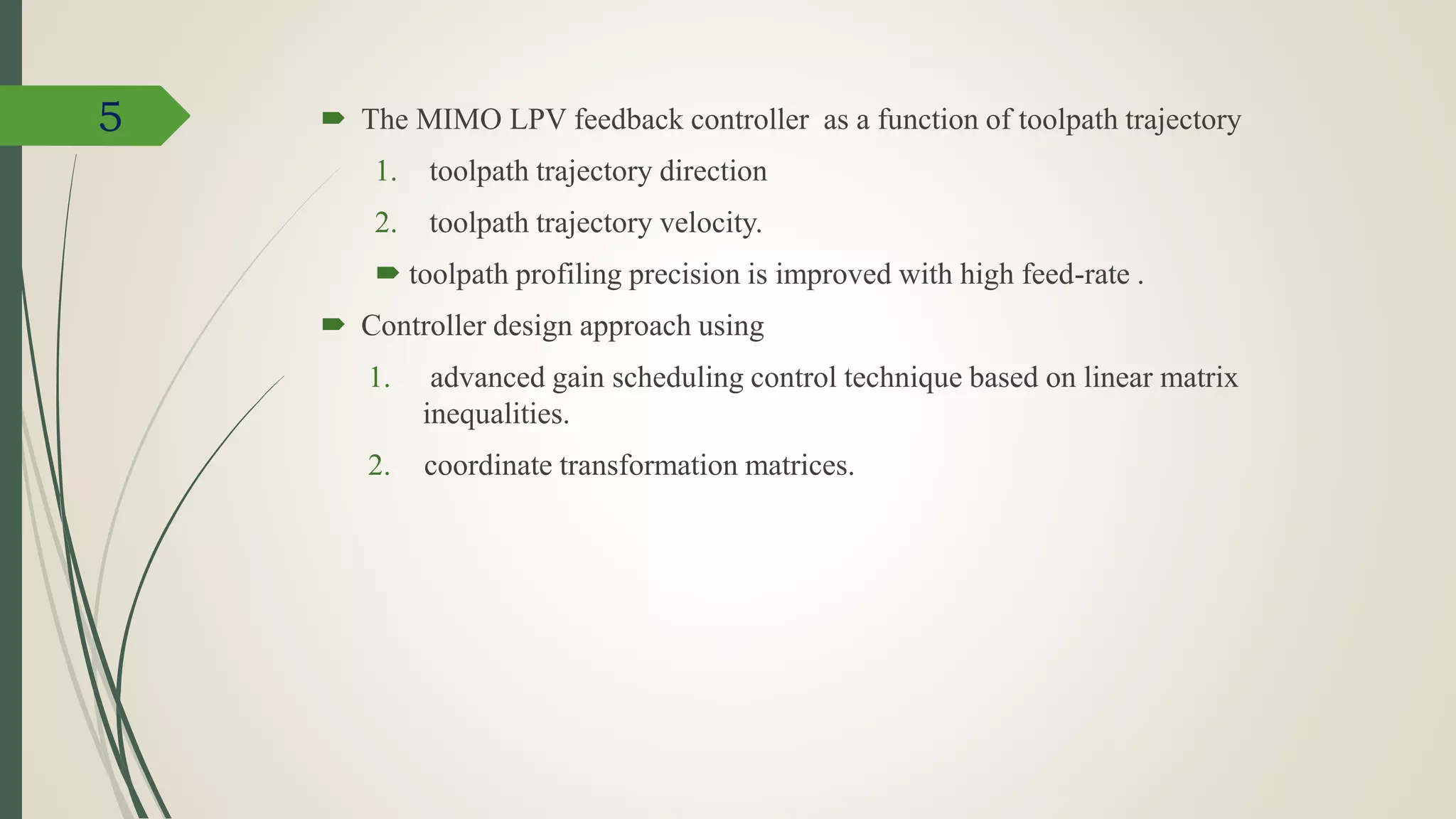

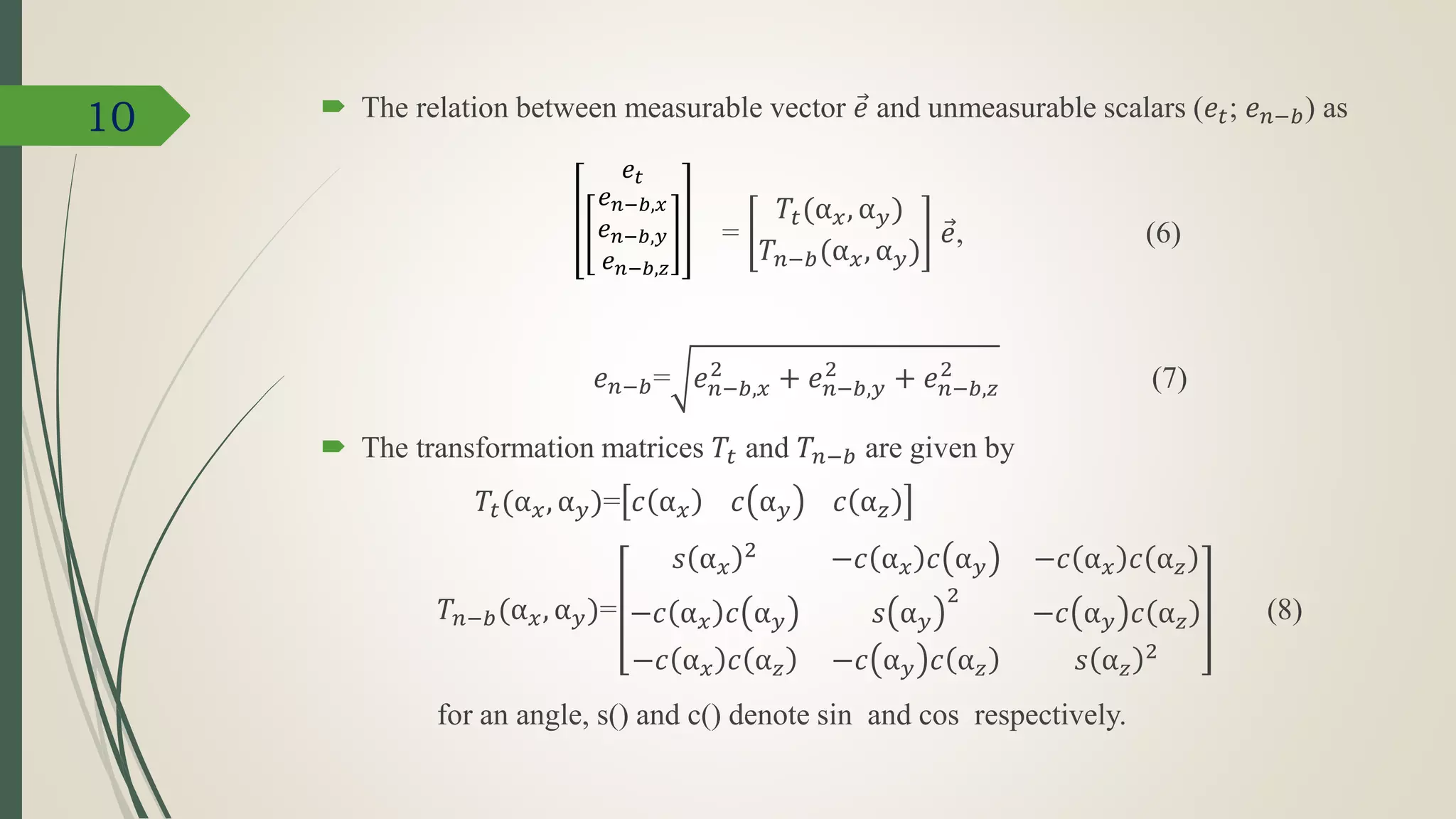

![CONTROLLER OBJECTIVES

The mapping from the vector 𝑒 to the scalar 𝑒 𝑛−𝑏 is nonlinear because of (7).

The mapping from 𝑒 to the vector in the left-hand side of (6) is linear.

Feedback controllers

minimizes the approximated contouring error 𝟄 𝑒𝑠𝑡 in (4) and

also suppresses vibration of the machine due to external forces.

Fig. 3: Feedback structure for contouring error minimization.

where the disturbance force vectors 𝑓 := [𝑓𝑥; 𝑓𝑦 ; 𝑓𝑧] 𝑇,

voltage input vector 𝑣 := [𝑣 𝑥; 𝑣 𝑦; 𝑣𝑧] 𝑇.

11](https://image.slidesharecdn.com/jj-171119154152/75/Contouring-Control-of-CNC-Machine-Tools-11-2048.jpg)

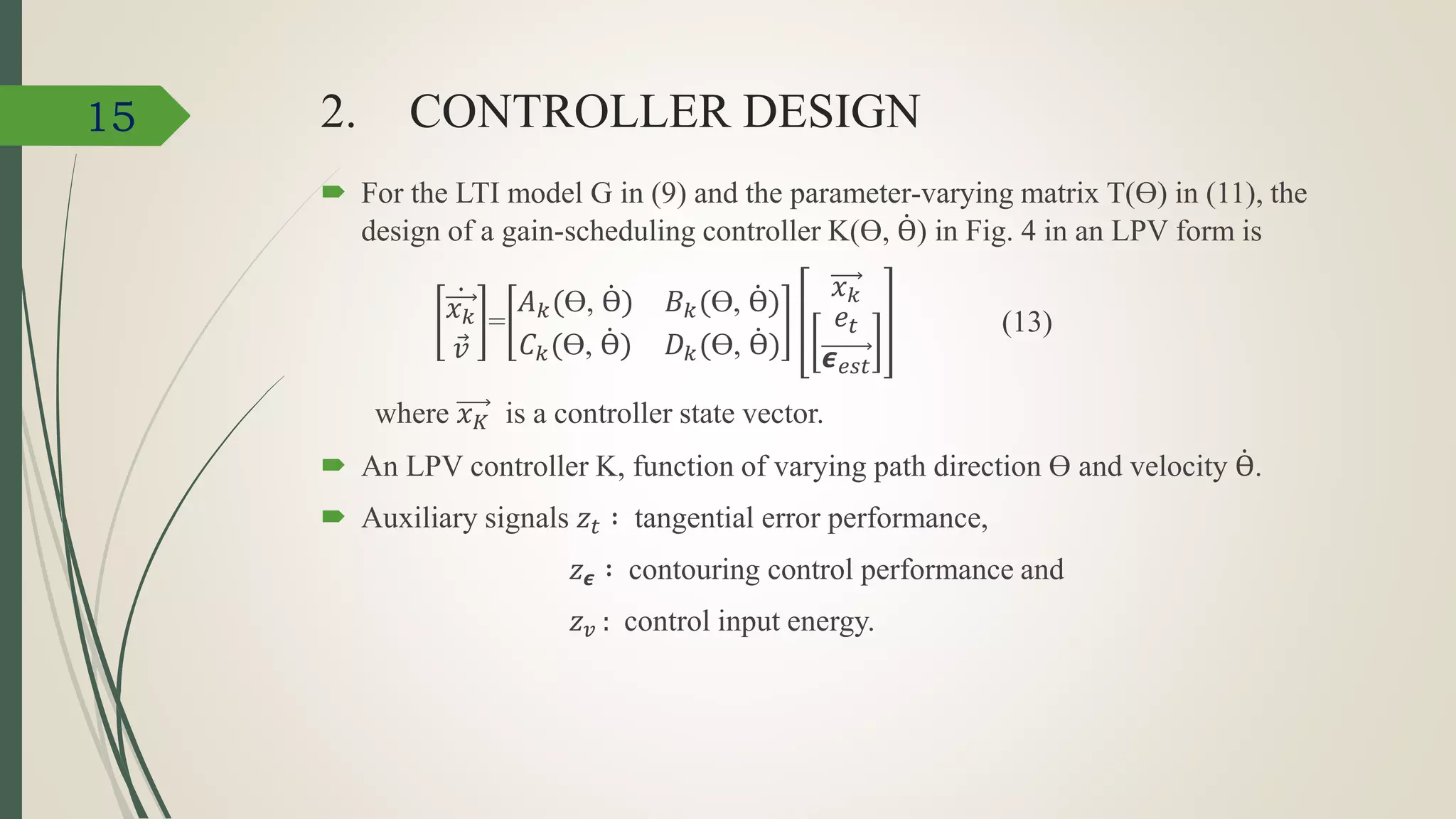

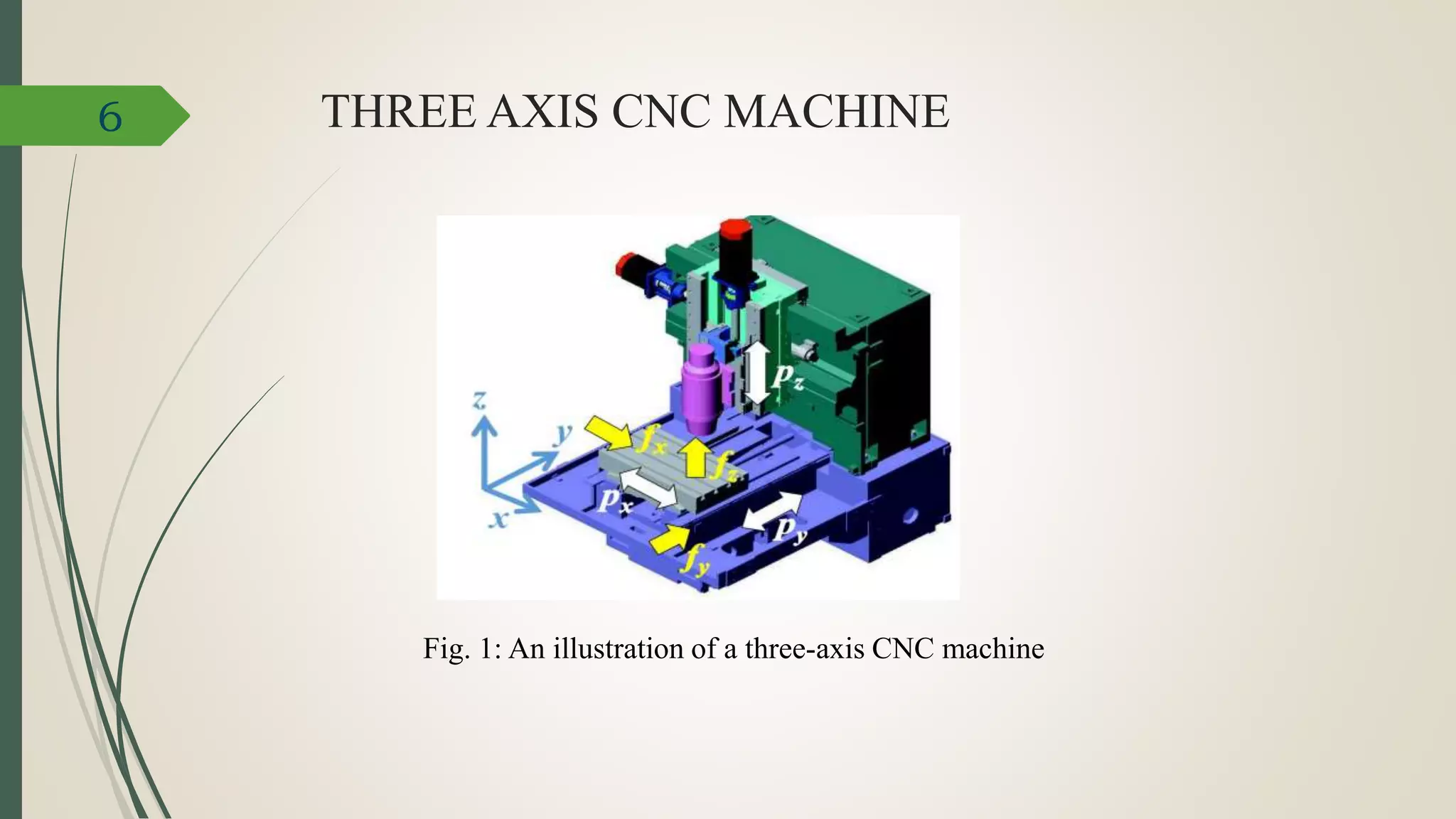

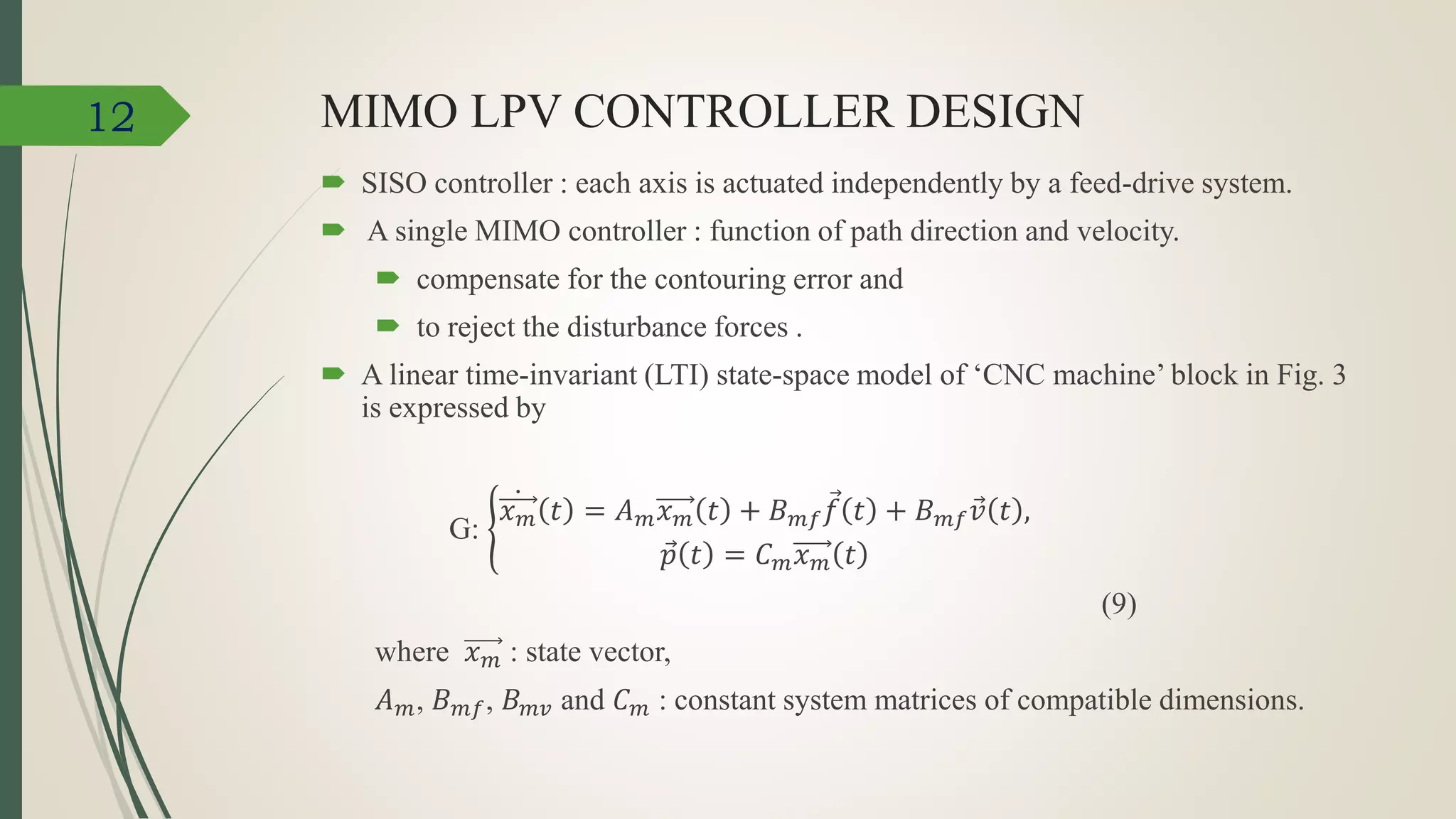

![1. CONTROLLER STRUCTURE

Fig. 4: controller structure for contouring control

The parameter Ɵ(the gain-scheduling parameter) is defined by

Ɵ = [α 𝑥, α 𝑦] 𝑇 (10)

The first system T(Ɵ) is a parameter-varying matrix which is the coordinate

transformation matrix defined by

T(Ɵ) =

𝑇𝑡(Ɵ)

𝑇𝑛−𝑏(Ɵ)

(11)

13](https://image.slidesharecdn.com/jj-171119154152/75/Contouring-Control-of-CNC-Machine-Tools-13-2048.jpg)

![ The output of the system T(Ɵ) are given in the left-hand side of (6) .

The vector 𝟄 𝑒𝑠𝑡 is given by

𝟄 𝑒𝑠𝑡 = [ 𝑒 𝑛−𝑏,𝑥 , 𝑒 𝑛−𝑏,𝑦 , 𝑒 𝑛−𝑏,𝑧] 𝑇 (12)

The K(Ɵ; Ɵ) block is a linear parameter-varying (LPV) controller.

14](https://image.slidesharecdn.com/jj-171119154152/75/Contouring-Control-of-CNC-Machine-Tools-14-2048.jpg)