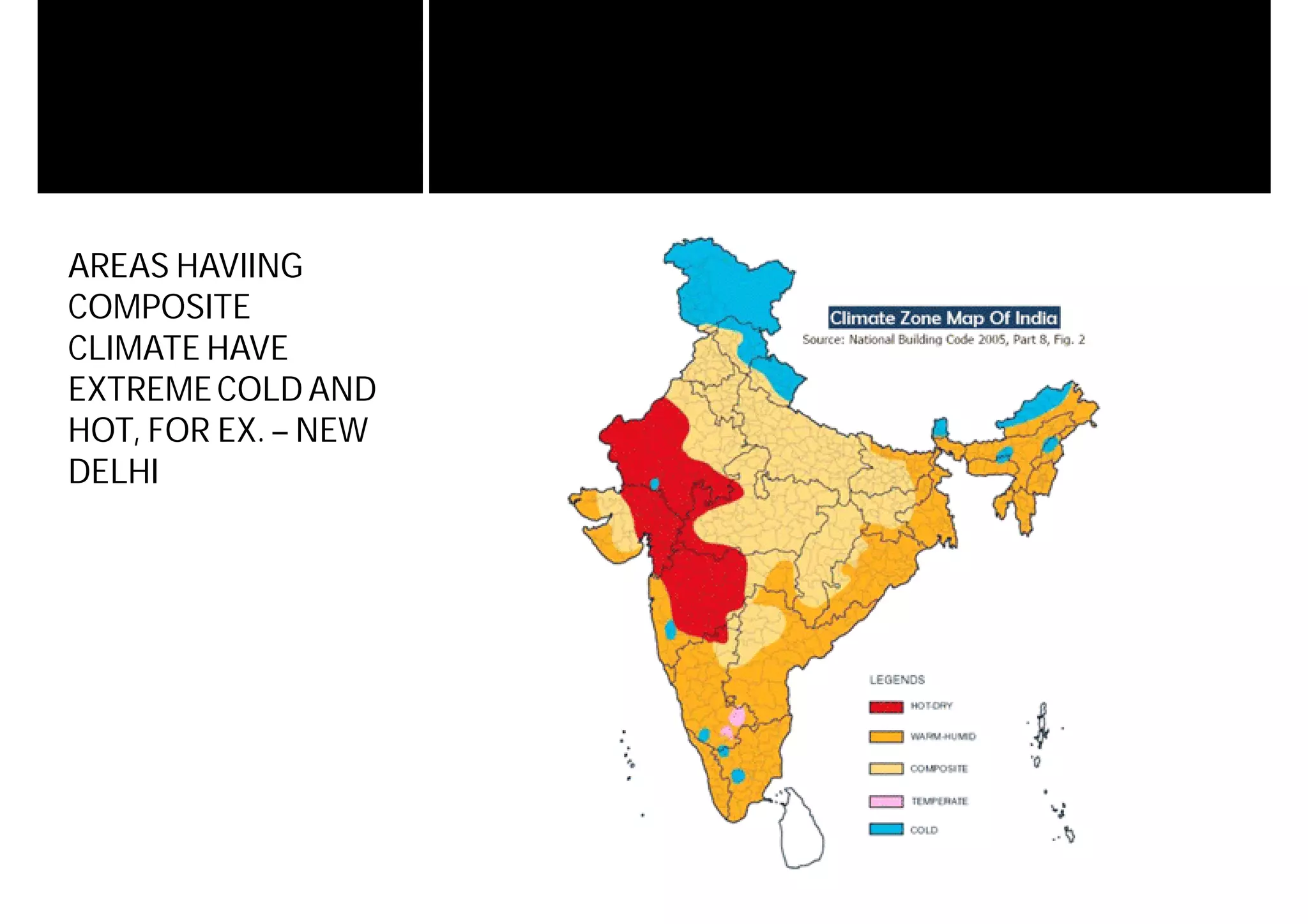

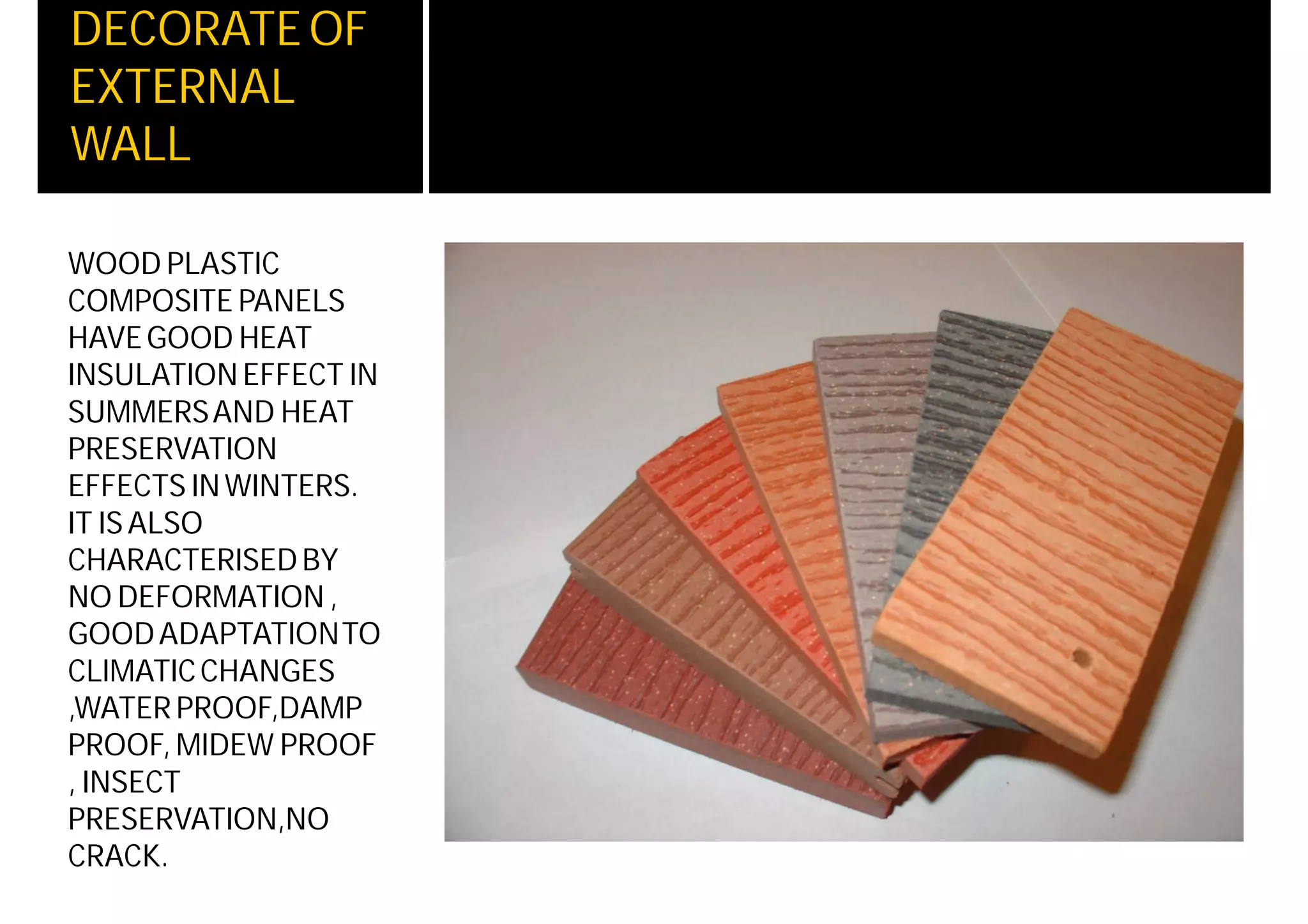

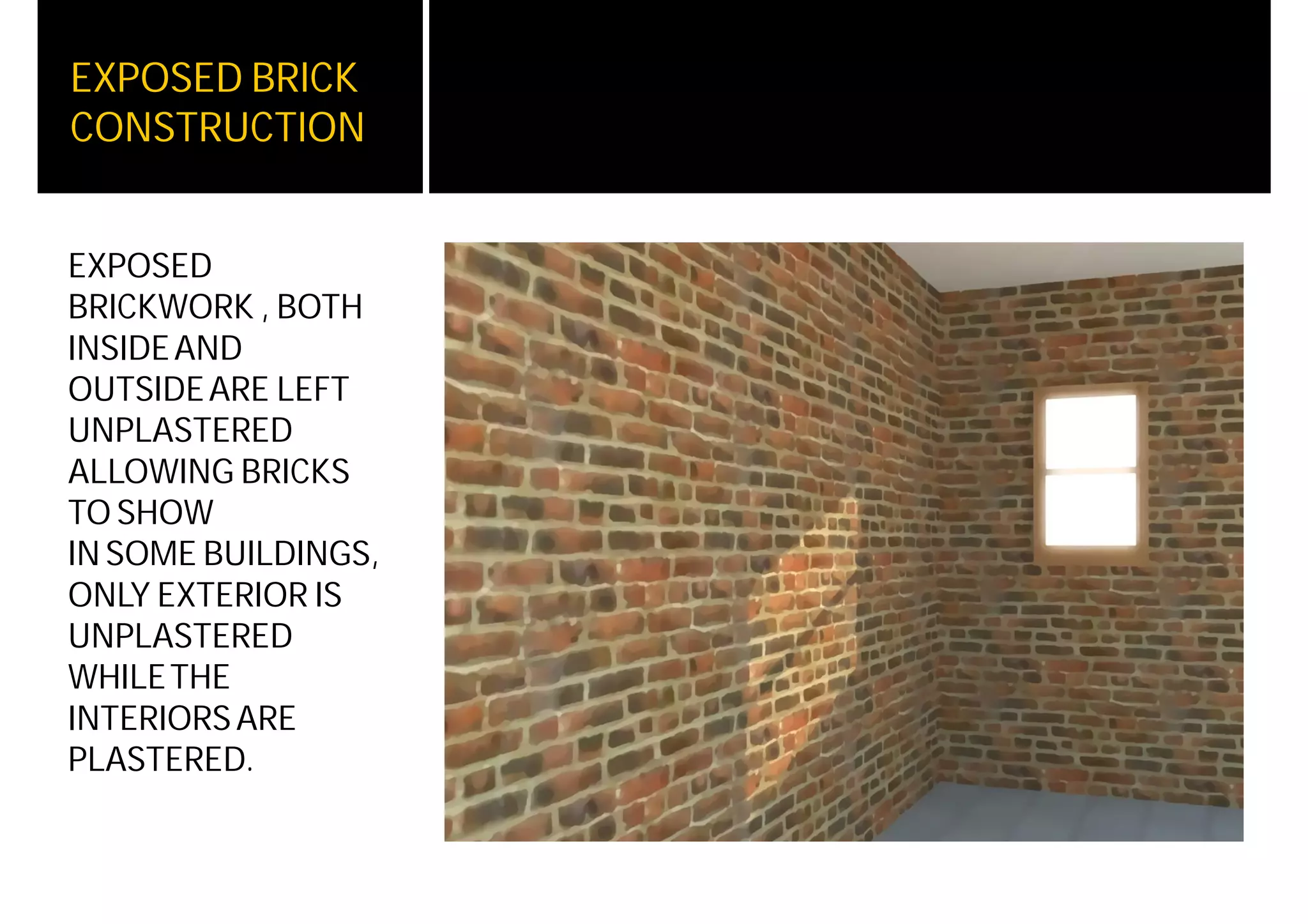

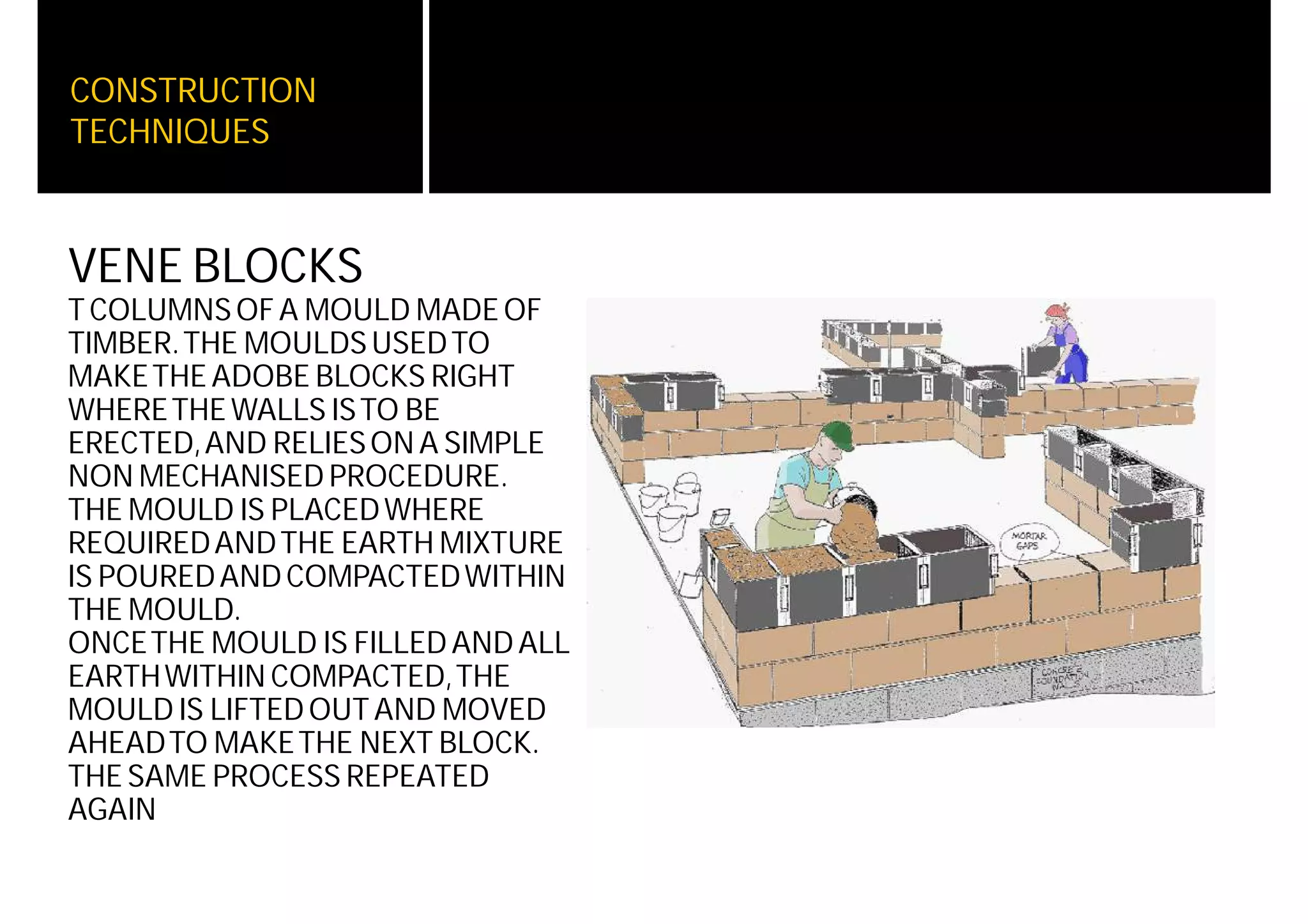

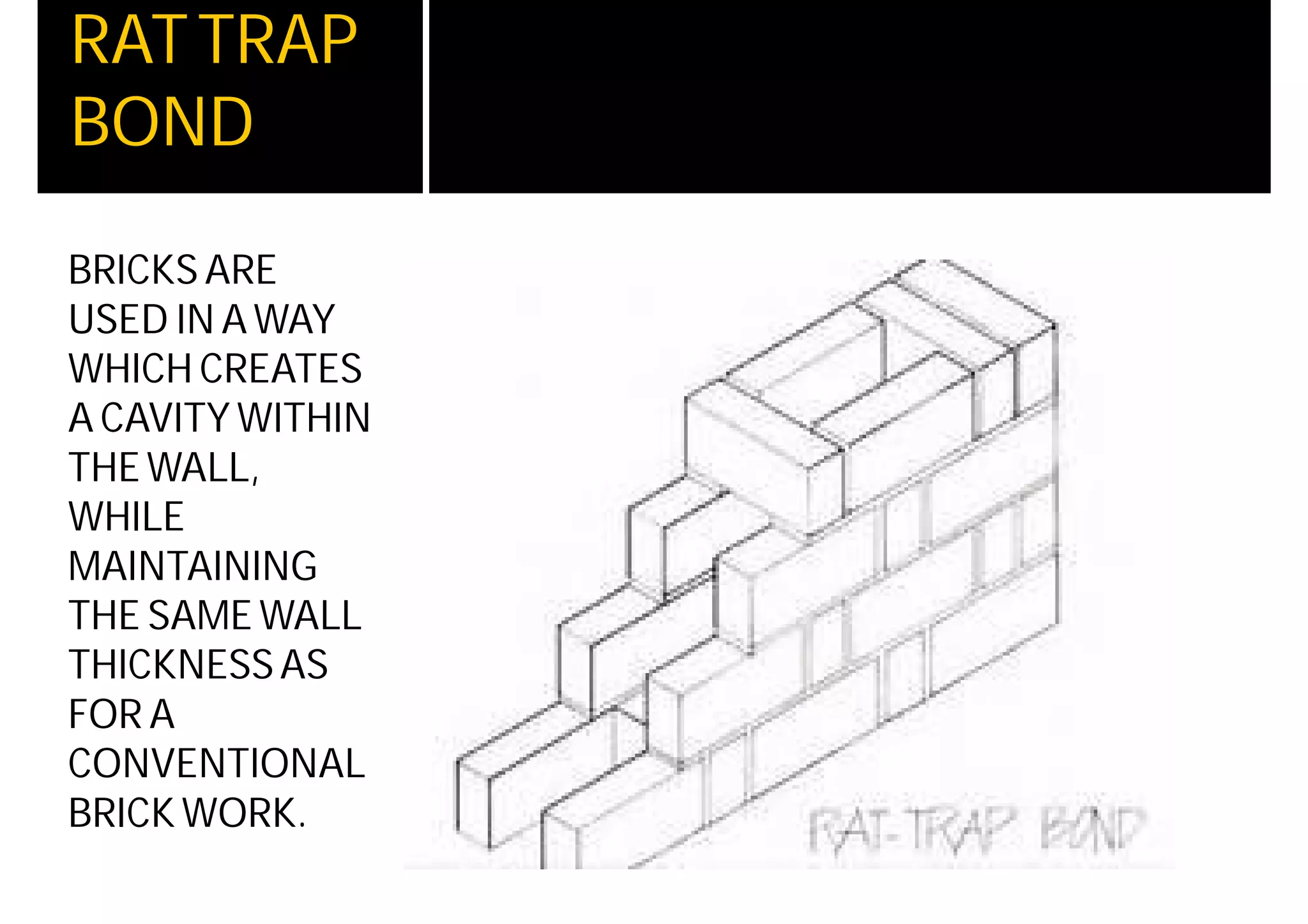

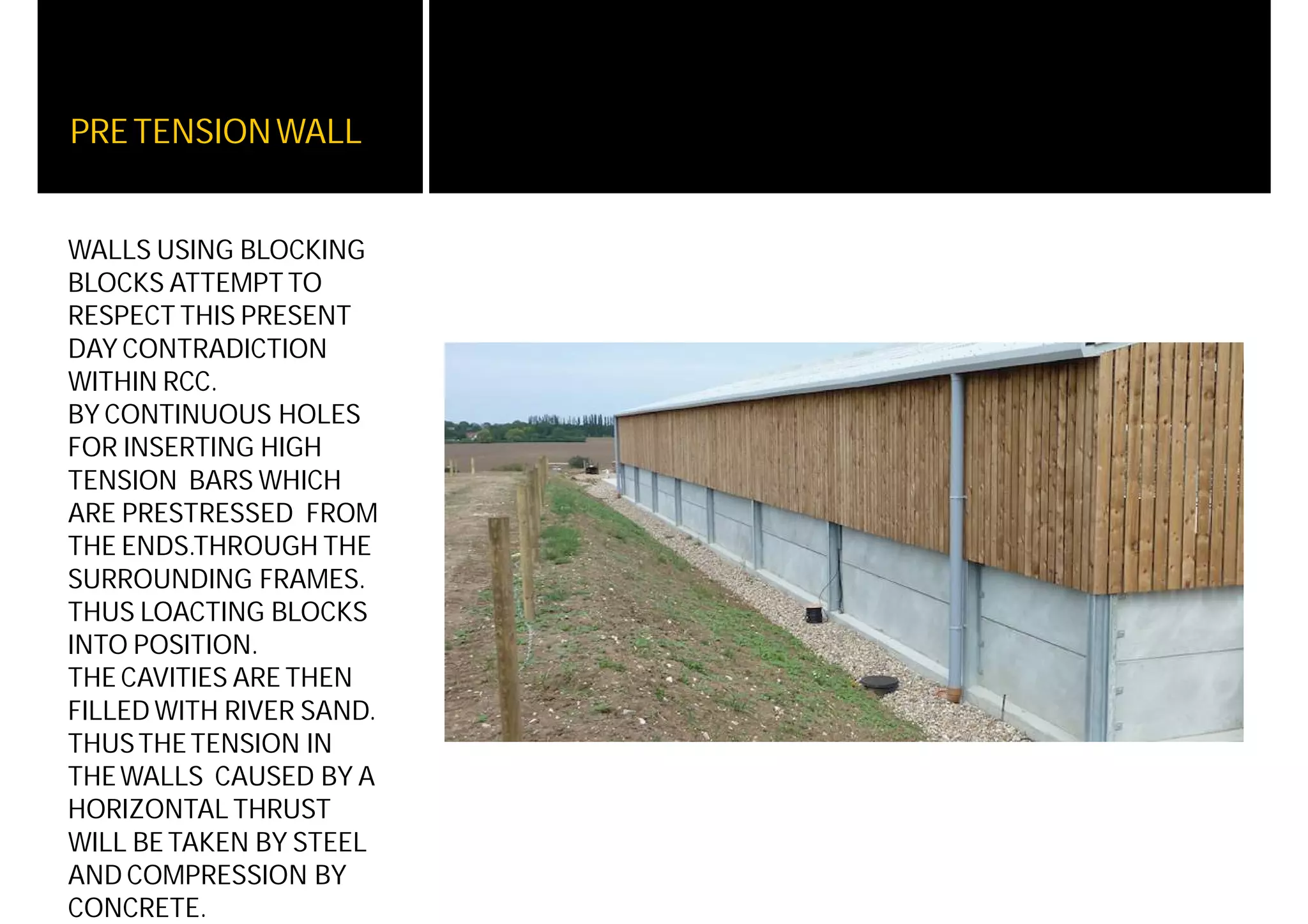

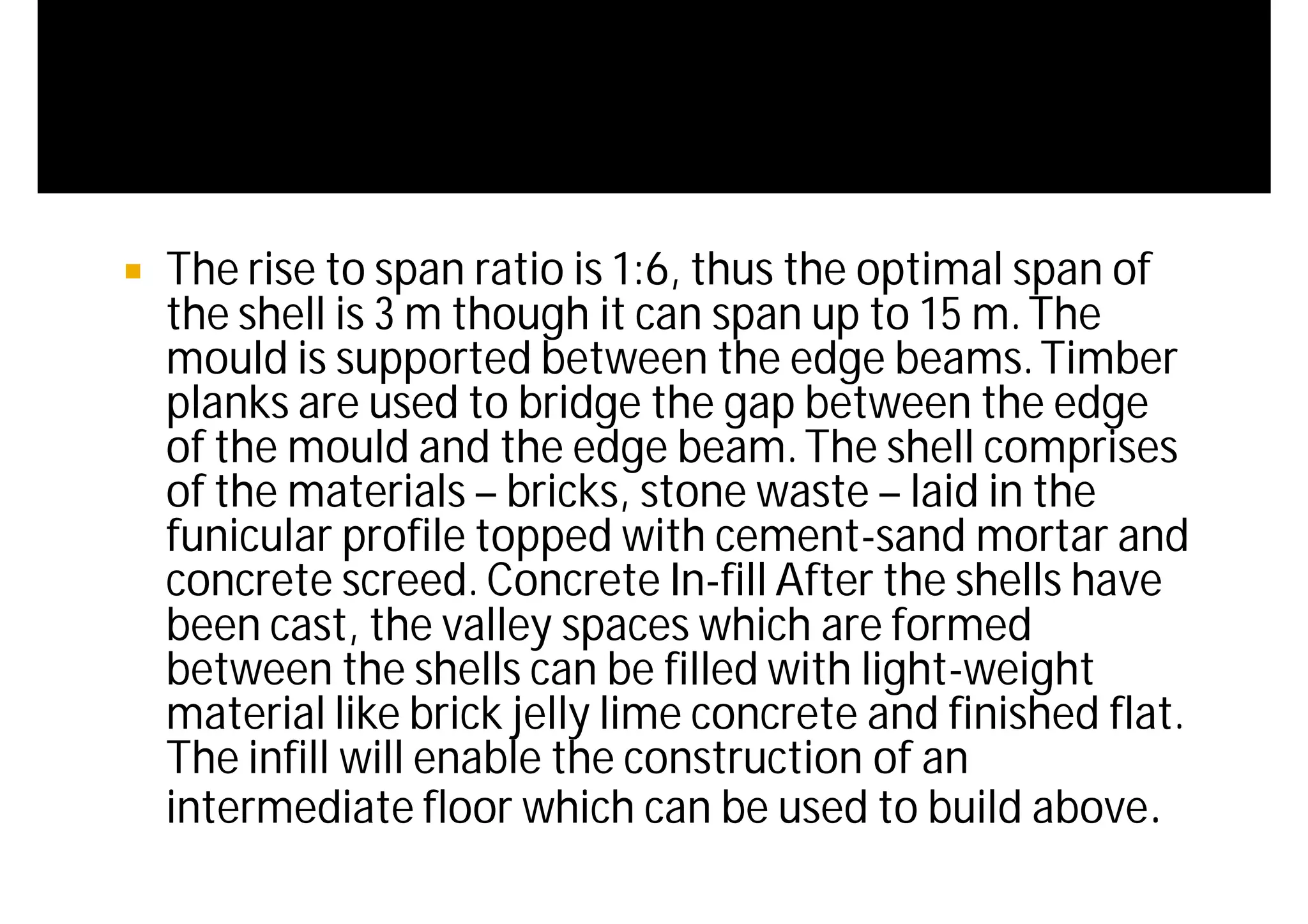

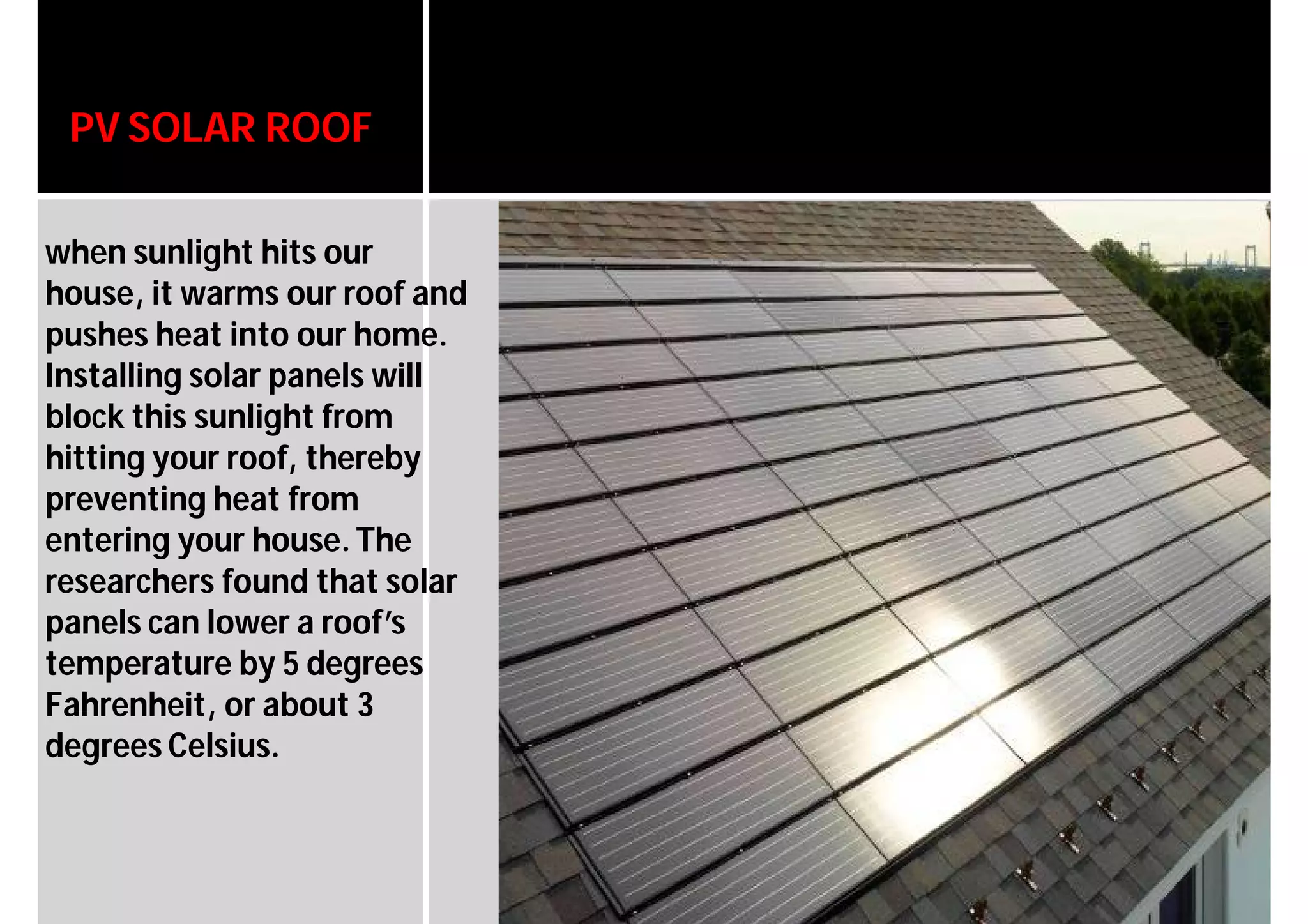

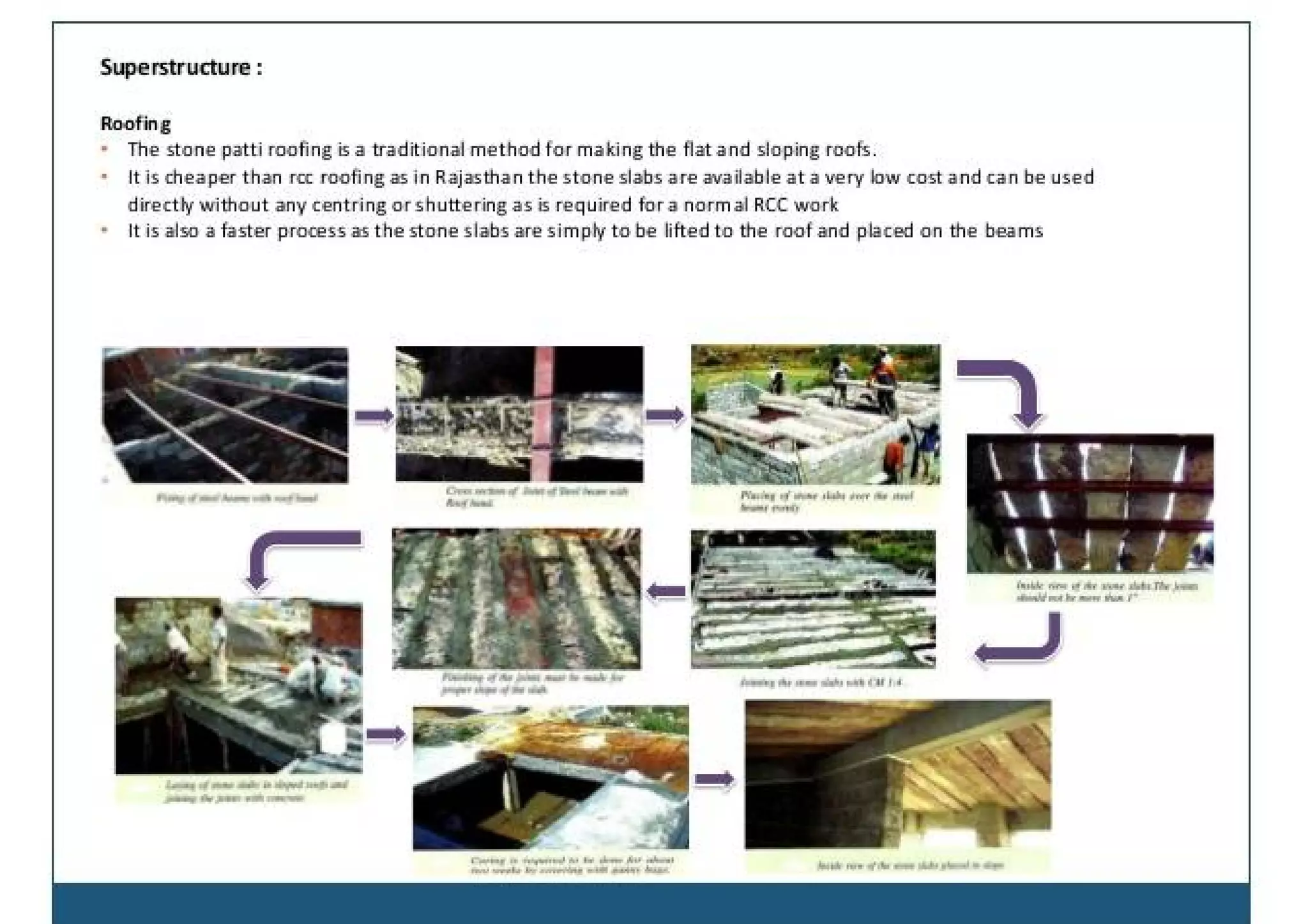

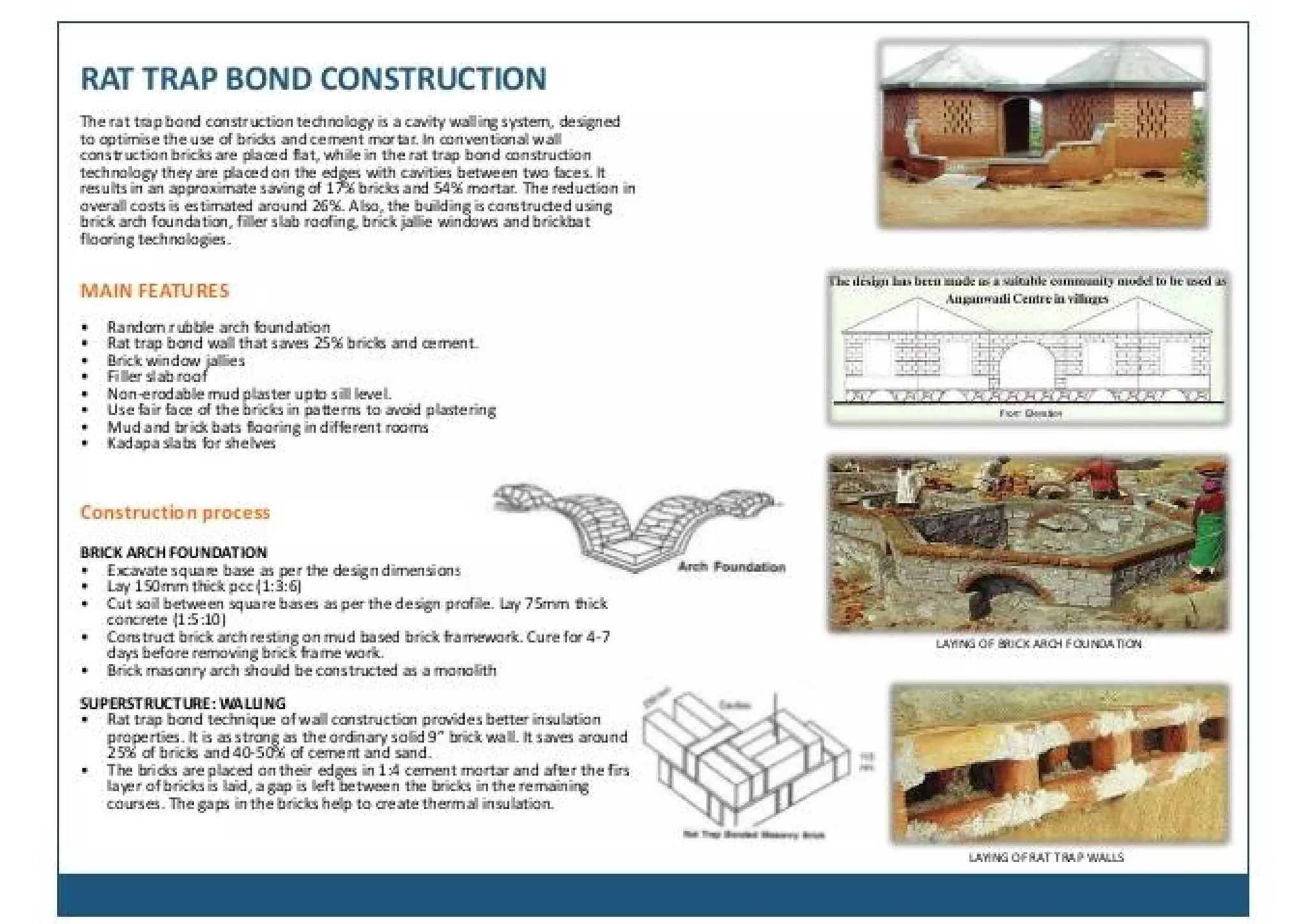

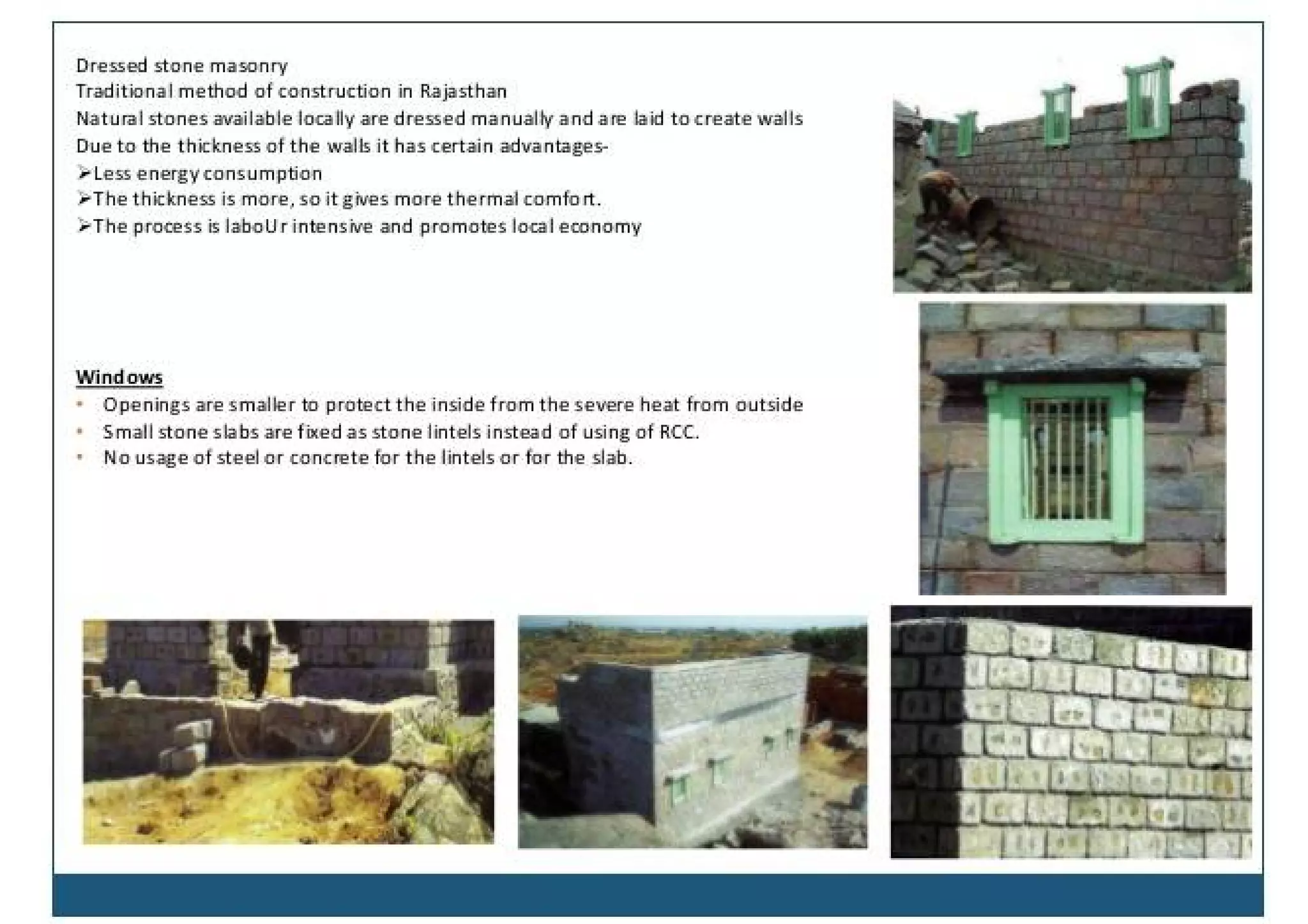

The document discusses various sustainable construction techniques and materials used in composite climate zones, focusing on thermal insulation and heat management. It highlights the benefits of local materials, innovative designs like funicular roofs, and the use of solar panels to enhance energy efficiency. Techniques such as straw thatch, bamboo, and exposed brick are emphasized for their effectiveness in minimizing heat gain and maximizing comfort.