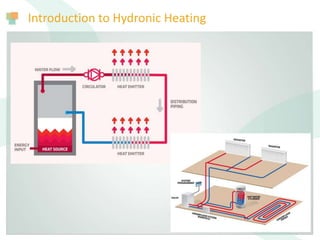

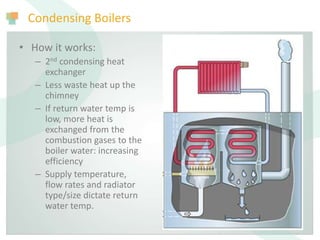

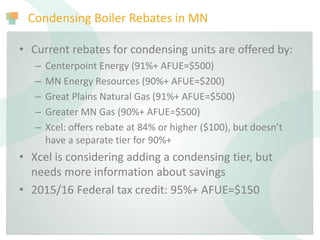

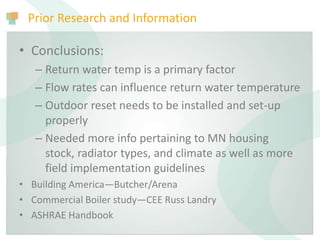

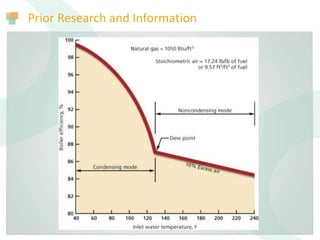

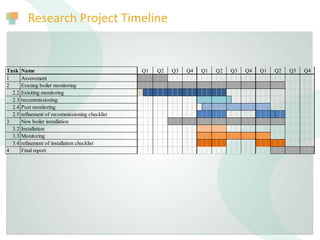

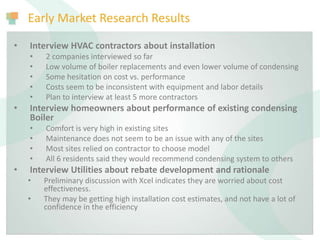

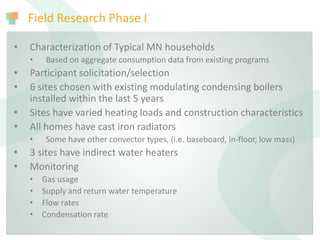

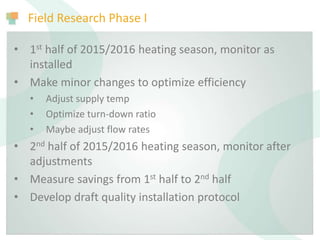

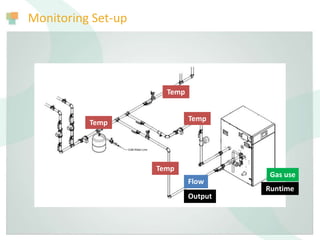

This document provides an overview and agenda for a hydronic heating conference. It discusses the benefits of condensing boilers over conventional boilers, including increased efficiency from condensing combustion gases. It also notes research being conducted on optimizing condensing boiler installations in Minnesota homes to improve efficiency and contractor confidence. The research involves monitoring existing condensing boiler installations, retrocommissioning them to lower supply temperatures and better match load, and installing new boilers using developed quality installation protocols.