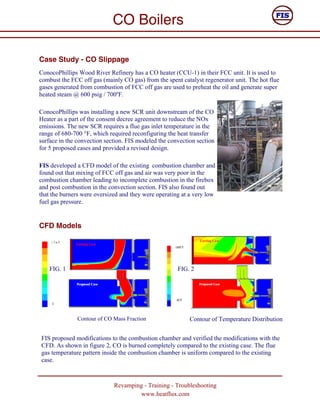

Furnace Improvement Services (FIS) is an engineering consulting company that specializes in CO boiler design, revamp, and troubleshooting. The document provides an overview of CO boilers and case studies of FIS projects involving CO boiler revamps, efficiency improvements, capacity increases, and NOx reduction. Key projects included replacing the convection section of a CO boiler to increase capacity and efficiency, and modifying a combustion chamber and burners to ensure complete combustion and reduce CO emissions. FIS has experience with over 300 projects and aims to provide low-cost solutions to improve CO boiler performance and compliance.