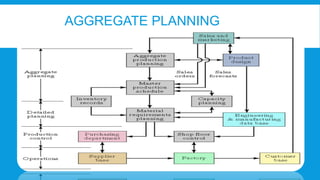

This document discusses computer integrated production planning systems. It outlines different types of companies that would utilize such systems, including automobile, mobile, robotics, and food manufacturing companies. It emphasizes that production planning needs to consider customer needs through market analysis and forecasting, as well as availability of raw materials. The document then describes how production planning systems bring all of these processes under one system and allow planning to occur at various levels from long to short range. It highlights how computer integration allows modification from anywhere and monitoring of the entire product lifecycle.