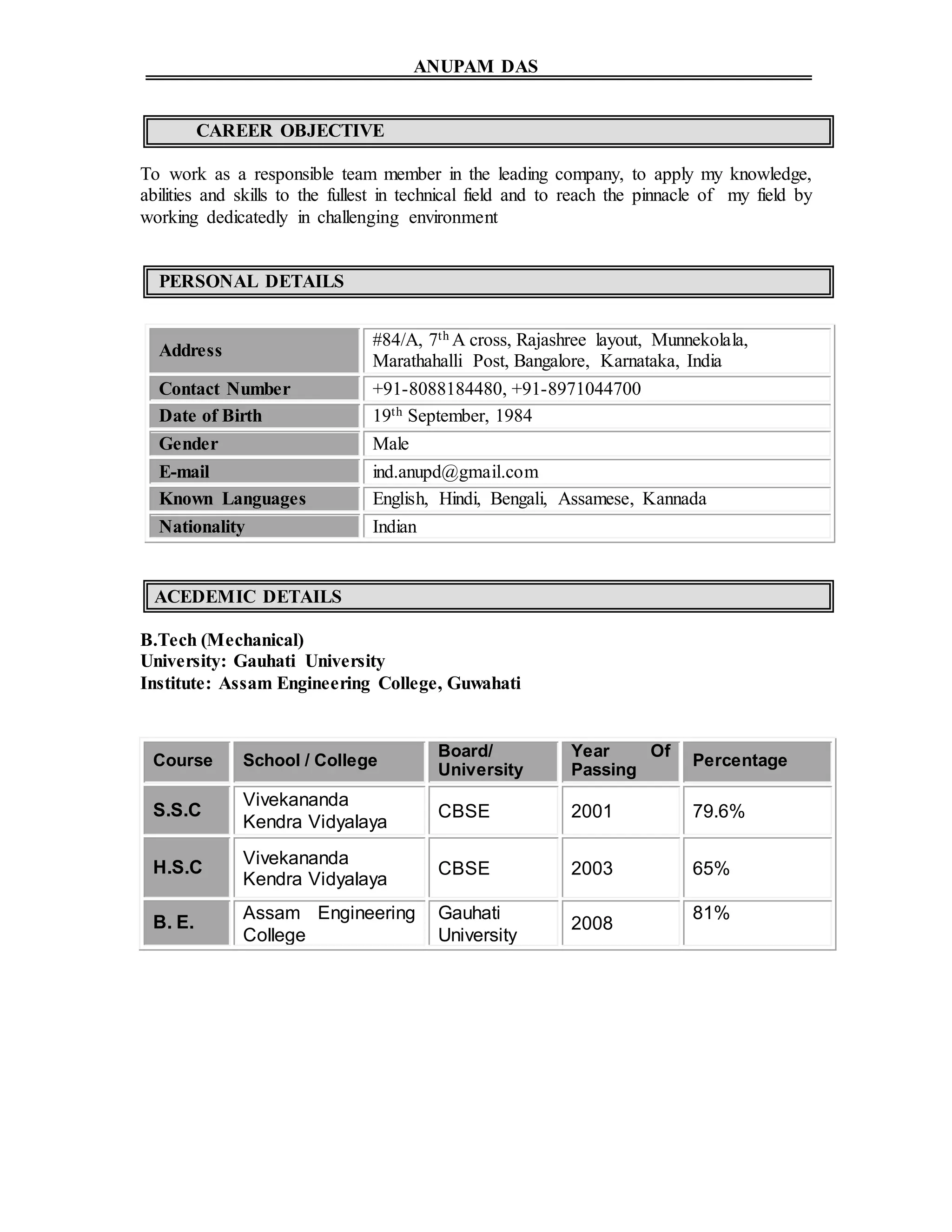

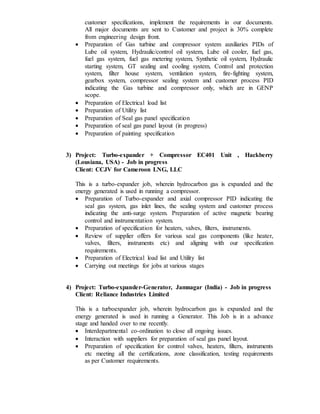

Anupam Das has over 10 years of experience in mechanical engineering and power plant design. He holds a B.Tech in Mechanical Engineering from Assam Engineering College. Currently, he works as a Lead Engineer at GE India Technology Centre, where he has designed systems for gas turbines and compressors used in power plants and other industrial applications. Previously, he worked as an Assistant Manager at Tata Consulting Engineers, where he gained experience in designing components for various thermal and solar power plants. He has strong technical skills in areas like piping and instrumentation diagram design, equipment sizing, and specifications preparation.