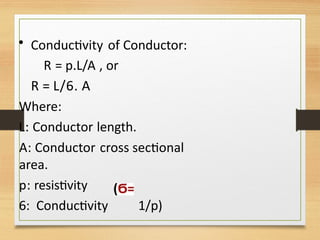

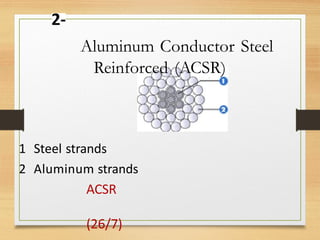

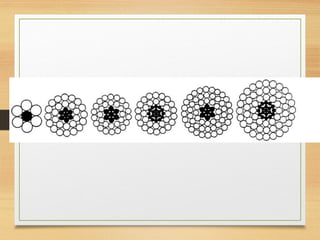

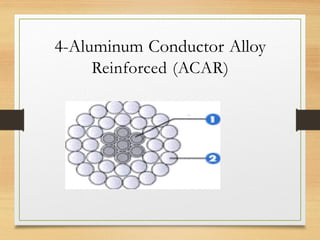

The document outlines the key considerations in the design of transmission lines, focusing on electrical and mechanical aspects. It emphasizes the importance of low voltage drop, power loss reduction, and high conductivity in conductors, as well as mechanical strength to withstand various stresses. Different types of conductors, such as aluminum and steel-reinforced options, are discussed regarding their cost-effectiveness, strength, and efficiency in supporting transmission over longer spans.