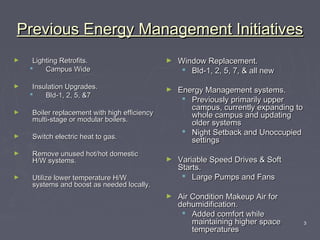

This document discusses previous and potential future energy management initiatives at the Christian Health Care Center in Wyckoff, NJ. It outlines lighting retrofits, insulation upgrades, boiler replacements, and other past projects. It describes a proposed micro-turbine/chiller cogeneration system that would provide electricity and thermal output. The system would include micro-turbines, an absorption chiller, cooling towers, and backup chillers. It analyzes the potential energy and cost savings from decreased demand charges and thermal output. Recommendations are provided to refine the measurement and control of thermal loads from the system.