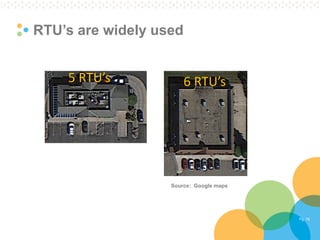

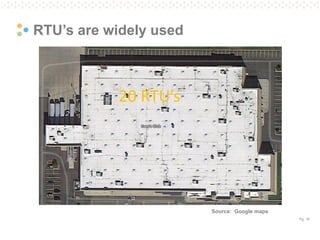

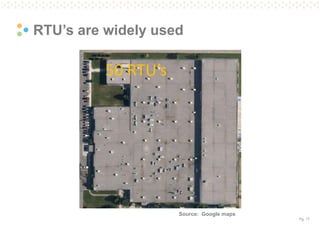

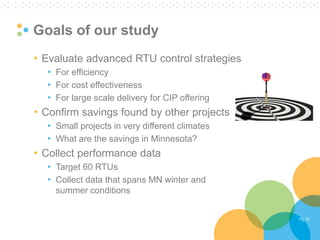

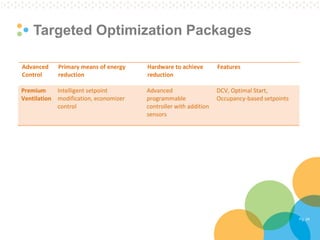

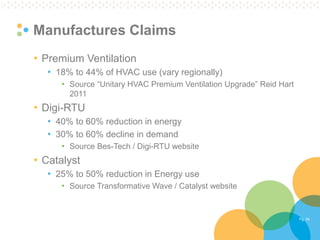

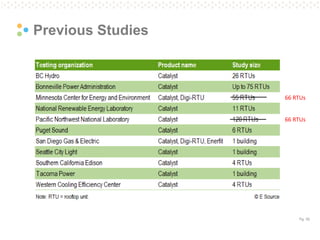

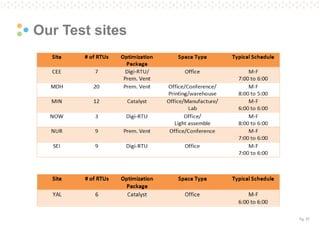

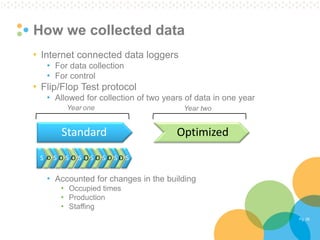

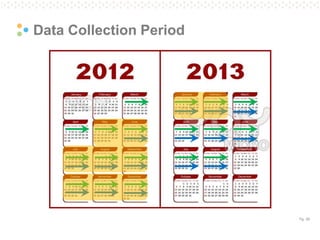

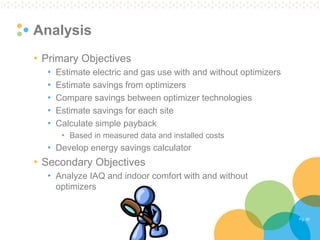

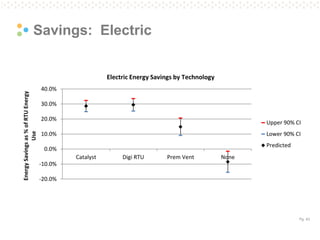

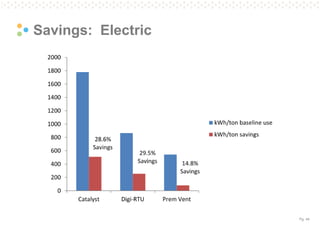

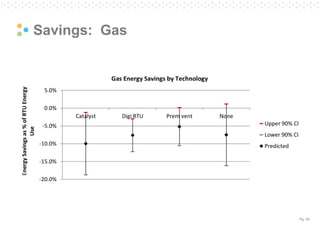

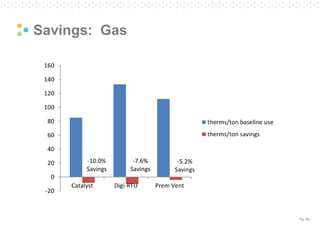

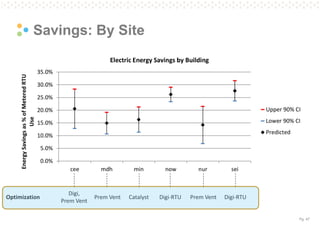

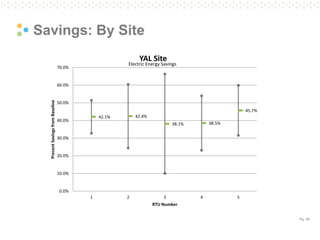

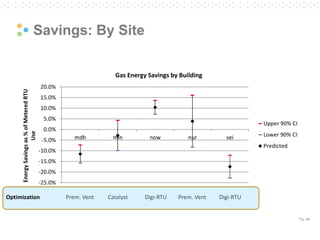

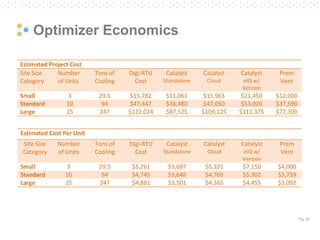

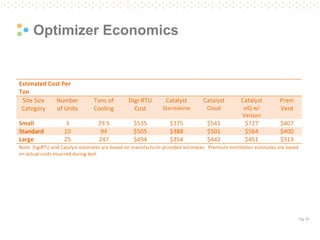

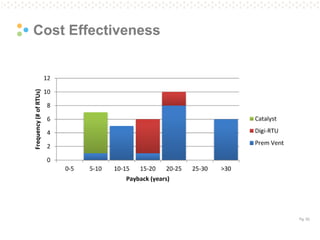

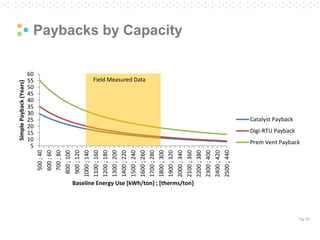

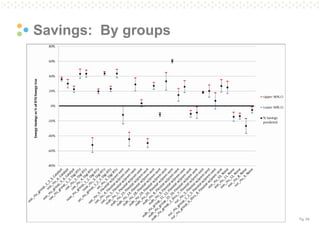

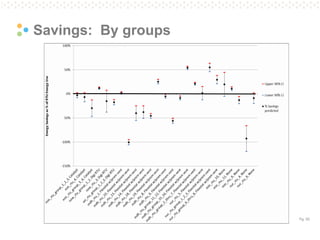

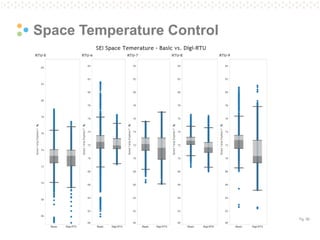

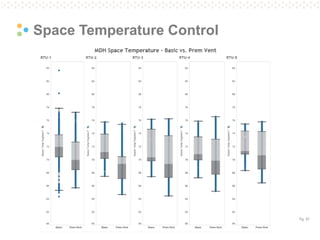

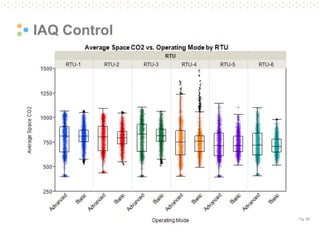

The document discusses a study on optimizing the efficiency of rooftop units (RTUs) in cold climates, highlighting various current research projects aimed at enhancing HVAC systems. Key findings indicate that while all technologies achieved significant electric savings, gas savings were inconsistent and advanced controls did not necessarily deliver cost-effective energy savings. The study emphasizes the importance of tailored optimizers for specific situations and the rapid expansion of the RTU market.