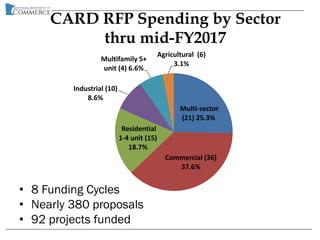

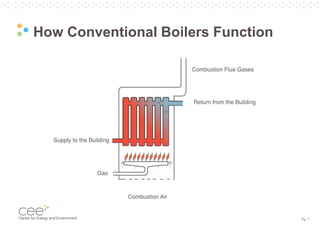

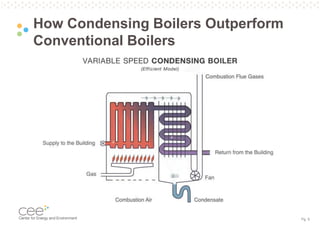

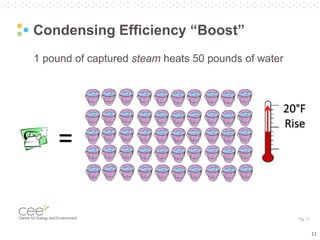

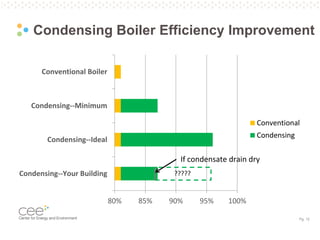

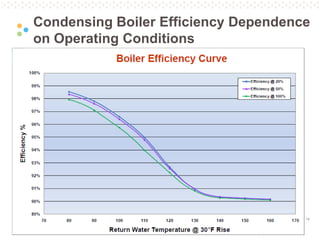

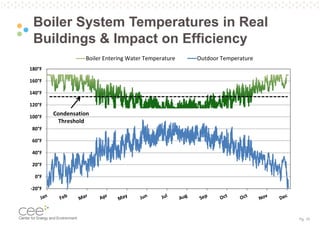

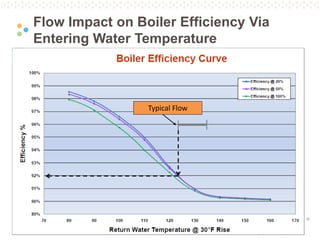

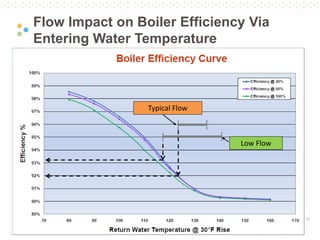

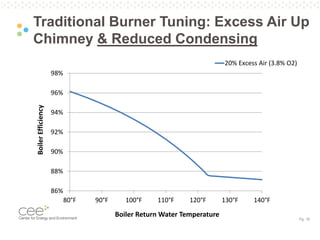

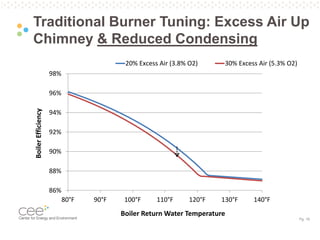

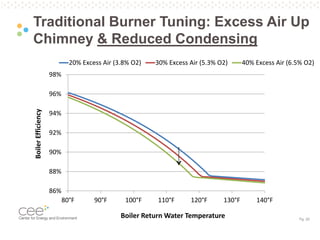

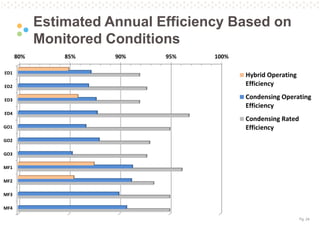

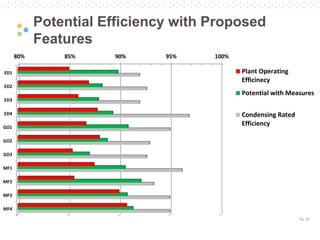

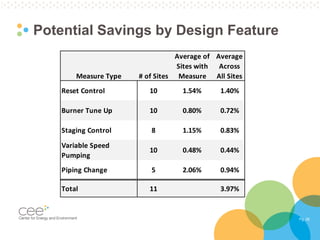

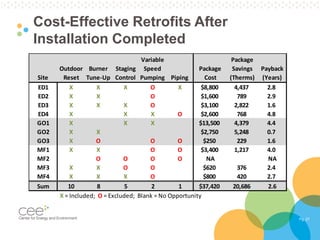

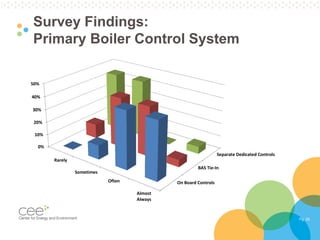

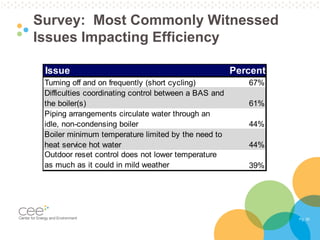

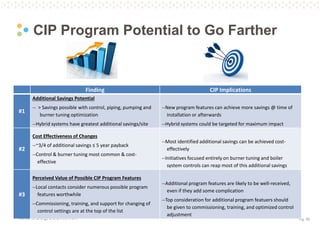

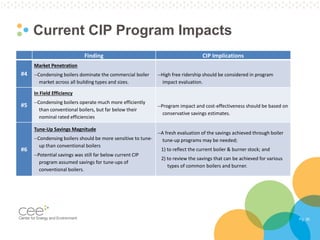

The document highlights the Minnesota Applied Research & Development Fund's initiative to optimize commercial condensing boilers for improved energy efficiency and reduced CO2 emissions. It reviews the performance advantages of condensing boilers over conventional types, emphasizing the importance of low return water temperatures and proper control systems. Additionally, the report evaluates market findings, potential efficiency improvements, and recommendations for cost-effective retrofits and operational practices.